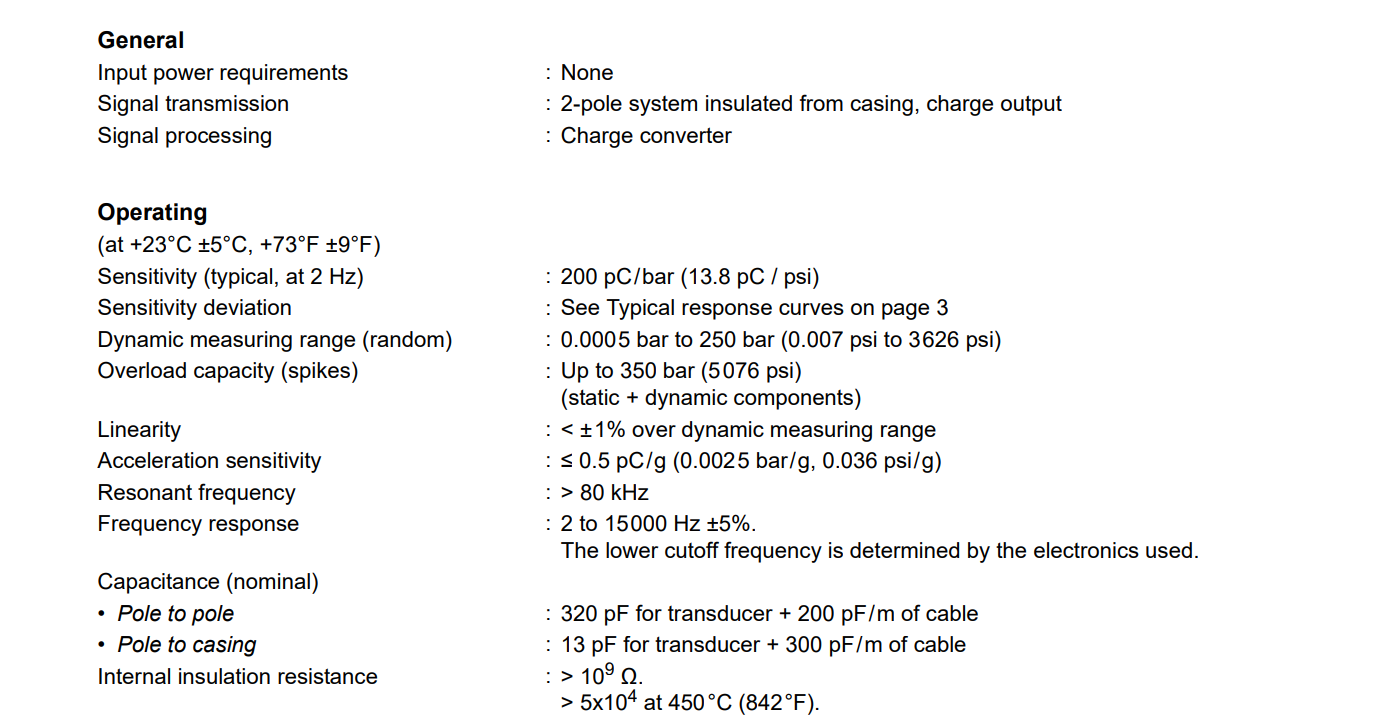

The CP216 is a high-performance piezoelectric pressure transducer from VM product line, specifically designed for dynamic pressure measurement in extreme environments. Utilizing special artificial piezoelectric materials, this transducer offers exceptional temperature stability and long-term reliability, making it suitable for dynamic pressure monitoring and development testing in high-temperature and high-pressure environments. The CP216 can directly measure dynamic pressure changes in gases or liquids and converts mechanical pressure signals into charge signals, providing accurate pressure data for various industrial applications.

