The CA202 piezoelectric accelerometer is a high-performance vibration monitoring device from VM product line, utilizing advanced piezoelectric sensing technology specifically designed for industrial vibration monitoring and measurement. The equipment offers exceptional environmental adaptability and measurement accuracy, capable of stable operation in extreme temperature conditions (-55 to 260°C) and potentially explosive environments.

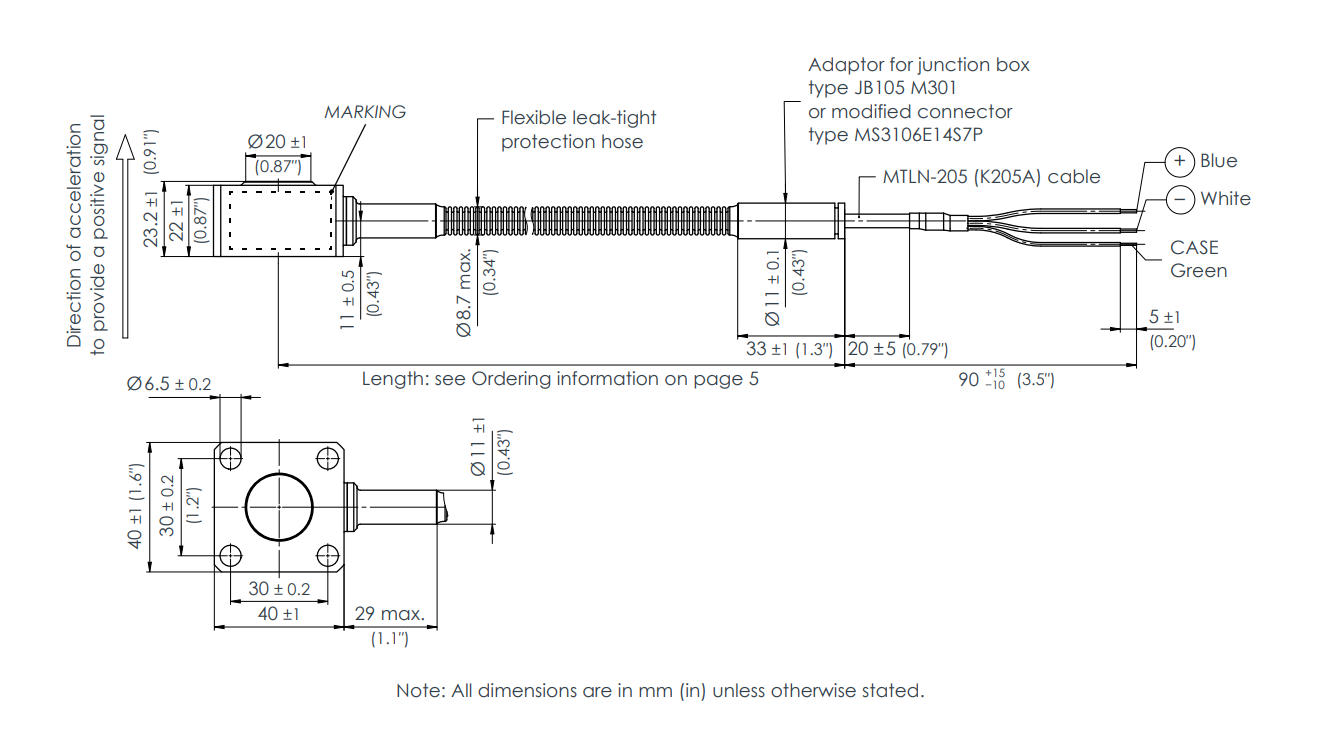

The CA202 features a symmetrical shear-mode polycrystalline measuring element structure with internal case insulation, equipped with integral cable and stainless steel protection hose, forming a completely sealed leak-proof assembly. This accelerometer is available in standard versions and explosion-proof certified versions to meet the application requirements of different industrial environments, particularly suitable for vibration monitoring of heavy industrial equipment.

