The TQ403 is a high-performance non-contact proximity measurement sensor from the VM product line. Together with the EA403 extension cable and IQS450 signal conditioner, it forms a complete proximity measurement system. Based on the eddy-current principle, the system is widely used for condition monitoring and protection of industrial rotating machinery, particularly suitable for vibration and position measurement in critical equipment such as steam turbines, gas turbines, hydraulic turbines, generators, turbo-compressors, and pumps.

The TQ403 system features high precision, high reliability, wide temperature range operation, and excellent environmental adaptability. It supports use in hazardous areas (explosion-proof environments) and provides both voltage and current output options, making it suitable for various industrial monitoring system integration requirements.

Working Principle

The TQ403 proximity measurement system operates based on the Eddy-Current Principle for non-contact displacement measurement. The system's working mechanism is as follows:

1. Electromagnetic Field Generation and Coupling Mechanism

The core of the TQ403 sensor is a precision-wound coil structure driven by a high-frequency AC signal from the IQS450 signal conditioner. When AC current passes through the coil, it generates a high-frequency alternating electromagnetic field in the surrounding space. This field has specific spatial distribution characteristics, with its strength decaying exponentially with increasing distance. When a conductive metal target enters this electromagnetic field, closed-loop eddy currents are induced on the target surface according to Faraday's law of electromagnetic induction. The strength and distribution characteristics of these eddy currents are closely related to the gap distance between the sensor and target, the electrical and magnetic properties of the target material, and the excitation frequency.

2. Impedance Modulation and Signal Extraction

The flow of eddy currents in the target material generates a reverse electromagnetic field opposite in phase to the original field, a phenomenon known as Lenz's law. The interaction between these two fields significantly changes the equivalent impedance of the sensor coil. This impedance change includes variations in both resistive and inductive components: the change in resistive component mainly stems from energy dissipation caused by eddy currents, while the change in inductive component originates from the weakening effect of the reverse field on the original field. There is a highly nonlinear functional relationship between the impedance change of the sensor coil and the gap distance. The system converts this nonlinear relationship into a highly linear voltage or current output through precision circuit design and algorithm processing.

3. Signal Conditioning and Linearization Processing

The IQS450 signal conditioner serves as the intelligent core of the entire system, containing a high-performance high-frequency oscillator, precision demodulation circuit, and advanced signal processing unit. The oscillator generates a high-frequency signal (typically 1-2 MHz) with stable frequency and constant amplitude to drive the sensor coil. The receiving circuit precisely extracts useful information from impedance changes using phase-sensitive detection (PSD) technology. The system employs digital temperature compensation technology and polynomial fitting algorithms to perform real-time linearization processing and temperature drift compensation on the raw signals from the sensor, ensuring excellent measurement accuracy throughout the entire operating temperature range.

4. Output Interface and System Integration

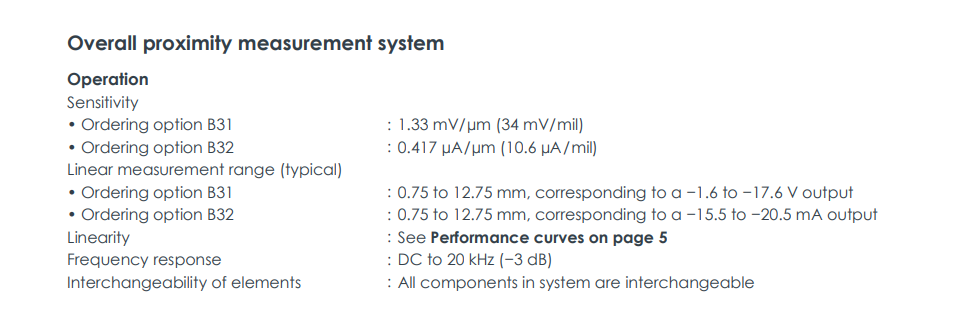

The processed measurement signals are output in two ways: voltage output mode uses a three-wire configuration providing linear output from -1.6V to -17.6V, corresponding to a measurement range of 0.75mm to 12.75mm; current output mode uses a two-wire configuration providing current signals from -15.5mA to -20.5mA. Both output methods feature short-circuit protection and reverse polarity protection, enabling direct integration with PLC, DCS, or dedicated machine monitoring systems. The system's output impedance, capacitance, and inductance parameters are optimized to ensure signal integrity and stability during long cable transmission.

