The IS200VVIBH1C Vibration Monitor Board is a core vibration monitoring and protection component within the GE Mark VI turbine control system. Acting as the system's "stethoscope," it is specifically designed to acquire, process, and analyze various vibration and position signals from critical parts of turbine machinery (such as bearings, shaft journals, and thrust collars). This board connects via TVIB or DVIB terminal boards to up to 14 compatible types of Bently Nevada® probes (including proximity probes, velocity sensors, accelerometers, seismic transducers, and Keyphasor® probes), enabling continuous, high-precision monitoring of turbine operational status. Its core mission is to prevent equipment damage and ensure the safe and stable operation of large rotating machinery by detecting abnormal mechanical vibrations and positional changes and issuing timely alarms or even trip signals. Whether for gas or steam turbines, the VVIB provides a complete solution ranging from basic protection to advanced vibration analysis.

2. Core Functions & Detailed Principles

The functionality of the IS200VVIBH1C extends far beyond simple signal acquisition. It incorporates complex signal processing algorithms and multi-layered protection logic, with its principles deeply integrated with sensor technology, digital signal processing, and control systems engineering.

2.1 Multi-Channel Signal Acquisition and Digitization

This forms the foundation for all advanced functions. The VVIB acts as a high-performance, multi-channel data acquisition system.

Technical Principle:

