The 3500/94M VGA Display Monitor is a high-performance display module under the 3500 Machinery Protection Systems. It is designed to comprehensively present monitoring information from the 3500 system, including system event lists, alarm event lists, all module and channel data, alarm and OK statuses, and up to nine custom display options. Using the 3500 Rack Configuration Software, users can flexibly configure these custom screens—for example, by default displaying bar graphs of IX-filtered vibration measurements for all channels or proximity probe gap voltages. The module supports organizing data into machine train groups and allows free organization of page layouts on custom screens.

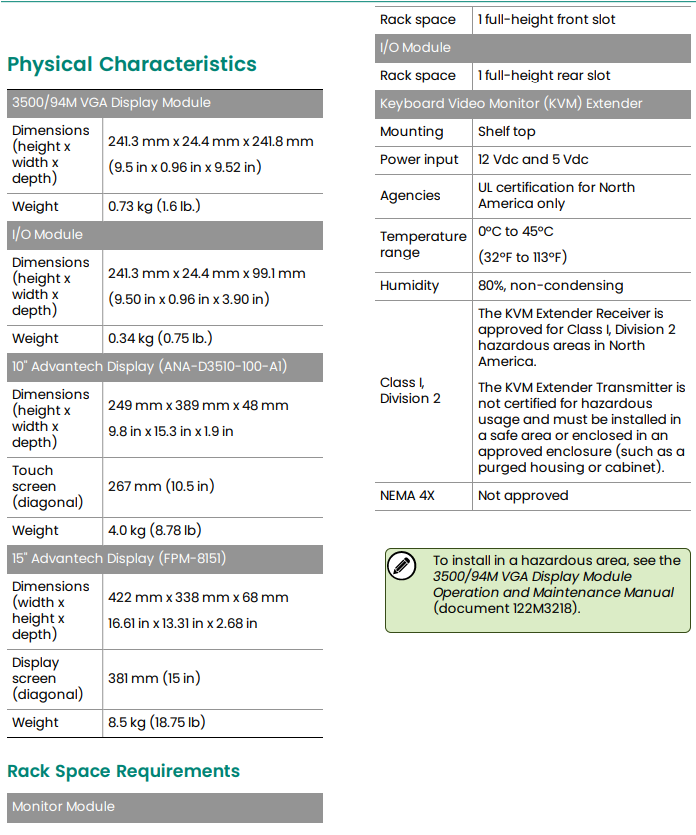

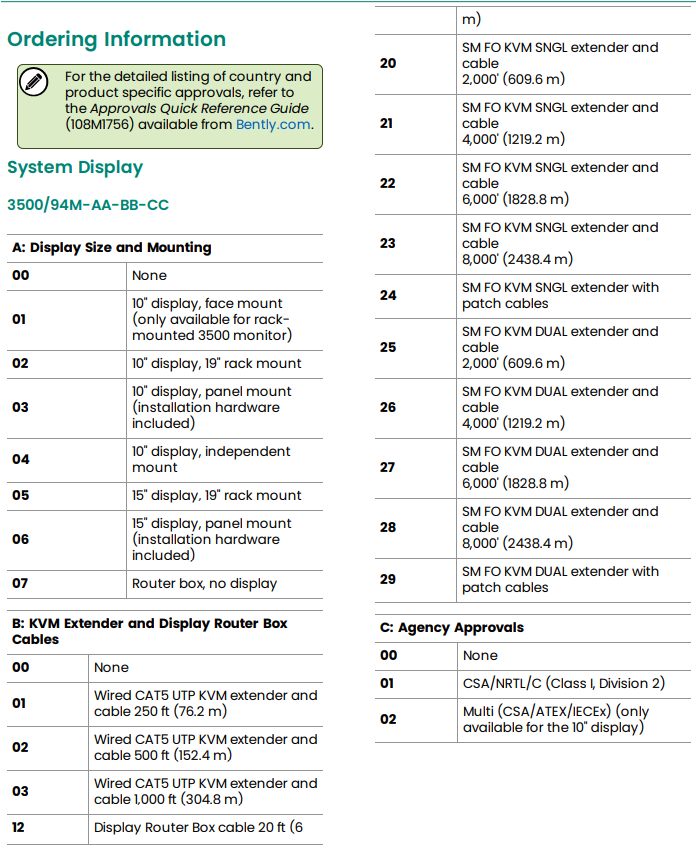