5. Calibration and Target Material Compensation

The system is factory-calibrated using VCL 140 steel (1.7225) as the standard target material, with sensitivity set to 1.33 mV/μm or 0.417 μA/μm. Since different materials have different electrical conductivity and magnetic permeability, recalibration or material coefficient correction is required if the target material changes in practical applications. The system supports customized calibration services. Users can provide specific material samples, and we will provide targeted calibration solutions to ensure measurement accuracy meets specific application requirements.

Features

The TQ403 system integrates multiple advanced technologies, offering excellent performance characteristics and broad application adaptability. Its main features include:

1. True Non-Contact Measurement Capability

The system adopts a completely non-contact measurement method, eliminating mechanical wear, frictional heat, and load effects associated with traditional contact sensors. This measurement method is particularly suitable for high-speed rotating machinery applications, enabling precise capture of rotor dynamic behavior without imposing any additional load or interference on the rotating body. The absence of physical contact between the sensor and target significantly extends equipment service life and reduces maintenance requirements.

2. Ultra-Wide Bandwidth and High Dynamic Response Characteristics

The system features an extremely wide frequency response range from DC to 20kHz (-3dB), a performance indicator that leads in industrial proximity sensors. The low-frequency end extends down to DC, enabling accurate measurement of slowly changing displacements and static positions; the high-frequency end reaches 20kHz, sufficient to capture high-frequency vibration components and impact events in most rotating machinery. This wide bandwidth characteristic enables the system to be used not only for vibration monitoring but also for advanced diagnostic applications such as gear meshing frequency analysis and bearing fault feature extraction.

3. Extended Measurement Range and Excellent Linear Performance

The TQ403 provides a wide measurement range of 12mm, significantly larger than traditional 2mm or 4mm proximity sensors, offering greater installation margin and safety margin for vibration monitoring of large rotating machinery. The system maintains excellent linear characteristics throughout the measurement range, with linearity error controlled within a minimal range after precision compensation. Users can know the accuracy characteristics of various measurement intervals through the provided performance curves, thereby selecting appropriate operating points based on actual application requirements.

