The VM600 IOC4T Input/Output Card is a critical signal interface component within VM product line, specifically designed to pair with the VM600 series MPC4 Machinery Protection Card. Installed at the rear of the VM600 rack and connected directly to the rack backplane via two connectors, this card serves as a vital bridge between sensors, monitoring systems, and external control equipment. Renowned for its robust signal processing capabilities, flexible configuration options, and rugged design, the IOC4T card is an indispensable component in industrial machinery protection and condition monitoring applications.

Features & Benefits

1. Versatile Signal Interface

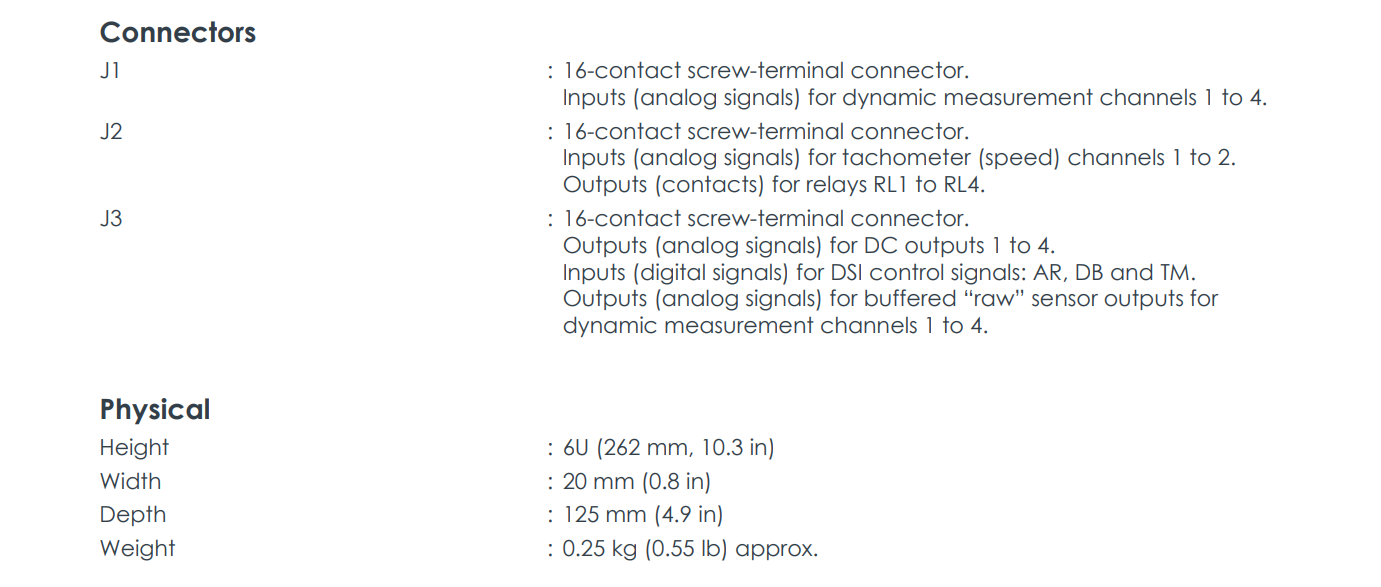

The IOC4T card provides 4 dynamic signal input channels and 2 tachometer (speed) input channels, capable of handling multiple vibration and speed signals simultaneously. All input and output connections are made via a 48-position screw-terminal block on the front panel, greatly facilitating field wiring.