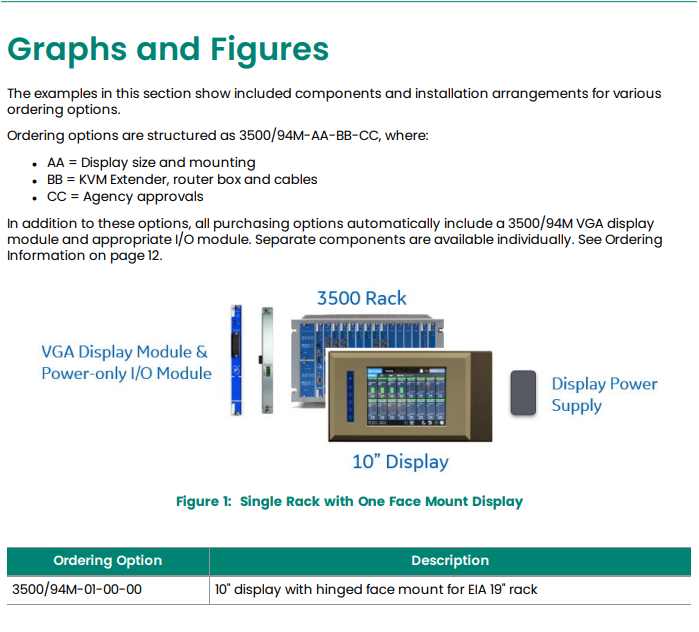

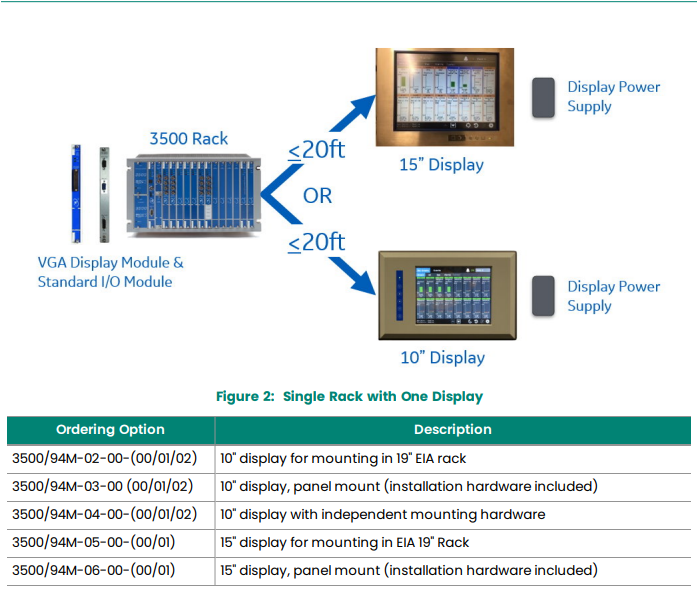

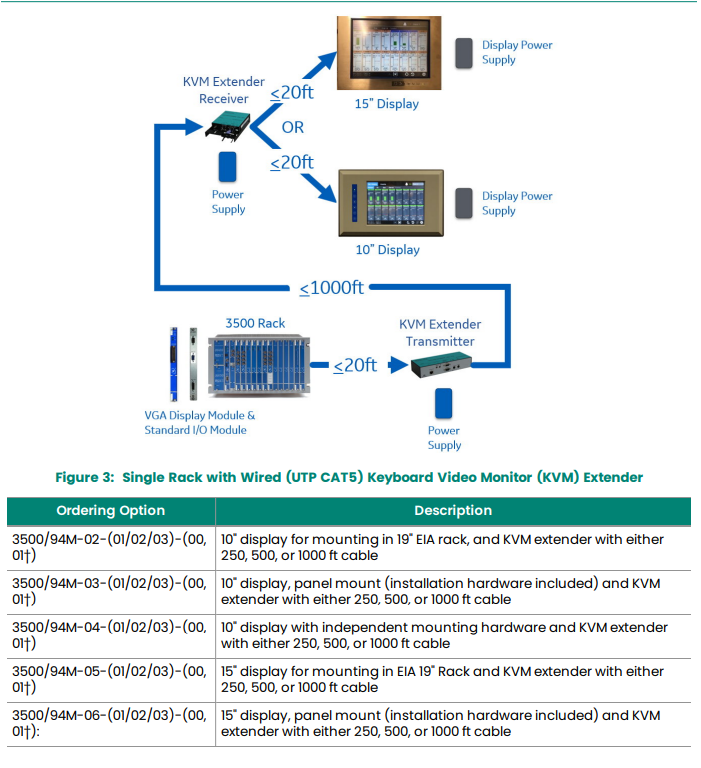

The 3500/94M system consists of three parts: a fixed front card (184826-01), two different types of rear cards (190214-01 and 190214-02), and a 10-inch or 15-inch VGA touch screen display. The display can be installed up to 6 meters from a 3500 rack using standard cables, or up to 10 kilometers away using a supported Keyboard Video Monitor (KVM) Extender, significantly enhancing system layout flexibility.

Key Features and Functions

1. Multi-functional Information Display

Comprehensive Data Visualization: Displays system events, alarm events, module and channel data, and alarm/OK status in real time.

