The CA202 144-202-000-115 is a medium-cable-length explosion-proof version within the Vibro-Meter (now part of Meggitt Group) CA200 series of piezoelectric accelerometers. This model features intrinsic safety explosion-proof design (Ex ia) and is equipped with a 6-meter integral cable, specifically designed for industrial applications requiring medium-distance vibration monitoring in potentially explosive environments. As a safety device certified by multiple global standards, it can operate safely and reliably in hazardous areas (Zone 0/1/2) such as petrochemical plants, natural gas processing facilities, and pharmaceutical manufacturing, providing an intrinsic safety solution for condition monitoring of critical rotating machinery.

While maintaining the core technical advantages of the CA200 series, this product strictly adheres to intrinsic safety explosion-proof standards, limiting the electrical spark and thermal energy that may be generated to safe levels, fundamentally preventing the ignition of surrounding explosive gas mixtures. The 6-meter cable length design balances installation flexibility and wiring economics, meeting the distance requirements for most sensor-to-safe-junction-box connections within hazardous areas while avoiding the complexity and cost increases associated with overly long cables.

This model not only possesses excellent vibration sensing performance but also serves as an important component of a complete safety monitoring system. It complies with multiple certification requirements including ATEX Directive 2014/34/EU, IECEx international standards, and cCSAus North American standards, providing users with compliant and reliable technical assurance for hazardous area applications worldwide.

2. Core Design Features and Safety Advantages

2.1 Intrinsic Safety Explosion-Proof Design

Highest Level Explosion Protection: Features Ex ia intrinsic safety design, suitable for gas environments in Zones 0, 1, and 2, providing dual-fault safety protection

Wide Gas Group Adaptability: Certified for Group IIC, can be safely used in the most explosive gas environments including hydrogen and acetylene

Broad Temperature Range Certification: Temperature classes cover T6 to T2, accommodating operating environment temperatures from -55°C to +260°C

2.2 Rugged Industrial-Grade Construction

Fully Sealed Welded Structure: Sensor housing and cable hose made of austenitic stainless steel (1.4441) and heat-resistant stainless steel (1.4541), forming a complete leak-proof unit through hermetic welding

Excellent Environmental Adaptability: Protection level equivalent to IP68, resistant to 100% humidity, water, steam, oil contamination, salt spray, and other harsh industrial environment erosion

High Mechanical Strength: Capable of withstanding 1000g impact loads, ensuring stable operation in severe vibration environments

2.3 Superior Electrical Performance

High-Sensitivity Measurement: Standard sensitivity of 100 pC/g, combined with low-noise design, can accurately capture vibrations from weak to severe

Wide Frequency Response: Frequency range of 0.5 Hz to 6 kHz, covering the characteristic vibration frequencies of most industrial machinery

Complete Electrical Isolation: Complete insulation between signal terminals and housing, insulation resistance ≥1×10⁹Ω, effectively preventing ground loop interference

2.4 Global Certification System

European ATEX Certification: LCIE 02 ATEX 6179 X

International IECEx Certification: IECEx LCI 10.0018X

North American cCSAus Certification: 70004630 (Class I, Division 2, Groups A-D & Zone 2)

Other Regional Certifications: Including UK UKEX, Russian EAC, and other national certifications

3. Typical Application Areas

3.1 Oil & Gas Industry

Offshore Platforms & FPSOs: Vibration monitoring of critical equipment such as main power generation sets, oil/gas processing compressors, and water injection pumps

Onshore Oil & Gas Processing Plants: Rotating equipment monitoring at natural gas compressor stations, LNG facilities, and desulfurization/decarbonization units

Refining & Petrochemical Units: Reactor feed pumps, recycle gas compressors in catalytic cracking, hydroprocessing, and ethylene cracking units

3.2 Chemical & Pharmaceutical Industry

Chemical Reaction Units: Reactor agitation systems, centrifuges, and dryers involving flammable solvents (alcohols, ketones, aromatic hydrocarbons)

Solvent Recovery Systems: Distillation column feed pumps, vacuum pumps, and solvent transfer compressors

Spraying & Coating Workshops: Ventilation system fans, exhaust devices, and raw material transfer pumps

3.3 Energy & Utilities

Gas-Fired Power Plants: Gas turbines and auxiliary systems in areas where combustible gases may accumulate

Coal Gasification & Syngas Units: Feed gas compressors, syngas circulators, and cryogenic separation equipment

Biogas & Biomass Power Generation: Gas pretreatment systems and boosting/transfer equipment

3.4 Other Hazardous Area Applications

Grain Processing & Feed Production: Critical rotating equipment in dust explosion-protected areas (dust explosion applicability needs confirmation)

