The 3500/60 Temperature Monitor is a key component of the Bently Nevada 3500 Machinery Condition Monitoring System, designed for the continuous monitoring and protection of critical rotating equipment. This module provides six channels of high-precision temperature monitoring and can accept inputs from both Resistance Temperature Detectors (RTDs) and Thermocouples (TCs). Its core function is to condition and process the input temperature signals and compare them against user-programmable alarm setpoints, thereby generating timely alerts in case of abnormal temperatures to prevent equipment damage from overheating or other temperature-related issues.

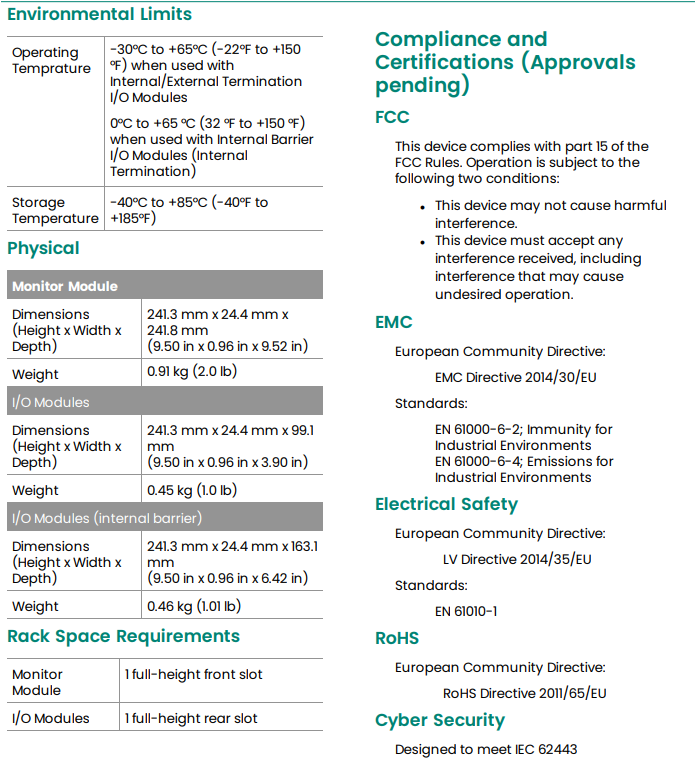

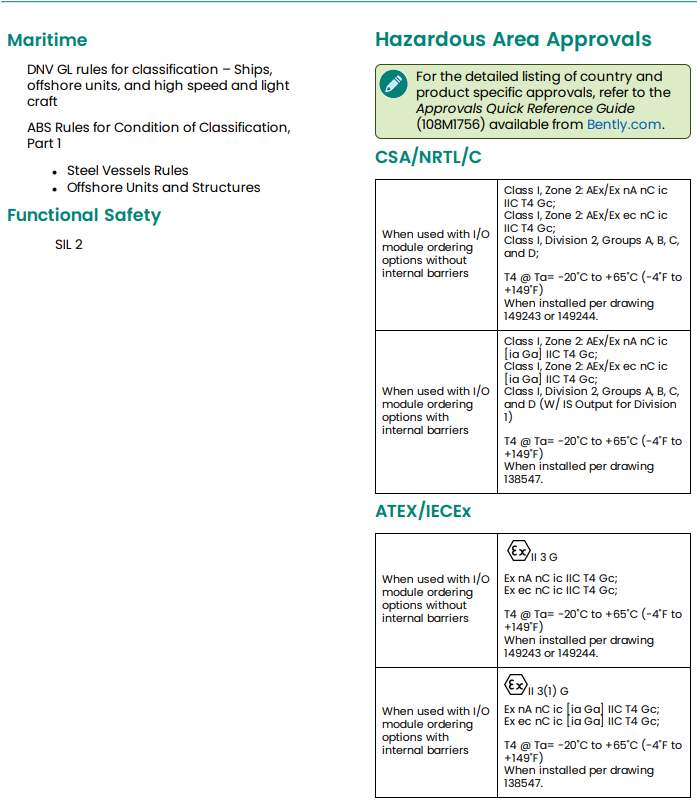

The 3500/60 module, known for its flexibility, high reliability, and ease of integration, is widely used in power generation, oil & gas, chemicals, marine, and other industries for monitoring critical assets such as steam turbines, gas turbines, compressors, pumps, and motors.

