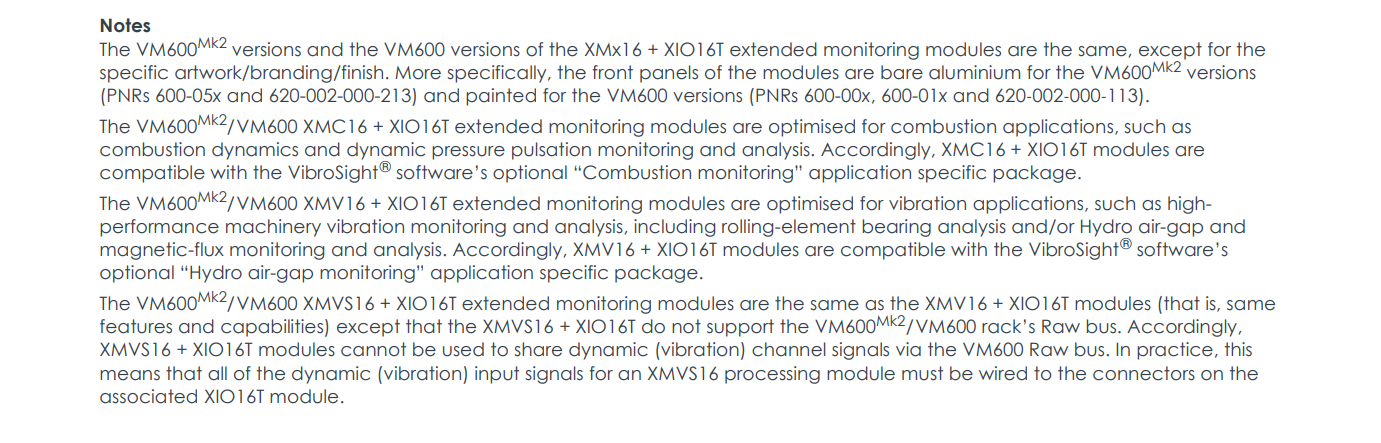

The VM600 XMV16 Extended Vibration Monitoring Module is a next-generation high-performance condition monitoring solution from VM product line, specifically designed for vibration monitoring and analysis of critical rotating machinery. As an essential component of the VM600 Mk2/VM600 system, the XMV16 works in tandem with the XIO16T input/output module to deliver top-tier monitoring performance with 16 dynamic channels and 4 tachometer channels. The module employs advanced 24-bit data acquisition technology and powerful digital signal processing capabilities, enabling high-resolution spectrum analysis up to 6400 lines, providing unprecedented machine health insights for industrial users.

The XMV16 module represents the latest development in vibration monitoring technology, offering significant improvements over its predecessor, the CMC16/IOC16T card pair, in terms of amplitude and spectral resolution, buffer memory capacity, module-level processing power, and data acquisition and storage rates. The module integrates seamlessly with VM software, providing powerful high-resolution plotting, integrated data management, and simplified network access interfaces, making it an ideal choice for modern predictive maintenance systems.

