The TQ912 is a high-performance reverse-mount eddy current proximity sensor from VM product line. It serves as one of the core components of the TQ9xx series eddy current proximity measurement chains, designed for non-contact measurement of relative displacement, vibration, and axial position of rotating machinery in demanding industrial environments. The TQ912, together with its matching EA90x extension cable and IQS900 signal conditioner, forms a complete, calibrated measurement chain. It is widely used in condition monitoring and safety protection systems for large rotating equipment such as steam turbines, gas turbines, hydraulic turbines, generators, turbo-compressors, and pumps.

The core measurement principle and key performance parameters of the TQ912 are essentially the same as those of the TQ902. Their critical distinction lies in the mechanical mounting style: the TQ912 is specifically designed for reverse-mount applications. This means the sensor's cable exits from the rear of the mounting nut, rather than from the side as in the standard mount (TQ902). This design offers greater flexibility and convenience for routing and installation at mounting points with space constraints or specific mechanical structures.

Operating based on the eddy-current principle, this sensor is an ideal choice for critical machinery protection and predictive maintenance applications, renowned for its high reliability, high accuracy, exceptional environmental resilience, and comprehensive safety certifications (including explosion-proof and functional safety certifications).

Working Principle

The operation of the TQ912 sensor is based on the Eddy-Current Principle, a non-contact electromagnetic induction measurement technique. Its core working process can be broken down into the following steps:

High-Frequency Excitation Signal Generation:

The TQ912 sensor itself is a passive device; its operational energy is supplied by the matching IQS900 signal conditioner. A high-frequency oscillator within the IQS900 generates a high-frequency (typically MHz range) alternating current, which is delivered to the TQ912 sensor via the connecting cable.

Electromagnetic Field Generation and Eddy Current Effect:

The head of the TQ912 sensor contains a precision-wound induction coil. When the high-frequency current flows through this coil, it generates a high-frequency alternating electromagnetic field around its front end, i.e., the sensor tip (made of high-performance engineering thermoplastic PPS - Polyphenylene Sulfide).

When this electromagnetic field acts on the surface of a conductive metal target (typically the shaft or shaft collar of rotating machinery), according to Faraday's law of electromagnetic induction, closed-loop currents, called eddy currents, are induced in the target's surface layer.

Impedance Change and Distance Sensing:

These induced eddy currents themselves generate a secondary magnetic field opposing the original field from the sensor coil, thereby counteracting (weakening) the energy of the original field.

This interaction causes a change in the effective impedance of the sensor coil. The distance (gap) between the sensor tip and the target surface directly determines the strength of this interaction: the closer the distance, the stronger the eddy current effect, and the greater the change in coil impedance; the farther the distance, the weaker the effect, and the smaller the impedance change.

Therefore, a definitive functional relationship exists between the change in the coil's impedance and the air gap distance between the sensor and the target.

Signal Demodulation and Output:

The change in the coil's impedance is detected by the demodulation circuit integrated within the IQS900 signal conditioner.

The signal conditioner processes and converts this complex impedance variation, ultimately outputting an analog signal (voltage or current) that is precisely proportional to the gap distance.

This output signal typically consists of two components:

A dynamic alternating current (AC) component: Corresponding to the rapid vibrational displacement of the shaft relative to the sensor.

A quasi-static direct current (DC) component: Corresponding to the average gap (position) between the sensor and the shaft.

In summary, the TQ912 converts physical distance changes into electrical parameter changes of the coil via electromagnetic induction, which are then transformed into standardized electrical signals by the signal conditioner, enabling precise non-contact displacement measurement.

Core Functions and Features

As the core of a high-performance measurement chain, the TQ912 sensor boasts the following outstanding functions and features:

Reverse-Mount Design:

This is the most distinctive feature of the TQ912. Its cable exits from the rear of the sensor body (mounting nut side), not the side as in the standard type. This design makes it particularly suitable for:

Applications where space behind the mounting hole is sufficient but lateral space is constrained.

Applications requiring the cable to be hidden inside a mounting sleeve or mechanical structure for better protection or neater cable routing.

Specifically designed sensor mounting adaptors.

Non-Contact High-Precision Measurement:

Based on the eddy-current principle, it requires no physical contact with the target, avoiding wear and loading effects, and accurately reproducing the dynamic vibration and position information of high-speed rotating shafts.

Offers a linear measurement range of 2 mm or 4 mm (depending on the signal conditioner option), with excellent linearity and sensitivity (e.g., 8 mV/μm or 4 mV/μm).

Wide Frequency Response:

The overall frequency response of the measurement chain can reach DC to 20 kHz (~3 dB), capable of accurately capturing everything from very slow axial movement to vibration of high-speed rotors running at tens of thousands of RPM, meeting the requirements of API 670 5th Edition for vibration monitoring systems.