2. Key Features

1. Multi-Channel and Multi-Sensor Type Support

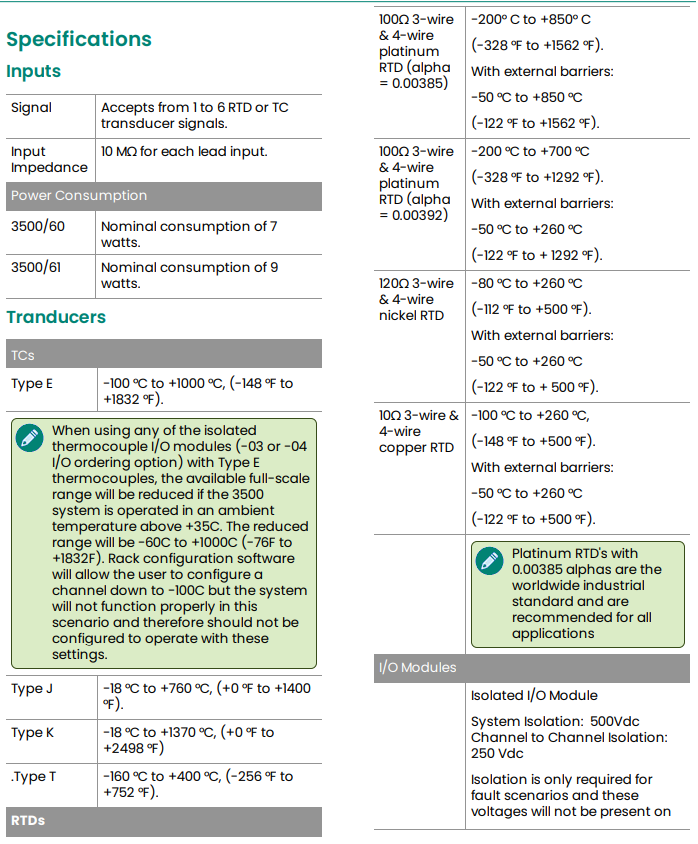

Six-Channel Input: A single 3500/60 module can simultaneously monitor up to six independent temperature points, offering high-density monitoring capability that saves rack space and cost.

RTD and TC Compatibility: The module supports two primary types of temperature sensors, allowing users to select the most suitable sensor type for their application needs. It can even accommodate a mix of RTD and TC inputs on the same module (depending on the I/O module type).

2. Flexible Configuration and I/O Module Options

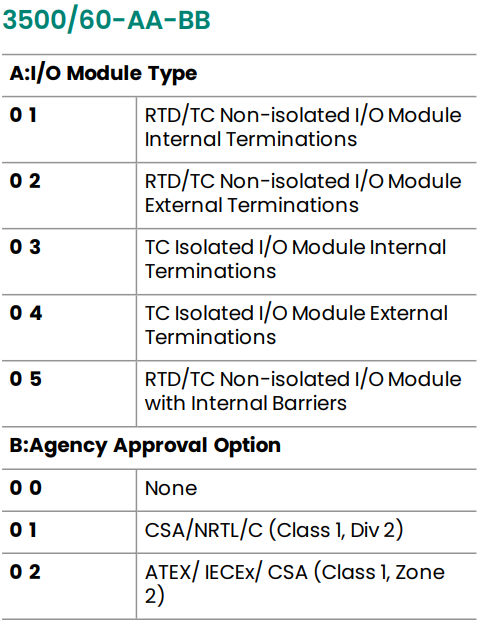

The module's functionality is realized through rear I/O modules, allowing users to select different types based on actual requirements:

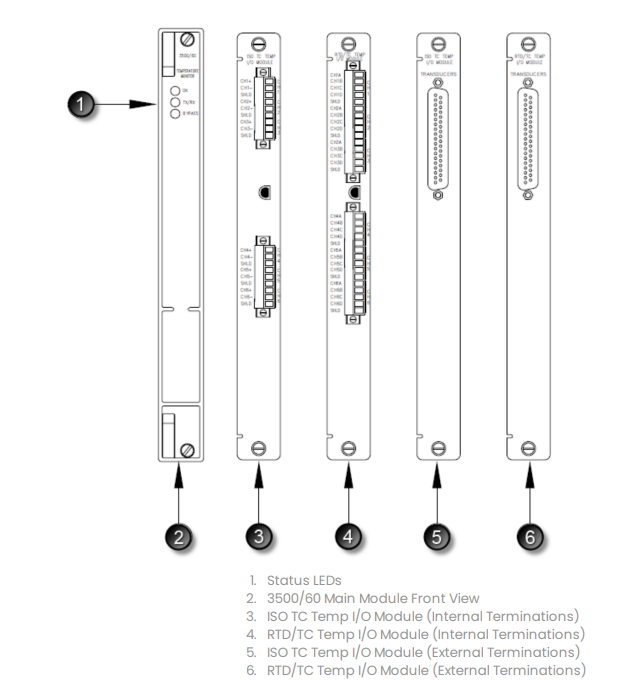

RTD/TC Non-Isolated I/O Module: Cost-effective, it can be configured to accept TC, RTD, or a mixture of both inputs. Suitable for standard industrial environments without severe electrical interference.

TC Isolated I/O Module: Provides up to 250 Vdc of channel-to-channel isolation, effectively suppressing external interference caused by ground potential differences or field wiring faults, ensuring measurement accuracy and system safety in harsh electrical environments.

I/O Module with Internal Barriers: Designed for hazardous areas, it integrates internal barriers, meeting explosion-proof requirements without external discrete barriers.

3. Programmable Alarm Management

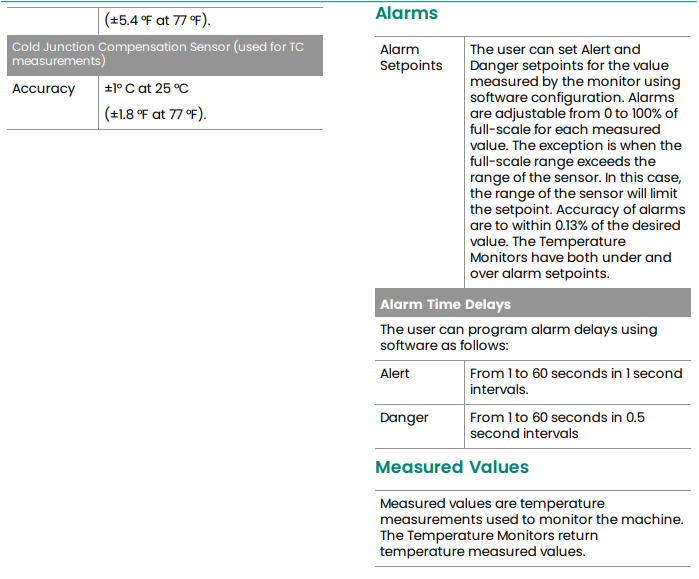

Two-Level Alarming: Each channel can be independently configured with Alert and Danger alarm setpoints, enabling graded warning and protection.

Flexible Setpoint Range: Alarm values are typically adjustable from 0% to 100% of each measurement range, unless limited by the inherent range of the sensor itself.

Programmable Alarm Delays: To prevent false alarms from transient fluctuations, users can set delay times:

Alert Delay: 1 to 60 seconds, in 1-second intervals.

Danger Delay: 1 to 60 seconds, in 0.5-second intervals. Shorter delays ensure a rapid response to dangerous conditions.