Key Features

1. High-Performance Data Acquisition & Processing

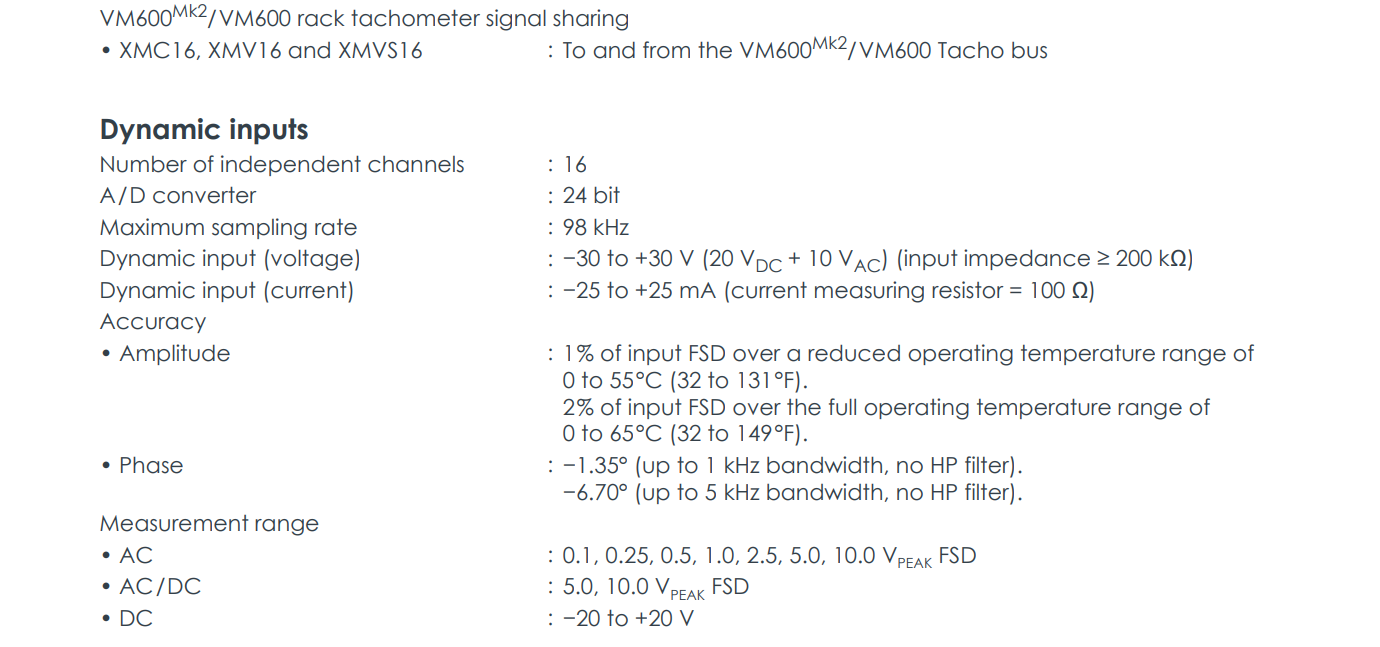

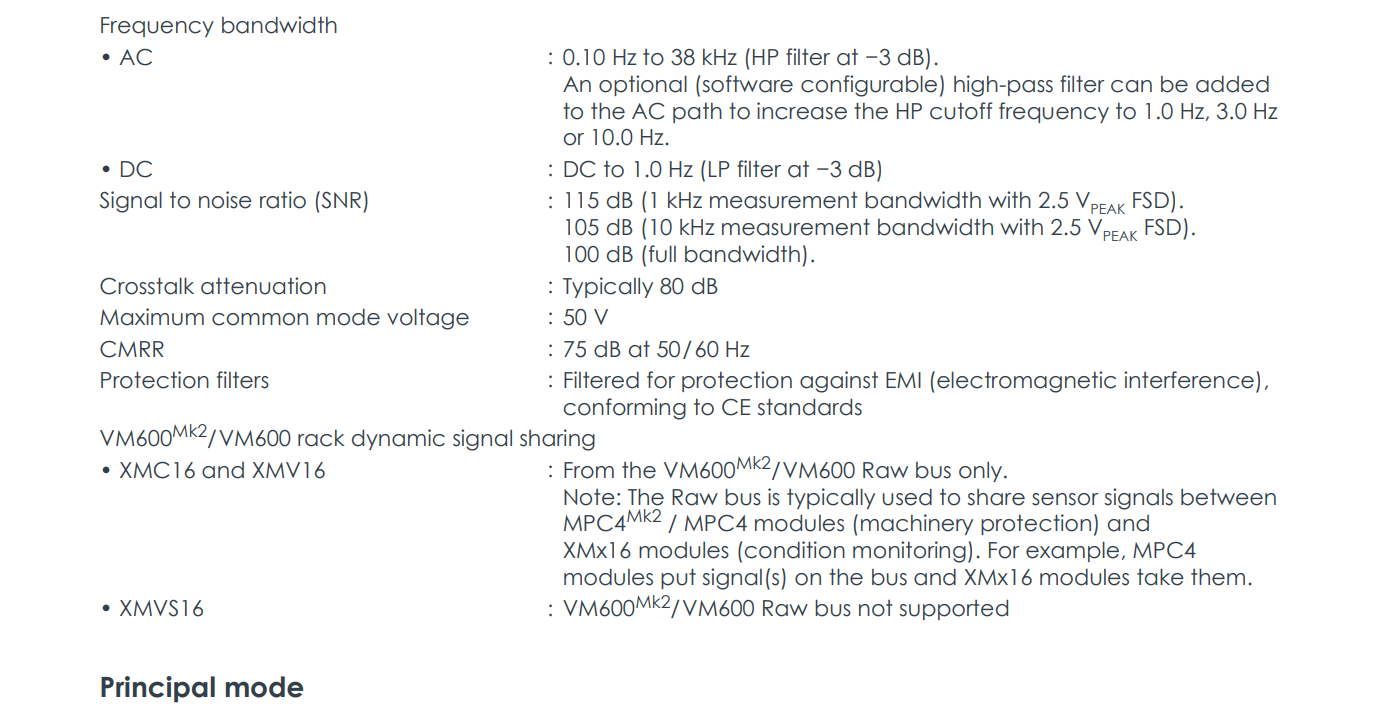

The XMV16 utilizes 24-bit analog-to-digital conversion with a maximum sampling rate of 98 kHz, ensuring high-fidelity vibration signal acquisition. The module offers exceptional signal-to-noise ratio (SNR) performance: 115 dB at 1 kHz measurement bandwidth with 2.5 V peak full scale, 105 dB at 10 kHz bandwidth, and 100 dB at full bandwidth. This high performance guarantees accurate and reliable monitoring data even in the most demanding industrial environments.

2. Multi-Mode Measurement Capability

The module supports three distinct measurement modes to meet various monitoring needs:

