The IPC707 is a high-performance, highly configurable signal conditioner from VM product line, specifically designed for use with piezoelectric sensors. Its primary function is to convert the charge output from piezoelectric sensors into standard current or voltage signals, making it suitable for vibration and pressure measurement systems, particularly in industrial safety monitoring and condition monitoring applications. The IPC707 not only offers excellent signal processing capabilities but also supports various filtering and diagnostic functions, meeting high reliability requirements in complex industrial environments. As an upgraded replacement for the IPC704 model, the IPC707 demonstrates significant improvements in performance, functionality, and safety.

Key Differences Between IPC707 and IPC704

| Feature | IPC707 | IPC704 |

| Diagnostic Function (BITE) | Yes. Monitors sensor, cable, and self-status. Outputs fault codes via DC bias. Supports functional safety (SIL 2, PL c). | No. |

| Filters | 3rd order Butterworth. HP and LP slope both ~60 dB/decade. Superior performance. | HP: 4th order (~24 dB/octave ≈80 dB/decade¹). LP: 2nd order (~12 dB/octave ≈40 dB/decade¹). |

| Transfer Sensitivity Range | Wider. No integrator: 0.1-110; With integrator: 981-98,100. | Narrower. Standard material: 0.1-10 / 981-98,100; GaPO₄ material: 0.1-50. |

| Input Dynamic Range | 50,000 pC (<10kHz) / 25,000 pC (10-20kHz) | 100,000 pC |

| Power Consumption | 20 mA max | 25 mA max |

| Connectors | Removable screw terminals, 4 input/4 output contacts. | Fixed screw terminals, 3 input/3 output contacts. |

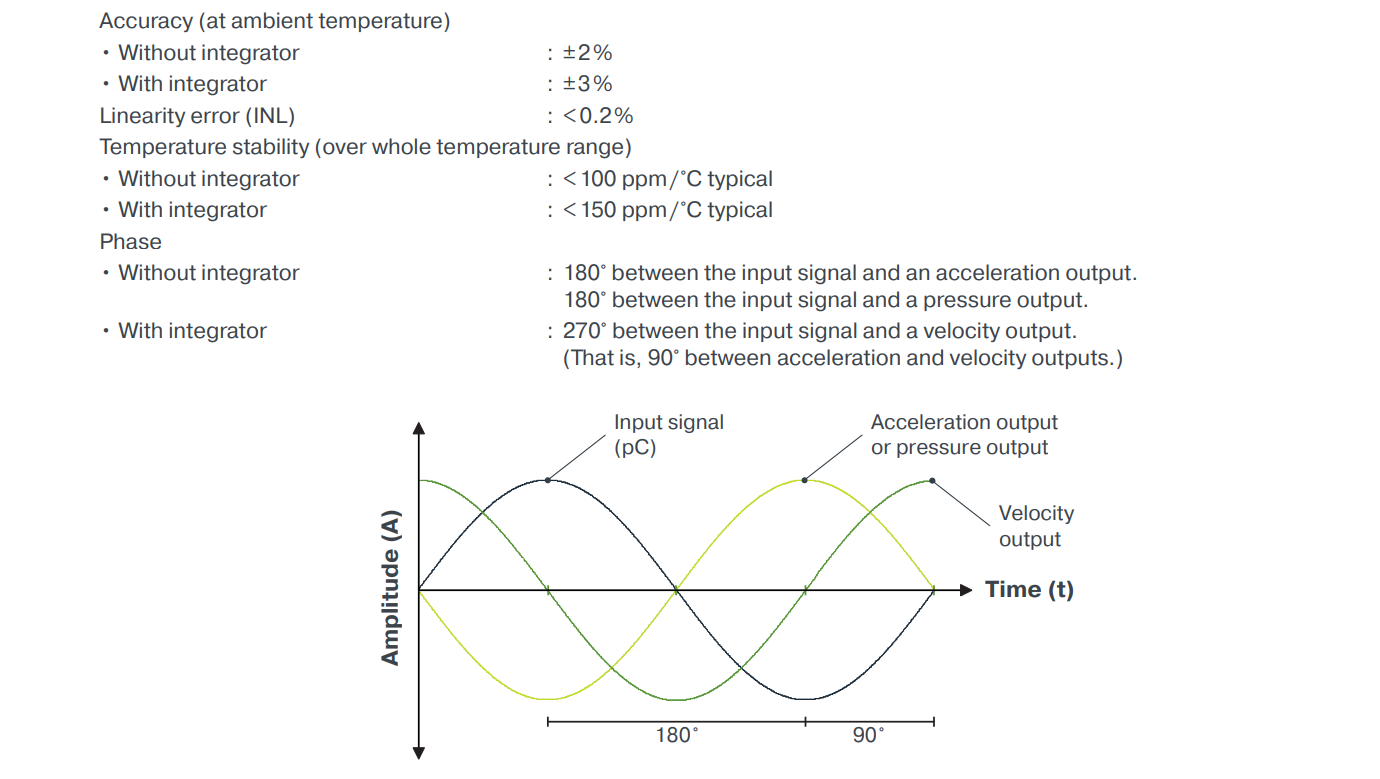

| Phase Response | Explicitly states 180° phase shift without integrator, 270° with integrator. | States the same. |

| Explosion-proof Certification | Newer, more comprehensive certification system, covers Zone 0 (Ex ia) and more regions (e.g., UKEX, EAEC RU). | Relatively older certification system, highest is Zone 1 (Ex ib). |

| Compliance & Safety | Explicitly complies with IEC 61508 SIL 2 and ISO 13849 PL c Cat 1. | Functional safety certifications not emphasized in documentation. |

| Product Positioning | Upgraded replacement for IPC704, with performance, functionality, and safety. | Previous generation product. |

¹ Note: dB/octave to dB/decade conversion is approximate for comparison.

Key Features and Characteristics

1 Extensive Sensor Compatibility

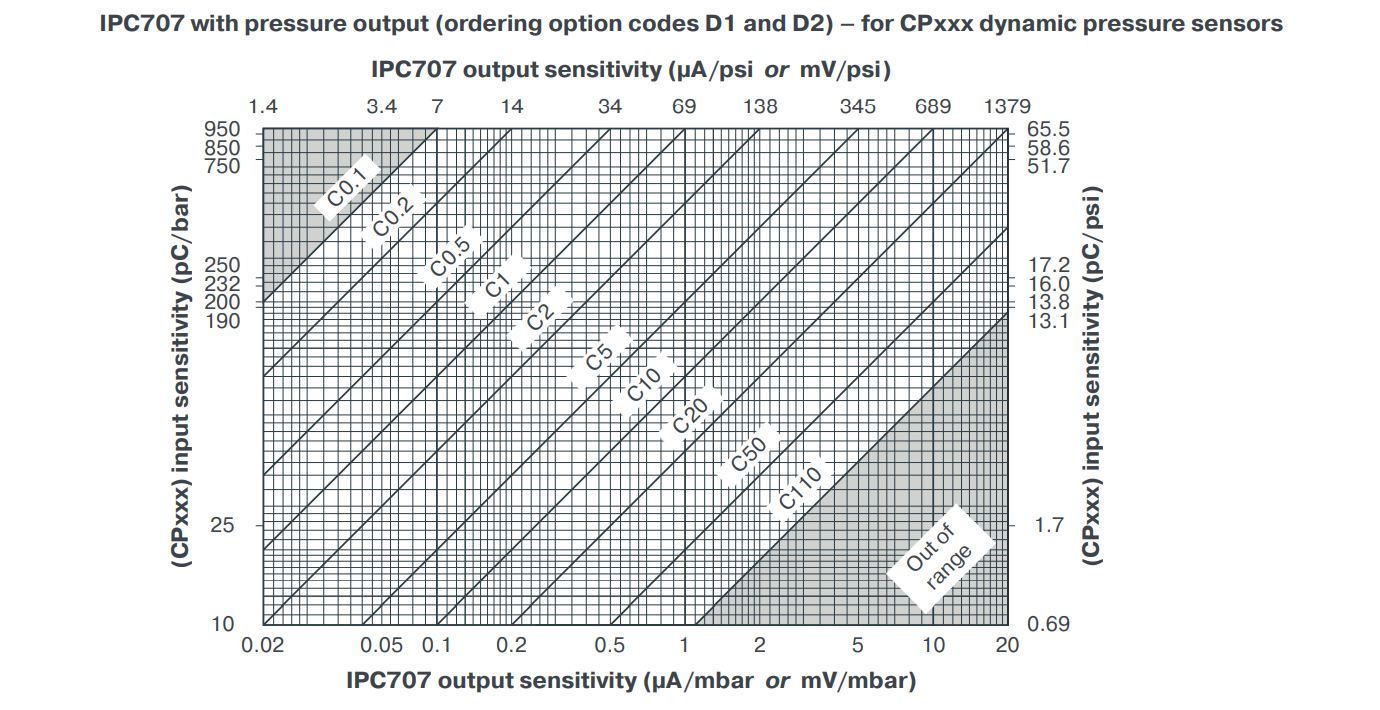

The IPC707 is designed for use with CAxxx series piezoelectric accelerometers and CPxxx series dynamic pressure sensors, while also being compatible with other piezoelectric sensors featuring differential (symmetrical) output characteristics. It can interface with both case-grounded and insulated sensors. While similar to the IPC704 in this aspect, the IPC707 has more specific and stringent requirements for input electrical characteristics, especially when utilizing its diagnostic functions.