Exceptional Environmental Adaptability:

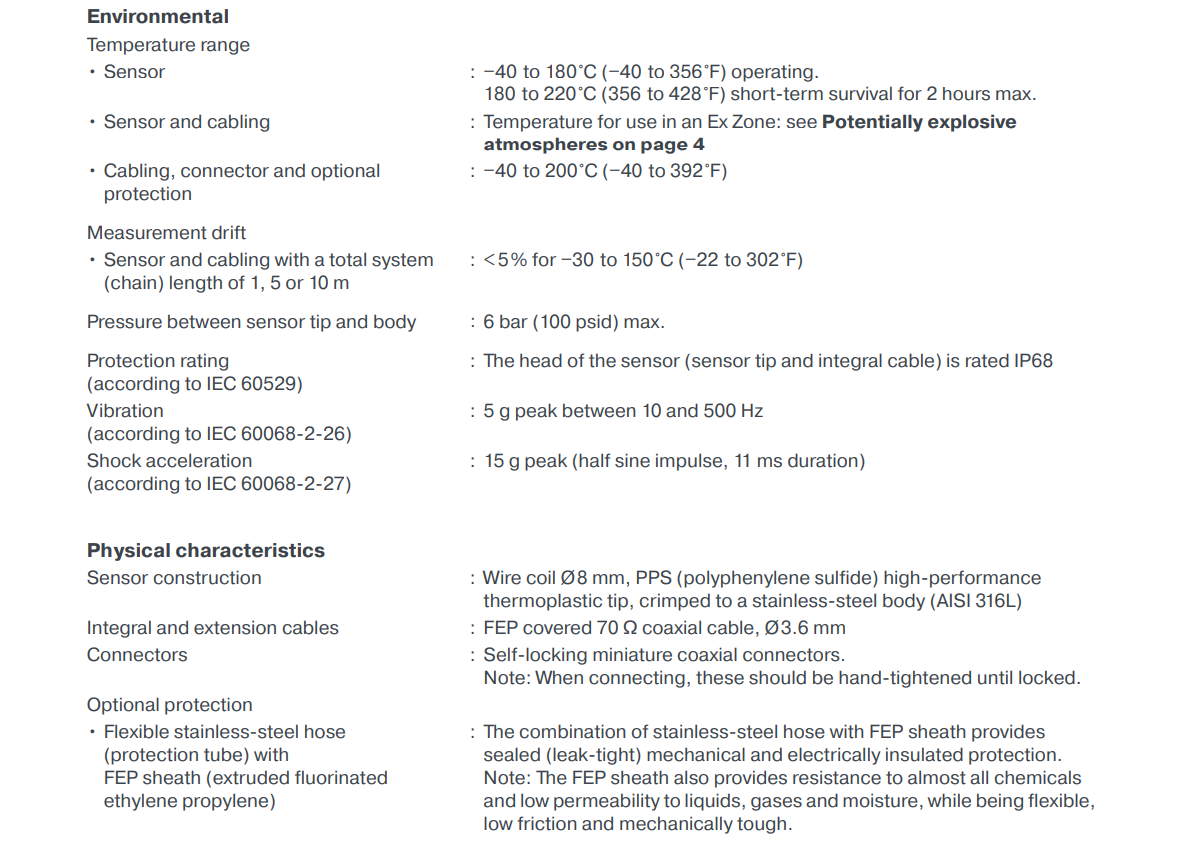

Wide Operating Temperature Range: The sensor body can operate continuously at ambient temperatures from -40°C to +180°C, and withstand short-term exposure to temperatures up to 220°C.

Robust Construction: The sensor body is manufactured from stainless steel (AISI 316L), and the head sensing coil is encapsulated in PPS material, offering excellent chemical resistance and mechanical strength.

High Protection Rating: The sensor head (probe and integral cable) has a protection rating of IP68, resistant to dust ingress and prolonged submersion in water.

Vibration and Shock Resistance: Can withstand vibration of 5 g peak (10 to 500 Hz) and shock of 15 g peak (half-sine wave, 11 ms duration).

Comprehensive Hazardous Area Certification (Optional):

Optional A5 (Ex) version is available, obtaining various international explosion-proof certifications suitable for use in hazardous areas (potentially explosive atmospheres).

Certifications cover multiple regions and standards including Europe (ATEX), International (IECEx), North America (cCSAus/UL), UK (UKEX), South Korea (KGS), Kazakhstan (EAEU), etc. (e.g., Ex ec, Ex ia for Gas and Dust environments).

In explosion-proof applications, the sensor is considered a "Simple Apparatus" and must be used with EA90x cables and IQS900 signal conditioners that also possess corresponding explosion-proof certifications.