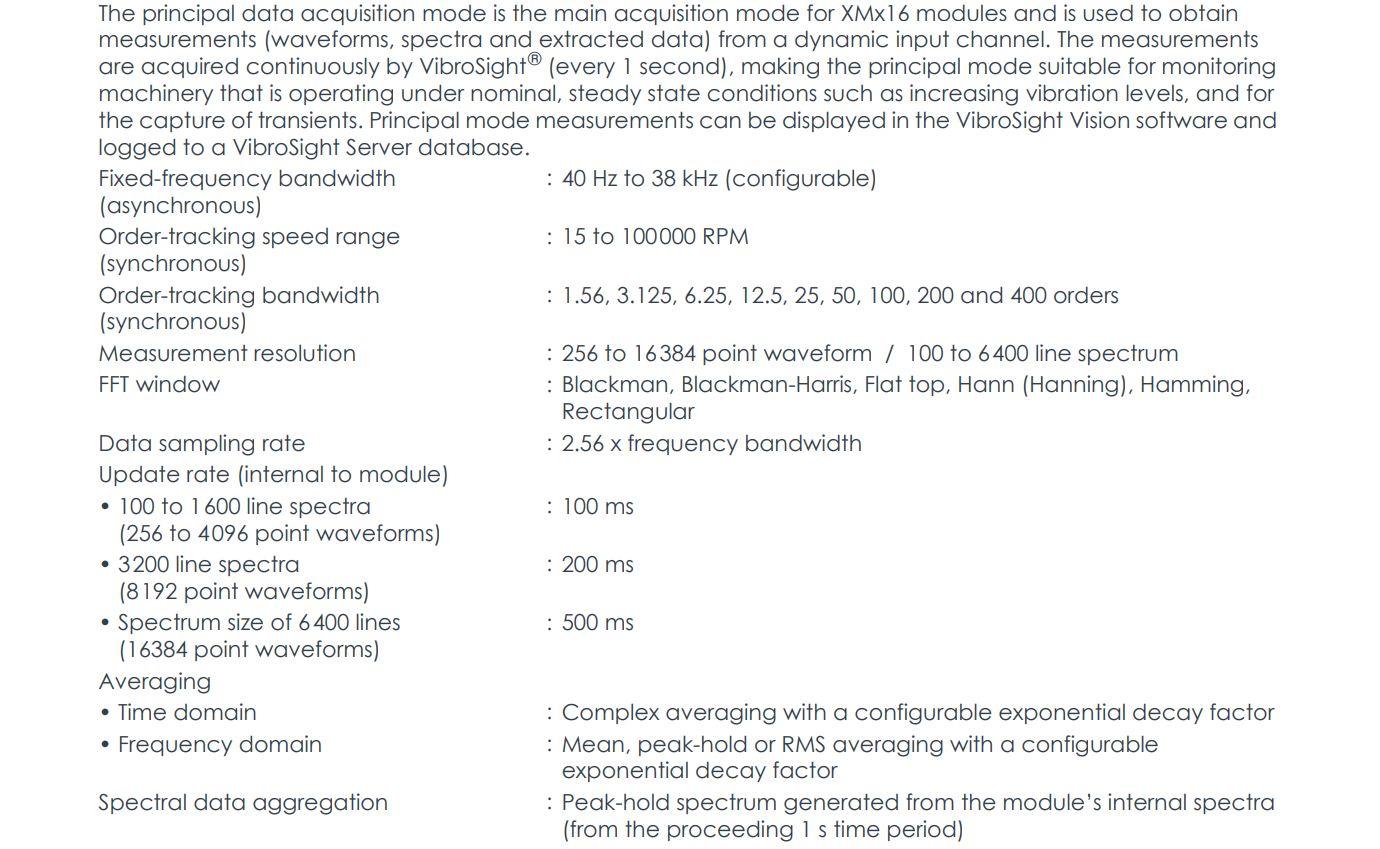

Principal Mode: Primarily used for continuous data acquisition during normal machine operation, suitable for monitoring increasing vibration levels and transient conditions

Auxiliary Mode: Acquires more detailed waveforms and spectral data at reduced update rates, complementing principal mode measurements

Direct Mode: Used to obtain digitized continuous long-duration waveforms from dynamic input channels preceding alarm events for detailed post-analysis

3. High-Resolution Spectrum Analysis

The XMV16 provides industry-leading spectral resolution up to 6400 lines (corresponding to 16384-point waveforms). Different resolutions correspond to different update rates: 1600-line spectra update every 100 ms, 3200-line spectra every 200 ms, and 6400-line spectra every 500 ms. This high resolution enables the detection of extremely subtle fault characteristics.

4. Flexible Configuration Options

Each channel can be configured with up to 20 processed outputs based on asynchronously (fixed frequency) or synchronously (order-tracked) acquired waveforms and spectra. Multiple qualifier functions are supported, including RMS, peak, peak-to-peak, true peak, true peak-to-peak, and DC (Gap). Outputs can be displayed in any standard unit (metric or imperial).