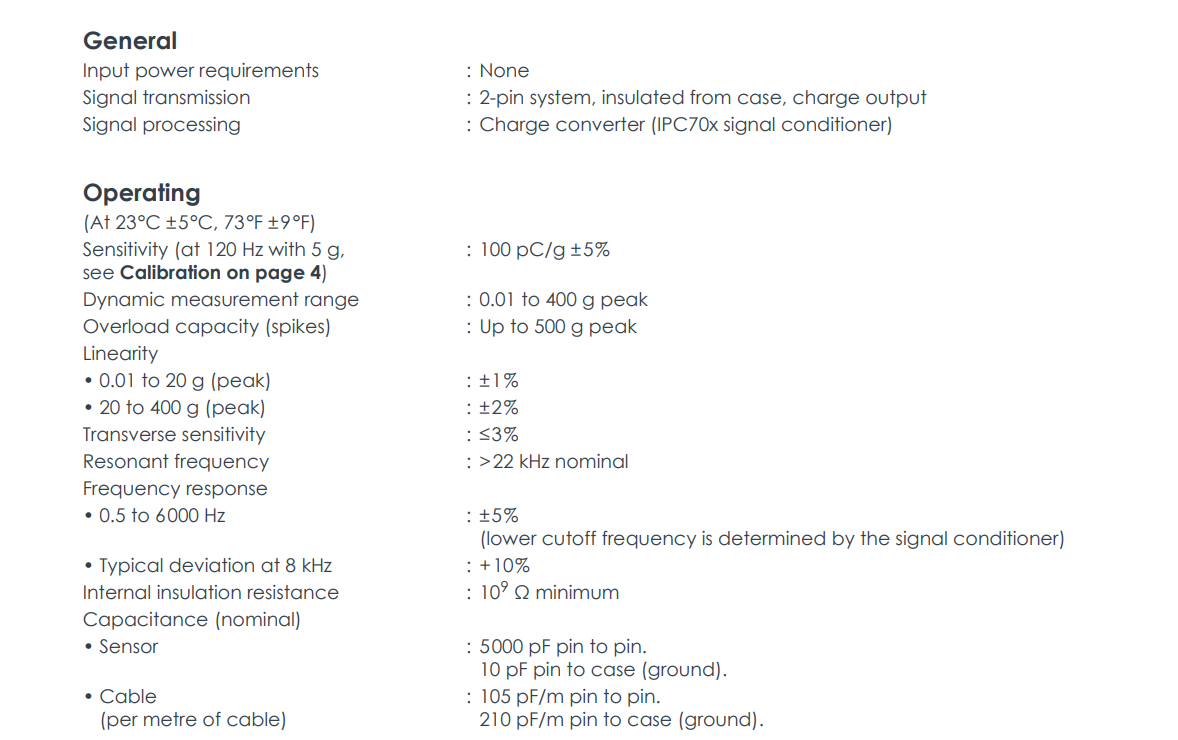

The device features high sensitivity (100 pC/g) and wide frequency response range (0.5 to 6,000 Hz), enabling precise capture of vibration signals from low to high frequencies. Its rugged stainless steel housing and sealed design provide resistance to various harsh environmental factors including humidity, water vapor, oil contamination, and salt spray.

Working Principle

The CA202 piezoelectric accelerometer operates based on the piezoelectric effect principle, involving precise physical conversion processes and signal processing technologies. The working mechanism can be detailed through the following core aspects:

1. Piezoelectric Effect and Electromechanical Conversion Mechanism

The device core employs a shear-mode polycrystalline piezoelectric sensing element. When the accelerometer experiences vibration, the mass applies shear force to the piezoelectric crystal. According to the piezoelectric effect principle, piezoelectric materials undergo polarization under mechanical stress, with internal lattice structure displacement causing uneven charge distribution, thereby generating charge signals proportional to the applied force on the crystal surface. This electromechanical conversion process offers extremely high linearity and stability, directly converting mechanical vibration energy into electrical signal output.