------------------------------------------------------------------------------------

Key Features

1. Extreme Environment Adaptability

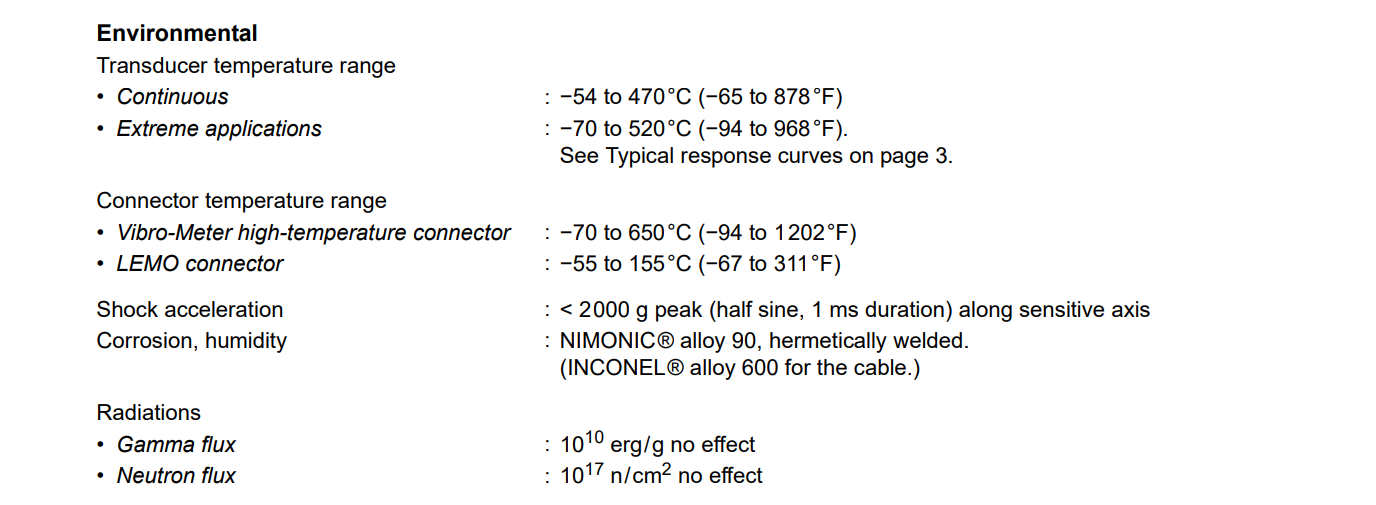

The CP216 exhibits outstanding temperature tolerance, enabling stable operation in extreme temperature environments:

Operating Temperature Range: -54°C to 470°C (continuous operation)

Extreme Application Temperature: -70°C to 520°C

Connector Temperature Range:

2. High-Pressure Measurement Capability

The transducer features a wide pressure measurement range:

Dynamic Measurement Range: 0.0005 bar to 250 bar

Overload Capacity: Up to 350 bar (static + dynamic components)

Rated Pressure Sensitivity: 200 pC/bar (13.8 pC/psi)

3. Wide Frequency Response Characteristics

The CP216 offers excellent frequency response characteristics:

Frequency Range: 2 Hz to 15 kHz ±5%

Resonant Frequency: > 80 kHz

Low-Frequency Cutoff: Determined by the electronics used

4. Robust Structural Design

Housing Material: NIMONIC 90 alloy, fully hermetic welding

Cable Material: INCONEL 600 alloy

Internal Insulation: Fully insulated design

Radiation Resistance: Capable of withstanding gamma and neutron radiation

5. Explosion-Proof Certification

The CP216 is available in explosion-proof certified versions for hazardous environments:

