The IQS900 is a high-performance, modular signal conditioner from the VM product line. It is a critical component specifically designed for condition monitoring and protection systems of rotating machinery, used to drive and process signals from non-contact proximity sensors (such as the TQ402/TQ412) based on the eddy-current principle. The IQS900 is intended to replace its predecessor, the IQS450, not only matching but often exceeding its performance, while introducing multiple modern improvements, making it an advanced solution that meets the demands for high reliability, safety, and intelligent diagnostics in today's industrial sectors.

This conditioner serves as the core "brain" of a complete proximity measurement system (typically consisting of a TQ4xx sensor, an EA402 extension cable, and the IQS900 signal conditioner). It is responsible for exciting the sensor, processing the returned weak signal, and converting it into a standardized, high-precision voltage or current output signal for use by subsequent monitoring systems. This enables continuous monitoring of key parameters such as mechanical vibration, axial displacement, and rotational speed.

Core Features and Benefits

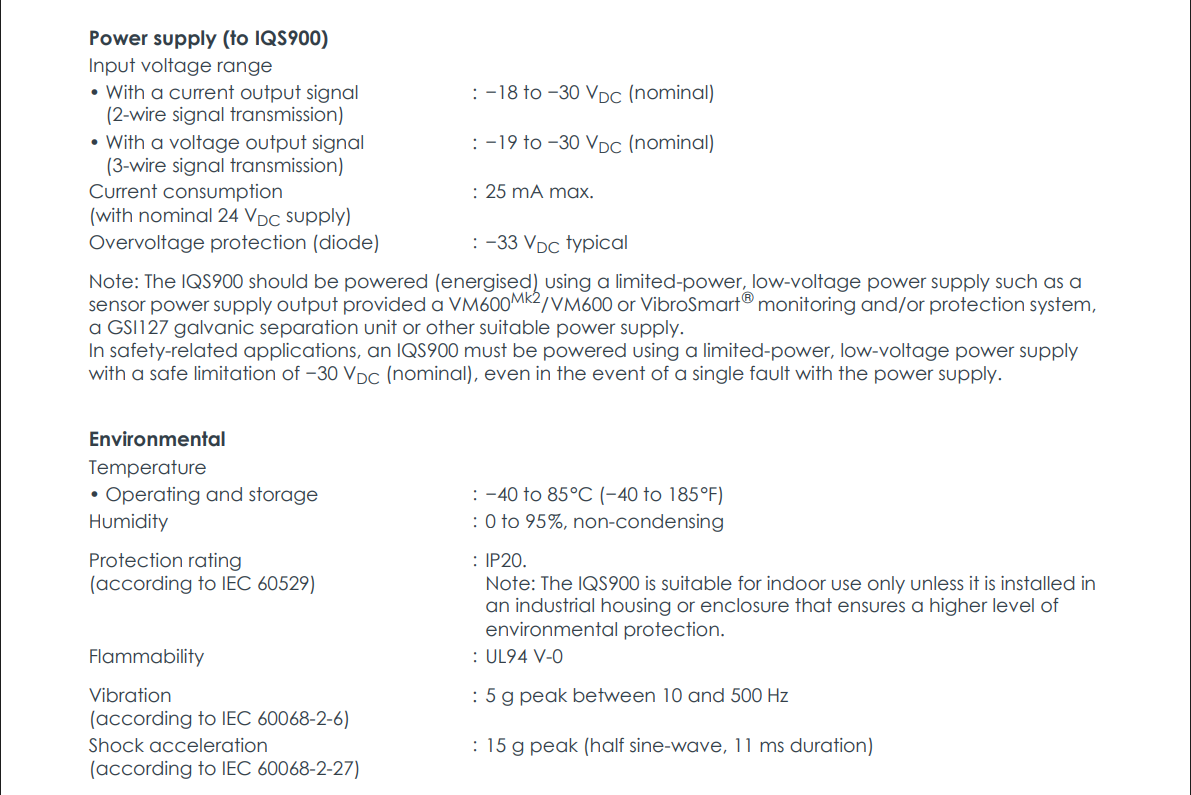

The IQS900's feature set is designed to deliver exceptional measurement performance, high system flexibility, and robust environmental adaptability. Its core functions include:

Dual Output Mode Compatibility:

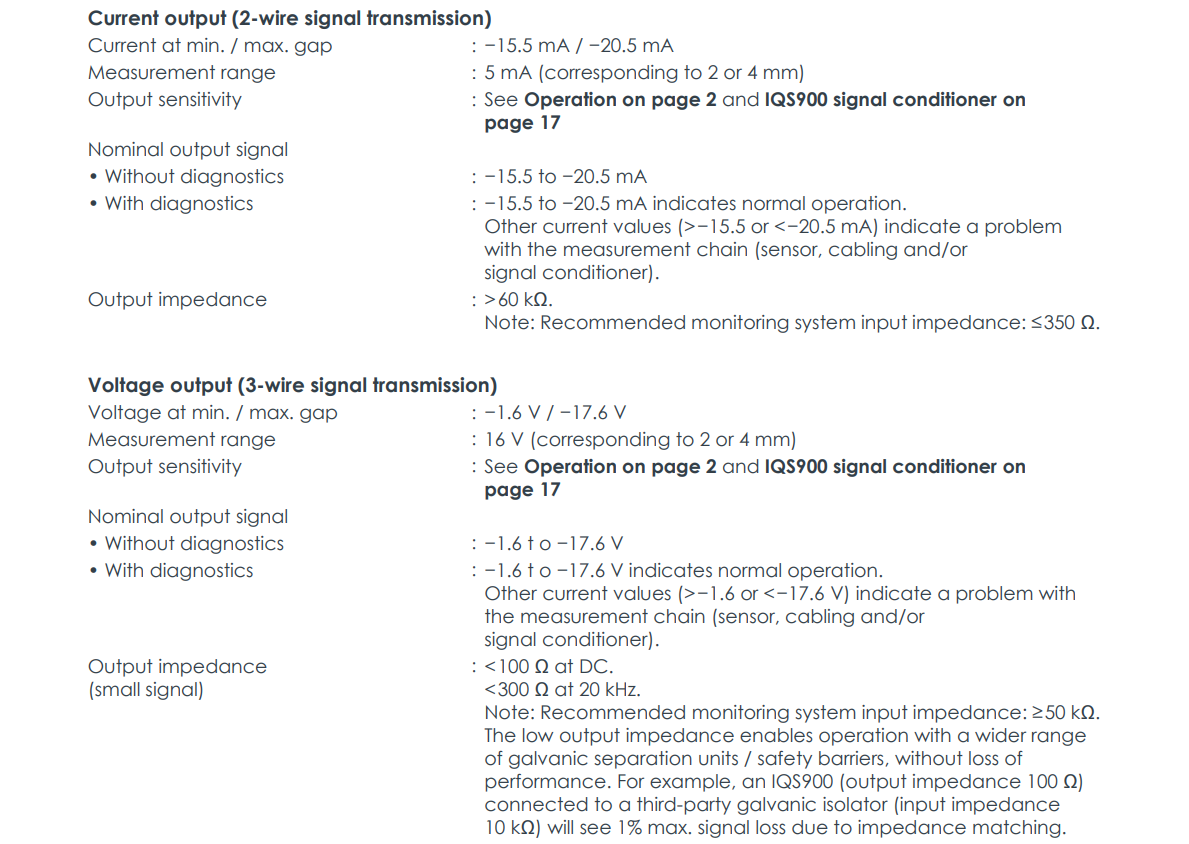

Current Output (2-wire): Provides a linear current signal from -15.5 mA to -20.5 mA (corresponding to 2mm or 4mm measurement ranges). This mode is ideal for long-distance signal transmission, offers strong noise immunity, and facilitates connection with current-input safety barriers or isolators.

Voltage Output (3-wire): Provides a linear voltage signal from -1.6 V to -17.6 V (corresponding to 2mm or 4mm measurement ranges). This mode features very low output impedance (<100 Ω at DC, <300 Ω at 20 kHz), enabling it to drive higher input impedance loads and work with a wider range of third-party isolators with minimal signal attenuation.

Built-in Diagnostics (Optional):

This is a major upgrade over previous generations. Users can opt for a version with diagnostics (Ordering Option C2).

This function continuously monitors the health of the entire measurement chain, including the sensor, coaxial cable, and the conditioner itself.