5. Powerful Signal Sharing Capability

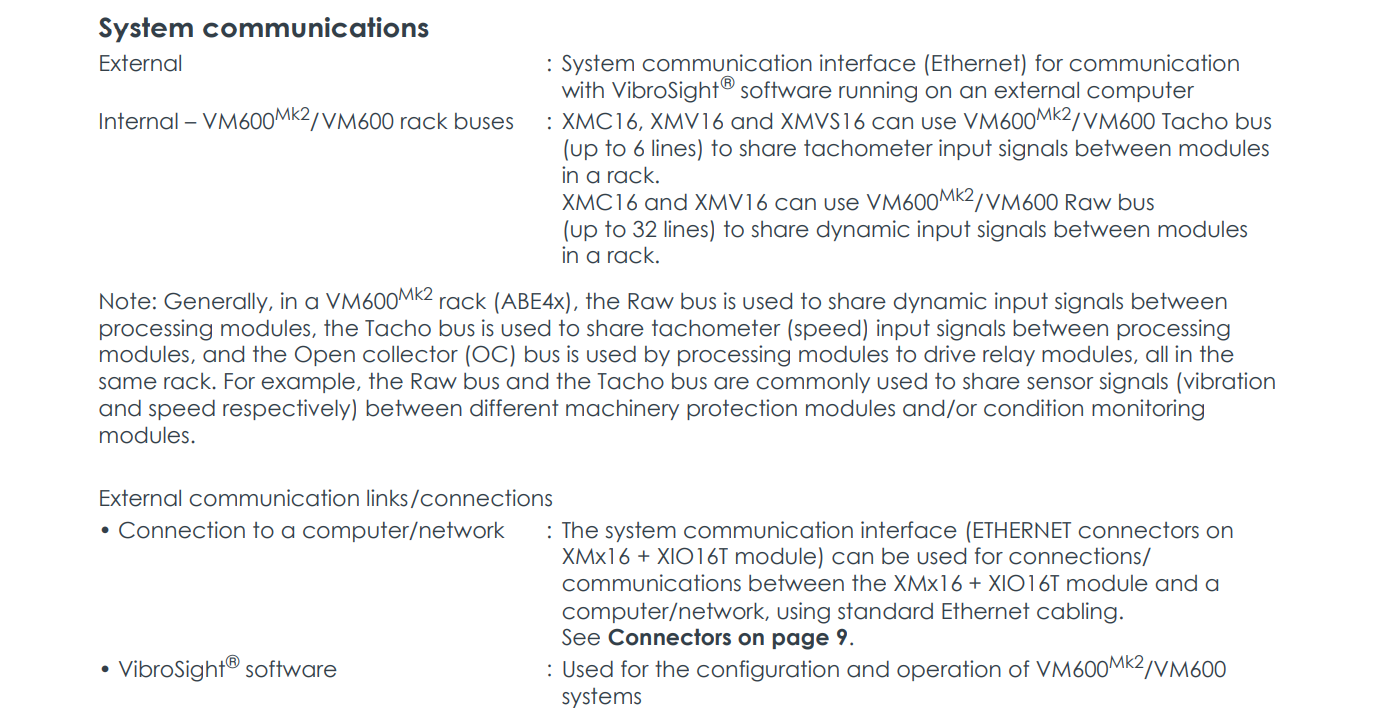

The XMV16 supports signal sharing within VM600 Mk2/VM600 racks, enabling dynamic input signal sharing via the Raw bus (up to 32 lines) and tachometer input signal sharing via the Tacho bus (up to 6 lines). This design significantly reduces external wiring requirements and simplifies system integration.

6. Advanced Event Capture Functionality

The module provides configurable pre-trigger and post-trigger data logging capabilities. Pre-trigger data logging can reach up to every 100 ms, while post-trigger data logging can also achieve up to every 100 ms for durations of up to 1 hour. The onboard buffer memory can store up to 1140 static data sets (extracted data) and 42 dynamic data sets (waveforms and/or spectra).

7. Multiple Averaging and Aggregation Methods

Various averaging methods are supported at both the processing block level and output (extracted data) level. Spectral data aggregation over one second is also available to capture any bursts or spikes in internal XMV16 module spectra.

8. Multi-Channel Processing Functions

Advanced processing functions are supported, including shaft absolute vibration, full spectrum, orbit and filtered orbit, shaft centerline, and Smax, meeting complex rotor dynamics analysis requirements.