Explosion-Proof Type: Ex ib Intrinsic Safety

Certification Standards: ATEX, IECEx, and other international standards

Applicable Zones: Zone 1/2 hazardous areas

6. Multiple Configuration Options

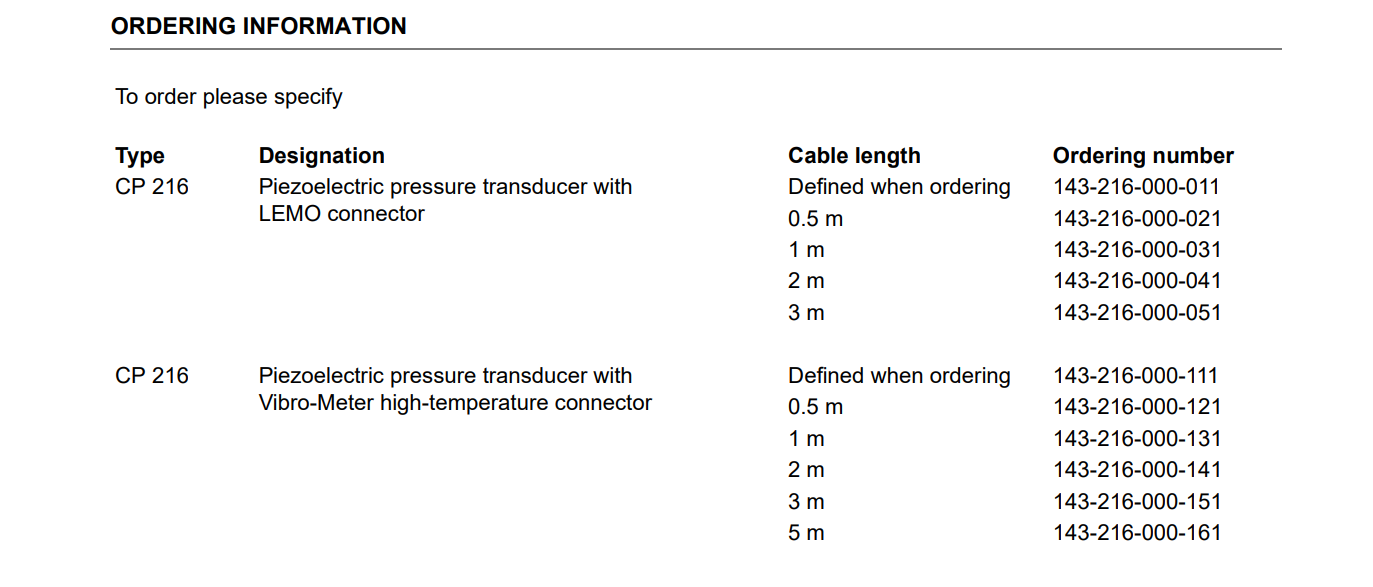

Cable Type: Mineral Insulated (MI) cable, twin conductors

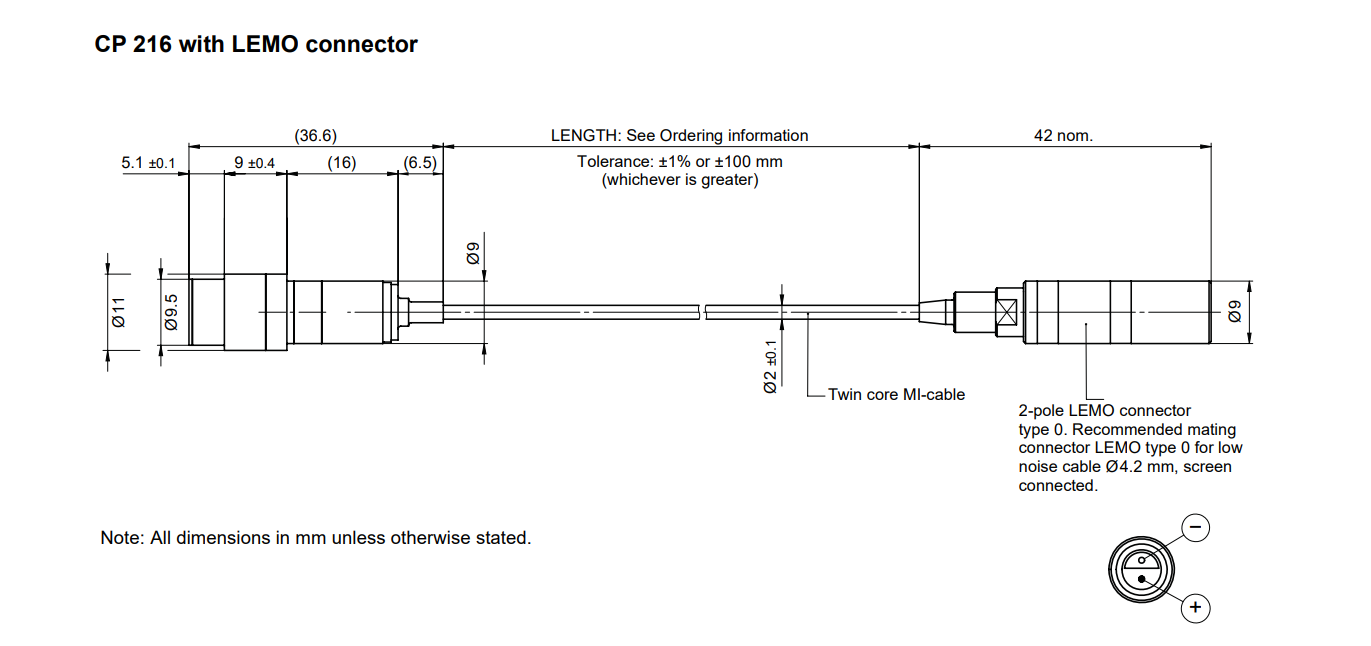

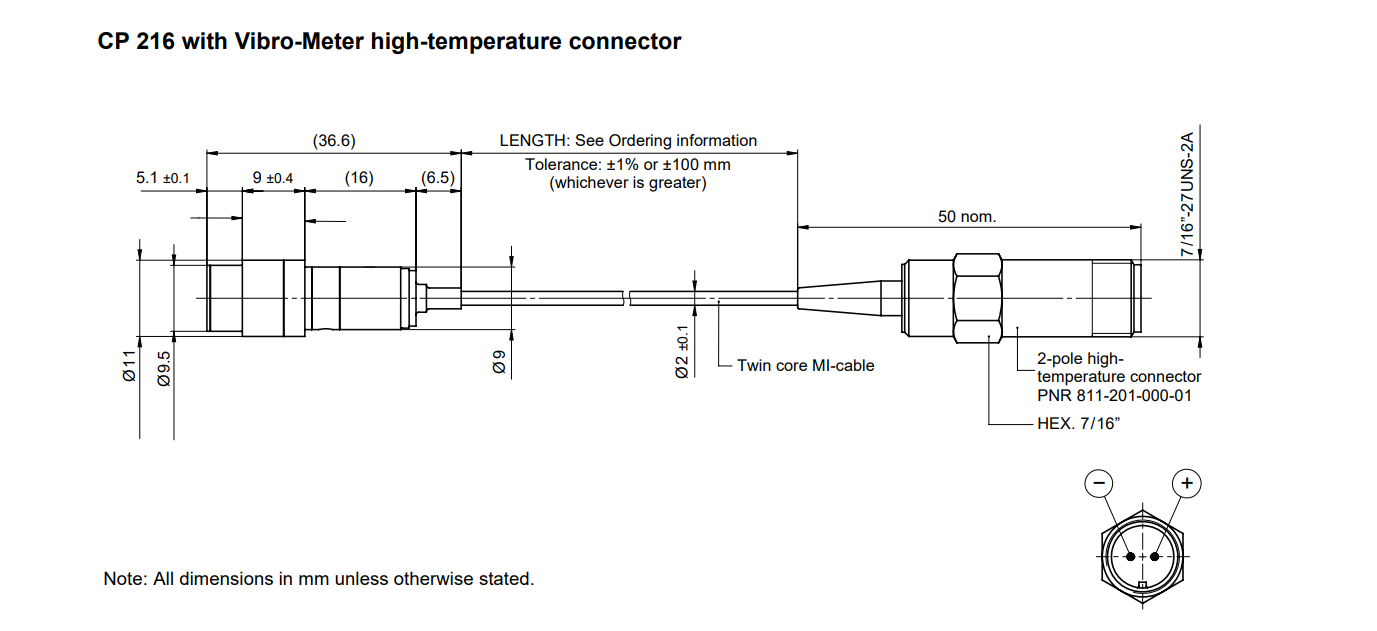

Connector Options: LEMO connector or Vibro-Meter high-temperature connector

Cable Lengths: 0.5m, 1m, 2m, 3m, 5m, or custom lengths

Working Principle

Fundamentals of Piezoelectric Effect

The core working principle of the CP216 is based on the piezoelectric effect, a unique physical phenomenon where certain materials generate electrical charge when subjected to mechanical stress. This effect is reversible: when an electric field is applied to piezoelectric materials, they undergo mechanical deformation. In pressure measurement applications, we utilize the direct piezoelectric effect—converting mechanical energy (pressure) into electrical energy (charge).

The sensor employs a special artificial piezoelectric material that has been carefully designed and processed to provide excellent temperature stability and long-term stability. Compared to natural piezoelectric materials, artificial piezoelectric materials offer more consistent performance and better environmental adaptability.