Custom Display Options: Supports up to nine custom screens. Users can define display content and layout as needed via configuration software, such as vibration bar graphs or gap voltage diagrams.

Machine Train Group Management: Supports organizing data by machine train, enabling operators to quickly view the status of specific equipment.

2. Touch Screen Operation and Display Compatibility

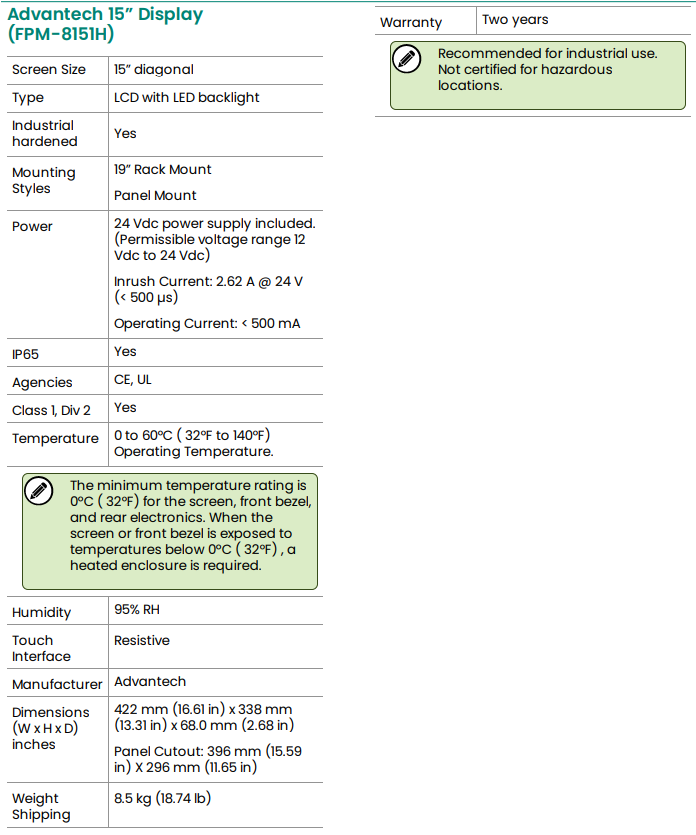

Industrial-Grade Touch Screens: Supports 10-inch and 15-inch Advantech VGA touch screens with high brightness and durability, suitable for harsh industrial environments.

Multiple Mounting Options: Supports various mounting methods including front panel mounting, 19-inch rack mounting, panel mounting, and independent mounting.