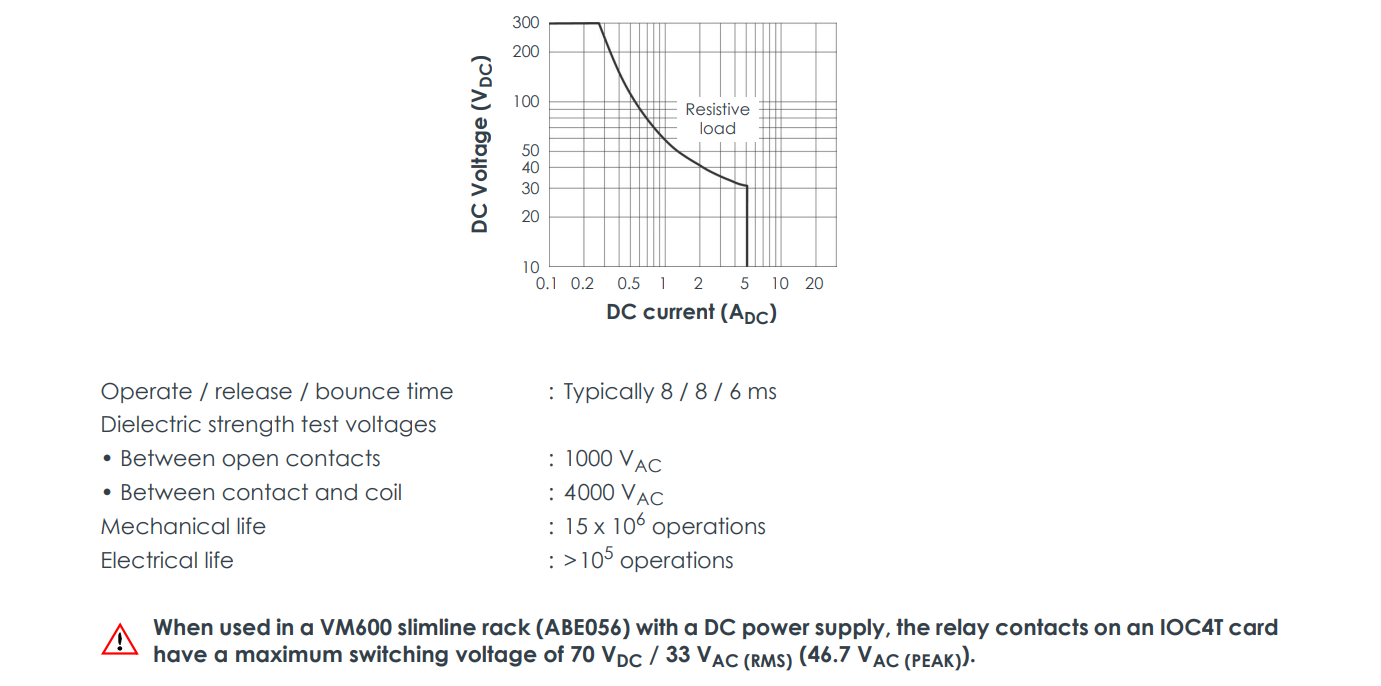

2. Powerful Relay Functionality

The card incorporates 4 programmable relays (RL1 to RL4), each configurable as either Normally Open (NO) or Normally Closed (NC) contacts. These relays can be assigned via software to any specific alarm signal, such as MPC4 fault, Sensor OK signal, Alarm, or Danger status. The relays are rated for 250 VAC/5 AAC with a maximum breaking capacity of 1250 VA.

3. Flexible Analog Outputs

Provides 4 analog output channels (one for each dynamic signal channel), individually selectable via jumpers for current output (4-20 mA) or voltage output (0-10 V) per channel. Output accuracy is as high as ≤±1.5%, with linearity error ≤±0.5%, ensuring high-fidelity signal transmission.

4. Expandable Digital Output Capability

Via the VM600 rack's Open Collector (OC) bus or Raw bus, the IOC4T can provide 32 fully programmable digital output signals to RLC16 relay cards and/or IRC4 intelligent relay cards within the same rack, significantly expanding the system's relay capacity.

5. Comprehensive Signal Conditioning & Protection

All inputs and outputs are filtered, providing protection against electromagnetic interference (EMI) and signal surges, complying with relevant EMC standards. Also provides buffered sensor "raw" signal outputs for subsequent analysis.

6. Discrete Signal Interface (DSI)

Provides three important control signal inputs:

Alarm Reset (AR): Closing a contact between DSI AR and DSI RET resets alarms latched by the MPC4/IOC4T card pair.