Upon detecting issues such as open circuits, short circuits, cable damage, sensor failure, or internal conditioner errors, it immediately signals an alarm by driving the output signal outside its normal operating range. For example, normal current output should be between -15.5 and -20.5 mA; output current higher than -15.5 mA or lower than -20.5 mA clearly indicates a system fault.

This feature is crucial for enabling predictive maintenance, reducing unplanned downtime, and enhancing overall system safety.

Safety Integrity Level (SIL) Certification:

Enhanced Immunity:

Test and Raw Signal Interfaces:

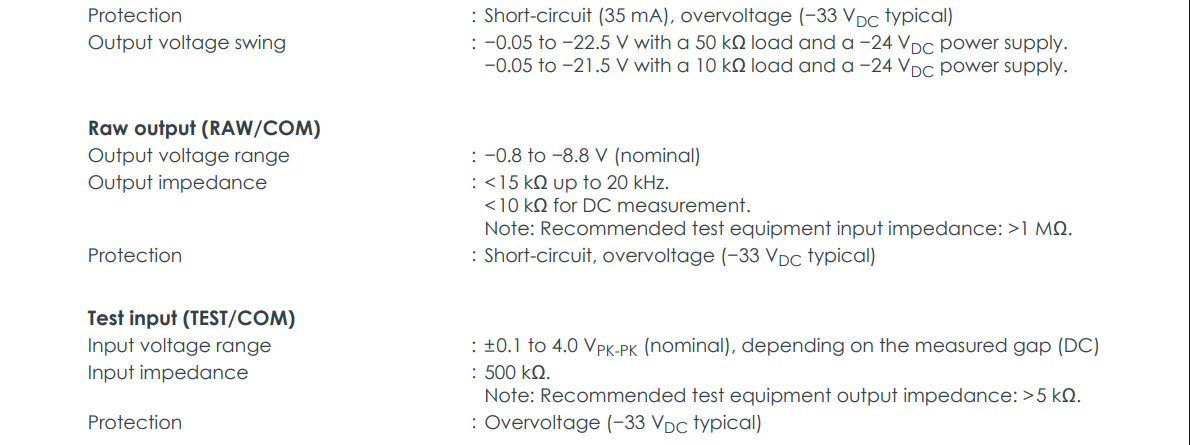

Raw Output (RAW/COM): Provides a voltage signal proportional to the sensor probe gap (-0.8 to -8.8 V nominal) before full conditioning. This interface can be used for advanced diagnostics, system commissioning, or connection to specialized test equipment.

Test Input (TEST/COM): Allows an external test signal (±0.1 to 4.0 Vp-p nominal, DC coupled) to be injected into the system to verify the functionality of the entire monitoring channel (from the conditioner onwards) without physically moving mechanical components.

Comprehensive Protection Mechanisms:

Includes features like output short-circuit protection and overvoltage protection (typical -33 VDC), enhancing device robustness during installation and operation, and preventing damage from wiring errors or accidental surges.