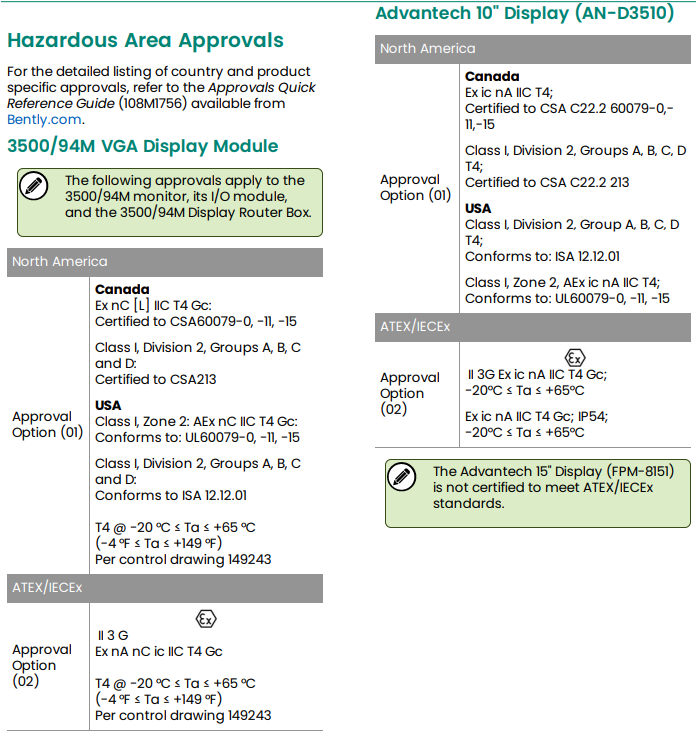

Hazardous Environment Certification: The 10-inch display is certified for Class I Division 2 and ATEX/IECEx standards, making it suitable for hazardous areas.