Component Interchangeability and System Integration:

The TQ912, EA902 extension cable, and IQS900 signal conditioner form a pre-calibrated measurement chain. Each component within the chain is interchangeable without requiring recalibration, greatly simplifying spare parts management and field maintenance.

Fully compatible with Parker Meggitt's VM600™/VM600 and VibroSmart® machinery condition monitoring systems; the output signal can be directly connected.

Its form, fit, and function are equivalent to the classic TQ4xx series sensors, serving as a direct upgrade replacement, facilitating upgrades for existing systems.

Support for Functional Safety Applications:

When paired with an IQS900 signal conditioner featuring diagnostics (ordering option C2), the entire measurement chain is SIL 2 (IEC 61508) and Cat 1 PL c (ISO 13849) "by design".

This enables the use of the TQ912 in safety-related systems, such as speed measurement chains in Overspeed Detection Systems (ODS), providing highly reliable input for critical control functions.

Flexible Configuration Options:

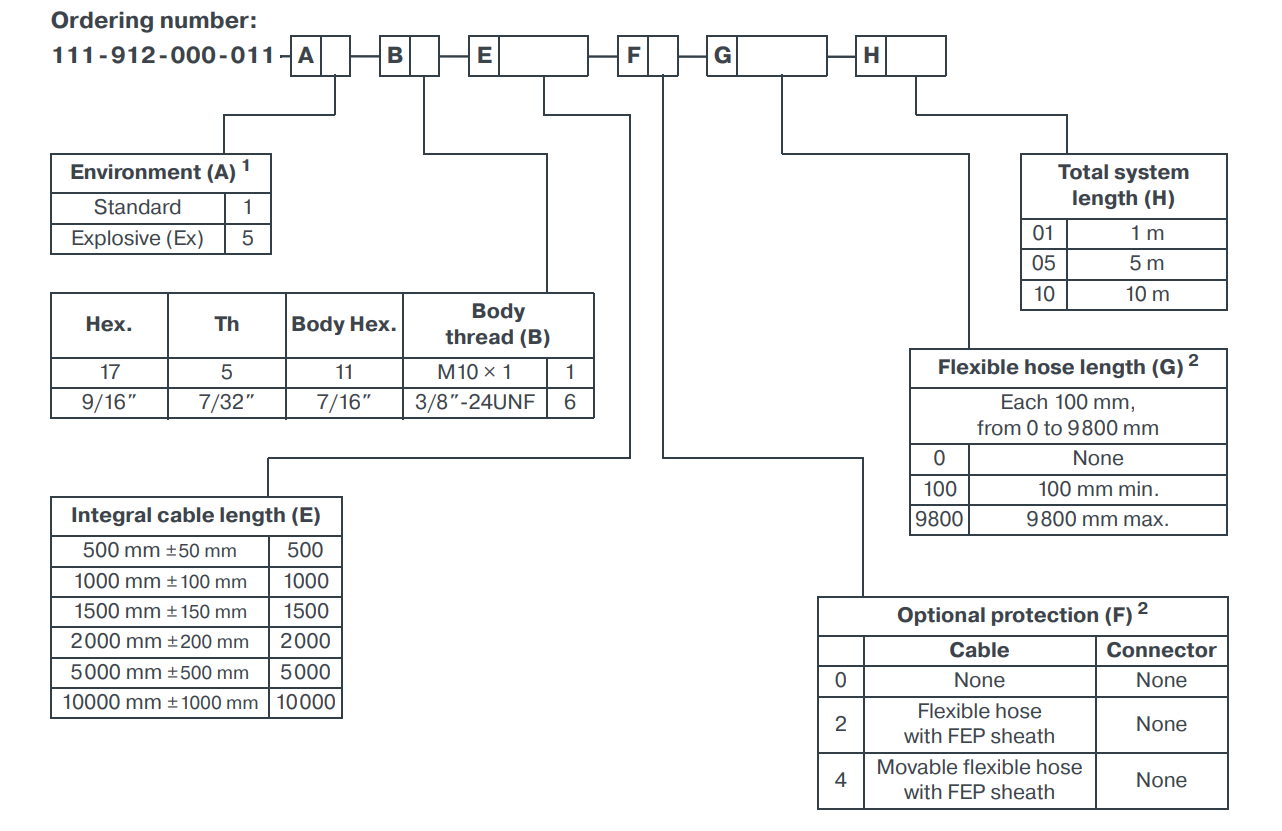

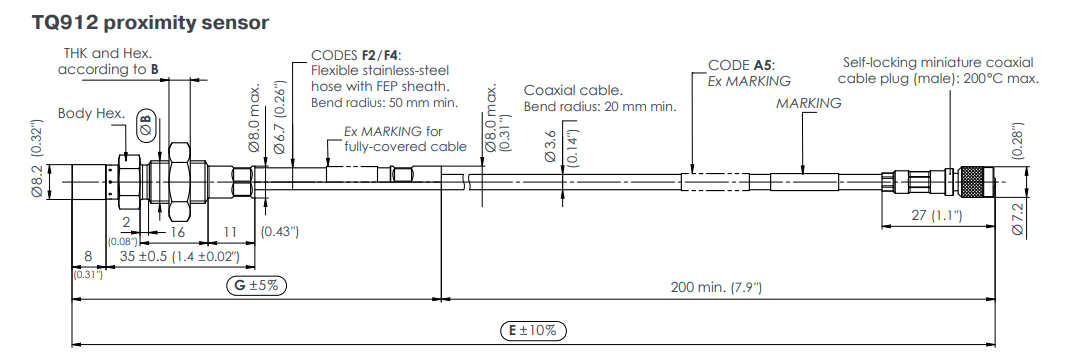

Multiple Thread Specifications: Offers both metric (e.g., M10x1, M14x1.5, M16x1.5) and imperial (e.g., 3/8"-24UNF, 1/2"-20UNF, 5/8"-18UNF) thread options to adapt to different mechanical design standards worldwide.

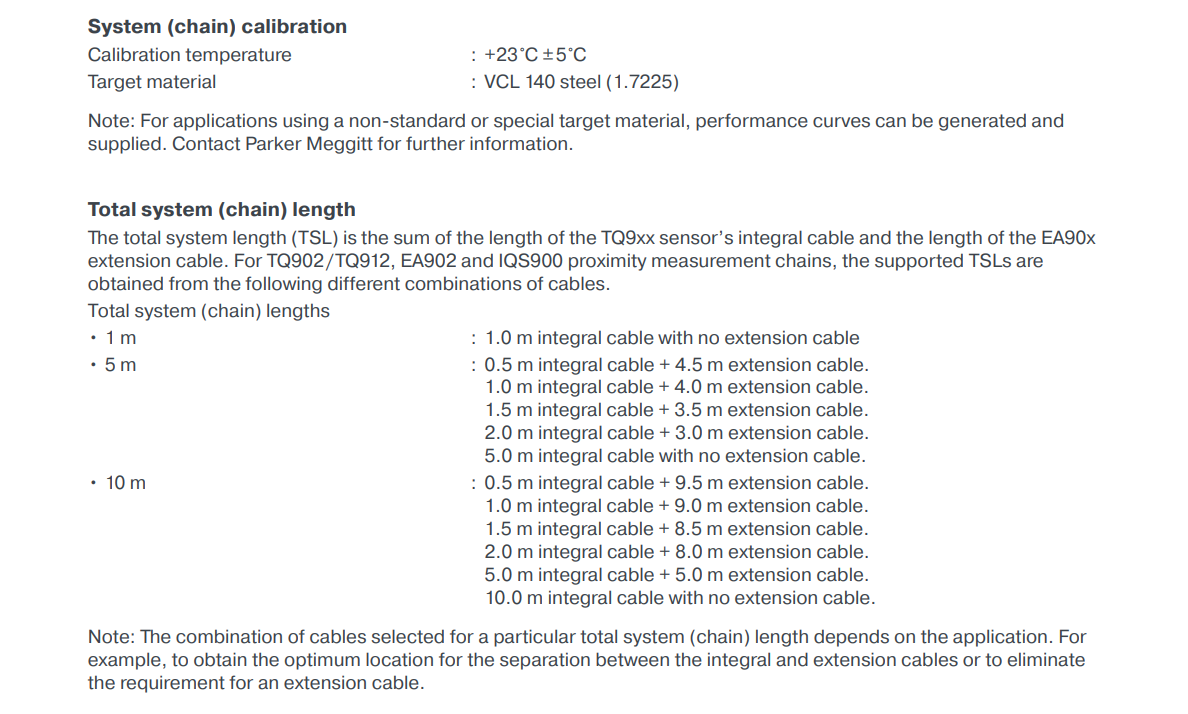

Multiple Cable Lengths: The sensor's integral cable is available in various standard lengths from 0.5 meters to 10 meters. It can be combined with different lengths of EA902 extension cables to achieve a Total System Length (TSL) of 1m, 5m, or 10m.

Optional Protection Kits: Provides flexible stainless steel hose with an FEP (Fluorinated Ethylene Propylene) sheath for sealed, chemical-resistant, and mechanical damage protection for the cable. Also optional is the IP172 Interconnection Protector to provide mechanical and environmental protection for the connection point between the sensor and the extension cable.