The CA202 piezoelectric accelerometer is a high-performance industrial vibration sensor from Meggitt's vibro-meter product line, designed for long-term vibration monitoring in harsh industrial environments and potentially explosive atmospheres. This product introduction focuses on model 144-202-000-116, which is the Explosion-proof (Ex) certified version with a 6-meter integral cable, suitable for vibration measurement in hazardous areas (Zones 0, 1, 2).

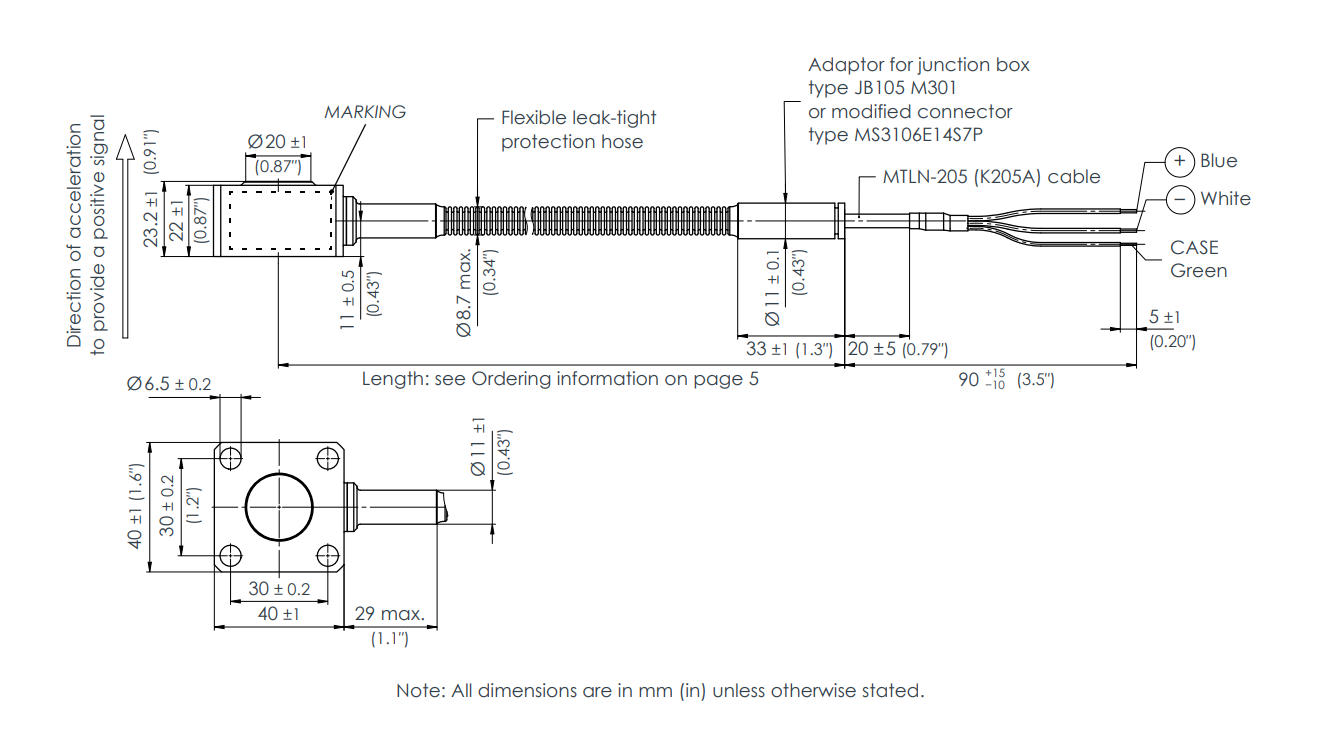

This sensor features a shear-mode polycrystalline measuring element with internal case insulation, offering a robust, symmetrical design with excellent temperature stability, high sensitivity, and a wide frequency response range. Its integral cable is encased in a flexible stainless steel protection hose and hermetically welded to the sensor case, forming a sealed assembly that is dustproof, waterproof, oil-resistant, and corrosion-resistant, ensuring reliable operation over the long term in severe conditions such as high temperature, high humidity, dust, and salt spray.