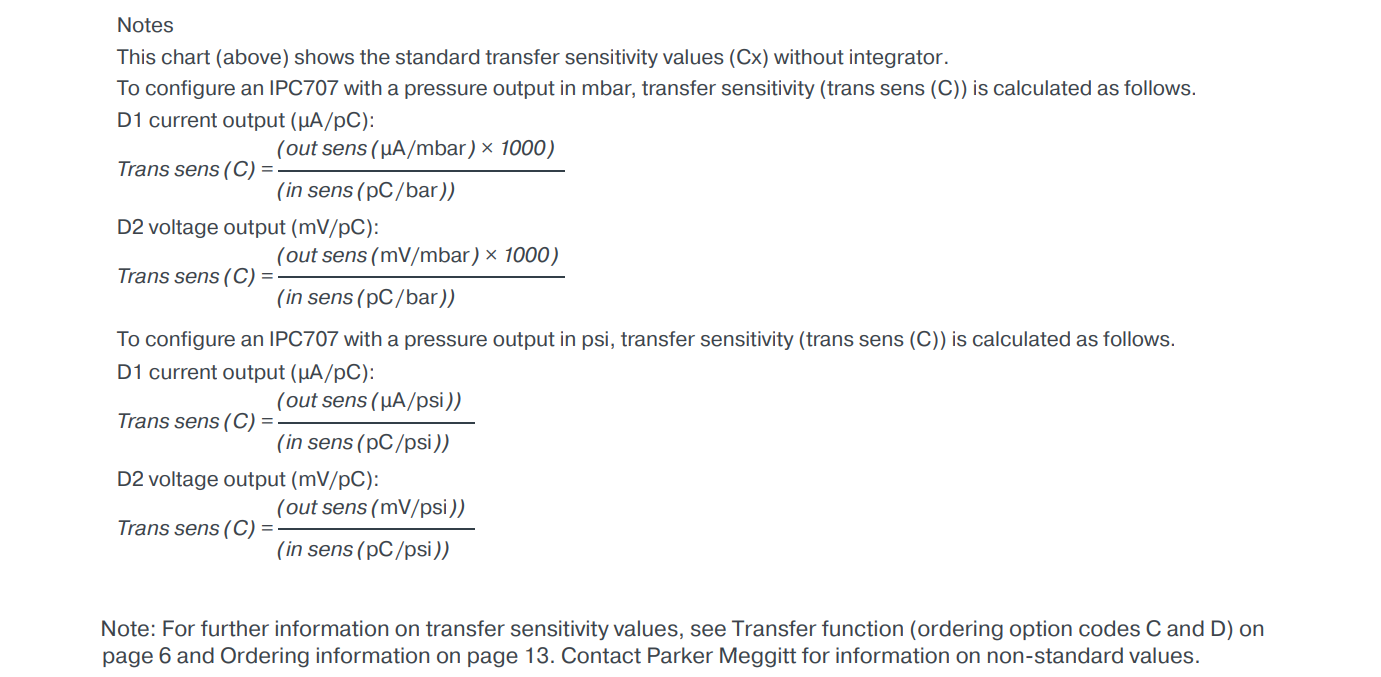

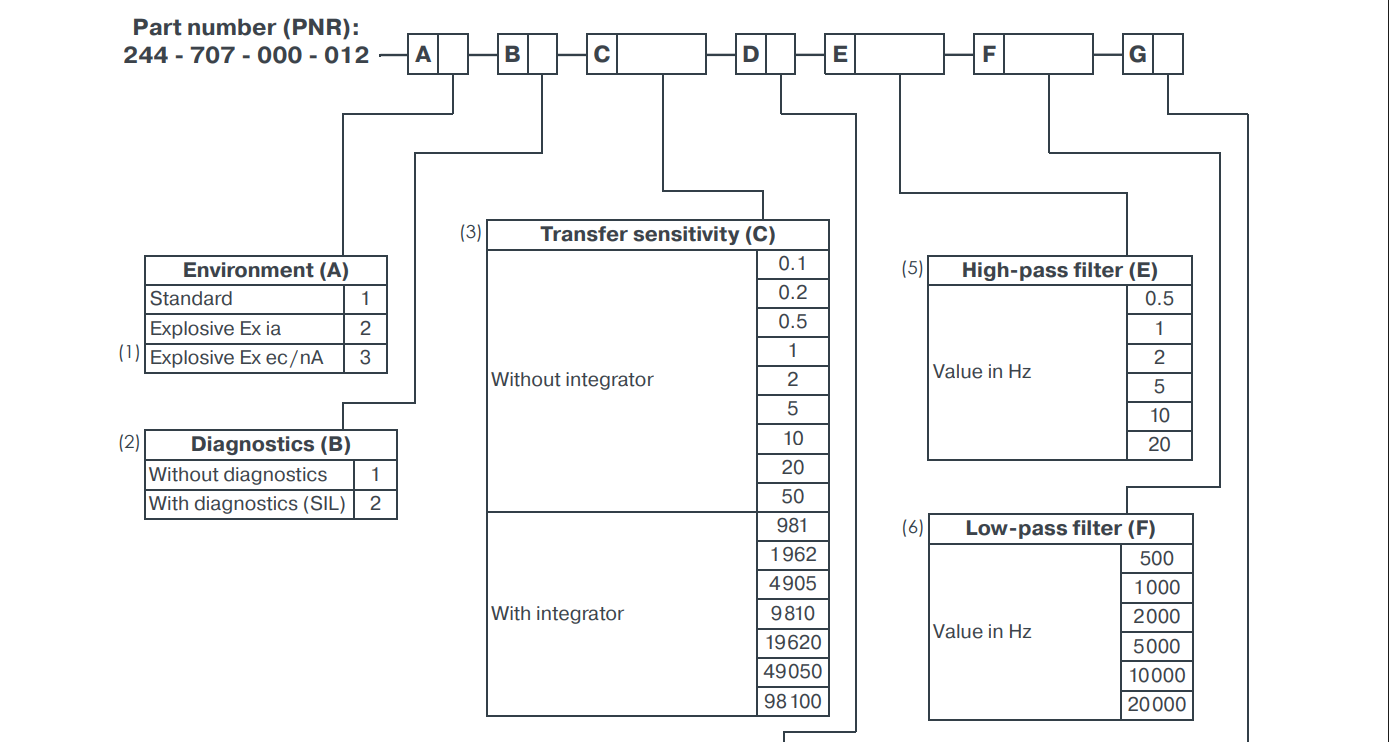

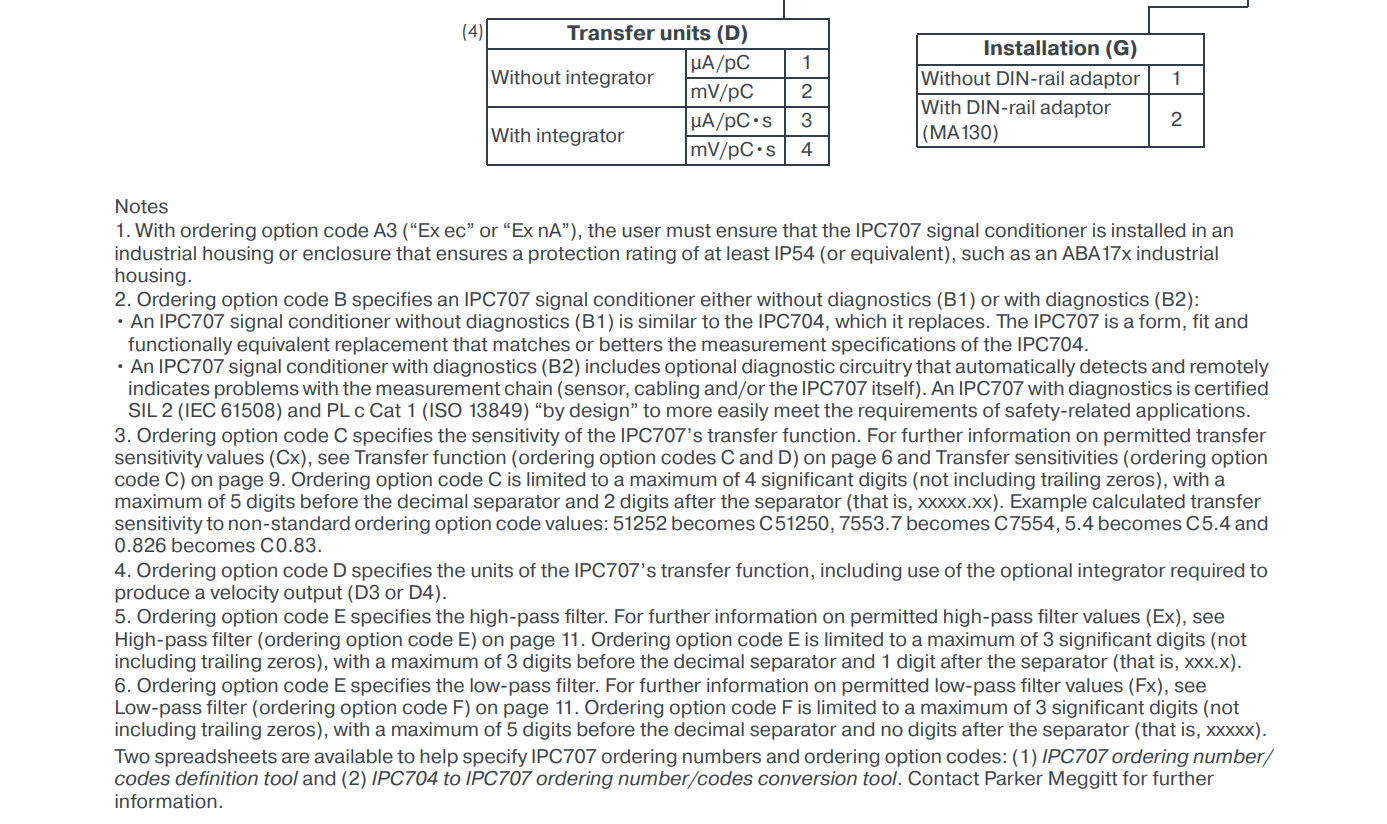

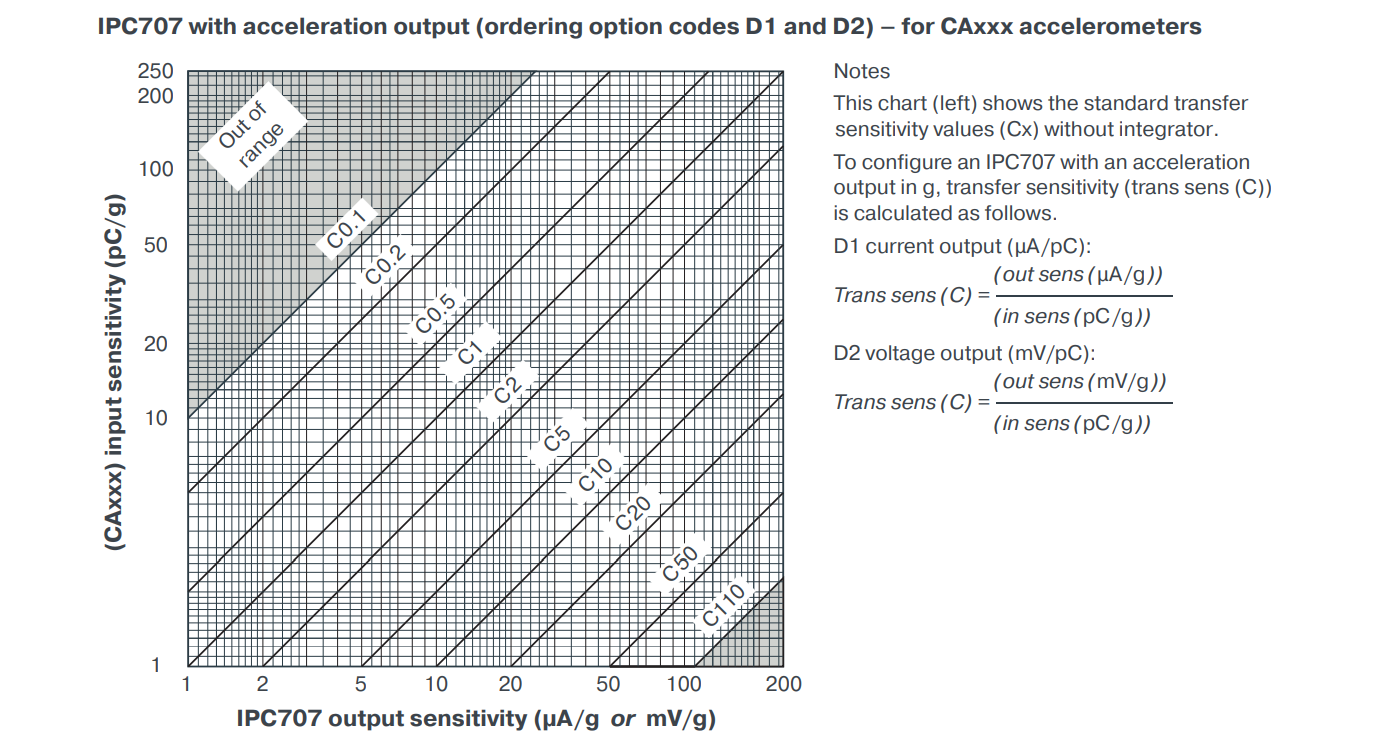

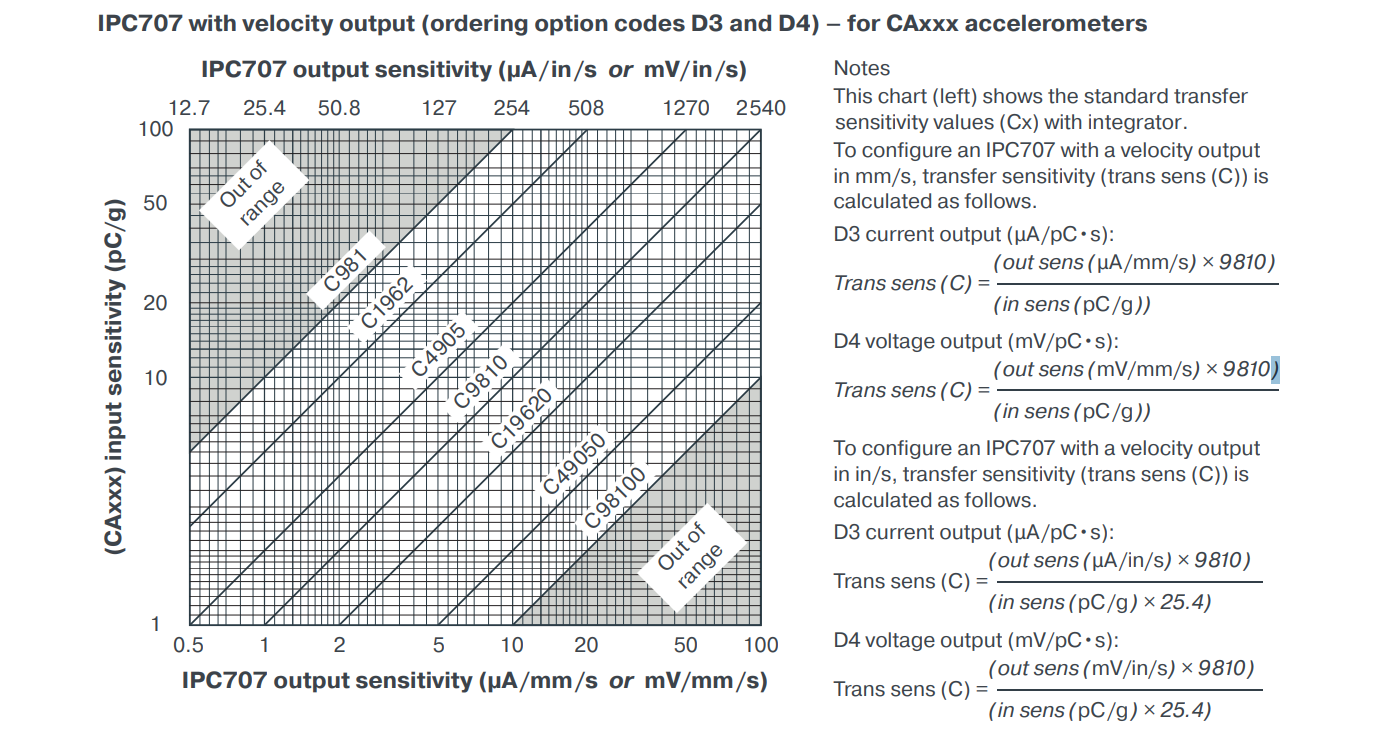

2 Flexible Transfer Function Configuration

pC to μA: Suitable for long-distance current signal transmission (2-wire system)

pC to mV: Suitable for short-distance voltage signal transmission (3-wire system)

Optional integrator: Converts acceleration signals to velocity signals, expanding application scope

The IPC707 offers a wider range of transfer sensitivity (without integrator: 0.1 to 110 μA/pC or mV/pC; with integrator: 981 to 98,100 μA/pC·s or mV/pC·s) and provides more standard value options compared to the IPC704 (standard material: 0.1 to 10; GaPO₄ material: 0.1 to 50).