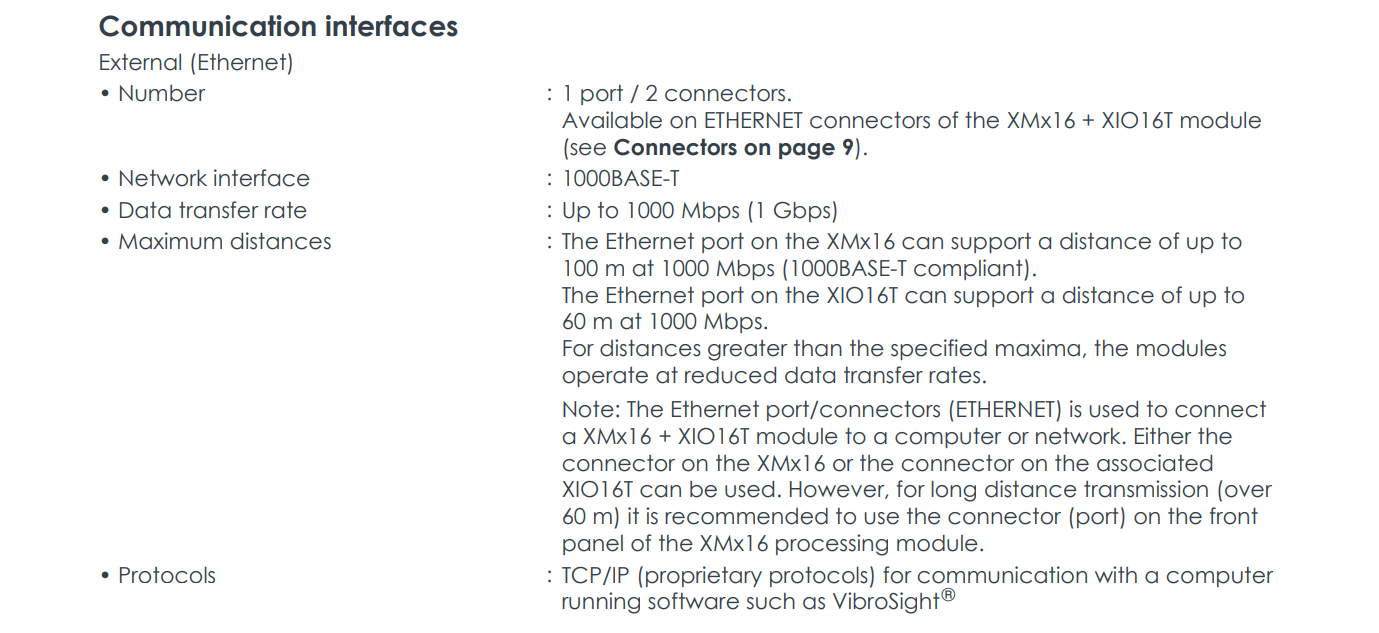

9. Gigabit Ethernet Communication

The module features a Gigabit Ethernet interface supporting data transfer rates up to 1000 Mbps. The front-panel ETHERNET connector supports transmission distances up to 100 meters, while the rear-panel connector supports up to 60 meters, providing excellent flexibility for system integration.

10. Hot-Swap Capability

Supports live insertion and removal of modules (hot-swappable) without interrupting system operation, significantly enhancing system maintainability and availability.

11. Comprehensive Environmental Adaptability

Operating temperature range: 0 to 65°C (32 to 149°F)

Storage temperature range: -40 to 85°C (-40 to 185°F)

Operating humidity: 0 to 90% relative humidity (non-condensing)

RoHS compliant with excellent environmental adaptability.

12. Safety Certifications

EAC marked, compliant with TR CU 020/2011 electromagnetic compatibility standards and TR CU 004/2011 electrical safety standards. Certified by the Russian Federal Agency for Technical Regulation and Metrology (Rosstandart) with pattern approval certificate OC.C.28.004.A N° 60224.

Working Principle

The working principle of the VM600 XMV16 Extended Vibration Monitoring Module is based on advanced digital signal processing technology. Working in conjunction with the XIO16T input/output module, it enables comprehensive monitoring and analysis of machine vibration conditions. The working principle can be divided into several key aspects:

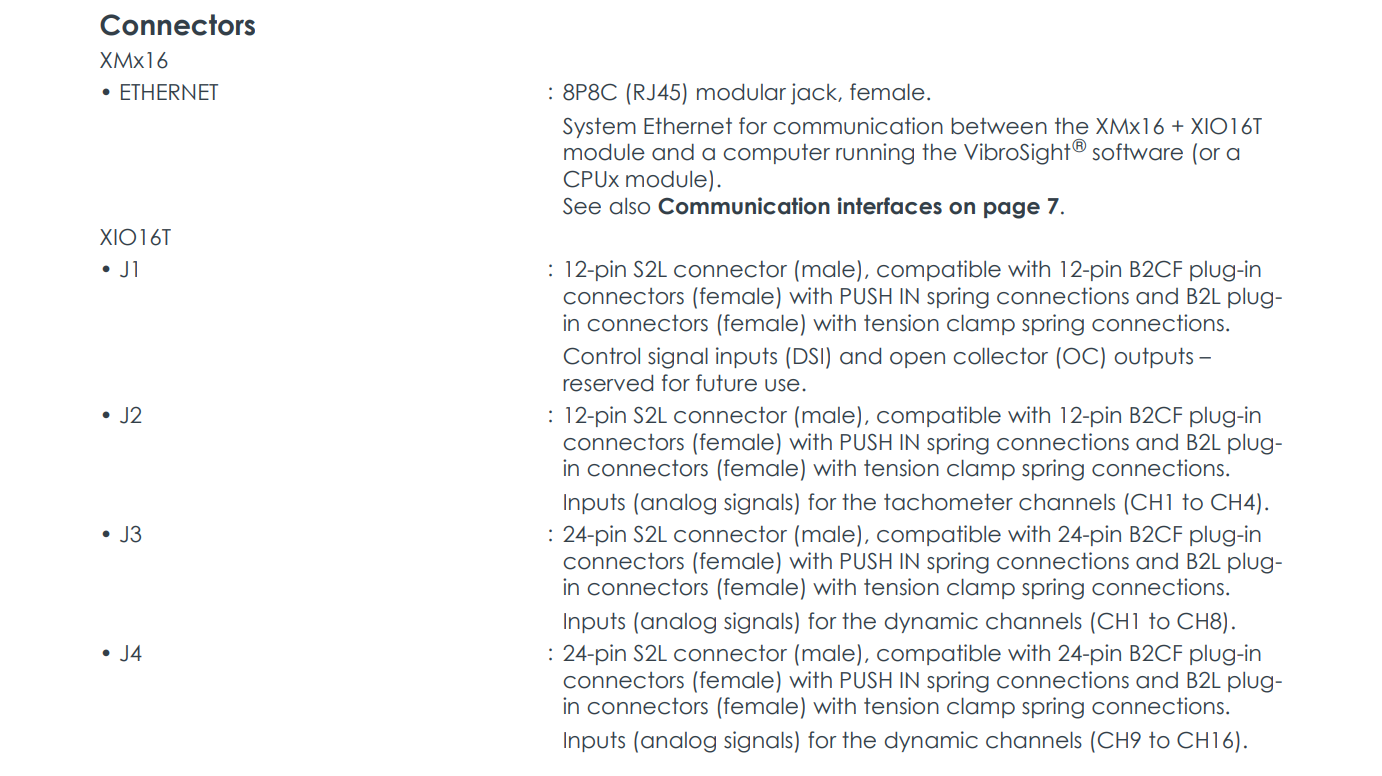

1. System Architecture & Signal Flow

The XMV16 processing module is installed in the front of the rack, while the XIO16T module is installed in the rear. Both connect directly to the rack backplane via connectors. Sensor signals are input through the XIO16T module's terminal block connectors, where they undergo signal conditioning and protection before being transmitted to the XMV16 module for processing via the backplane.