Danger Bypass (DB): Closing a contact between DSI DB and DSI RET inhibits (bypasses) the danger relay outputs.

Trip Multiply (TM): Closing a contact between DSI TM and DSI RET multiplies the alarm levels by a software-configurable scale factor, enabling adaptive monitoring.

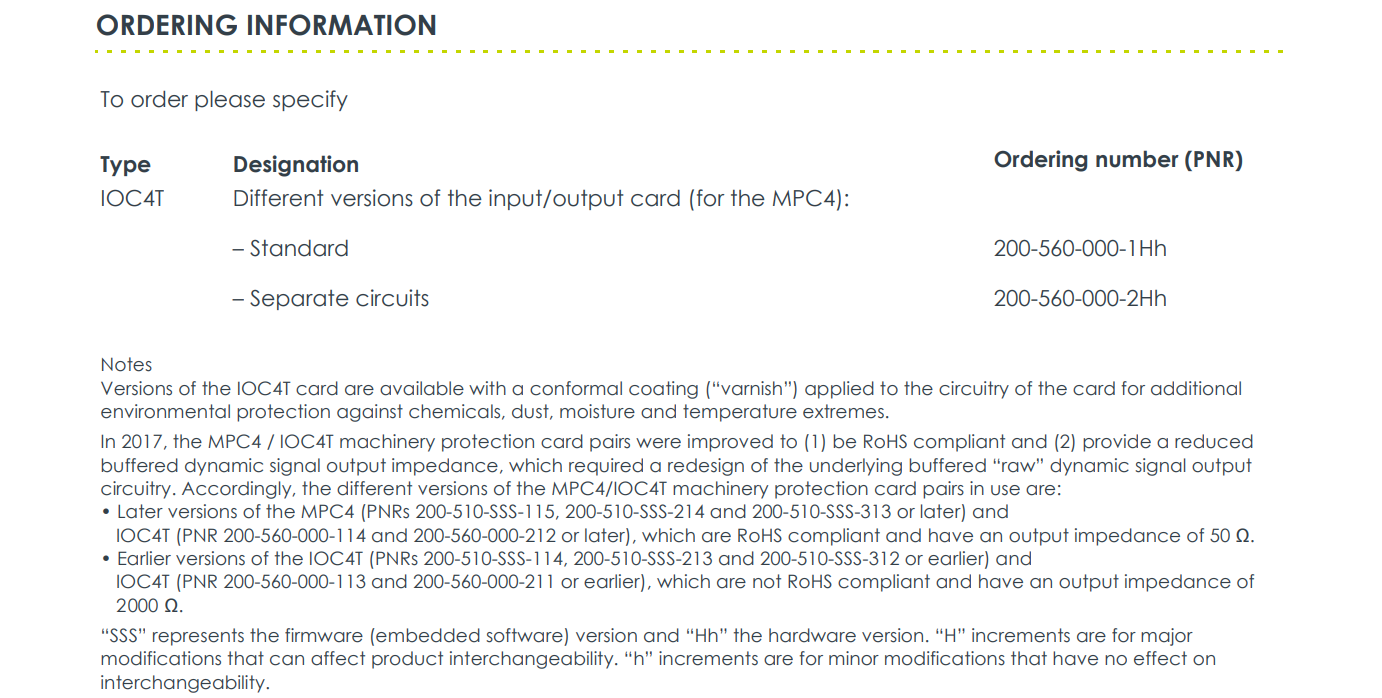

7. High-Reliability Design

Supports hot-swappable operation, allowing cards to be inserted or removed while the system is running without interruption. Available in "Standard" and "Separate Circuits" versions, the latter complying with IEC 60255-5 standards, suitable for applications requiring electrical isolation.