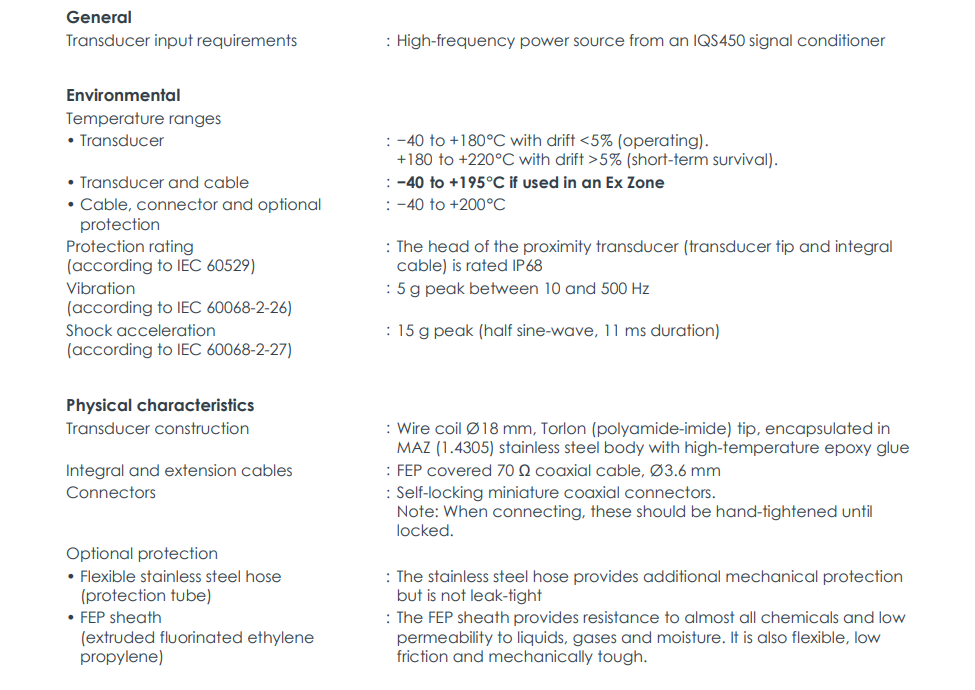

4. Extreme Environmental Adaptability and Robustness Design

The system can operate stably in extreme temperature ranges from -40°C to +180°C, with short-term tolerance up to +220°C in harsh environments. The sensor head features IP68 protection rating, providing complete protection against dust ingress and continuous immersion. Mechanically, the sensor can withstand vibration acceleration of 5g peak (10-500Hz) and shock acceleration of 15g peak (half-sine wave, 11ms duration), ensuring reliable operation in harsh industrial environments.

5. Comprehensive Explosion-Proof Certification and Safety Assurance

The system provides multiple explosion-proof certified versions to meet different regional and international standard requirements: Ex ia version complies with IECEx, ATEX, cCSAus and other certifications, suitable for Zone 0/1/2 hazardous areas; Ex nA version is suitable for Zone 2 areas. Each explosion-proof type has corresponding certificates and special conditions for use. Users can select the appropriate explosion-proof based on actual application environment.

6. Flexible Output Configuration and System Integration Options

The system provides both voltage and current output modes to meet different interface requirements. The voltage output mode provides a dynamic range of 16V with output impedance of 500Ω; the current output mode provides a dynamic range of 5mA using a two-wire connection method, greatly simplifying wiring requirements. Both outputs feature short-circuit protection and overload protection, ensuring equipment protection in accidental situations.

