The IS200TDBTH2A is a discrete input/output terminal board within the TDBT series, specifically designed for Mark VIe control systems utilizing Triple Modular Redundancy (TMR) architecture. This terminal board supports DIN rail or panel mounting and is characterized by high reliability, modular construction, and flexible configuration capabilities, making it suitable for industrial automation, process control, and safety-critical systems.

The IS200TDBTH2A provides 24 group-isolated contact input channels and 12 Form-C relay output channels. It supports a standard 24 V DC wetting voltage and is adaptable to various industrial signal interface requirements. Its design balances signal integrity, noise immunity, and system diagnostics, making it a crucial I/O interface component in redundant control systems.

2. Key Features

2.1 Discrete Input Functionality

The IS200TDBTH2A provides 24 dry contact voltage input channels. Each input group features group isolation and can accept an externally supplied nominal 24 V DC wetting voltage (actual operating range: 16–32 V DC). The input circuits possess the following characteristics:

Noise Suppression: Each input is equipped with a hardware filter and surge suppression circuitry, effectively mitigating high-frequency noise and voltage transients to enhance signal stability.

Current Limiting: The first 21 input circuits are current-limited to 2.5 mA, and the last three circuits (22–24) are limited to 10 mA, protecting the circuitry under overcurrent or short-circuit conditions.

Threshold Detection: The input signal threshold voltage is set at 50% of the wetting voltage, ensuring reliable logic state recognition.

Wetting Voltage Monitoring: The system continuously monitors the wetting voltage. If the voltage drops below 40% of the nominal value, a diagnostic alarm is triggered and the fault state is latched.

2.2 Relay Output Functionality

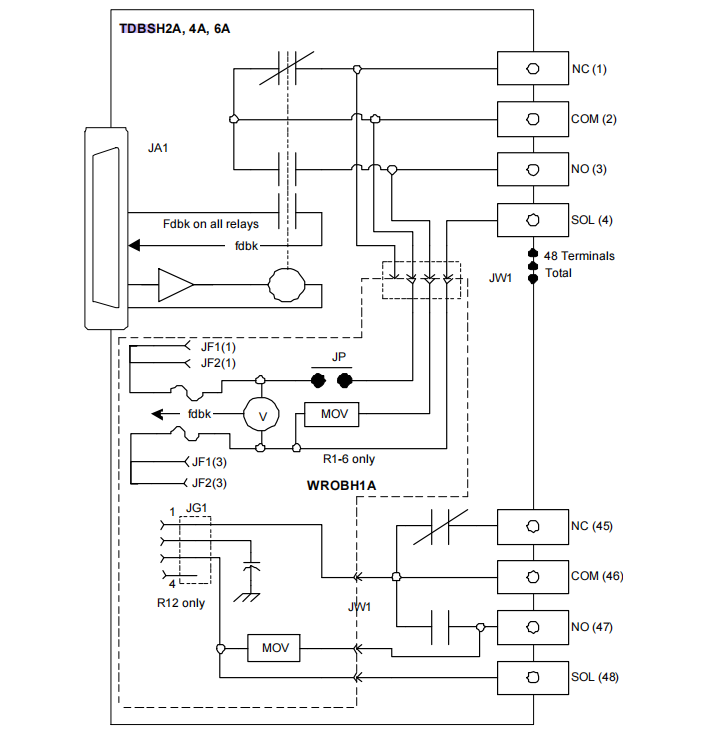

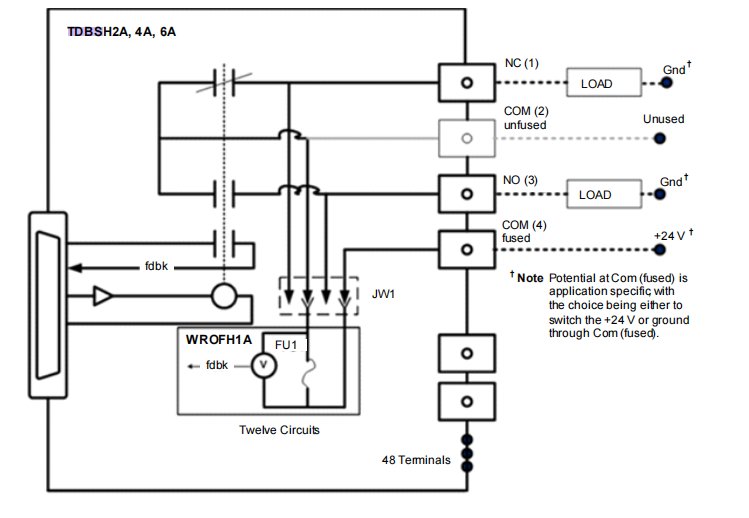

The IS200TDBTH2A provides 12 Form-C relay outputs. Each relay includes Normally Open (NO), Normally Closed (NC), and Common (COM) contacts, supporting both AC and DC loads with the following features:

Load Capacity:

Relay Lifespan:

Electrical Life: 100,000 operations

Mechanical Life: 5,000,000 operations

Contact Material: Silver-nickel alloy, offering good conductivity and wear resistance.

Response Time: Typical switching response time ≤ 25 ms.