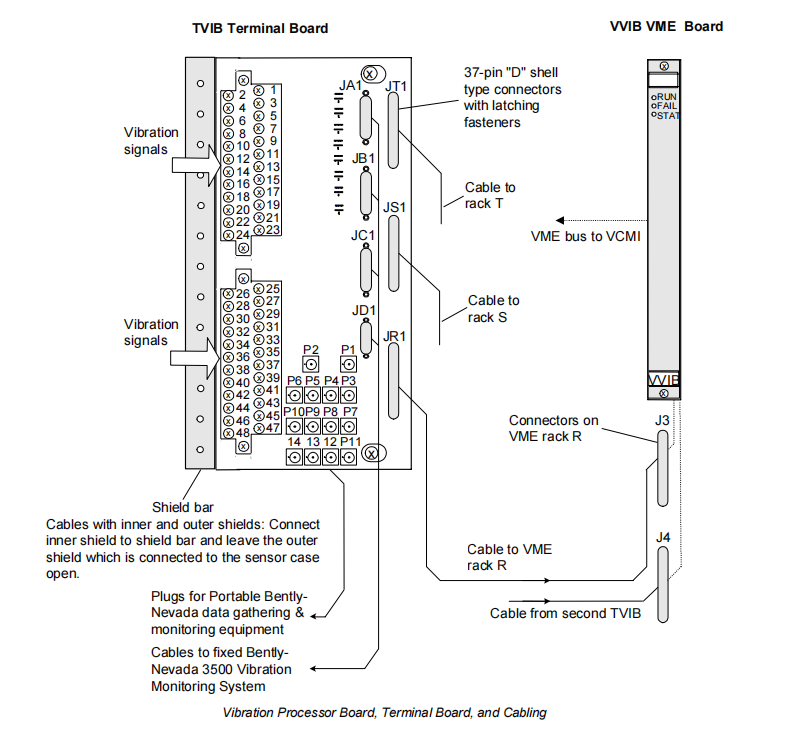

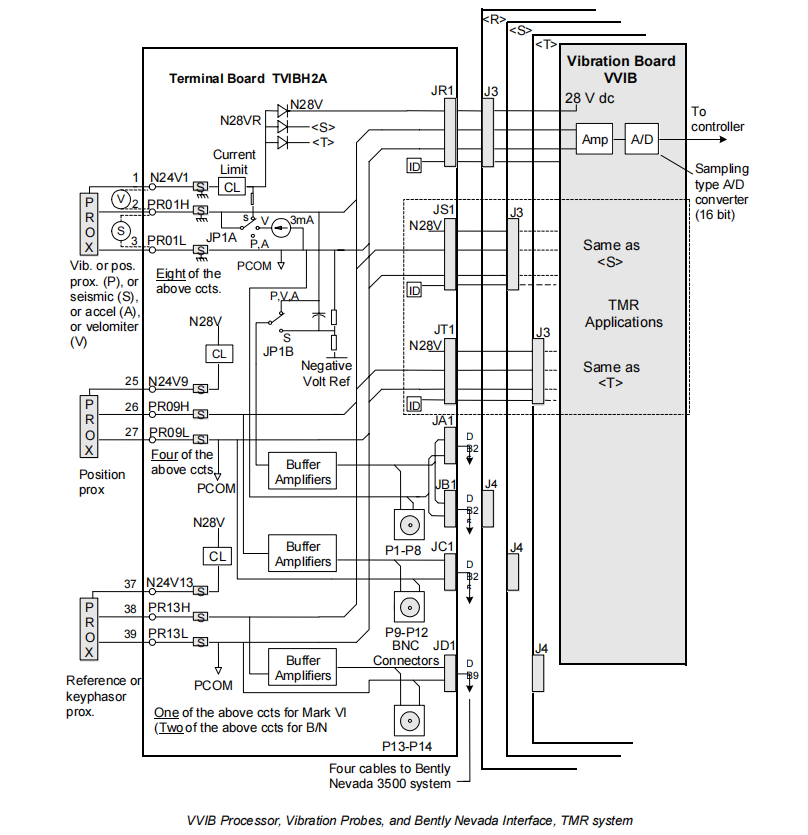

Interface and Expansion: A single IS200VVIBH1C processor board can simultaneously connect to two TVIB terminal boards, thereby expanding the total monitoring channels to 26. Each TVIB terminal board provides 13 channels: 8 for vibration measurement, 4 for position measurement, and 1 dedicated to the Keyphasor signal. This design provides ample interfaces for monitoring large, multi-bearing rotors.

Signal Conditioning and Power Supply: The TVIB terminal board not only provides signal termination points but also supplies the -28 V DC excitation power required for active probes (like the Proximitors needed for proximity probes). In TMR (Triple Modular Redundant) systems, the power is made redundant via a diode high-select circuit, ensuring that a single power supply failure does not affect monitoring. Buffer amplifiers on the terminal board provide preliminary conditioning of the raw analog signals from the probes, ensuring signal integrity after long-distance transmission.

High-Precision Analog-to-Digital Conversion: The conditioned analog signals are transmitted to the IS200VVIBH1C board via shielded cables. The IS200VVIBH1C board employs a 16-bit successive approximation A/D converter (with 14-bit effective resolution) to sample all these input channels at high speed and simultaneously. The sampling rate is dynamically adjusted based on the number of configured channels: a 4.6 kHz fast scan mode is used when 8 or fewer vibration channels are active, while the rate drops to 2.3 kHz for more than 8 channels to balance processing load. This simultaneous sampling technique ensures all channel data is captured at the same instant, laying a crucial foundation for subsequent phase analysis and accurate peak detection.

2.2 Vibration and Position Parameter Calculation

The IS200VVIBH1C's core algorithms process the digitized raw signals through a series of steps to extract physically meaningful engineering values.

Technical Principle:

Peak-to-Peak Calculation and Filtering: For vibration signals (channels 1-8), the IS200VVIBH1C uses a 160-millisecond time window to capture the dynamic range of the signal. Within this window, the firmware continuously tracks the signal's maximum (Vmax) and minimum (Vmin) values, calculating their difference as the raw peak-to-peak value (Vpp). To improve the signal-to-noise ratio and target specific frequency ranges, the signal also passes through configurable digital filters. The filter type (FilterType) can be selected based on the sensor type, including None, Low-pass, High-pass, or Band-pass. For seismic and velocity transducers, filters with up to 8-pole steep attenuation can be configured to precisely shape the frequency response.

Gap/Position DC Component Extraction: For proximity probes, the output signal contains a DC component (representing the average gap or position) and an AC component (representing vibration). The IS200VVIBH1C uses a second-order low-pass filter with an 8 Hz cutoff frequency to smoothly extract the DC component for position monitoring functions such as rotor axial position, differential expansion, and eccentricity.

Engineering Unit Scaling: The calculated voltage values (whether AC Vpp or DC Vgap) are converted into physically meaningful engineering units using user-configured scaling factors (VIB_Scale) and offsets (ScaleOff), for example, mils for displacement and inches/second (in/sec) for velocity. This allows the control logic and operators to directly interpret the measurements.

2.3 Keyphasor Processing and Speed Measurement

Channel 13 is specifically designed to process the Keyphasor signal, which is the cornerstone of advanced vibration analysis.

Technical Principle:

Keyphasor Principle: The Keyphasor is typically a proximity probe aimed at a keyway or notch on the shaft. Each time the keyway passes the probe, the gap changes abruptly, generating a pulse signal. This pulse marks the reference phase point for each revolution of the rotor.

Pulse Detection and Speed Calculation: The IS200VVIBH1C employs a hardware comparator circuit with software-adjustable hysteresis to accurately capture the rising edge of each Keyphasor pulse. These pulses are fed into an FPGA (Field-Programmable Gate Array), where internal counters precisely measure the time interval between consecutive pulses. The firmware uses this interval to directly calculate the instantaneous rotor speed (RPM). At very low speeds where the hardware comparator becomes unreliable, the runtime code analyzes the gap signal itself on channel 13 (GAP13_KPH1) to count pulses, ensuring accurate speed measurement across the entire operating range.