4. High-Reliability Design and TMR Support

Status Indication: The module front panel features LED indicators for real-time status display:

OK LED: Indicates normal module operation.

TX/RX LED: Indicates the module is communicating with other modules in the 3500 rack.

Bypass LED: Indicates the module is in Bypass Mode.

Triple Modular Redundant (TMR) Configuration: For applications requiring extremely high safety and availability, three 3500/60 modules can be installed side-by-side to form a TMR system. This system employs two-out-of-three voting logic, ensuring that no single point of failure can cause a system misoperation or loss of protection, significantly enhancing system fault tolerance.

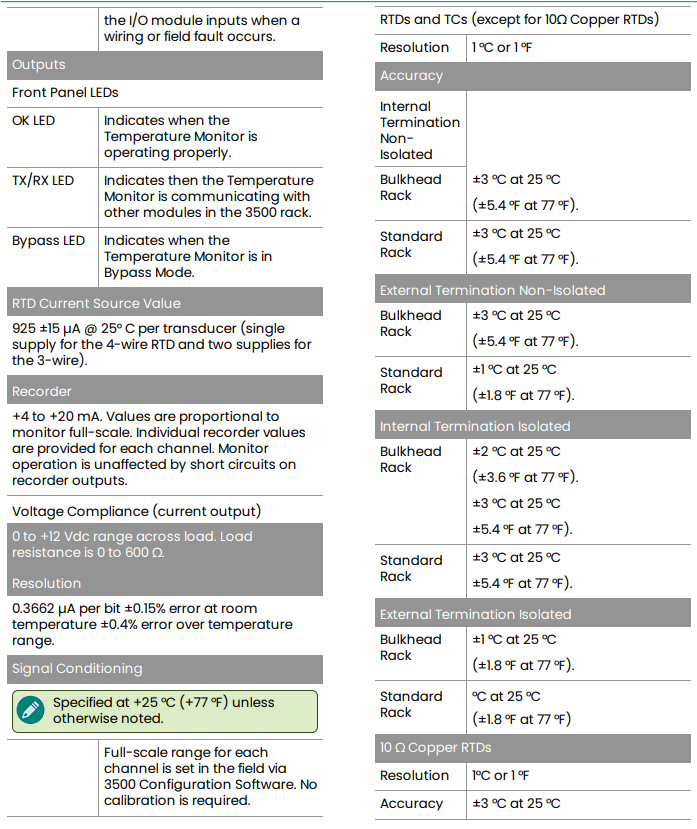

5. No Recorder Outputs (Key Difference from 3500/61)

The 3500/60 module does not provide analog recorder outputs. This is the only major difference from the 3500/61 module. The 3500/61 provides 4-20 mA analog outputs for all six channels for connection to chart recorders or data acquisition systems, while the 3500/60 focuses on core monitoring and alarm functions.

3. Detailed Working Principle

1. Signal Input and Sensor Excitation

The module's operation begins with receiving weak electrical signals from field sensors.

For RTDs (Resistance Temperature Detectors): The resistance of an RTD changes with temperature. The 3500/60 module provides a precise constant current source (925 µA ±15 µA @ 25°C) to excite the RTD sensor. For 3-wire RTDs, the module uses two current sources to compensate for errors introduced by lead resistance; for 4-wire RTDs, it uses a single current source, with the additional sense wires eliminating the effect of lead resistance for the highest measurement accuracy. The module precisely calculates the RTD's resistance by measuring the voltage drop across it and, based on the known excitation current, then converts this resistance value to a temperature value using standard RTD conversion tables (e.g., Pt100, α=0.00385).

For TCs (Thermocouples): Thermocouples generate a small millivolt-level voltage proportional to the temperature difference based on the Seebeck effect. To measure the absolute temperature, the temperature of the thermocouple's cold (reference) junction must be known. The 3500/60 module's I/O module incorporates a high-precision Cold Junction Compensation (CJC) sensor, with an accuracy of ±1°C @ 25°C. The module continuously monitors the temperature of the CJC sensor and combines this reading with the thermoelectric voltage generated by the thermocouple. Using the mathematical model or lookup table for the specific thermocouple type (e.g., Type K, E, J, T), it calculates the true temperature at the hot junction.