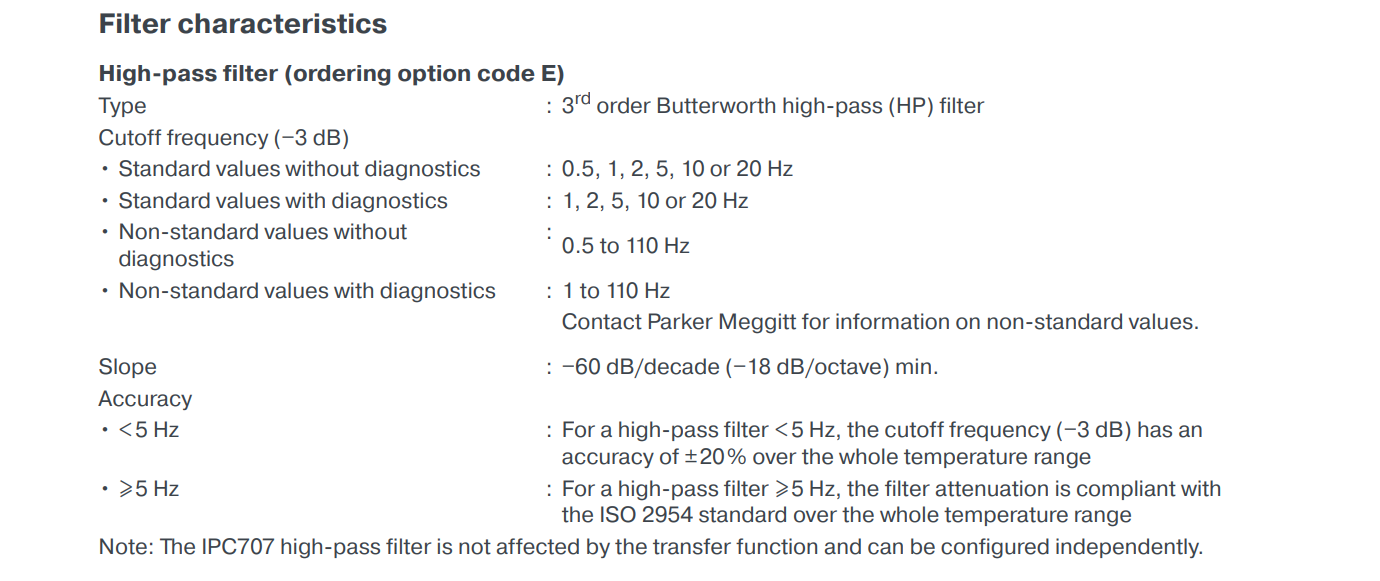

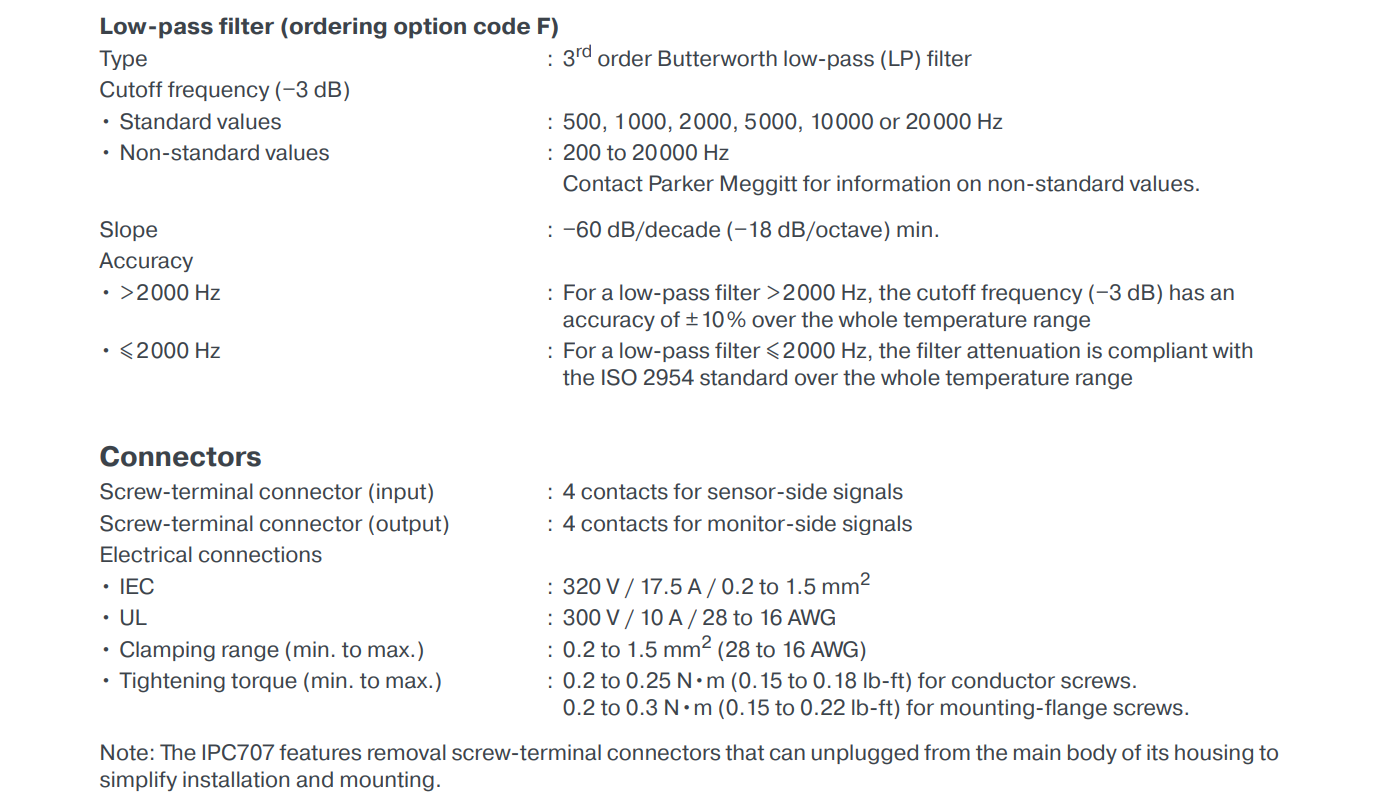

3 Configurable Filters

High-pass filter (HP): 3rd order Butterworth filter with selectable cutoff frequencies from 0.5 Hz to 20 Hz (minimum 1 Hz when diagnostics enabled), slope ~60 dB/decade

Low-pass filter (LP): 3rd order Butterworth filter with selectable cutoff frequencies from 200 Hz to 20 kHz, slope ~60 dB/decade

The filters can be configured independently of the transfer function, allowing users to customize according to actual needs. Compared to the IPC704 (HP as 4th order 24 dB/octave, LP as 2nd order 12 dB/octave), the IPC707 features higher-order filters with steeper roll-off characteristics for improved filtering performance.