2.3 Modularity and Expandability

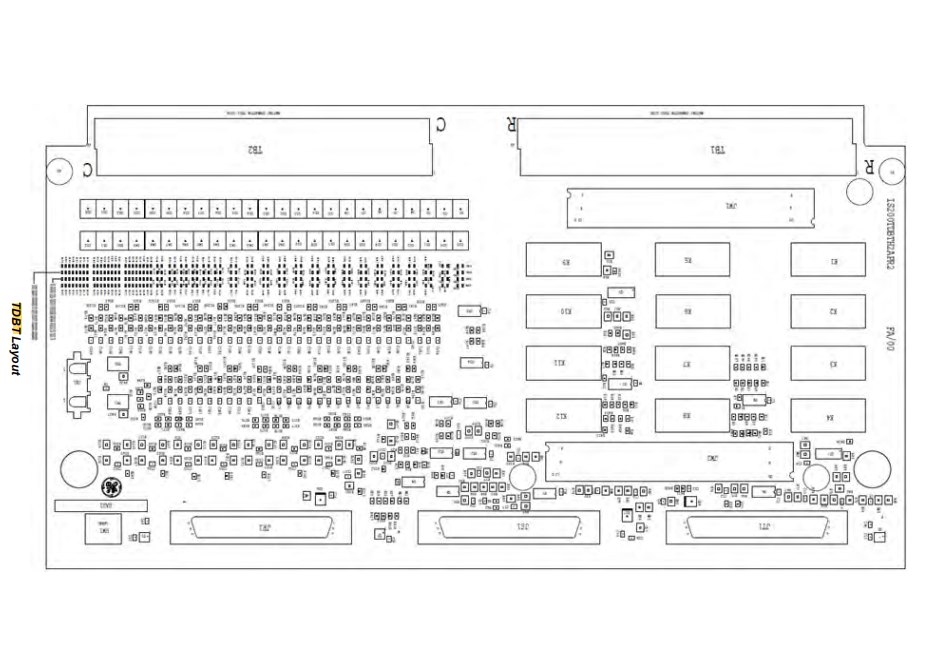

PDIO I/O Module Interface: The IS200TDBTH2A provides three D-type connectors (JR1, JS1, JT1) for connecting three PDIO I/O modules, enabling redundant communication with the R, S, and T controllers.

WROB Option Board Support: The WROBH1A option board can be installed to provide fused protection and power sensing for the first six relays, and dedicated power for the 12th relay.

Pluggable Terminal Blocks: All wiring is done via Euro-style pluggable terminal blocks, supporting #24–#12 AWG wires, facilitating easy installation and maintenance.

2.4 Diagnostics and Monitoring

The IS200TDBTH2A incorporates comprehensive diagnostic mechanisms, including:

Wetting Voltage Monitoring: Detects whether the input power supply is normal.

Relay Status Feedback: Monitors the actual position of each relay via an isolated set of contacts; feedback signals are fanned out to all three PDIOs.

Fuse Status Detection (if WROBH1A is used): Monitors the status of the six fuse pairs on the board, ensuring power circuit safety.

Hardware Identification: Each connector has a read-only ID chip storing the board type, serial number, and revision number; the system automatically detects hardware compatibility.

3. Working Principle

3.1 Discrete Input Circuit Principle

The input circuit design of the IS200TDBTH2A is based on the principles of dry contact detection and voltage threshold comparison. External contacts (e.g., push buttons, limit switches) are connected via the TB2 terminals, and the wetting voltage is supplied through the JE1 connector. The operational workflow is as follows:

Wetting Voltage Supply:

For the IS200TDBTH2A, all wetting voltage output terminals are connected in parallel, supplied from JE1 pin 1 (positive) and pin 3 (return).

When an external contact closes, current flows through the input circuit, completing the loop.

Signal Conditioning:

The input signal first passes through a hardware filter to remove high-frequency noise and transient interference.

The signal then enters an opto-isolator, providing electrical isolation between the field side and the control side to prevent ground loops and voltage interference.

Digital Conversion and Transmission:

The isolated signal is converted to a digital signal by the I/O processor.

The digital signal is transmitted via Ethernet to the corresponding PDIO module, which then forwards it to the R, S, or T controllers for TMR processing.

Fault Detection:

3.2 Relay Output Circuit Principle

The relay output section of the IS200TDBTH2A uses electromagnetic relays as the actuating elements. The control logic is as follows:

Control Signal Source:

Relay Operation:

When the control signal is "close," the relay coil is energized, pulling the moving contact to connect COM with NO.

When the control signal is "open," the relay coil is de-energized, and the moving contact returns via spring action, connecting COM with NC.

Option Board Enhancement:

If the WROBH1A option board is installed, the first six relays receive dual-end fuse protection (fuses on both positive and negative sides), suitable for floating ground power systems.

The 12th relay receives dedicated power via the JG1 connector, without fuses.

Status Feedback:

3.3 System Communication and Redundancy Mechanism

The IS200TDBTH2A establishes a triple-redundant communication link with the controllers through three PDIO modules:

This architecture ensures that even if one controller or communication path fails, the system can maintain normal operation through the remaining paths.

4. Installation and Wiring Instructions