2.4 Advanced Vibration Analysis (1X, 2X, and Tracking Filters)

The IS200VVIBH1C goes beyond simple overall vibration monitoring, capable of decomposing the vibration vector to provide diagnostic-grade information.

Technical Principle:

Modulation and Filtering: The raw vibration signal (e.g., from channel 1) is multiplied by sine and cosine reference signals derived from the Keyphasor signal (at 1X or 2X running speed). This process "down-converts" the vibration component at the 1X (or 2X) frequency to a DC level, while other frequency components are "up-converted" to higher frequencies.

Vector Extraction: The multiplied signals pass through an extremely low cutoff frequency (0.25 Hz) 4-pole low-pass filter, which removes all high-frequency noise, ultimately outputting two DC signals representing the In-Phase (real) and Quadrature (imaginary) parts of the 1X vibration vector.

Magnitude and Phase Calculation: The peak magnitude (Vib1Xy) of the 1X vibration is obtained by calculating the square root of the sum of the squares of the real and imaginary parts. The phase angle (Vib1xPHy) of the vibration vector relative to the Keyphasor pulse is obtained by calculating the arctangent of the ratio of the imaginary part to the real part. This phase information is crucial for determining the orientation of rotor unbalance or misalignment.

1X and 2X Vibration Component Analysis: This function determines the magnitude and phase of vibration components synchronous with (1X) or at twice (2X) the running speed. Its core is synchronous demodulation (phase-locked amplification) technology.

Tracking Filters: This function is designed for applications like LM series gas turbines that use accelerometers. Its principle is similar to 1X/2X analysis, but instead of locking onto the Keyphasor frequency, it can dynamically track three independent speed signals (LM_RPM_A, B, C) provided by the controller, demodulating the vibration amplitude (LMVibxA, B, C) at these three specific speeds in real-time. This is extremely useful for monitoring multi-shaft units or vibration behavior when passing through critical speeds.

2.5 Multi-Layer Protection and Limit Checking

All processed data ultimately serves the protection function.

Technical Principle:

Configurability: Users can enable (SysLimxEnable), set the limit value (SysLimitx), select the check type (greater-than-or-equal-to or less-than-or-equal-to, SysLimxType), and decide whether to latch (SysLimxLatch) for each limit block. The latching function means that once triggered, the alarm state will remain until manually reset, ensuring abnormal conditions are not missed.

Application: These limits are used to trigger different levels of alarms (Warning) and dangerous trips (Trip). For example, a vibration value exceeding Limit1 might trigger a warning alarm to alert maintenance personnel, while exceeding the higher Limit2 would directly initiate a unit trip for emergency shutdown.

System Limit Checking: Each vibration and position channel is equipped with two fully configurable system limit blocks.

Intelligent Fault Logic: The system incorporates intelligent interlock logic. For instance, if a probe fault based on the DC component is detected (e.g., open or short circuit), the system can inhibit the vibration trip based on the AC component, preventing a false shutdown caused by the sensor failure itself.

3. Hardware Specifications & Interface

Channel Capacity: Supports up to 2 TVIB terminal boards, totaling 26 monitoring channels.

Probe Compatibility: Fully supports Bently Nevada proximity, velocity, accelerometer, seismic, and Keyphasor probes.

Signal Sampling: 16-bit A/D converter, with sampling rates up to 4.6 kHz (simultaneous sampling).

Power Supply: Provides -28 V DC redundant power for Proximitors on the terminal boards.

Physical Interface: Communicates with the controller in the VME rack and terminal boards via 37-pin "D"-shell connectors with latching fasteners.

Output Interface: The TVIBH2A terminal board provides BNC connectors to route buffered signals directly to portable data acquisition equipment or a permanent Bently Nevada 3500 monitoring system, enabling data replication and advanced analysis.

4. Diagnostics & Maintenance

The IS200VVIBH1C possesses robust self-diagnostic and system diagnostic capabilities.

Hardware Diagnostics: Continuously monitors A/D converter calibration levels to ensure measurement accuracy; checks terminal board ID chips to prevent hardware misconfiguration; monitors input signals for out-of-limit conditions (open or short circuit).

Status Indication: Provides intuitive status information via front panel LEDs for power, online status, communication links, diagnostic alarms, and over-temperature warnings.

Software Diagnostics: All system limit statuses and probe fault information are available to the Mark VI controller via variables like L3DIAG_VVIB and can be displayed and logged on WorkstationST, facilitating troubleshooting and historical data analysis.