4 Built-in Diagnostic Function (BITE) - New Core Feature of IPC707

Continuously monitors the status of sensors, cables, and the conditioner itself

Indicates system status through DC bias values of output signals:

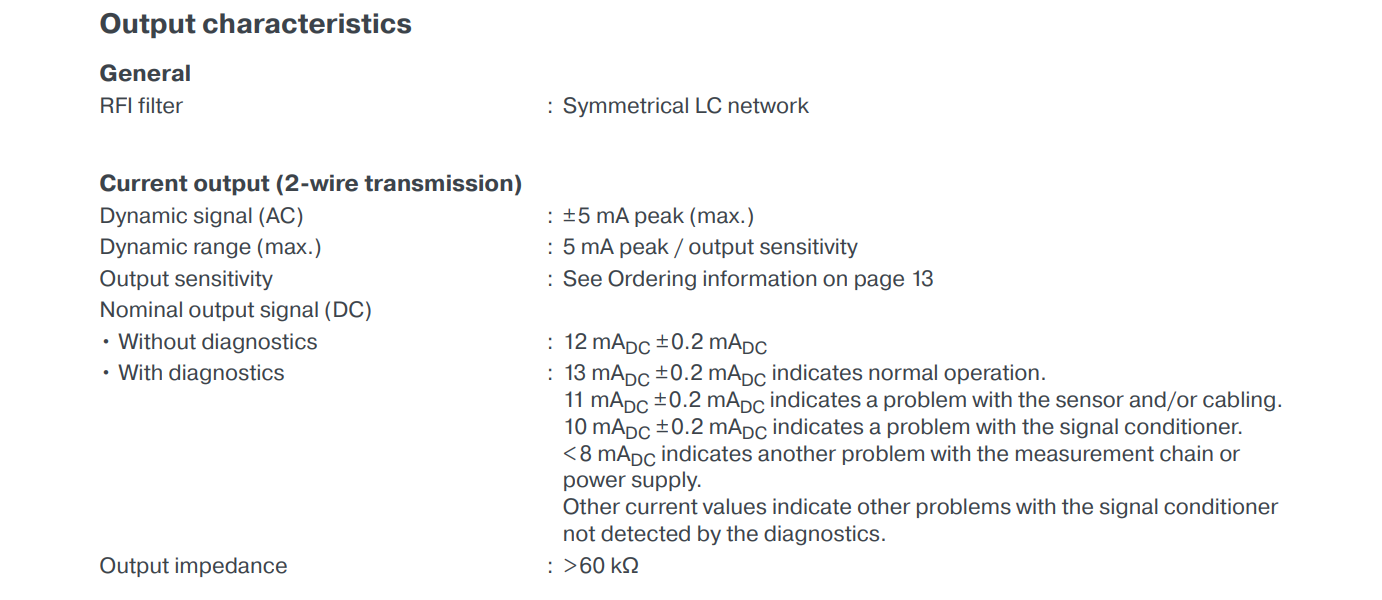

Current output: Normal at 13 mA, sensor/cable fault at 11 mA, conditioner fault at 10 mA

Voltage output: Normal at 8 V, sensor/cable fault at 6 V, conditioner fault at 5 V

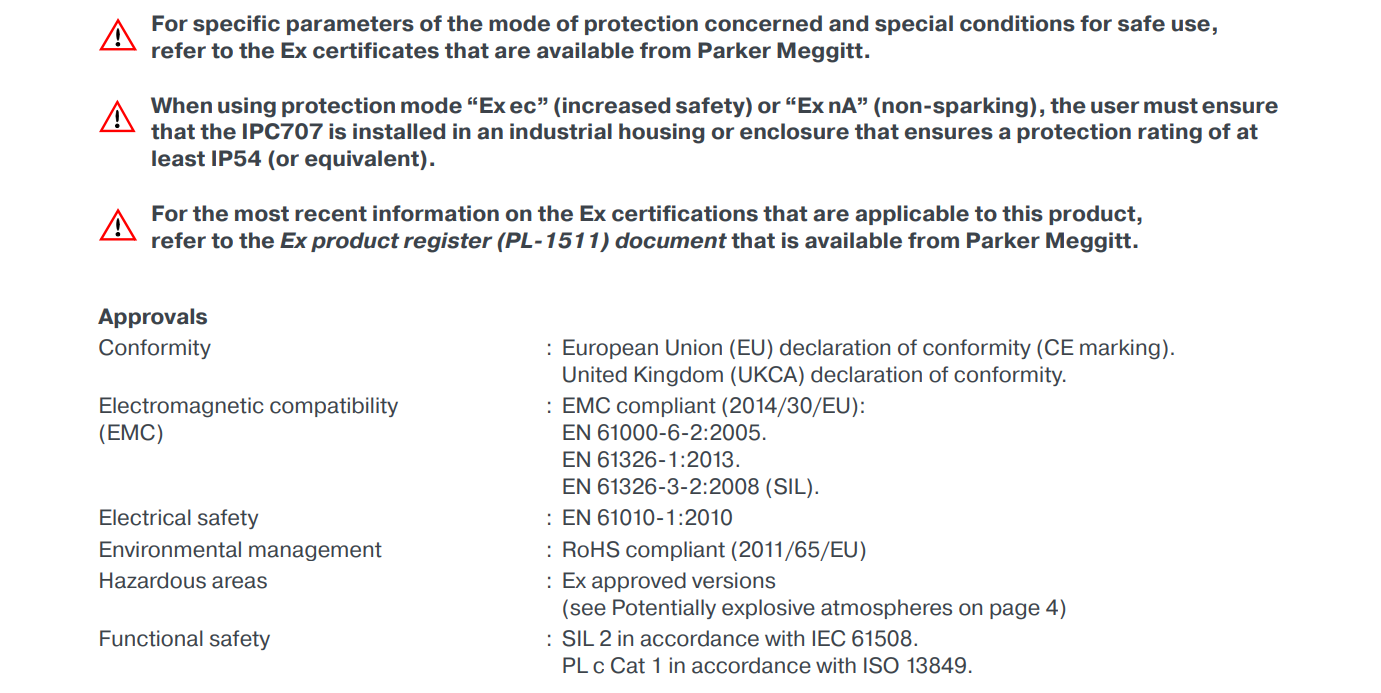

This functionality makes the IPC707 suitable for functional safety systems, complying with IEC 61508 SIL 2 and ISO 13849 PL c Cat 1 standards. This is a key functionality absent in the IPC704 and represents one of the core advantages of the IPC707.