Sensing Element Structure

The CP216 employs a compression-mode design where the core sensing element consists of a precision-machined stack of piezoelectric crystals. This stack comprises multiple piezoelectric discs arranged in mechanical series and electrical parallel configuration. This design offers several advantages:

Enhanced Sensitivity: Multiple discs increase charge output capability

Improved Stability: Symmetrical structure reduces temperature gradient effects

Better Linearity: Uniform pressure distribution ensures improved linear response

The piezoelectric discs are precisely mounted within a metal housing and contact the measured medium through a thin diaphragm. When pressure acts on the diaphragm, it is transmitted to the piezoelectric stack, causing minimal deformation.

Charge Generation Mechanism

When piezoelectric materials experience mechanical stress, their crystal lattice structure deforms, causing changes in internal electric dipole moments, which generates charge on the material surface. This charge is proportional to the applied pressure:

Q = d × F

Where:

Q is the generated charge (in pC)

d is the piezoelectric constant (material property)

F is the applied force (proportional to pressure)

For the CP216, its nominal sensitivity is 200 pC/bar, meaning each bar of pressure change produces 200 pC of charge output.

Signal Output Characteristics

The CP216 employs a charge output mode, which is a high-impedance signal output method. This output approach has several important features:

Passive Operation: The sensor requires no external power supply, simplifying system design

Noise Immunity: High-impedance signals are relatively insensitive to electromagnetic interference

Long-Term Stability: No active electronic components ensure极高 reliability

The sensor outputs a charge signal related to the rate of pressure change, making it particularly suitable for dynamic pressure measurement rather than static pressure measurement.

Temperature Compensation Mechanism

To maintain stable performance across a wide temperature range, the CP216 incorporates multiple temperature compensation techniques:

Material Selection: Uses special piezoelectric materials with excellent temperature stability

Symmetrical Design: Compensating elements arranged symmetrically to reduce temperature gradient effects

Thermal Expansion Matching: All components have matched thermal expansion coefficients