2. Signal Conditioning and Digitization

The raw signals from the sensors are very weak and susceptible to noise. Therefore, multiple stages of signal conditioning are performed internally:

Filtering: Hardware filters are used to suppress line frequency interference and high-frequency noise.

Amplification: The signal is amplified to a level suitable for processing by the Analog-to-Digital Converter (ADC).

Isolation (for TC Isolated I/O Modules): Before the signal enters the system's core processing section, it passes through an isolation barrier (e.g., optocouplers or magnetic isolators) that electrically isolates the input ground of each channel from the system ground. This prevents high common-mode voltages from damaging the module or affecting measurements on other channels.

Analog-to-Digital Conversion (ADC): The conditioned analog signal is converted into a digital signal by a high-resolution ADC. The module's resolution is 1°C or 1°F, ensuring that even small temperature changes can be detected.

3. Temperature Calculation and Linearization

The digitized signal is processed by the module's microprocessor. For RTDs, the processor executes linearization algorithms to convert the resistance value into a linear temperature value. For TCs, the processing is more complex, involving the following steps:

Read the CJC sensor temperature.

Convert the CJC temperature into the corresponding thermoelectric voltage that the specific thermocouple type would generate at that temperature (using polynomials or lookup tables).

Add this calculated voltage to the measured total thermoelectric voltage from the thermocouple to obtain the total voltage corresponding to the actual hot junction temperature.

Finally, convert this total voltage into the final hot junction temperature value using inverse functions or lookup tables.

4. Alarm Logic and Output

The calculated real-time temperature value is compared against the user-preset Alert and Danger setpoints for each channel. The comparison logic incorporates the user-defined alarm delays. If the real-time temperature continuously exceeds the setpoint for a duration longer than the delay time, the module triggers the corresponding alarm state.

The alarm status is output through two primary paths:

Internal Communication: The alarm status is sent to the 3500 rack backplane, where it can be used by other modules in the system (e.g., relay modules) to trigger shutdowns, audible/visual alarms, or other protective actions.

Front Panel Indication: Although the 3500/60 lacks dedicated alarm LEDs, its status can be clearly viewed through the rack interface module or upstream software.

5. System Communication and Data Integration

The 3500/60 module communicates at high speed via the 3500 rack's backplane with the system's "brain" – such as the Rack Interface Module (3500/15, 3500/20M, etc.). All configuration parameters, real-time temperature data, alarm statuses, and module health information are transmitted via this backplane. The Rack Interface Module then relays this data to the plant's Distributed Control System (DCS), Safety Instrumented System (SIS), or Asset Management System (AMS) using industrial standard protocols like Modbus or OPC UA, enabling plant-wide monitoring and data logging.

6. Accuracy and Environmental Considerations

The module's measurement accuracy is influenced by several factors, including the I/O module type, rack type, and ambient temperature.

I/O Module Type: Isolated I/O modules often offer higher accuracy (e.g., ±1°C for external termination isolated type in a standard rack) due to better noise immunity compared to non-isolated types (e.g., ±3°C for external termination non-isolated).

Rack Type: Bulkhead racks typically provide better accuracy than Standard racks due to superior shielding and grounding design.

Ambient Temperature: The specified accuracy in the datasheet is typically at +25°C. Over the entire operating temperature range (-30°C to +65°C), the accuracy may slightly degrade, but the error is strictly controlled within a defined range (e.g., ±0.4% error over the temperature range for the recorder output).

4. Application Scenarios

The 3500/60 Temperature Module is suitable for the following industrial scenarios:

Bearing temperature monitoring for gas turbines, steam turbines, and compressors.

Temperature protection for pumps, fans, gearboxes, and other rotating machinery.

Winding temperature monitoring for power transformers and generators.

Temperature monitoring for chemical reactors and pipelines.

Temperature monitoring for marine power systems.