3. Multi-Rack Data Centralized Display

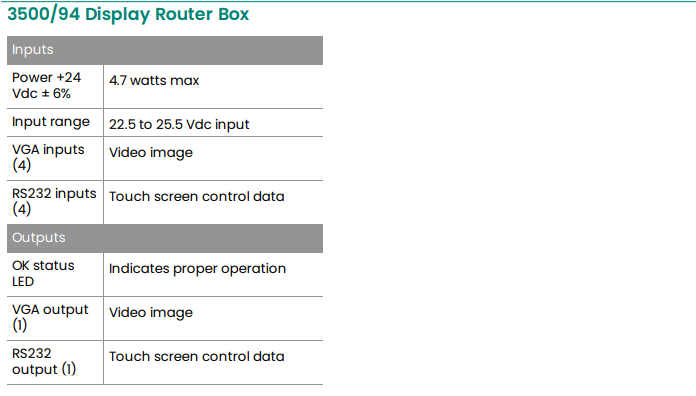

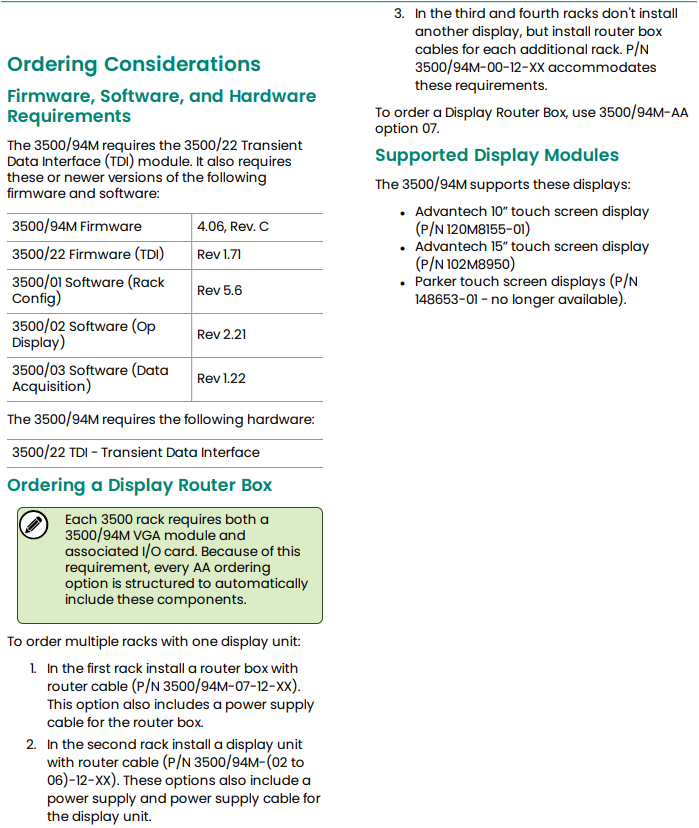

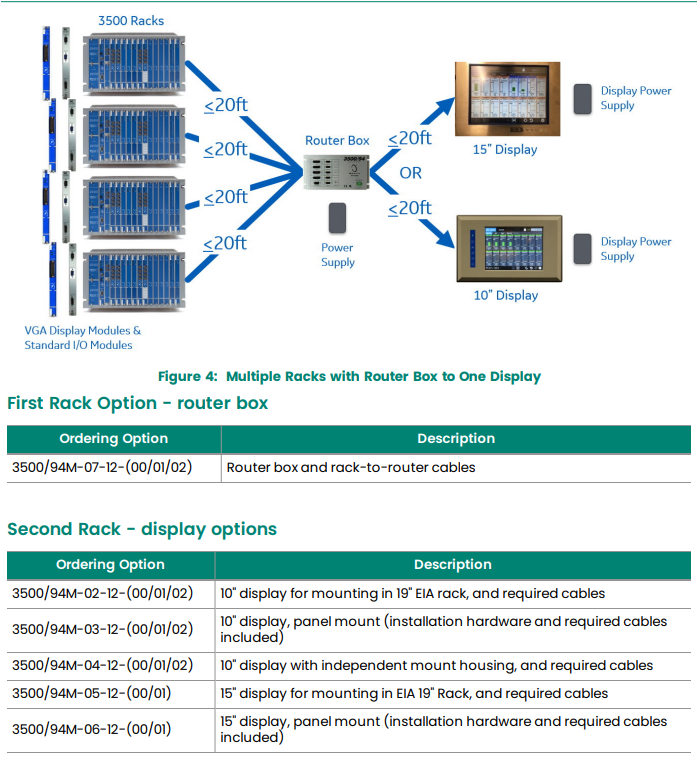

Display Router Box: Through an optional router box, a single display can simultaneously show data from up to four 3500 racks, significantly reducing the number of on-site displays.

Status Indication: The upper right corner of the display continuously shows alarm and OK statuses. The rack selection button on the router box changes color to indicate abnormal status in any connected rack.

4. Remote Data Access Support

Wired CAT5 UTP KVM Extender: Supports transmission up to 305 meters with minor image quality degradation. The receiver is certified for Class I Division 2 hazardous areas in North America.

Single-Mode Fiber Optic KVM Extender: Supports transmission up to 10 kilometers with no loss in image quality. Must be installed in a safe area or an approved protective enclosure.

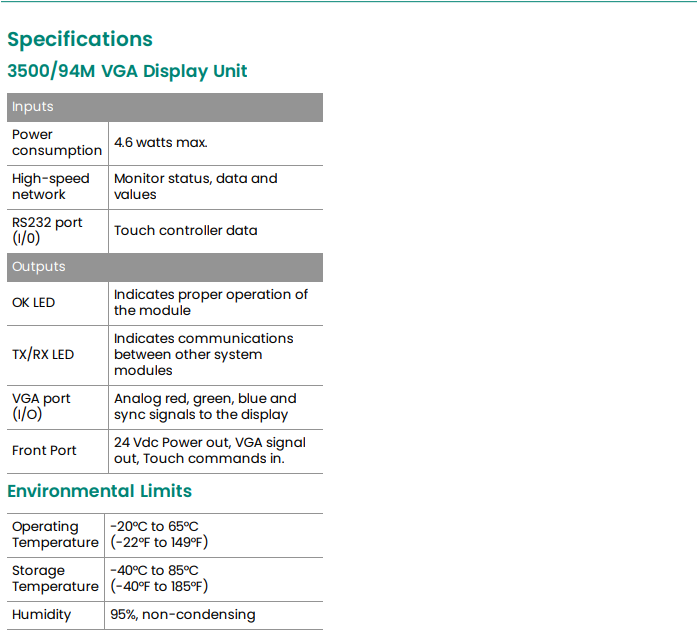

5. Low Power Consumption and High Reliability Design

Power Optimization: Maximum power consumption is only 4.6 watts, suitable for high-density rack deployment.