The shear-mode design provides significant advantages over compression-mode designs: it exhibits lower sensitivity to base strain and temperature changes, delivering more stable output performance. The selection of polycrystalline piezoelectric materials ensures consistent sensitivity and linear characteristics across a wide temperature range.

2. Symmetrical Structure and Differential Output Design

The CA202 adopts a unique symmetrical sensor structure containing two symmetrically arranged piezoelectric elements. This design produces differential output signals that effectively suppress common-mode interference and improve signal quality. When subjected to axial acceleration, the two piezoelectric elements generate charge signals of equal magnitude but opposite polarity. Through differential amplification, useful signals are enhanced while common electromagnetic interference and temperature drift noise are effectively suppressed.

The internal case insulation design ensures complete isolation between signal pins and the housing, preventing ground loop formation and further improving anti-interference capability. This design is particularly suitable for use in complex industrial electromagnetic environments, ensuring purity and accuracy of measurement signals.

3. Signal Generation and Transmission Characteristics

The device produces charge output signals with sensitivity of 100 pC/g ±5%. Charge signals have the important characteristic of being unaffected by cable capacitance, making them suitable for long-distance transmission. The internal sensor capacitance is 5000 pF (between pins) and 10 pF (between pin and case), while cable capacitance is 105 pF/m (between pins) and 210 pF/m (between pin and case).

This high-impedance charge output requires charge amplifiers (such as IPC70x series signal conditioners) to convert charge signals into low-impedance voltage signals for subsequent processing. The charge output method avoids cable noise and impedance matching issues faced by voltage output sensors.

4. Sealed Structure and Environmental Protection Mechanism

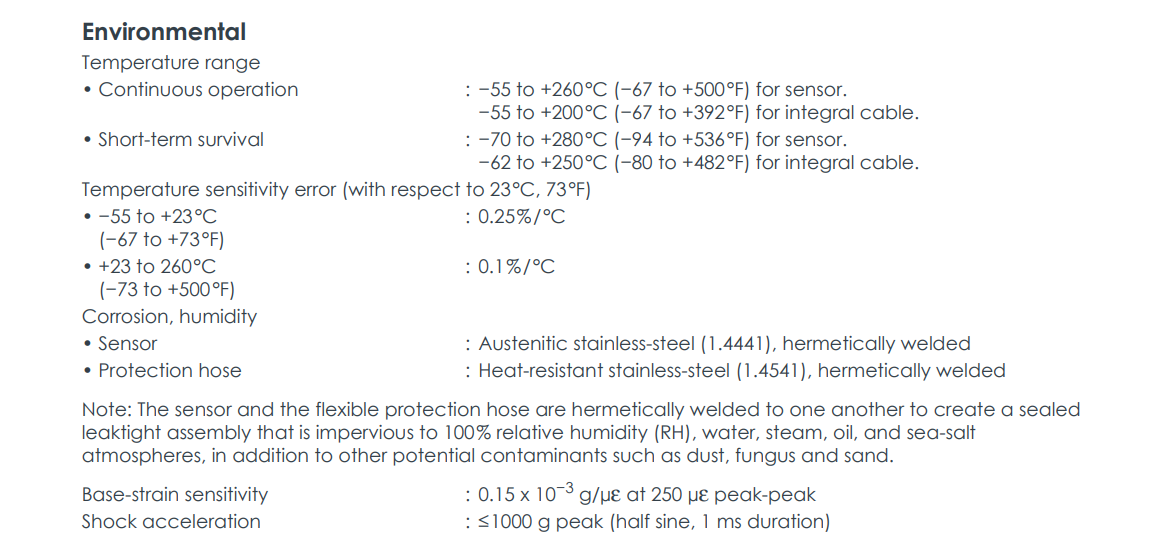

The sensor features an austenitic stainless steel (1.4441) housing hermetically welded with a heat-resistant stainless steel (1.4541) protection hose to form a completely sealed leak-proof assembly. This sealed design provides resistance to 100% relative humidity, water, steam, oil, sea-salt atmospheres, and other potential contaminants such as dust, fungus, and sand.