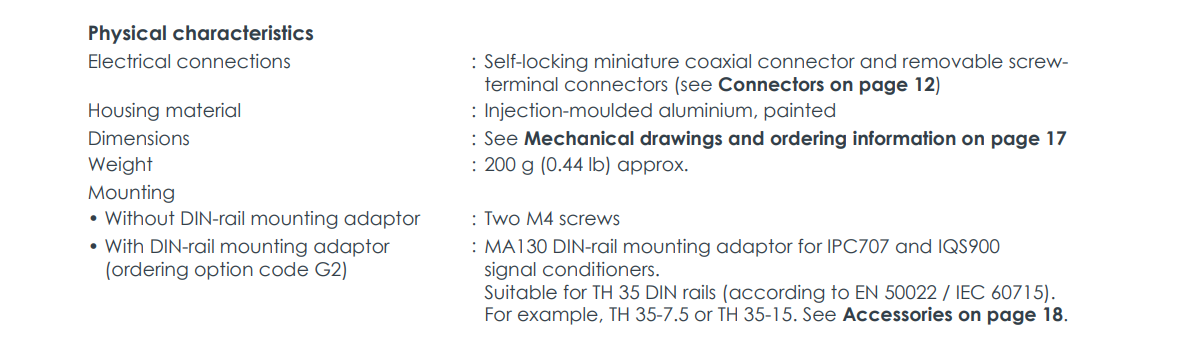

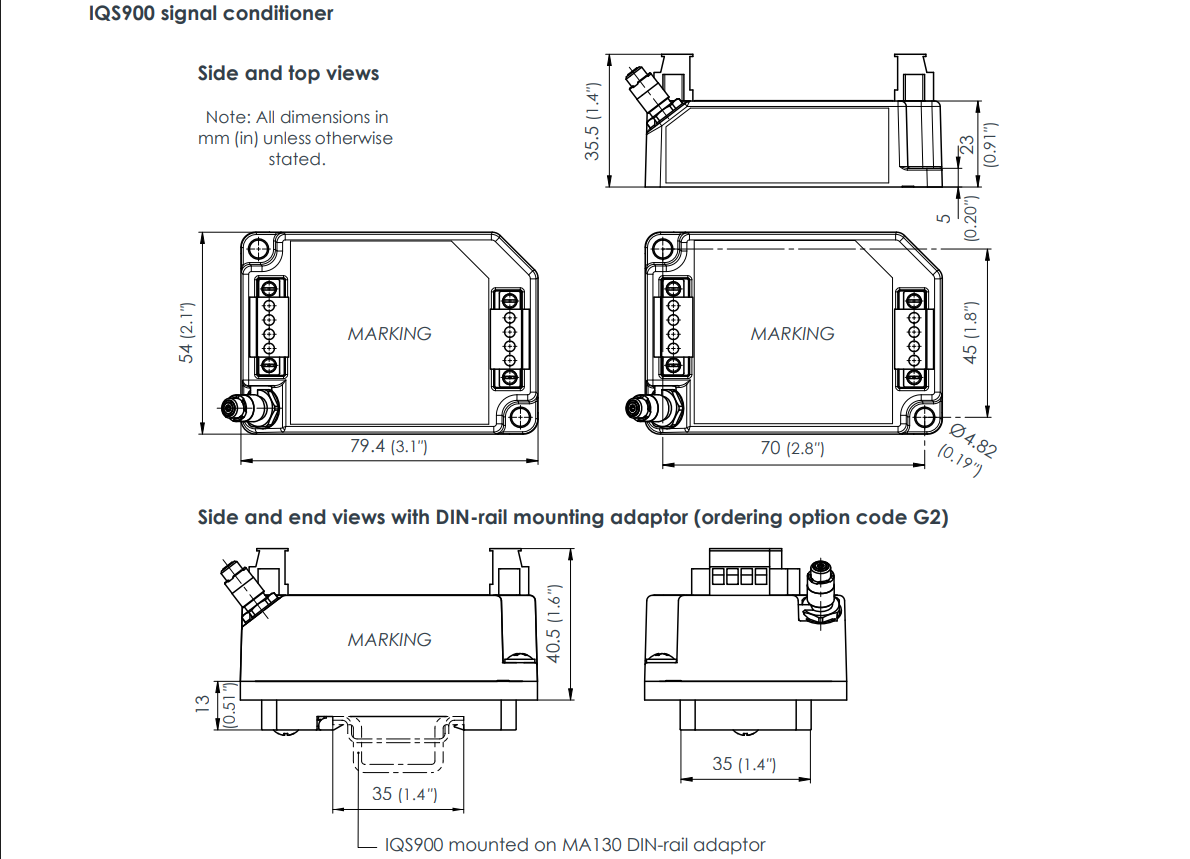

Flexible Mounting Options:

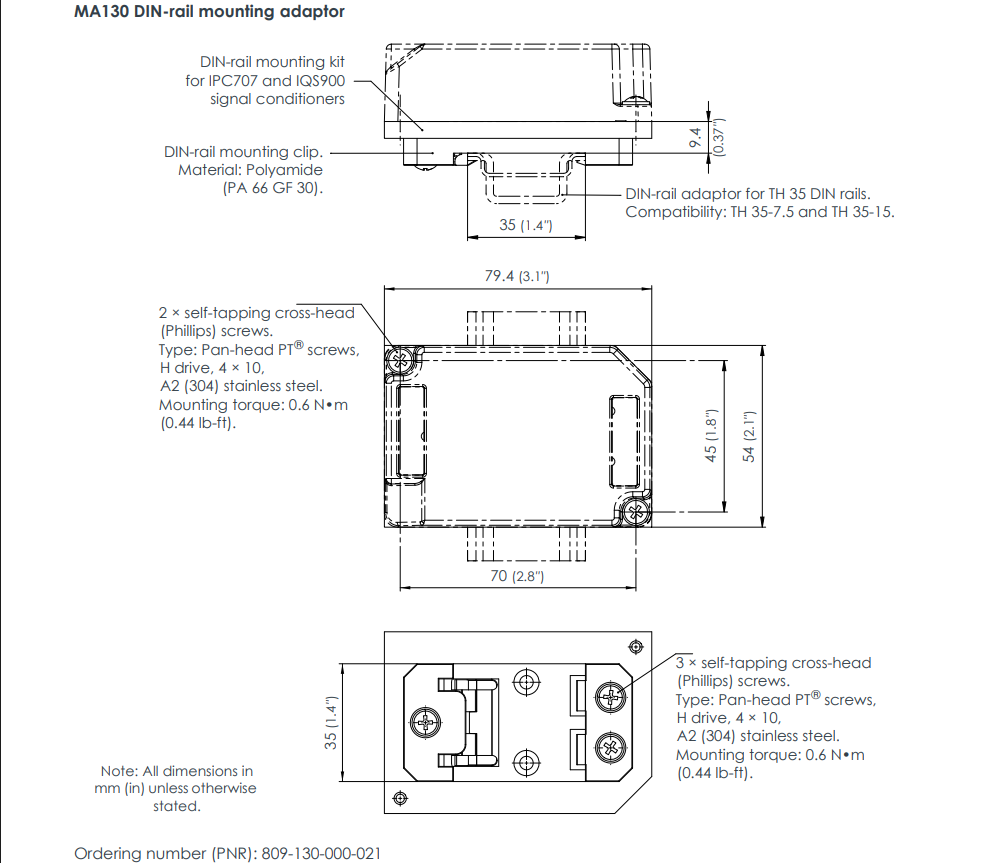

Can be mounted directly using two M4 screws.

Optional MA130 DIN-Rail Mounting Adaptor (Ordering Option G2) allows for easy installation on standard TH 35 DIN rails (per EN 50022 / IEC 60715), greatly facilitating integration and maintenance within control cabinets.

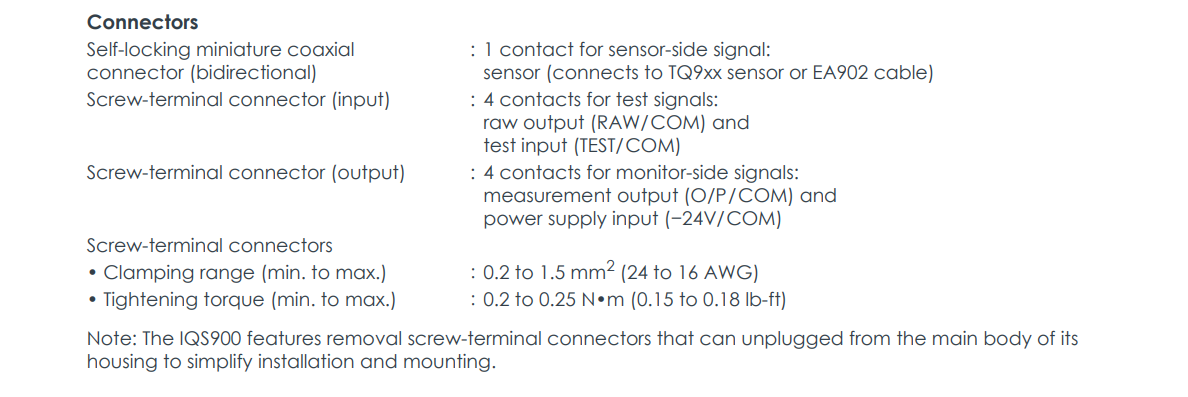

Removable Terminal Blocks:

Comprehensive Explosion Protection Certifications:

Ex ec [Gas]: Suitable for Zone 2.

Ex ia [Gas]: Suitable for Zones 0, 1, 2 (Intrinsic Safety).