7. Excellent Component Interchangeability and System Scalability

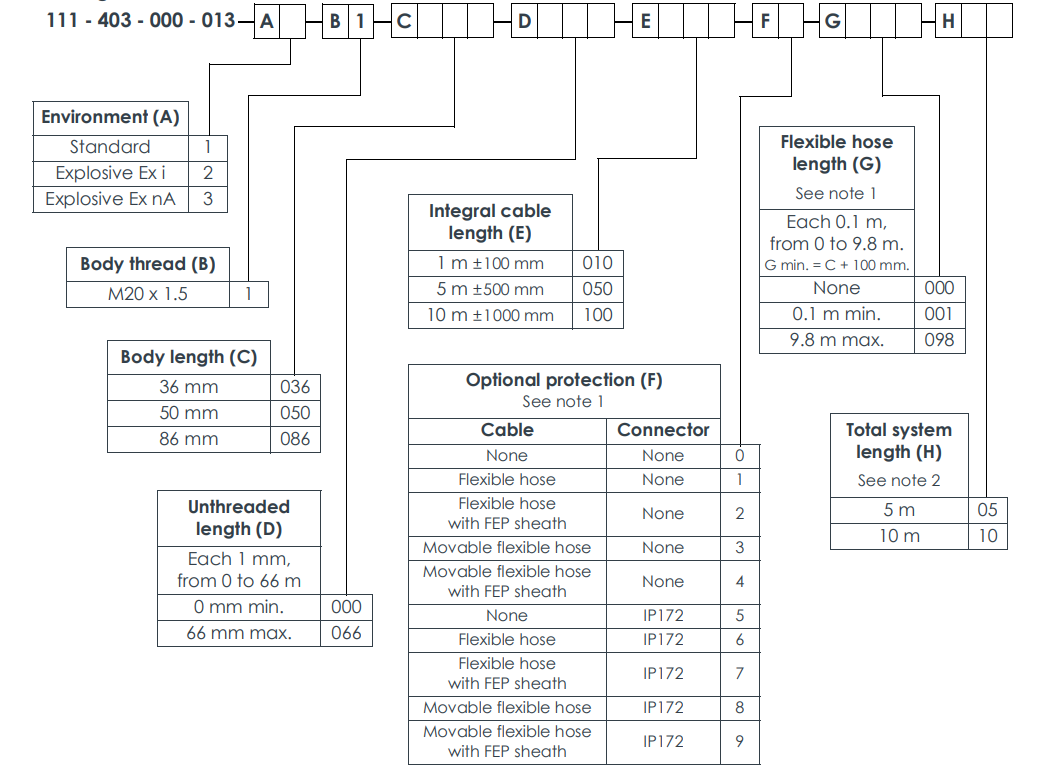

The system adopts a modular design concept where all components (sensor, cable, conditioner) are fully interchangeable without recalibration. It supports various cable length combinations (1m/5m/10m integral cable + extension cable) with total system lengths of 5m or 10m. The system also supports "electrical trimming", optimizing system performance by adjusting the electrical length of the cable to ensure signal integrity during long cable transmission.

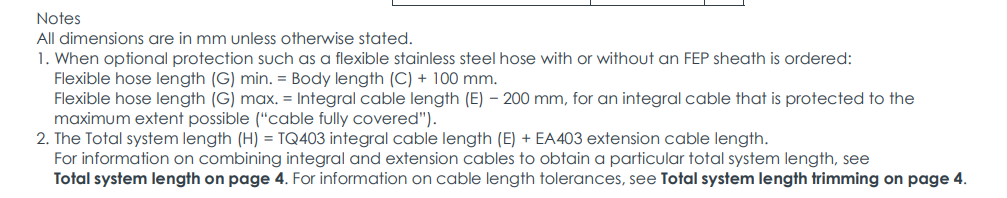

8. Rugged Mechanical Structure and Multiple Protection Options

The sensor head is made of Torlon® (polyamide-imide) material, which offers excellent high-temperature stability, mechanical strength, and chemical corrosion resistance. The housing uses MAZ (1.4305) stainless steel material, providing excellent mechanical protection. Users can also optionally equip stainless steel flexible hoses (minimum bend radius 50mm) and FEP sheaths to further enhance cable mechanical protection and environmental adaptability.

9. Broad System Compatibility and Application Adaptability

The system can be seamlessly integrated with VM's corresponding monitoring systems or powered independently by external power supply. It provides DIN rail mounting options (MA130 mounting adapter) for easy installation in control cabinets. The system also offers various accessory choices, including industrial enclosures, junction boxes, and interconnection protectors, meeting installation requirements for various application environments.

Technical Specifications Summary

| Item | Specification |

| Measurement Principle | Eddy-Current Effect |

| Measurement Range | 12 mm |

| Output Options | Voltage: -1.6 V to -17.6 V

Current: -15.5 mA to -20.5 mA |

| Frequency Response | DC to 20 kHz (-3 dB) |

| Linearity Error | Refer to Performance Curves (Page 5) |

| Operating Temperature | -40°C to +180°C |

| Protection Rating | IP68 (Sensor Head) |

| Explosion-Proof Certification | Ex ia IIC T6–T3 Ga (Zone 0/1/2)

Ex nA IIC T6–T3 Gc (Zone 2) |

| Cable Type | 70 Ω Coaxial Cable, FEP Sheath |

| Connector | Self-Locking Miniature Coaxial Connector |

| Weight | Approx. 140 g (Standard) / 220 g (Ex Version) |

Application Areas

The TQ403 system is widely used in the following industrial scenarios:

Turbomachinery: Shaft relative vibration and axial position monitoring for steam turbines, gas turbines, and hydraulic turbines

Power Generation Equipment: Condition monitoring of generators and exciters

Compressor Sets: Vibration protection for centrifugal and axial compressors

Pump Equipment: Mechanical health monitoring for high-speed pumps and multi-stage pumps

Other Rotating Machinery: Fans, gearboxes, motors, etc.