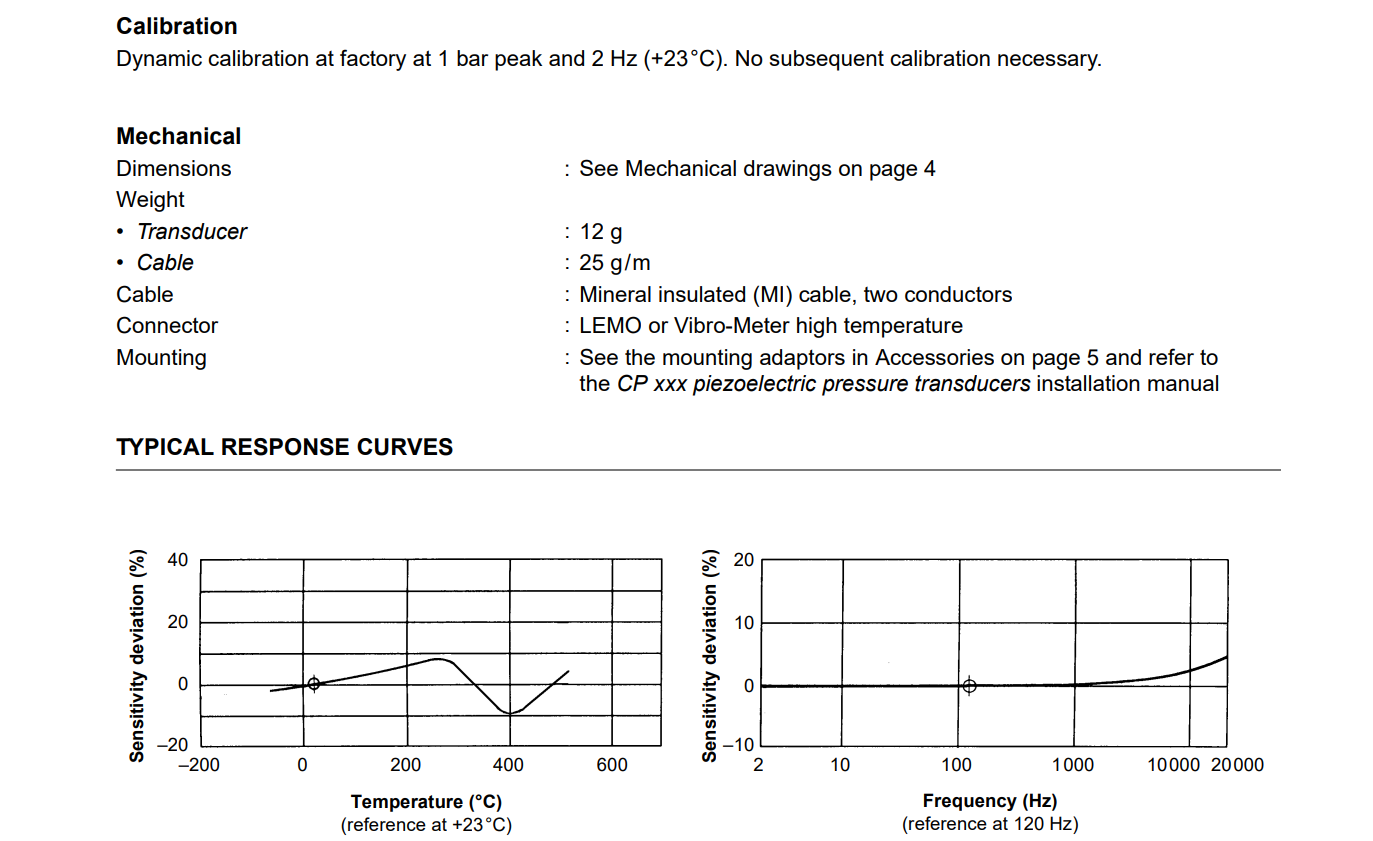

The sensor's temperature characteristics are carefully optimized to maintain predictable performance across the extreme temperature range from -70°C to 520°C. Typical temperature response curves show that sensitivity changes with temperature exhibit good linear characteristics, facilitating temperature compensation.

Frequency Response Characteristics

The CP216's frequency response characteristics are determined by both its mechanical structure and piezoelectric properties:

Low-Frequency Response: Low-frequency cutoff determined by the sensor's leakage resistance and subsequent charge amplifier input impedance

High-Frequency Response: High-frequency cutoff determined by the sensor's mechanical resonant frequency

Flat Response Region: Provides ±5% flat response in the 2 Hz to 15 kHz range

The sensor's resonant frequency exceeds 80 kHz, ensuring sufficient phase and amplitude margin within the operating frequency range.