The protection hose not only provides mechanical protection but also maintains cable flexibility, with minimum bend radius allowing installation in confined spaces. The integral cable design eliminates reliability issues that may arise from connectors, ensuring long-term stable signal transmission.

5. Temperature Compensation and Stability Control

The device exhibits excellent temperature stability, with temperature sensitivity error of 0.25%/°C in the -55 to +23°C range and 0.1%/°C in the +23 to 260°C range. This temperature compensation characteristic is achieved through selected piezoelectric materials and structural design, ensuring consistent performance across a wide temperature range.

The sensor employs thermally symmetric design to reduce measurement errors caused by thermal gradients. The base strain sensitivity is extremely low at only 0.15 × 10^{-3} g/μϵ, meaning thermal deformation of the mounting surface hardly affects measurement accuracy.

6. Frequency Response and Dynamic Characteristics

The device frequency response ranges from 0.5 to 6,000 Hz (±5%), with resonant frequency above 22 kHz. The low-frequency response is determined by the matching signal conditioner, while high-frequency characteristics are determined by the sensor's mechanical structure. The shear-mode design provides higher resonant frequency, ensuring flat response across a wide frequency range.

The dynamic measurement range extends from 0.01 g peak to 400 g peak, with overload capability up to 500 g peak. This wide dynamic range enables precise measurement of various mechanical motions from微小 vibrations to severe impacts.

7. Explosion-Proof Safety Mechanism

Explosion-proof versions employ intrinsic safety (Ex ia) and non-sparking (Ex nA) protection types, meeting various international explosion-proof standards. The intrinsic safety design ensures that no sparks or hot surfaces capable of igniting explosive atmospheres are generated under fault conditions by limiting circuit energy.

Protection circuits include current limiting and energy discharge mechanisms, ensuring compliance with explosion-proof requirements under all operating conditions. This design enables safe application in Zone 0/1/2 hazardous areas.

Features

The CA202 piezoelectric accelerometer offers multiple advanced features to meet stringent industrial vibration monitoring requirements:

1. High-Precision Measurement Performance

The device provides high sensitivity of 100 pC/g, enabling detection of minute vibration signals. Excellent linearity: ±1% in the 0.01 to 20 g range and ±2% in the 20 to 400 g range. Transverse sensitivity less than 3% ensures accuracy of primary measurement direction vibrations.

2. Extreme Environmental Adaptability

Extremely wide operating temperature range: -55 to +260°C for the sensor, -55 to +200°C for the integral cable. Short-term survival temperatures are even higher: up to -70 to +280°C for the sensor and -62 to +250°C for the cable. This temperature range covers the vast majority of industrial application scenarios.

3. Rugged Mechanical Construction

Austenitic stainless steel housing provides excellent mechanical strength and corrosion resistance. Hermetically welded structure ensures complete leak-proof performance, resisting erosion from various harsh environmental factors. The device can withstand shock acceleration up to 1000 g peak (half-sine, 1 ms duration).