Aerospace Fuel Testing: Aviation fuel pumps and fuel system test benches

Specialty Material Production: Process equipment involving flammable gas raw materials

4. System Integration & Safety Installation Guide

4.1 Intrinsic Safety Loop Architecture

System Design Requirements:

Loop Integrity: Must form a complete intrinsic safety loop

Parameter Matching: Sensor safety parameters must be compatible with safety barrier parameters

System Certification: All associated equipment must have corresponding explosion-proof certifications

4.2 Pre-Installation Preparation

4.2.1 Safety Assessment

Confirm hazardous area classification (Zone 0/1/2) of installation location

Identify type and group of explosive gases

Assess impact of ambient temperature on temperature class

4.2.2 Parameter Verification

Obtain CA202-115 explosion-proof certificate and safety parameters (Ui, Ii, Pi, Ci, Li)

Select compatible safety barrier ensuring: Uo≤Ui, Io≤Ii, Po≤Pi, Ccable+Ci≤Co, Lcable+Li≤Lo

Perform written loop calculations and archive

4.3 On-Site Installation Steps

4.3.1 Sensor Mechanical Installation

Surface Preparation: Clean mounting surface, ensure flatness ≤0.01mm

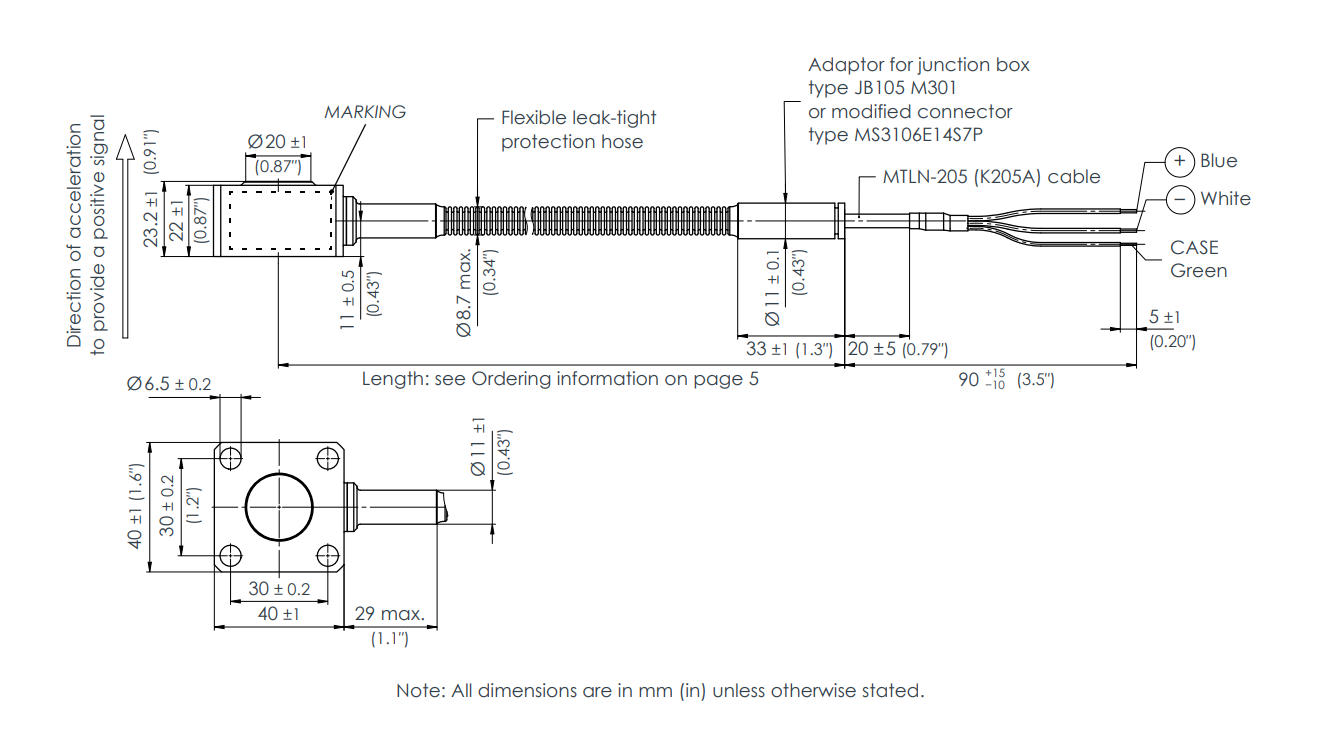

Positioning & Drilling: Position and drill 4×M6 mounting holes per drawing, depth 20mm, tap depth 14mm

Mounting & Fixing: Use M6×35 screws with spring washers, apply LOCTITE 241 thread locking compound

Torque Control: Use torque wrench, tighten in cross-pattern sequence to 15 N·m

4.3.2 Cable Routing (Within Hazardous Area)

Route Planning: Select shortest and safest routing path, avoid sharp bends

Bend Radius: Ensure minimum cable bend radius ≥50mm (static)

Fixation Spacing: Use stainless steel cable clamps, fix every 1-1.5 meters

Stress Relief: Provide service loops at sensor exit and junction box entry points

Separation Requirements: Maintain ≥50mm separation between IS cables and power cables, cross at 90° angle when necessary

4.3.3 Electrical Connection

Junction Box Selection: Use junction boxes with appropriate explosion-proof rating (Ex d, Ex e, etc.)