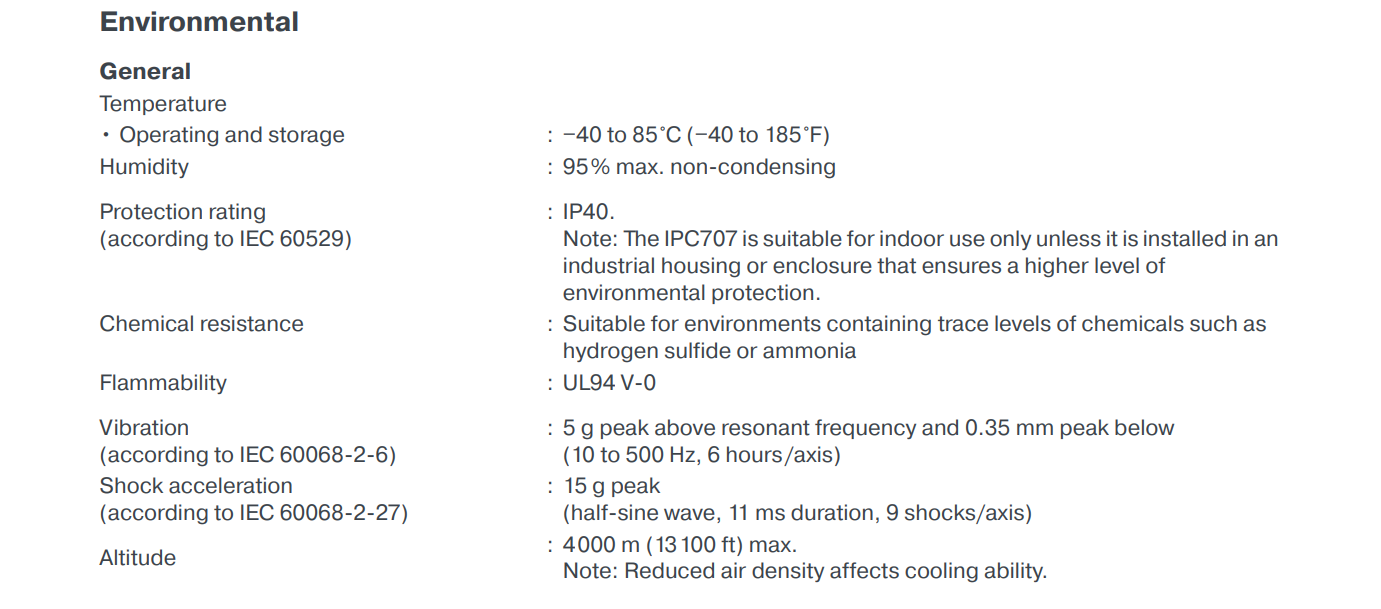

5 suitability for Hazardous Environments

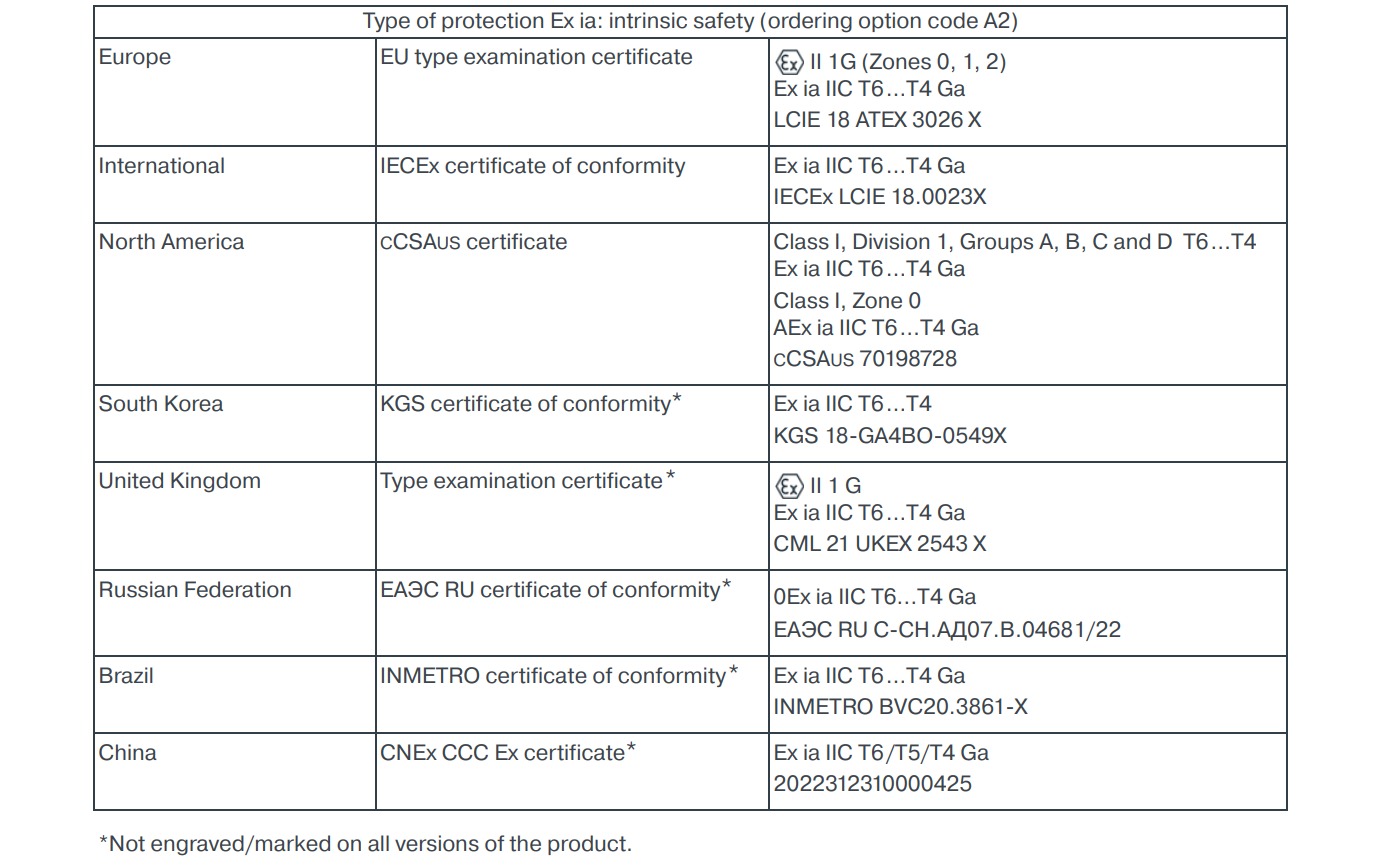

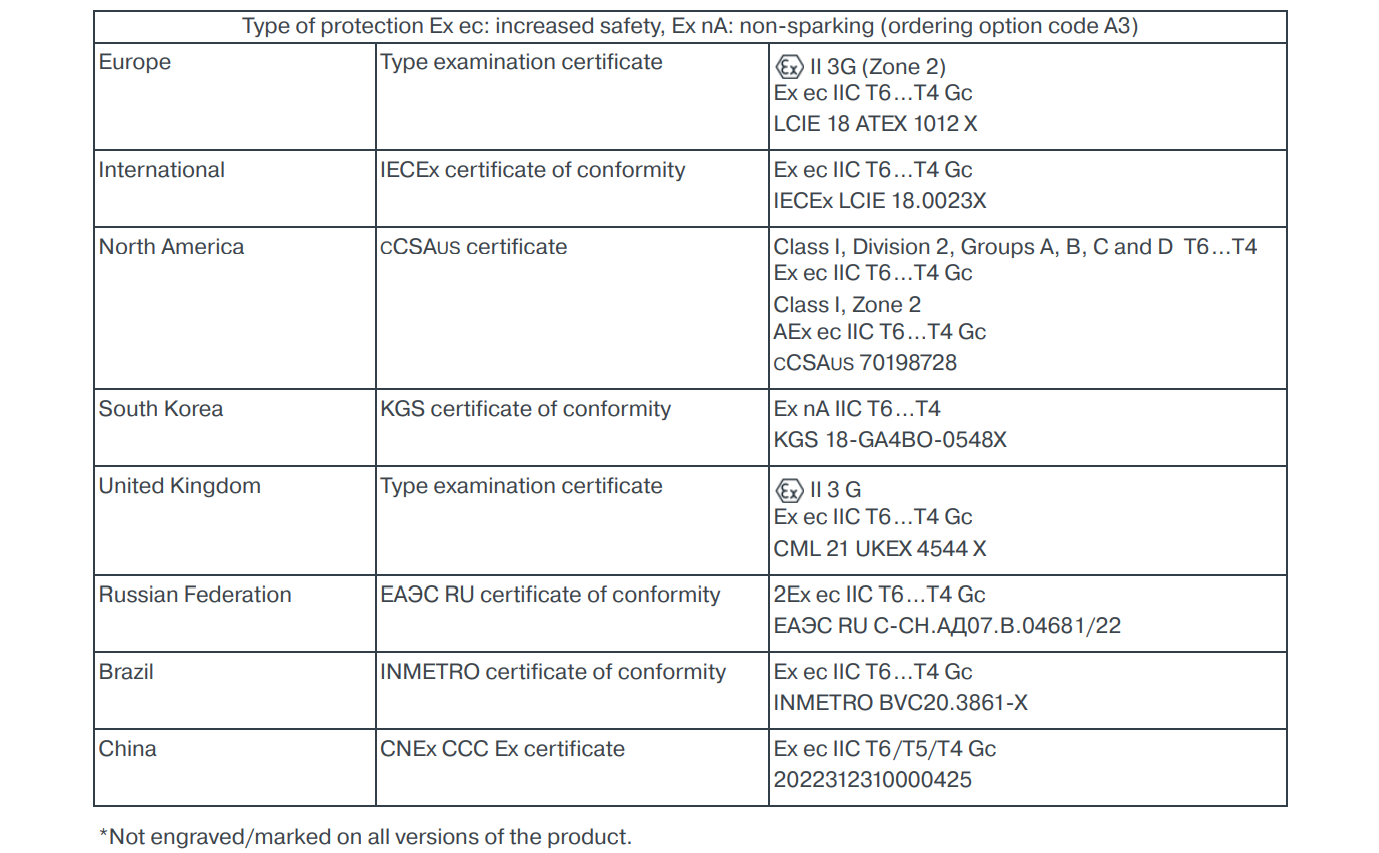

Available in various explosion-proof certified versions including:

Ex ia: Intrinsically safe, suitable for Zone 0/1/2

Ex ec/Ex nA: Increased safety/non-sparking, suitable for Zone 2

Certifications cover multiple regions including Europe (ATEX), International (IECEx), North America (cCSAus), South Korea, UK, Russia, Brazil, and China. While the IPC704 also offers explosion-proof versions (Ex ib, Ex nA), the IPC707's certification system is more comprehensive and up-to-date, covering more regions and the more stringent Zone 0.