As the "front-end" sensing unit of a vibration monitoring system, the CA202 is typically integrated with vibro-meter® charge amplifiers (e.g., IPC70x series), galvanic separation units (GSI XXX), and subsequent monitoring systems (e.g., MMS or VM 600 systems) to form a complete vibration measurement chain. It is widely used for condition monitoring and early fault warning in various types of rotating machinery.

2. Key Features and Benefits

High-Reliability Design: Features a fully welded austenitic stainless steel case and a heat-resistant stainless steel protection hose, forming a hermetically sealed assembly that protects against humidity, water, steam, oil, salt spray, dust, fungus, and sand.

Exceptional Environmental Suitability: The sensor operates over a wide temperature range of -55°C to +260°C, with the cable capable of withstanding continuous temperatures from -55°C to +200°C, making it suitable for both extremely cold and hot environments.

Excellent Electrical and Mechanical Performance:

High Sensitivity: 100 pC/g, enabling effective detection of weak vibration signals.

Wide Frequency Response: 0.5 Hz to 6000 Hz (±5%), covering the vibration frequency components of most industrial machinery.

High Insulation Resistance: ≥10^9 Ω, ensuring clean signal transmission and minimizing leakage interference.

Low Transverse Sensitivity: ≤3%, improving directional measurement accuracy.

Comprehensive Explosion-Proof Certifications: Model 144-202-000-116 holds dual Intrinsic Safety (Ex ia) and Non-Sparking (Ex na) explosion-proof certifications. It complies with requirements for multiple regions and standards including Europe (ATEX), International (IECEx), North America (cCSAus), Korea (KGS), the United Kingdom (UKEX), and Russia (EA3C RU), allowing for safe use in designated hazardous areas.

Easy Installation and Maintenance: Provides standard mounting holes for secure installation using the supplied M6 screws and spring lock washers. The product is supplied with factory dynamic calibration, typically eliminating the need for on-site recalibration.

3. Measurement Principle and Technical Background

The CA202 is a piezoelectric accelerometer. Its core is a seismic sensor based on the piezoelectric effect. The internal structure consists of one or more quartz or ceramic crystal elements and a seismic mass. When the sensor vibrates with the measured object, the seismic mass applies a periodic mechanical stress (in shear or compression mode) to the piezoelectric crystals.

According to the piezoelectric effect, this mechanical stress generates a charge signal on the crystal surface proportional to the applied acceleration. This high-impedance charge signal is transmitted via a low-noise cable to an external charge amplifier (IPC XXX). The charge amplifier converts the weak charge signal into a low-impedance, interference-resistant current-modulated signal (e.g., 4-20 mA).

This current signal can be transmitted over long distances (over 1000 meters) via simple twin-core shielded cable. It is finally sent to a galvanic separation unit (GSI XXX), which demodulates it into a voltage signal proportional to vibration acceleration (or velocity after integration). This voltage signal is then processed, displayed, and used for alarm generation by backend monitoring systems (e.g., PLC, DCS, or dedicated vibration analyzers).

The CA202 belongs to the category of "accelerometers with separate electronic conditioners." Its advantages include:

Extreme Temperature Tolerance: The sensor itself contains no electronics and can operate continuously in environments up to 260°C.

High Signal Quality: The charge amplifier can be placed close to the sensor but in a more favorable environment, reducing signal loss and interference over long transmission distances for the raw charge signal.

System Flexibility: Different measurement needs can be adapted by changing charge amplifiers with different sensitivities or adjusting their settings.

4. Application Areas

With its robustness, wide temperature range, and explosion-proof features, the CA202 piezoelectric accelerometer is widely used for vibration monitoring in the following industrial sectors:

5. Installation, Wiring, and Safety Precautions

5.1 Pre-Installation Notes

Safety First: Read and strictly adhere to the accompanying Safety Guidelines. For equipment used in potentially explosive atmospheres, it is essential that the explosion-proof markings on the product nameplate correspond exactly to those described in the EC Type Examination Certificate or equivalent certification document.

