The IS200PPDAH1B is a Power Diagnostic I/O Pack designed for the Mark VIe and Mark VIeS control systems, serving as the successor and upgrade to the IS200PPDAH1A. As the core feedback unit within the Power Distribution Module (PDM), this module is responsible for collecting, processing, and reporting the operational status of the entire power system, including critical information such as power bus voltages, branch circuit status, ground fault detection, and bulk power supply health. The IS200PPDAH1B communicates with the controllers via a dual-redundant Ethernet interface, offering high reliability and real-time performance.

The most significant upgrade of the IS200PPDAH1B is its core processor, which has been updated from the BPPB (used in the IS200PDAH1A) to the more advanced BPPC processor board. This hardware change delivers improved processing performance and higher reliability. The IS200PPDAH1B is officially supported starting with ControlST V04.07 and is the recommended model for new systems and upgrades. Furthermore, beginning with ControlST V05.02, the PPDAH1B can send power distribution feedback data to the Mark VIeS Safety Controller, significantly enhancing its value in safety-critical applications.

2. Key Functions

Power System Status Acquisition: The IS200PPDAH1B can receive feedback signals from up to six core power distribution boards, including:

Power Bus Voltages: 28V DC control power, 125V DC battery power, 24/48V DC power, and 100-250V AC input power.

Branch Circuit Status: Fuse status, switch position, and output circuit validity.

Ground Fault Detection: Detects faults in floating DC systems by monitoring the voltage offset from earth.

Bulk Power Supply Health: Reads dry contact status signals to determine the health of external power modules.

Electronic Identification & Auto-Configuration: The module uses electronic ID lines to automatically identify the type and revision of each connected power distribution board, enabling "plug-and-play" configuration. The PPDA populates the IONet signal space based on the identified boards, eliminating the need for manual setup.

Dual-Redundant Ethernet Communication: Two Ethernet ports provide redundant communication paths to the R, S, and T controller networks. Data reporting continues uninterrupted even if one network link fails.

Status Indication via LEDs: The front panel features 24 LEDs that provide an immediate visual summary of the power system's health, including:

Pbus R/S/T regulation within 28V±5%.

Status of R/S/T power sources.

125V/24V battery voltage and grounding status.

Branch circuit output status.

User-defined alarm indications.

Diagnostics & Alarming: The IS200PPDAH1B performs comprehensive self-diagnostics, including:

Power-up self-tests (RAM, Flash, Ethernet ports, processor hardware).

Continuous internal power supply monitoring.

Verification of hardware matching between the terminal board, acquisition card, and processor card.

Health checks of the analog input circuits.

All diagnostic signals are accessible and manageable via the ToolboxST software.

3. Operational Principle

Signal Input & Processing: The PPDA connects to a host board (e.g., JPDS, JPDM, JPDG, JPDC) via a 62-pin connector. Each connected distribution board provides one "feedback group," which includes:

A feedback ground reference.

Five analog signal channels.

An ID signal line.

The PPDA performs differential measurement on each analog signal relative to its group's feedback ground, providing excellent common-mode noise rejection.

Electronic ID Mechanism: The PPDA reads the ID signal from each feedback group to determine the type of connected board (e.g., JPDB, JPDE, JPDF). Based on this identification, it applies the corresponding signal processing logic.

Analog Signal Conversion & Alarm Generation: A 16-bit analog-to-digital converter samples the input signals. The PPDA firmware compares these values against user-configurable thresholds (e.g., voltage tolerances, ground fault triggers) to generate alarms, which are reported to the controller via IONet.

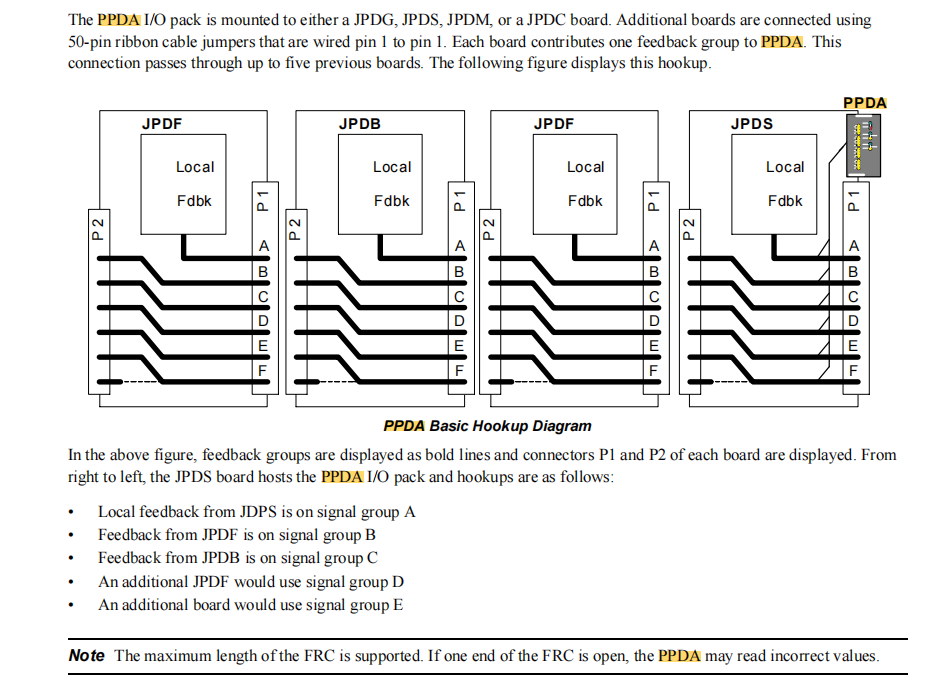

Feedback Daisy-Chain: The PPDA must be hosted on a main distribution board and must be the terminal point of the diagnostic daisy-chain. Other core boards are connected in series using 50-pin ribbon cables from their P2 connector to the P2 connector of the next board.