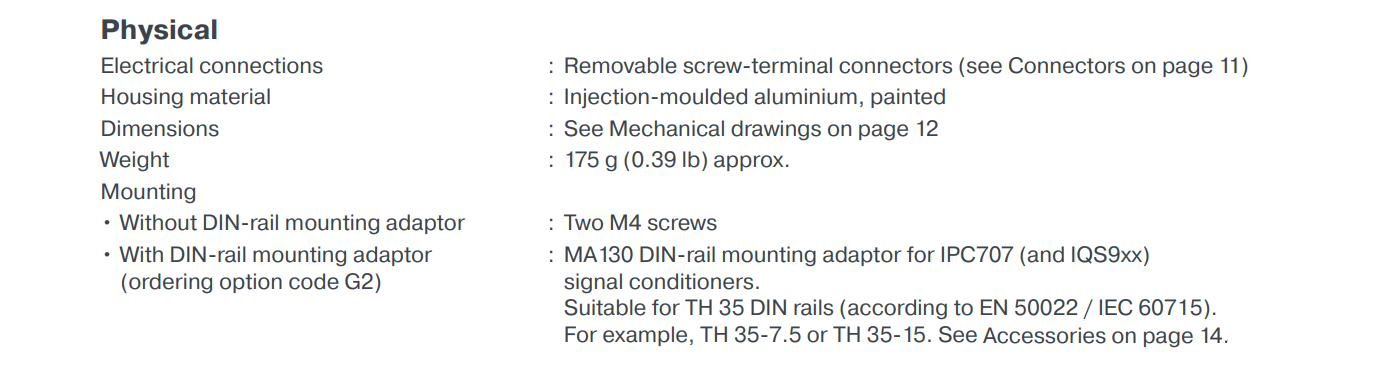

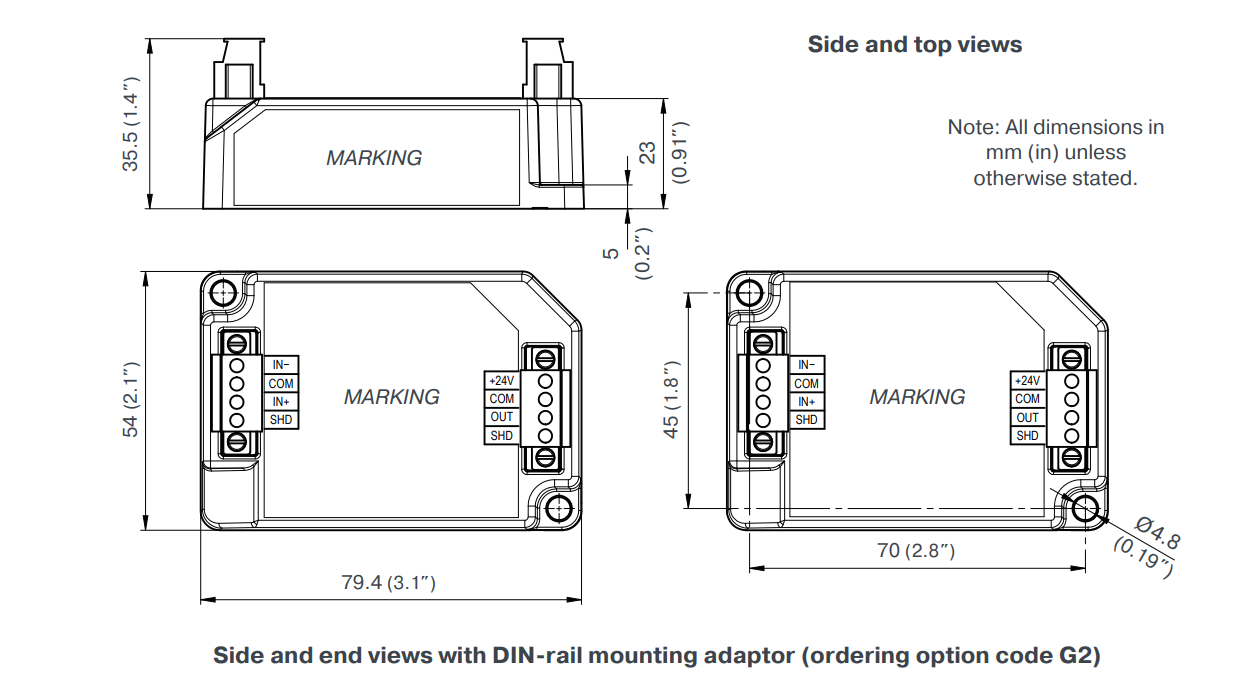

6 Mechanical and Installation Design

Housing made of injection-molded aluminum with IP40 protection rating (for indoor use). Protection level can be enhanced using ABA17x industrial housings.

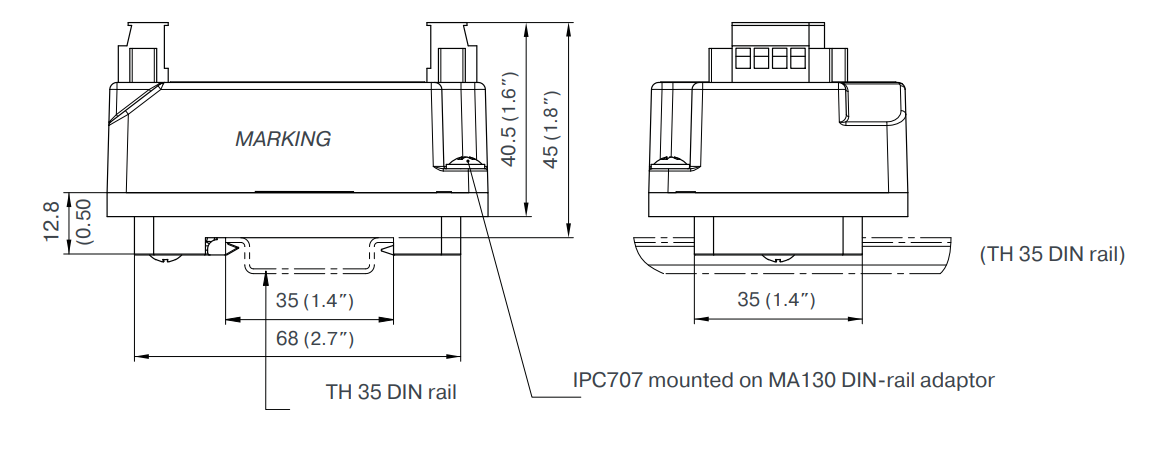

Supports screw mounting or DIN rail mounting (optional MA130 adapter, compatible with IPC704).

Removable screw-terminal connectors (4 input/4 output contacts each) facilitate installation and maintenance. The IPC704 has 3 fixed screw terminals.

7 Electrical Characteristics

Supply voltage: 18–30 VDC, typically 24 VDC

Power consumption: Max. 20 mA (IPC704: 25 mA)

Input dynamic range: Up to 50,000 pC (<10 kHz), slightly more conservative than IPC704's 100,000 pC, but optimized for high frequencies (10-20kHz) at 25,000 pC.

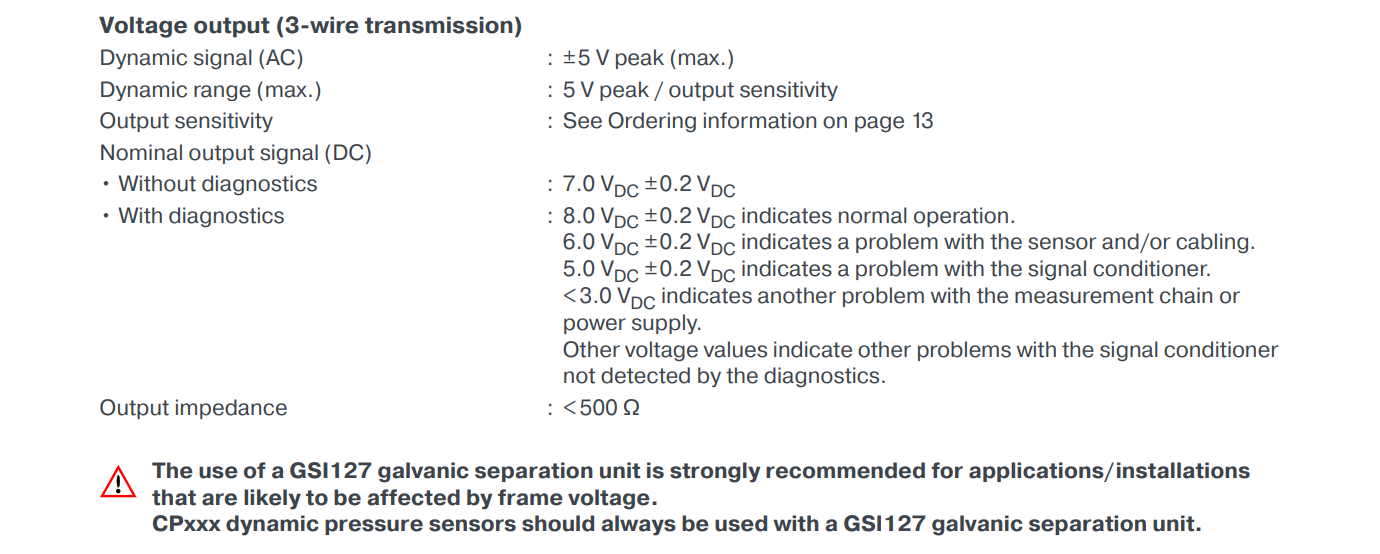

Output signals:

Current output: ±5 mA peak, impedance >60 kΩ, quiescent current 12 or 13 mA (with diagnostics)

Voltage output: ±5 V peak, impedance <500 Ω, quiescent voltage 7.0 or 8.0 V (with diagnostics)