Installation and Matching Considerations

Proper installation is crucial for sensor performance:

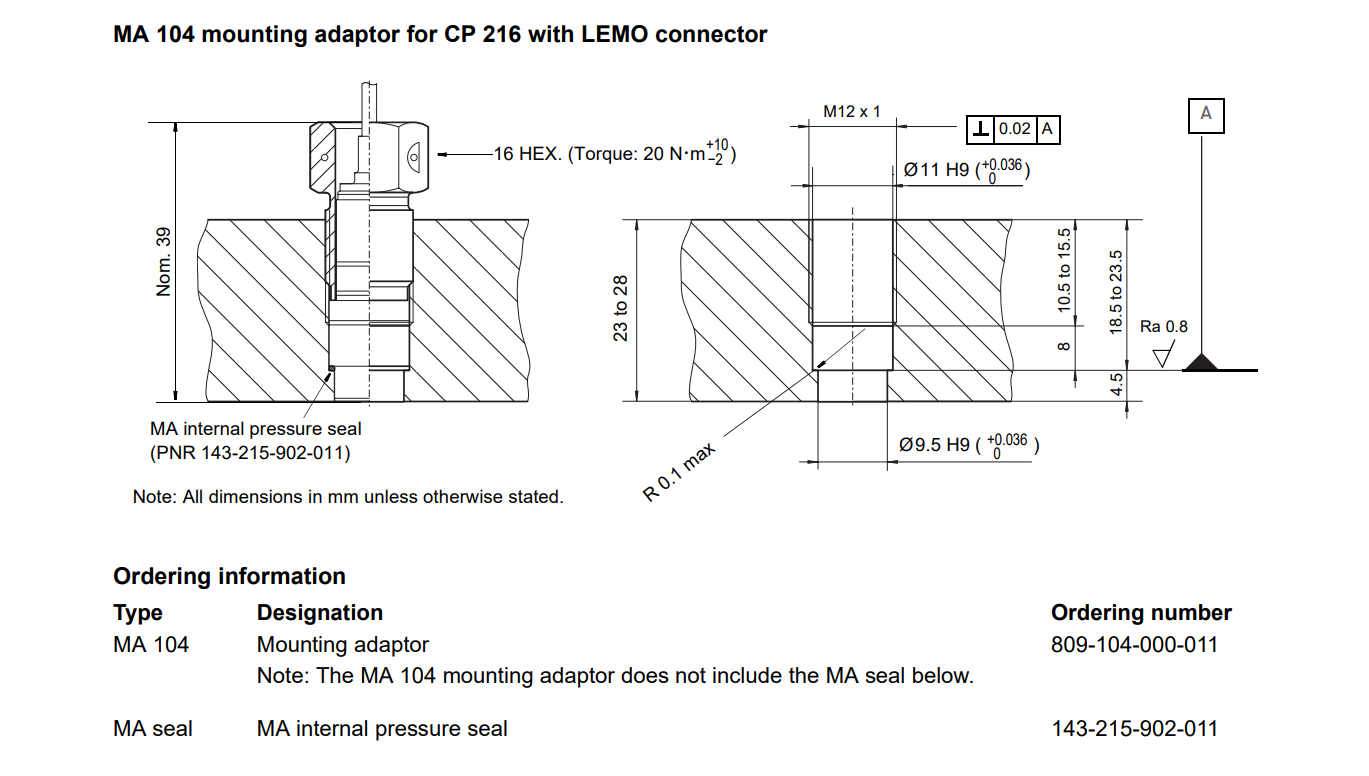

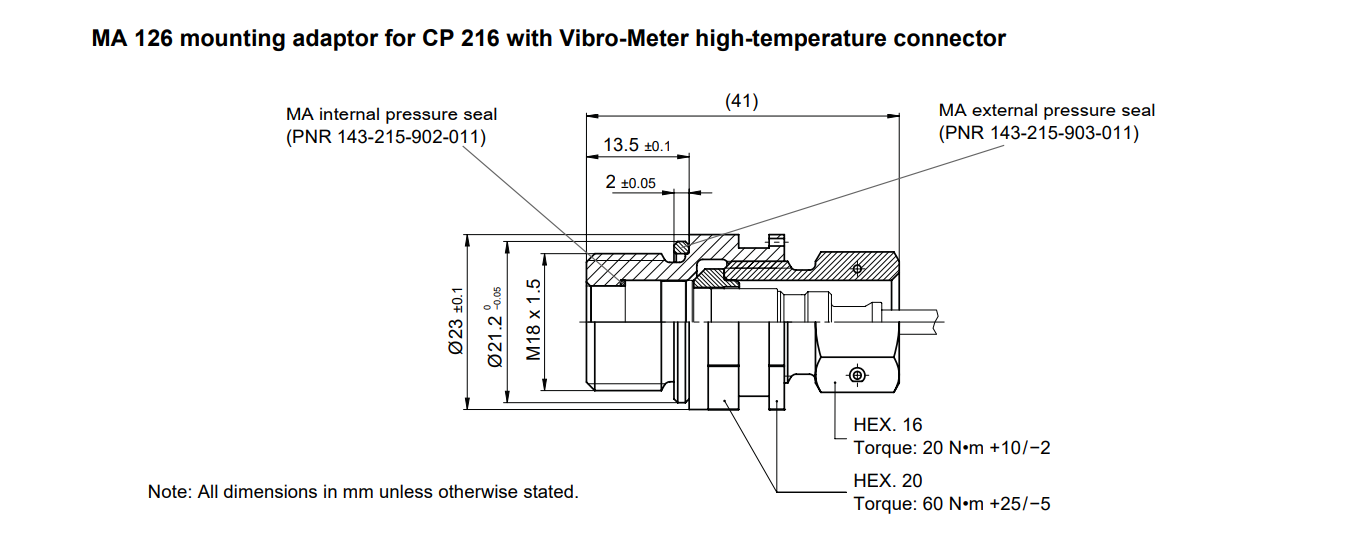

Installation Torque: Requires precise installation torque (20 N·m) to ensure good mechanical coupling

Sealing Design: Uses dedicated pressure seals to prevent medium leakage

Thermal Isolation: May require thermal isolation measures in high-temperature applications

The sensor must be used with appropriate signal conditioners (such as IPC704), where charge amplifiers convert high-impedance charge signals into low-impedance voltage or current signals for long-distance transmission and processing.

Environmental Adaptability Design

The CP216's design considers various extreme environmental factors:

Vibration Resistance: Robust structural design withstands 2000 g shock acceleration

Corrosion Resistance: Uses advanced alloy materials to resist corrosive media

Radiation Resistance: Special design enables tolerance to high radiation environments

Calibration and Stability

The sensor undergoes dynamic calibration at the factory (1 bar peak, 2 Hz, +23°C), and due to its exceptional stability, typically requires no subsequent recalibration. Long-term stability primarily depends on the aging characteristics of the piezoelectric material, and this artificial piezoelectric material undergoes special treatment to achieve extremely low aging rates.

------------------------------------------------------------------------------------

Application Areas

1. Aerospace