LED Status Display Logic: Most of the 24 LEDs are firmware-controlled to display key system status:

LEDs 1–3: Pbus R/S/T regulation.

LEDs 4–6: R/S/T power source status.

LEDs 8–9: 125V battery voltage and grounding.

LEDs 13–14: 24V battery voltage and grounding.

LEDs 19–20: AC Input 1 and 2 status.

LEDs 12, 17, 18, 24: Can be driven by user application code for custom status or alarms.

4. Installation & Configuration

Installation Steps:

Plug the PPDA directly into the JA1 connector of the host board.

Mechanically secure the I/O pack using the threaded studs and a mounting bracket to prevent strain on the connector.

Connect one or two Ethernet cables (ENET1 is typically connected to the R controller network).

Connect the power cable; the pack supports hot-plugging with soft-start capability.

Use ribbon cables to connect the P2 connectors of other core boards to the host board's P2 connector, forming the feedback daisy-chain.

ToolboxST Configuration: Key configuration parameters in ToolboxST include:

PS28vEnable: Enable/disable 28V power feedback.

InputDiagEnab: Enable/disable input diagnostics.

DC_125v_Trig_Volt: 125V DC fault trigger voltage.

Gnd_Mag_Trig_Volt: Ground fault trigger voltage.

ACFdbkInVoltage: AC input nominal voltage.

FuseDiag: Enable/disable fuse status diagnostics.

Compatibility & Limitations:

JPDS Host: +5 auxiliary boards (uses 1 group)

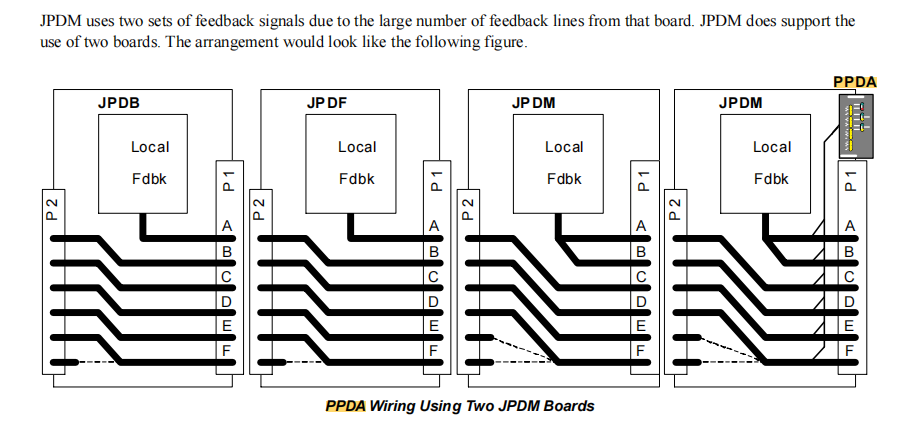

JPDM Host: +4 auxiliary boards (uses 2 groups)

JPDC Host: +4 auxiliary boards (uses 2 groups)

JPDG Host: +3 auxiliary boards (uses 3 groups)

PPDAH1B requires ControlST V04.07 or later.

It supports a maximum of 6 feedback groups. The number of connectable auxiliary boards depends on the host type:

Mixing JPDS and JPDM, or JPDC with JPDS/JPDM, is not allowed.

5. Detailed Comparison: IS220PPDAH1B vs. IS220PPDAH1A

The IS220PPDAH1B is a targeted upgrade of the IS220PPDAH1A. While both share the same core architecture and basic functions, there are critical differences in key components and specific features, as detailed below:

| Comparison Item | PPDAH1A | PPDAH1B | Implications of the Difference |

| Core Processor | Features the BPPB processor board. | Features the BPPC processor board. | The BPPC is a newer, more reliable processor platform. This change primarily addresses the end-of-life status of the BPPB, ensuring long-term product availability and support. |

| Product Lifecycle Status | Has reached end-of-life. Document states "These processors are reaching end of life." | The recommended replacement and successor model, in active support. | For new projects and modernizations, the IS220PPDAH1B should be selected to avoid future maintenance risks due to part obsolescence. |

| Mark VIeS Safety Controller Integration | No mentioned support for sending data to the Mark VIeS Safety Controller. | Explicitly supported. From ControlST V05.02, it can send power distribution data to the Mark VIeS Safety Controller. | This is a key enhancement of the IS220PPDAH1B. It allows power system status to be integrated directly into the safety loop, improving the integrity and reliability of the overall control system safety architecture. |

| Onboard Accelerometer Feature | Supported in versions prior to ControlST V05.02. | No longer supported starting with ControlST V05.02. | This is a breaking change. When upgrading from an older system, if the existing application uses the accelerometer variable, the ToolboxST configuration must be manually checked and modified. |

| Operating Temperature Range | -30°C to +65°C (-22°F to +149°F) | -40°C to +70°C (-40°F to +158°F) | The IS220PPDAH1B has a wider operating temperature range, particularly improved tolerance for high ambient temperatures, enabling stable operation in harsher industrial environments. |

Summary: The IS220PPDAH1B is not a simple model refresh but a significant upgrade driven by the need to address supply chain issues, enhance environmental robustness, and expand system integration capabilities, especially with the safety system. Although it removes the less commonly used accelerometer, its improvements in processor performance, operating temperature range, and safety controller integration make it the superior choice for modern control system requirements.