Ex ia [Dust]: Suitable for Zones 20, 21, 22 (Intrinsic Safety).

The IQS900 is available in various certified versions (Ordering Option A5) for use in hazardous areas (potentially explosive atmospheres). Its protection modes include:

It holds certifications from numerous global regions, including European ATEX, International IECEx, North American cCSAus, Korean KGS, UK UKEX, and Russian EAC, ensuring compliance for global markets.

In-Depth Working Principle Explanation

The core working principle of the IQS900 is the eddy-current effect. Its operation is a precise closed-loop electronic process, which can be broken down into the following stages:

High-Frequency Excitation Signal Generation:

Driving the Sensor and Eddy Current Generation:

This high-frequency signal is transmitted via the coaxial cable to the connected TQ402 or TQ412 proximity sensor. The core of the sensor is a precision coil encapsulated within a probe tip made of Torlon.

When the high-frequency current flows through the coil, it generates a high-frequency alternating electromagnetic field around it.

Eddy Current Effect and Energy Loss:

When the sensor's probe approaches a metal target (typically a machine shaft), the alternating electromagnetic field induces closed-loop currents, called eddy currents, within the target surface.

According to Lenz's Law, these eddy currents generate a new magnetic field opposing the original field, resisting its changes.

This process consumes energy, causing a change in the effective impedance of the sensor coil. Specifically, both the coil's inductance (L) and resistance (R) change. The distance (gap) between the sensor probe and the target directly determines the degree of this energy loss: a smaller gap results in stronger eddy current effect, greater energy loss, and more significant coil impedance change.

Signal Demodulation and Extraction:

The change in the sensor coil's impedance modulates (alters) the amplitude of the high-frequency signal reflected back from the sensor to the IQS900. The distance information is encoded in this amplitude variation.

The demodulator circuit inside the IQS900 is responsible for detecting this modulated high-frequency signal. It acts like a precise radio receiver, filtering out the high-frequency carrier wave and extracting only the low-frequency amplitude variation signal (i.e., the envelope), which is proportional to the gap.

Signal Conditioning and Standardized Output:

Amplification: Boosts the weak voltage signal to a usable level.

Linearization: Uses internal algorithms and circuit compensation to correct for the inherent non-linearity of the sensor, ensuring the output is highly linear with the mechanical gap across the entire specified range.

Temperature Compensation: Employs a temperature-compensated design to minimize the impact of ambient temperature variations on measurement accuracy.

The demodulated raw signal is very weak and may contain non-linearity and temperature drift. The IQS900's conditioning circuitry processes it through several stages:

After conditioning, the circuit produces a clean, stable DC voltage signal that is precisely proportional to the gap.

Output Stage Conversion:

Voltage Output Mode: Directly output through a voltage follower circuit with very low output impedance (<100Ω). This ensures the output voltage remains stable even with long cables or lower load impedance.

Current Output Mode: Utilizes a precision V-I (Voltage-to-Current) converter circuit to proportionally convert the voltage signal into a 4-20 mA range current signal (specifically -15.5 to -20.5 mA). This circuit maintains a constant current value, unaffected by changes in load resistance (within a certain range).

Diagnostics Function Operation (if equipped):

The diagnostics module continuously monitors key parameters, such as oscillator amplitude, output stage current/voltage values, and power supply voltage.

It contains complex algorithms and threshold comparators. If any parameter deviates from a preset normal operating window (e.g., sensor coil open circuit causing oscillator failure, or cable short circuit causing abnormal output), it immediately overrides the normal measurement output and forces it to a predefined fault state value (outside the -15.5/-1.6V or -20.5/-17.6V range), thereby clearly communicating a fault condition to the upstream monitoring system.

Primary Applications

The IQS900 system is an ideal choice for the following major critical equipment:

Steam Turbines, Gas Turbines: Monitoring rotor vibration and blade pass frequency.

Hydro Turbines: Monitoring shaft runout and axial displacement.

Turbo Compressors (Centrifugal, Axial): Monitoring vibration to prevent damage from conditions like surge.

Large Pumps, Fans: Monitoring vibration status to avoid seal and bearing damage.

Generators, Motors: Monitoring bearing condition and air gap uniformity.