Personnel Qualification: Installers should possess professional technical training in electronics and mechanical engineering (professional certificate/diploma or equivalent) and be familiar with relevant safety procedures.

Electrostatic Discharge (ESD) Protection: When handling the sensor and the circuit boards of electronic conditioners (charge amplifiers), Electrostatic Sensitive Device (ESD) handling procedures must be followed, such as wearing an anti-static wrist strap and touching a grounded metal object to discharge static electricity.

5.2 Key Mechanical Installation Points

Mounting Location: Prioritize mounting on rigid components like bearing housings, as close to the bearings as possible. Avoid mounting on machine casings or structures with low stiffness to prevent their own resonance from introducing measurement errors.

Mounting Surface Preparation:

The surface must be flat, clean, and perpendicular to the measurement axis.

Recommended surface flatness ≤ 0.01 mm, roughness grade N7.

Drill and tap holes according to the drawing (4 x M6).

Sensor Fixing:

Use the supplied M6 x 35 socket head cap screws and spring lock washers.

It is recommended to apply a medium-strength thread-locking adhesive such as LOCTITE 241 to the screws to prevent loosening due to vibration.

Using a torque wrench, tighten the four screws evenly in a crisscross pattern. The final torque must not exceed 15 N·m.

Cable Fixing:

Use mounting clips suitable for tubes with approximately 8 mm diameter to secure the cable firmly at intervals of 100-200 mm.

Do not bend the cable excessively. The minimum bending radius of ≥ 50 mm must be maintained, and a smooth stress relief loop should be formed at bends.

Avoid routing the cable near high-voltage or high-frequency power lines to prevent electromagnetic interference.

Securely fixing the cable at regular intervals can reduce low-frequency noise caused by the triboelectric effect.

5.3 Electrical Connection and System Integration

The CA202 must be integrated with compatible vibro-meter® equipment to form a complete measurement chain:

Charge Amplifier (IPC XXX): Mount in a location with minimal vibration and suitable ambient temperature (-25°C to +70°C). Correctly connect the CA202's integral cable and the transmission cable (K 2XX series) to the amplifier's terminal strips according to the wiring diagram.

Transmission Cable (K 2XX): A twin-core shielded cable used to connect the charge amplifier to the galvanic separation unit. It can be routed through a flexible metallic conduit (e.g., KS 106) for additional mechanical protection.

Galvanic Separation Unit (GSI XXX): Typically mounted on a DIN rail within a cabinet or control room. It provides power for the two-wire loop and reads the current signal, converting it into a voltage signal for the monitoring system. Note that the shield of the transmission cable should not be grounded at the galvanic separation unit end to avoid ground loops.

Grounding: Strictly follow the requirements in the Installation Manual (e.g., Figures 5-11, 6-13) for single-point grounding. Correct grounding for the entire system is crucial for noise suppression and measurement accuracy.

5.4 Special Requirements for Potentially Explosive Atmospheres

Installation, operation, and maintenance must strictly comply with the Special Conditions for Safe Use specified in the "Schedule" section of the product's EC Type Examination Certificate or its equivalent.

Any modification, transformation, or repair carried out without the written authorization of Vibro-Meter / Meggitt will invalidate the explosion-proof certification and product warranty.

Ensure the installation environment (temperature, gas group, etc.) complies with the product's explosion-proof marking (e.g., T6...T2).

6. Maintenance and Technical Support

Routine Maintenance: Periodically inspect the mechanical fixing of the sensor and cable for security, and check for any physical damage or dents. Inspect the sealing integrity of junction boxes and amplifier housings.

No Regular Calibration Required: The product is supplied with precise factory dynamic calibration. On-site recalibration is typically not necessary unless data is suspect after severe shock or abnormal operation.

Troubleshooting: If measurement signals are abnormal, systematically check the measurement chain: Is the sensor mounting secure? Are cable connections firm and correct? Is grounding proper? Is power supply normal?

Technical Support and Repair: For unresolved faults, contact Meggitt SA or your local authorized representative. Users must never disassemble the sensor or electronic conditioners themselves. All repairs must be performed by trained, qualified personnel authorized by Meggitt.