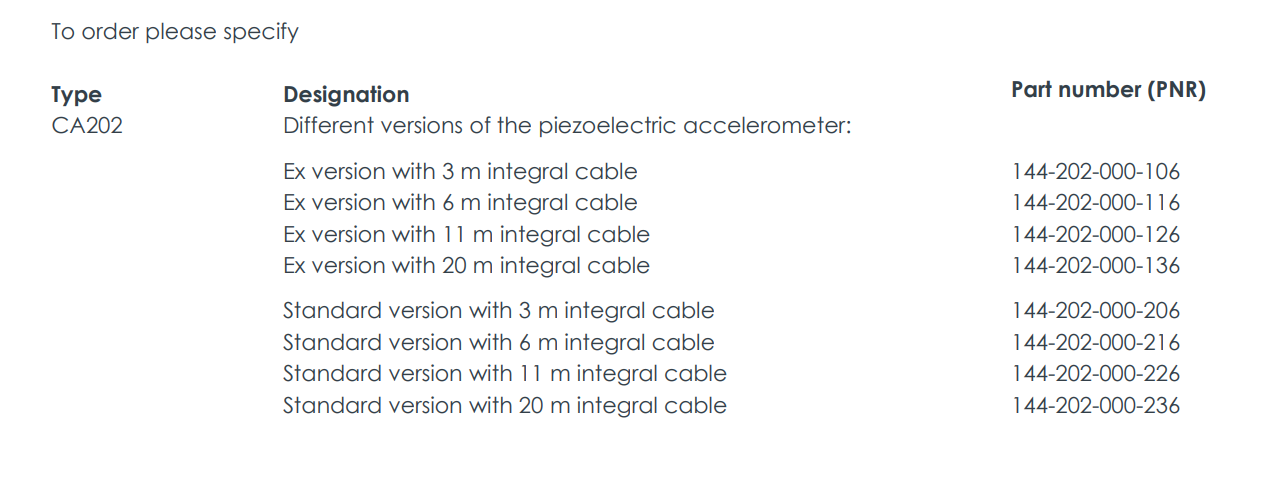

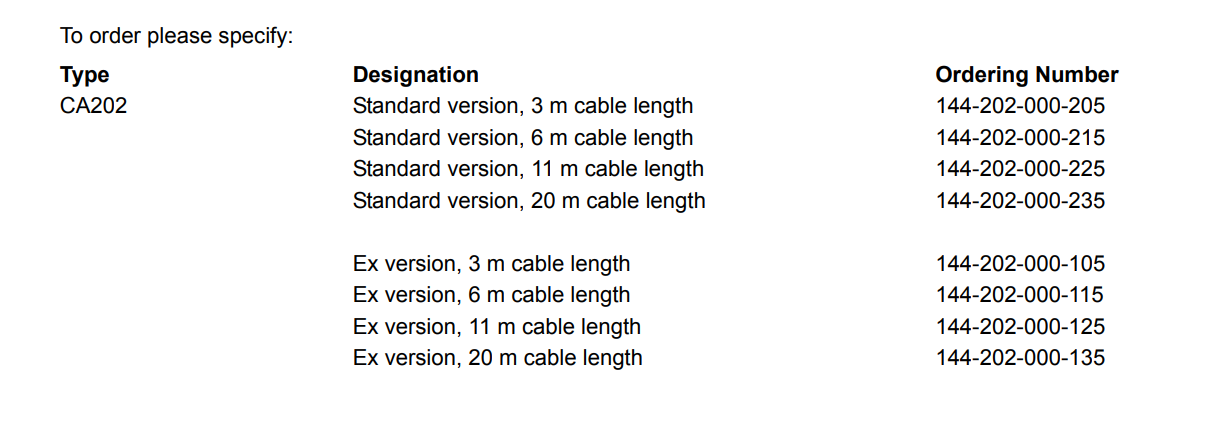

4. Flexible Installation Options

Four cable length options: 3 meters, 6 meters, 11 meters, and 20 meters, meeting different installation distance requirements. Standard M6 mounting holes with M4 spring lock washers, mounting torque of 15 N·m. No additional electrical insulation mounting surface required.