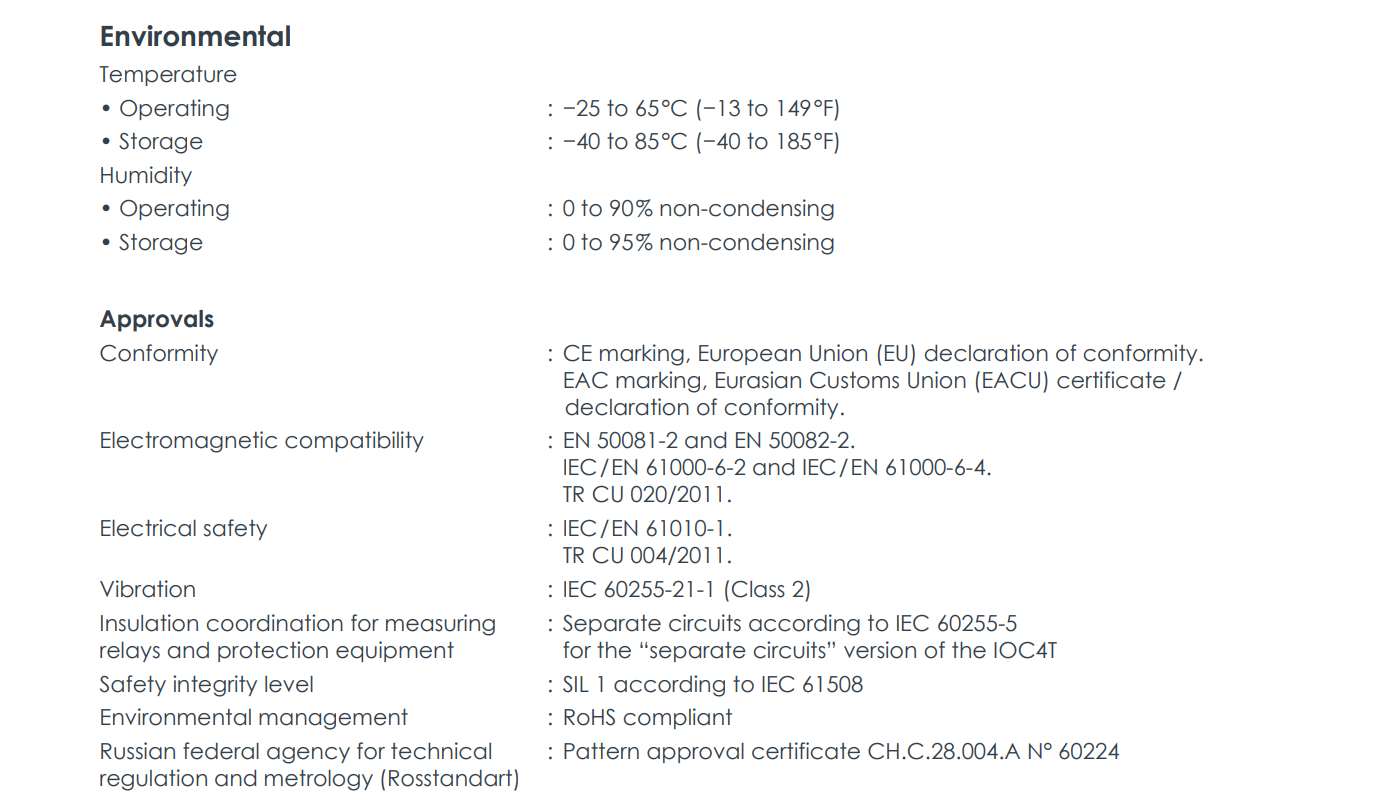

8. Environmental Robustness

Operating Temperature Range: -25 to 65°C (-13 to 149°F)

Storage Temperature Range: -40 to 85°C (-40 to 185°F)

Operating Humidity: 0 to 90% non-condensing

RoHS compliant. Optional conformal coating version available for additional protection against chemicals, dust, moisture, and extreme temperatures.

9. Safety Certifications

CE and EAC markings. Complies with EMC standards including EN 50081-2, EN 50082-2, IEC/EN 61000-6-2, IEC/EN 61000-6-4, and electrical safety standard IEC/EN 61010-1. Achieves Safety Integrity Level (SIL) 1 according to IEC 61508.