Wide Temperature Operation: Operating temperature from -20°C to 65°C, storage temperature from -40°C to 85°C, and humidity tolerance up to 95% non-condensing, adapting to harsh industrial environments.

Status Diagnostics: The front panel is equipped with OK LED and TX/RX LED to indicate module operational status and communication status, facilitating quick troubleshooting.

6. Flexible System Integration and Expansion

Modular Architecture: The 3500/94M module works with dedicated I/O modules, supporting various display options and extension cables.

Strong Compatibility: Requires cooperation with the 3500/22 Transient Data Interface (TDI) module and specific versions of firmware and software (e.g., Rack Configuration Software V5.6 or above).

Detailed Working Principle

1. Data Flow Architecture

The 3500/94M acts as a display gateway located at the display layer of the 3500 monitoring system. Its data flow is divided into three layers:

Data Acquisition Layer: Periodically reads data from various monitoring modules (e.g., vibration, temperature, speed modules) in the 3500 rack via a high-speed internal bus. The acquired data packets include real-time engineering values (e.g., vibration velocity, displacement, temperature), raw waveforms, spectrum data, and module/channel status words (health status, alarm/danger status, bypass status, etc.).

Data Processing Layer: The module internally maintains a dynamic data image area that stores the latest rack status. Upon receiving a display request, it retrieves data directly from this image area to ensure real-time responsiveness. Data processing includes timestamp alignment, data packaging, and protocol encapsulation (e.g., VGA video signal generation, touch command parsing).

Display Output Layer: Outputs analog RGB and sync signals to the display via the VGA interface and receives touch screen commands via the RS232 interface. Supports local display (≤6 meters) or remote display (via KVM Extender), enabling data visualization and interactive operation.

2. Display Control Mechanism

VGA Video Generation: The module converts data into standard VGA signals (supporting resolutions from 800×600 to 1024×768) and outputs them to the display. The video signal includes real-time data pages, alarm bars, status bars, and other elements.

Touch Command Processing: Commands from the resistive touch screen are transmitted to the module via the RS232 serial port. The module parses these commands and executes corresponding operations (e.g., page switching, parameter viewing, alarm acknowledgment).

Multi-Source Data Integration: When using the Display Router Box, the module integrates data from multiple racks, switches between displaying content from different racks via a polling mechanism, and provides a rack selection button on the interface.

3. Remote Transmission Technology

KVM Extender Working Principle:

Wired CAT5 UTP Extender: Transmits VGA signals and serial data over CAT5 unshielded twisted pair cables using digital signal compression technology. Supports transmission up to 1000 feet, with the receiver certified for hazardous areas.

Single-Mode Fiber Optic Extender: Transmits lossless digital signals over fiber optics using optical modulation and demodulation technology to convert electrical signals into optical signals, enabling long-distance (10 km) high-quality transmission. Requires optical cables and fiber optic transceivers.

Signal Conditioning and Compatibility: The extender includes built-in signal amplification and clock recovery circuits to reduce signal attenuation and jitter caused by long-distance transmission, ensuring display stability and touch response accuracy.

4. System Redundancy and Reliability Design

Power Redundancy: The display and supported router box can be powered by independent 24V DC power supplies, supporting a wide voltage input range (10-28V DC) with overcurrent and reverse connection protection.

Communication Redundancy: The module communicates with the rack's internal network via a high-speed dual bus, ensuring continuity and integrity of data acquisition.

Environmental Adaptability: Both the front and rear electronics of the display are designed for industrial use. The 10-inch screen supports startup at temperatures as low as -20°C (requires a heated enclosure below this temperature), and the 15-inch screen supports startup at 0°C, meeting various environmental requirements.

5. Configuration and Maintenance Functions

Software Configuration: Custom screen content, data grouping, and display styles are defined using the 3500 Rack Configuration Software and downloaded to the module's non-volatile memory.

Firmware Upgrade: Supports online firmware upgrades via Ethernet or serial port, ensuring continuous functional enhancement and compatibility maintenance.

Diagnostic Logging: The module records operational status, communication errors, and touch events, facilitating post-failure analysis and system optimization.