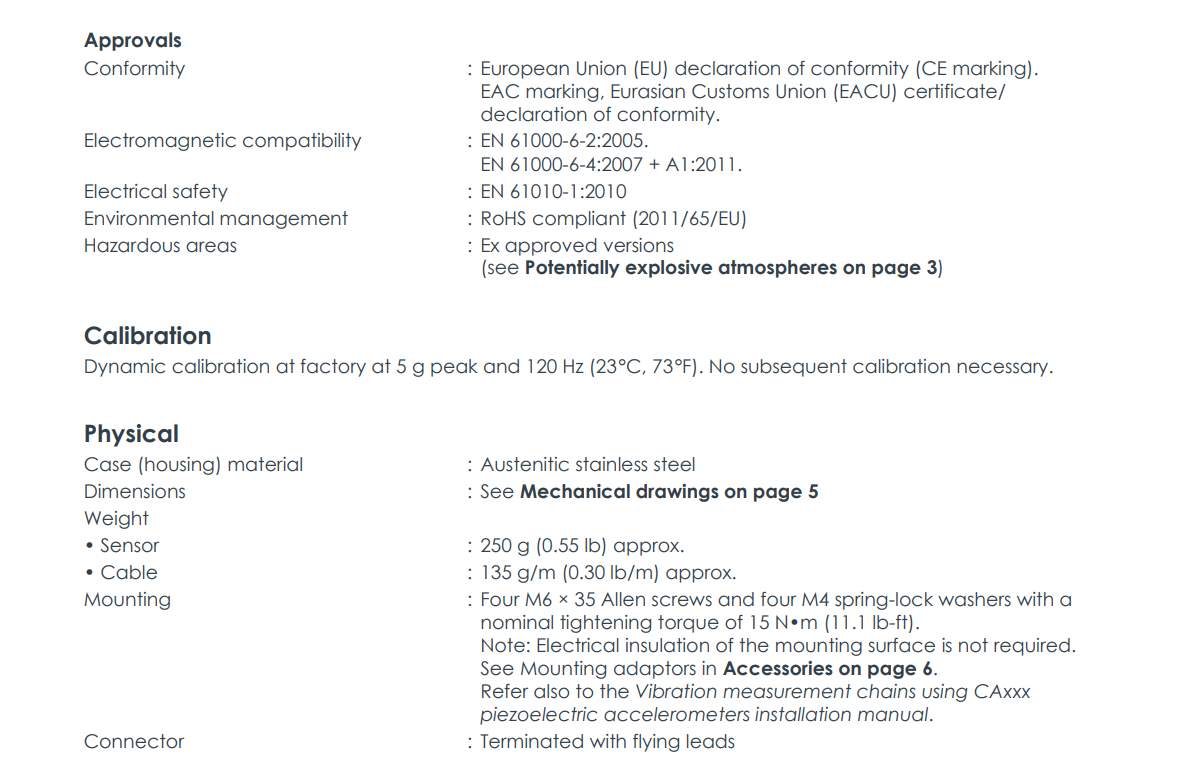

5. Comprehensive Certification Support

Multiple international certifications: CE marking, EAC marking, ATEX, IECEx, cCSAus, etc. Complies with EN 61000-6-2/4 electromagnetic compatibility standards and EN 61010-1 electrical safety standards. Meets RoHS environmental requirements.

6. Easy Integration and Maintenance

Differential output and internal insulation design simplify system integration. Integral cable structure enhances reliability and reduces maintenance needs. MA133 mounting adapter kit available, including Micaver (mica-glass) thermal isolation base for special installation requirements.

Technical Specifications Summary

| Item | Specification |

| Sensitivity | 100 pC/g ±5% |

| Frequency Response | 0.5 to 6,000 Hz (±5%) |

| Dynamic Range | 0.01 to 400 g peak |

| Overload Capacity | 500 g peak |

| Operating Temperature | -55 to +260°C (sensor) |

| Resonant Frequency | >22 kHz |

| Linearity | ±1% (0.01-20 g), ±2% (20-400 g) |

| Protection Rating | Hermetically sealed |

| Weight | Approx. 250 g (sensor) |

Application Areas

The CA202 piezoelectric accelerometer is widely used in the following fields:

Industrial Machinery Monitoring: Vibration monitoring of large rotating machinery such as turbines, compressors, and pumps

Energy Industry: Condition monitoring and fault diagnosis of power plant equipment

Petrochemical Industry: Equipment vibration monitoring in potentially explosive environments

Aerospace: Vibration testing of engines and auxiliary equipment

Heavy Industry: Predictive maintenance of metallurgical and mining equipment