Engine combustion chamber pressure monitoring

Turbomachinery dynamic pressure measurement

Aerodynamic pressure monitoring in flight testing

2. Energy Industry

Gas turbine combustion monitoring

Steam turbine pressure fluctuation analysis

Nuclear power plant safety monitoring systems

3. Industrial Processes

Compressor pulsation pressure measurement

Pump system pressure fluctuation analysis

Combustion process monitoring

4. Research and Development Testing

------------------------------------------------------------------------------------

Supporting Equipment

1. Signal Conditioners

2. Mounting Accessories

3. Cable Assemblies

EC153, EC222, EC119: Various dedicated cable assemblies

Features: High-temperature resistance, noise immunity

4. Isolation Equipment

------------------------------------------------------------------------------------

Technical Advantages

1. Exceptional Reliability

Passive design based on piezoelectric technology and fully welded construction ensure reliability, suitable for long-term continuous monitoring applications.

2. Broad Environmental Adaptability

Wide operating temperature range from extremely low to extremely high temperatures enables adaptation to various harsh environments.

3. Accurate Dynamic Measurement

Excellent frequency response characteristics and high sensitivity enable capture of rapid pressure changes and minute pressure fluctuations.

4. Easy Integration

Standardized output interfaces and multiple installation options facilitate easy integration into various measurement systems.