Working Principle

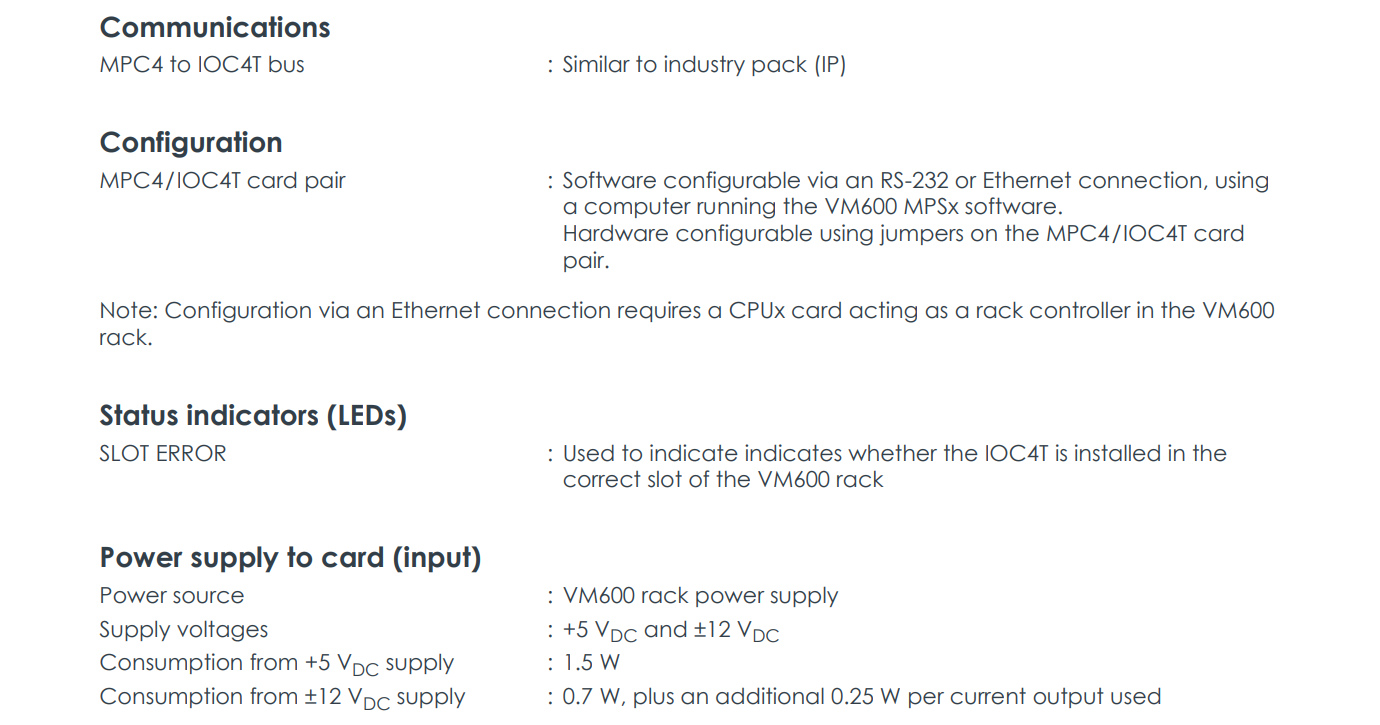

The IOC4T Input/Output card operates as a dedicated signal interface for the MPC4 Machinery Protection card in slave mode, communicating with the MPC4 via an Industry Pack (IP) interface. Its working principle can be broken down into several key aspects:

1. Signal Flow Architecture

The IOC4T card occupies a critical position in the signal chain: raw sensor signals enter via the front terminal blocks (J1, J2), undergo necessary signal conditioning and protection, and are then transmitted to the MPC4 card via backplane connector P2 for processing. After the MPC4 card completes signal processing (including alarm determination, etc.), the processed results and generated signals are sent back to the IOC4T card via the backplane, finally being output to external systems by the IOC4T card via the front terminal blocks (J2, J3).