Terminal Connection: Connect red/white signal wires to SIG+/SIG-, handle shield according to single-point grounding principle

Sealing Protection: Use explosion-proof cable glands to ensure junction box sealing integrity

Clear Identification: All IS loops should have blue identification or labels

4.4 Safe Area Interface

Safety Barrier Installation: Install in safe area or in Zone 2 explosion-proof cabinets

Grounding Treatment: IS loop shield grounded at single point at safety barrier

System Connection: Safety barrier output connected to signal conditioner and monitoring system

5. Maintenance, Inspection & Safety Compliance

5.1 Regular Maintenance Schedule

5.1.1 Daily Checks

Visual inspection of sensor and cable appearance integrity

Confirm mounting fasteners are not loose

Check cable hose for wear or deformation

5.1.2 Quarterly Checks

Check junction box sealing performance

Verify grounding system integrity

Measure loop insulation resistance

5.1.3 Annual Checks

Comprehensive explosion-proof integrity check

Calibration verification (if required)

Update safety documentation records

5.2 Fault Diagnosis & Handling

5.2.1 Common Fault Phenomena

Signal Loss: Check power supply, safety barrier, cable connections

Excessive Noise: Check grounding, shielding, cable routing

Signal Drift: Check temperature effects, mounting stress

5.2.2 Safety Handling Principles

Prioritize fault diagnosis from safe area

Work within hazardous areas must be performed under work permit

Repairs involving intrinsic safety loops must be performed by qualified personnel

5.3 Special Safety Requirements

5.3.1 "X" Special Conditions for Use

This model's explosion-proof certificate carries "X" marking, indicating special conditions for use:

Ambient Temperature Limitations: Must strictly adhere to relationship between temperature class and ambient temperature

Installation Personnel Qualification: Must be installed and maintained by qualified personnel trained in explosion protection

Documentation Integrity: User must possess complete explosion-proof certificate and technical documentation

5.3.2 Repair Limitations

Users are prohibited from disassembling the sensor body

Modifying cable length or structure on-site is prohibited

Repair work must be returned to manufacturer or authorized service center

5.4 Documentation Management

Technical Documentation That Must Be Kept:

Product explosion-proof qualification certificate and annexes

Intrinsic safety loop calculation sheets

Installation drawings and wiring diagrams

Calibration certificates and test reports

Maintenance records and repair reports

6. Technical Advantages Summary

6.1 Safety Reliability

Multiple global explosion-proof certifications ensure safety in hazardous area applications

Intrinsic safety design provides highest level of explosion protection

Fully sealed welded structure ensures long-term environmental resistance

6.2 Technical Advancement

Wide temperature range operation capability, adapts to extreme environments

High-precision vibration measurement, provides accurate equipment condition data

Complete EMC design, strong anti-interference capability

6.3 Economic Usability

6-meter cable length optimizes installation cost and flexibility

Maintenance-free design reduces total lifecycle cost

Global certifications reduce project compliance costs and time

6.4 System Compatibility

Compatible with Meggitt's full range of safety barriers and monitoring systems

Standard signal output, easy integration into existing systems

Provides complete technical support and application guidance

7. Ordering Information & Technical Support

7.1 Product Configuration

Basic Model: CA202 Ex ia Version

Cable Length: 6-meter integral stainless steel hose cable

Connection Method: Flying lead terminals

Standard Accessories: Mounting screws, washers, calibration certificate

7.2 Optional Accessories

Mounting brackets and thermal insulation kits (MA133)

Explosion-proof junction boxes and cable glands

Dedicated safety barriers and signal conditioners

7.3 Technical Support

Provide explosion-proof application consultation and loop design guidance

On-site installation guidance and technical training

Responsive after-sales service network

7.4 Important Declaration

This product must be used in accordance with the requirements of the explosion-proof certificate. Any installation and use that does not comply with regulations will invalidate the explosion-proof certification and may cause serious safety accidents. Before selecting and installing, users should carefully read the complete technical documentation and consult the manufacturer's explosion-proof technical experts when necessary.