Detailed Working Principle

The core function of the IPC707 is to convert the high-impedance charge signal generated by piezoelectric sensors into low-impedance voltage or current signals, conditioning them for long-distance transmission to monitoring systems. Its signal processing follows a precise electronic chain:

1. Input Protection and RFI Filtering:

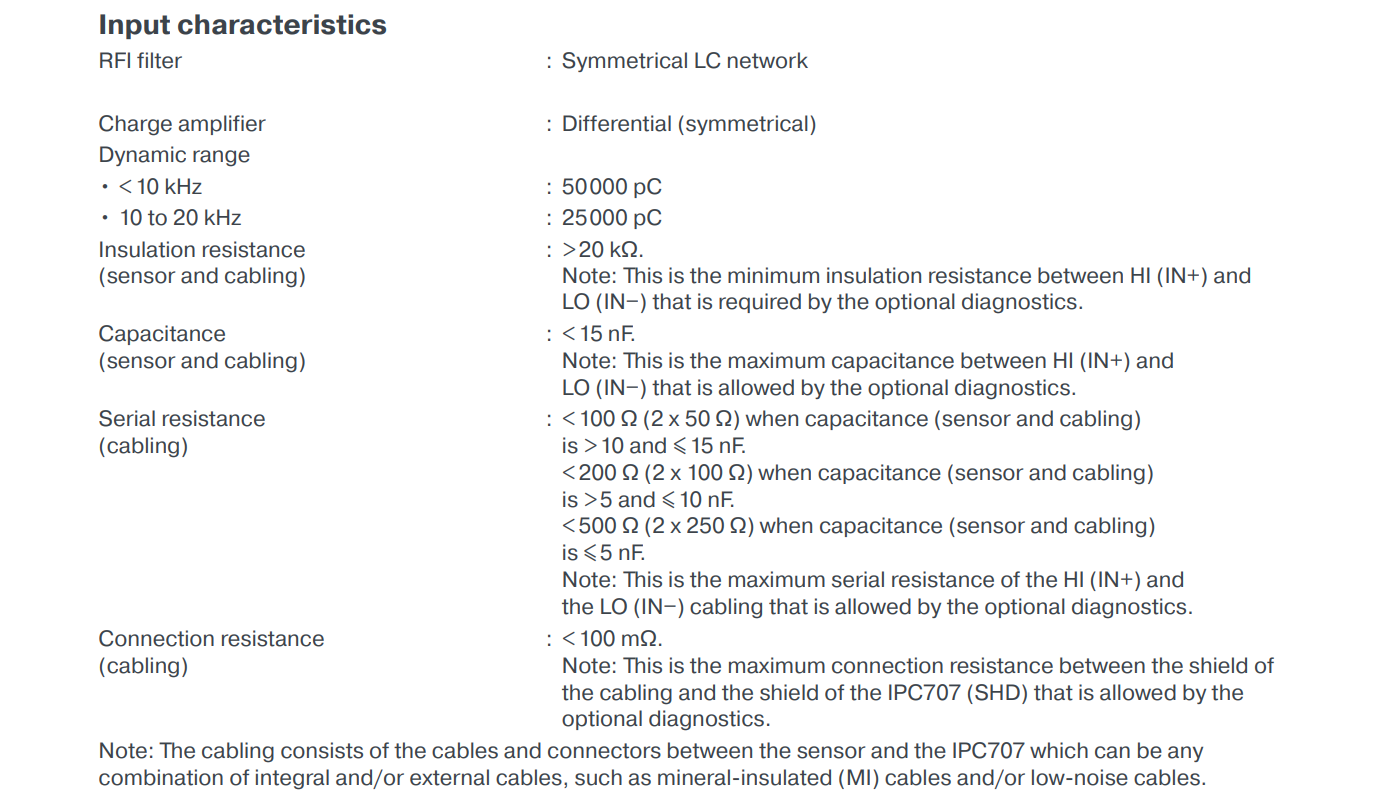

Sensor signals are transmitted via cables to the input of the IPC707. First, the signal passes through a symmetrical LC network RFI filter. This filter effectively suppresses external radio frequency interference (RFI) and electromagnetic interference (EMI), ensuring a high signal-to-noise ratio for subsequent circuits and preventing high-frequency noise from contaminating the weak charge signal. This is crucial for reliable measurement in industrial environments.

2. Differential Charge Amplifier:

The filtered signal is fed into a differential (symmetrical) charge amplifier. This is the first key conversion step in signal conditioning. The core function of the charge amplifier is to linearly convert the charge signal (in picocoulombs, pC) produced by the piezoelectric sensor into a low-impedance voltage signal. The differential design provides excellent common-mode rejection ratio (CMRR), effectively suppressing common-mode noise (e.g., ground loop interference) introduced into the two signal lines during transmission, significantly improving signal quality.

3. Signal Conditioning and Filtering:

The voltage signal from the charge amplifier then enters the configurable filtering stage.

High-Pass Filter (HPF): This is a 3rd order Butterworth high-pass filter used to remove low-frequency noise and unwanted DC offset components from the signal. Its cutoff frequency is configurable from 0.5 Hz to 110 Hz. This is very effective for isolating slow drifts caused by base vibration or temperature changes, ensuring the output signal contains only valid AC measurement components.

Optional Integrator: If the application requires measuring velocity instead of acceleration, an integrator circuit can be enabled. The integrator mathematically integrates the acceleration signal (voltage proportional to acceleration), outputting a voltage signal proportional to velocity.

Low-Pass Filter (LPF): Following this is a 3rd order Butterworth low-pass filter used to filter out high-frequency noise in the signal and provide anti-aliasing. Its cutoff frequency is configurable from 200 Hz to 20,000 Hz. This ensures the output signal's bandwidth is limited to the frequency range of interest, complies with the Nyquist sampling theorem, and prepares the signal for subsequent digital processing.

4. Output Stage Amplification and Configuration:

The filtered signal is sent to a configurable amplification stage, where its gain is set according to the user-selected transfer sensitivity. Finally, the signal enters the configurable output stage:

Current Output Mode (2-wire): The output stage converts the voltage signal into a dynamically varying (AC) current signal superimposed on a static direct current (DC) bias. The dynamic current range is ±5 mA peak, and the static bias is typically 12 mA. When diagnostics are enabled, this static bias is modulated to 13 mA (normal), 11 mA (sensor/cable fault), or 10 mA (conditioner fault). This current transmission method is ideal for long-distance transmission (up to 1 km) as it is insensitive to cable resistance and has strong anti-interference capabilities.

Voltage Output Mode (3-wire): The output stage directly provides a dynamically varying (AC) voltage signal superimposed on a static direct current (DC) bias voltage. The dynamic voltage range is ±5 V peak, and the static bias is typically 7.0 V. With diagnostics enabled, this static bias is modulated to 8.0 V (normal), 6.0 V (sensor/cable fault), or 5.0 V (conditioner fault). Voltage transmission is suitable for shorter-distance applications.

5. Output Protection and Filtering:

Before the signal is finally output, it passes through another symmetrical LC network RFI filter, providing final protection for the output signal and preventing external interference from affecting signal integrity through the output cable.

6. Diagnostic Function (BITE) Principle:

The diagnostic function of the IPC707 is a major highlight. Its diagnostic circuit continuously monitors the electrical characteristics of the entire measurement chain:

Sensor and Cable Monitoring: It monitors the insulation resistance at the input (must be >20 kΩ), cable capacitance (must be <15 nF), cable series resistance (different limits based on capacitance value), and shield connection resistance (must be <100 mΩ).

Fault Indication: When any parameter exceeds the preset range, the diagnostic circuit does not interrupt the measurement signal but indicates the fault type by changing the DC bias component of the output signal. The upstream monitoring system (e.g., VM600) can remotely and automatically determine the health status of the measurement chain by continuously monitoring this DC component, issuing timely alarms, thereby enabling predictive maintenance and meeting functional safety requirements.

7. Power Management:

The entire circuit is powered by an external 18-30 VDC power supply, with internal circuitry stabilizing it to the required operating voltage. In safety-related applications, the power supply is required to have safe isolation and a voltage limit of 40VDC.

Application Areas

Vibration Monitoring Systems: For vibration measurement and protection of rotating machinery (e.g., turbines, compressors, pumps).

Pressure Monitoring Systems: Suitable for dynamic pressure measurement, such as combustion pressure, hydraulic pulses.

Functional Safety Systems: Thanks to its diagnostic functions, the IPC707 can be used in safety-related control loops, complying with SIL 2 and PL c standards. This is an application the IPC704 cannot directly fulfill.

Condition Monitoring and Predictive Maintenance: Enhances system reliability and maintenance efficiency through real-time diagnostics.