2. Input Signal Processing

Dynamic vibration signals (typically from velocity or accelerometer sensors) are input via the J1 terminal block. These signals are first filtered for EMI and surge protection, then split into two paths: one is transmitted directly to the MPC4 card for detailed analysis; the other is buffered and amplified before being output as "raw" sensor signals from the J3 terminal block for external recording or analysis equipment.

Speed signals are input via the J2 terminal block, also filtered and protected before being transmitted to the MPC4 card for phase reference and speed measurement.

3. Output Signal Generation

Analog output signals are generated from the processed results of the MPC4 card. Four Digital-to-Analog Converters (DACs) on the IOC4T card convert digital signals into 0-10 V voltage signals. Additionally, four voltage-to-current converters can transform the voltage signals into 4-20 mA current signals (jumper selectable). This design allows users to flexibly choose the output type based on field requirements.

4. Relay Control Logic

The status of the four internal relays (RL1-RL4) is entirely controlled by the MPC4 card via software. Users can assign any alarm or status signal to these relays via the VM600 MPSx software. The relay driver circuit provides necessary electrical isolation and driving capability to ensure reliable switching.

5. Discrete Signal Interface Operation

The DSI inputs operate on a contact detection principle, monitoring the contact status between the AR, DB, TM inputs and the DSI RET reference terminal. Notably, the AR input is edge-sensitive, requiring a high-to-low transition to trigger the reset function. This design prevents malfunctions caused by contact bouncing or sustained closure.

6. Digital Output Expansion

The 32 programmable open-collector outputs are connected to other relay cards in the rack via the backplane buses (OC bus or Raw bus). The status of these outputs is determined by the MPC4 card, with the IOC4T providing necessary driving and isolation functions. Users can select which bus to use for signal transmission via jumpers.

7. Power Management

The IOC4T card receives its operating power (+5 VDC and ±12 VDC) from the VM600 rack power supply. The power circuit includes filtering and protection designs to ensure stable operation under various conditions. Current outputs consume additional power (approx. 0.25 W per output), which must be considered in system power budget calculations.

8. Hot-Swap Mechanism

Through carefully designed power sequencing circuits and signal isolation, the IOC4T card supports hot-swap functionality. When a card is inserted into a running system, the power circuit powers up in the correct sequence to avoid current surges; when a card is removed, the signal lines are disconnected before the power, preventing signal interference.

9. Status Monitoring and Diagnostics

A SLOT ERROR LED indicator provides basic installation status feedback, helping users confirm the card is correctly installed in the rack slot. More detailed status information and diagnostics require access via the MPC4 card and VM600 MPSx software.

10. Special Design of the Separate Circuits Version

The "Separate Circuits" version of the IOC4T card offers enhanced electrical isolation, with higher isolation ratings between input/output circuits and between channels, complying with IEC 60255-5 requirements. This makes this version particularly suitable for heavy industrial applications requiring high levels of electrical isolation.

Applications

The IOC4T, used paired with an MPC4 card, is highly suitable for the following application areas:

Rotating Machinery Protection: Vibration protection and condition monitoring of critical equipment such as steam turbines, gas turbines, hydro turbines, compressors, fans, and pumps.

Industrial Process Monitoring: Machinery condition monitoring in industries such as petrochemicals, power generation, and metallurgy.

Predictive Maintenance Systems: Integration with condition monitoring systems for equipment health assessment and predictive maintenance.

Functional Safety Systems: Executing protection functions in safety-related applications achieving up to SIL 1.

Key Specifications Summary

Dynamic Signal Inputs: 4 channels, EMI protected

Tachometer Inputs: 2 channels, EMI protected

Analog Outputs: 4 channels, 0-10 V or 4-20 mA (jumper selectable)

Relay Outputs: 4 relays, 250 VAC/5 AAC

Digital Outputs: 32 programmable open-collector outputs

Operating Temperature: -25 to 65°C (-13 to 149°F)

Power Requirements: +5 VDC (1.5 W), ±12 VDC (0.7 W + 0.25 W per current output)

Connections: Screw-terminal blocks (48 positions)

Dimensions: 6U H × 20mm W × 125mm D

Weight: approx. 0.25 kg