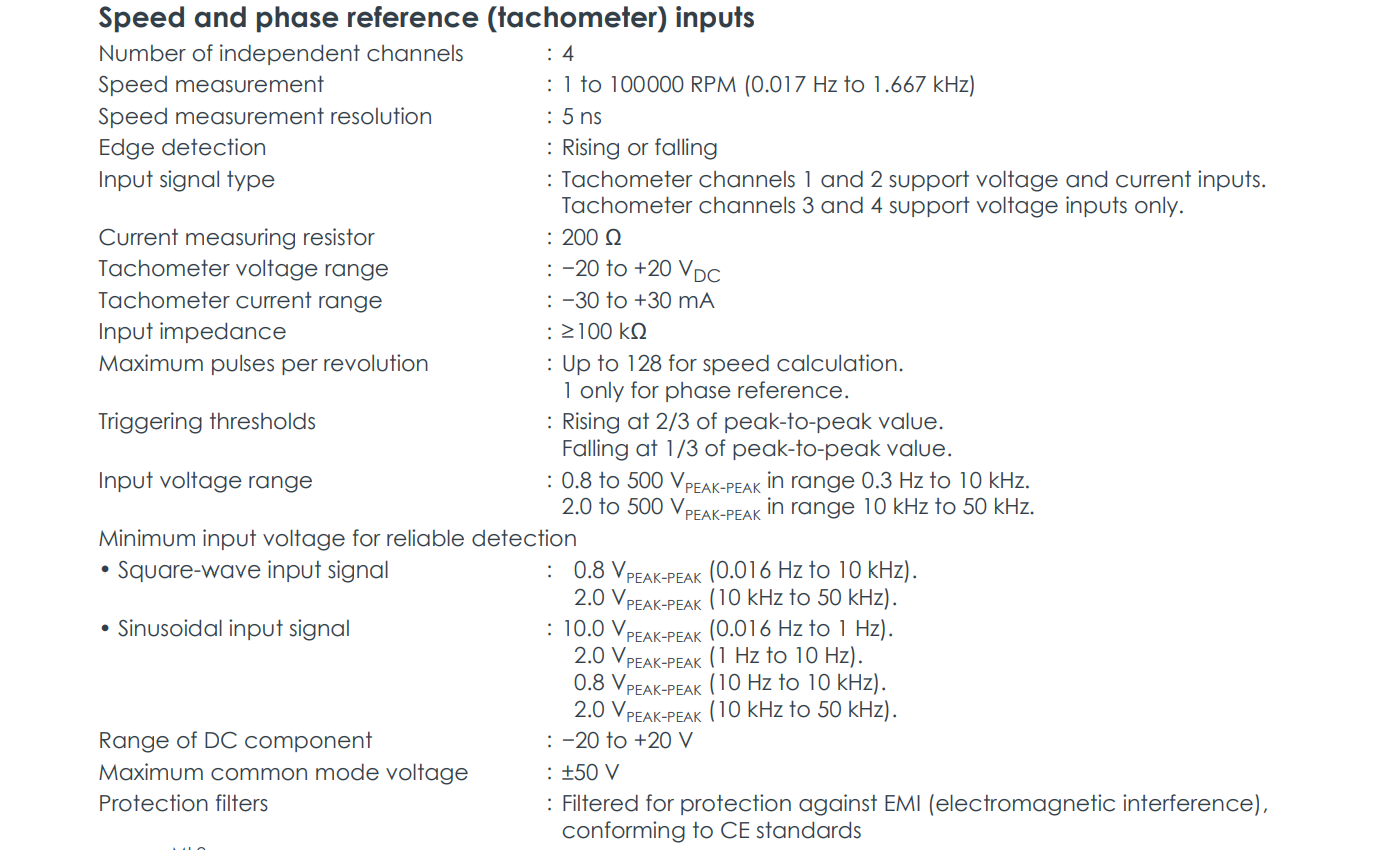

The XIO16T module performs all analog signal conditioning functions and supports external communications. It protects all inputs against signal surges and EMI to meet EMC standards. The module's inputs are fully software-configurable and can accept signals representing speed and phase reference (e.g., from TQxxx sensors) as well as vibration signals derived from acceleration, velocity, and/or displacement (e.g., from CAxxx, CExxx, CVxxx, and TQxxx sensors).

2. Signal Acquisition & Digitization

The XMV16 module performs analog-to-digital conversion and all digital signal processing functions, including processing of each waveform and spectrum, and related processed outputs (extracted data). The module acquires and processes data at high resolution (24-bit ADC) to generate waveforms and spectra using three different measurement modes: principal, auxiliary, and direct.

In principal mode, the module performs continuous data acquisition suitable for normal machine operation, such as increasing vibration levels and transient conditions. Waveforms and spectra acquired in principal mode are used to generate related processed outputs (extracted data). Auxiliary mode is used to obtain more detailed waveforms and spectra at reduced update rates, complementing principal mode measurements. Direct mode is used to obtain digitized continuous long-duration waveforms from dynamic input channels preceding alarm events, using third-party programs for data visualization.

3. Data Processing & Analysis

Processing cycle times on the XMV16 module depend on the waveform (points)/spectrum (lines) resolution configured for principal and auxiliary measurement modes. These internal processing cycle times help determine the rate at which waveforms, spectra, and extracted data become available as module outputs.

While measurement data can be obtained from the XMV16 module at data update rates up to 100 ms, the VibroSight® software data update rate is 1 second. This means the VibroSight server polls XMV16 modules at a maximum rate of once per second. For example, a module configured for a 100 ms data update rate in principal measurement mode provides VibroSight® with every tenth waveform, spectrum, and related extracted data.

4. Spectral Data Aggregation

To prevent potential loss of important information in the XMV16 module's internal measurement data, spectral data aggregation can be used to capture peaks in intermediate (internal) spectra without significantly increasing network traffic. This aggregation function performs peak-hold on spectral data over one second, ensuring that no transient fault characteristics are missed.

5. Event Detection & Data Logging

Events are generated when values exceed any of five user-configurable severity levels or exceed rate-of-change alarms. The amount of pre-event data stored in the XMV16 module's onboard buffer memory is configurable and can be used for data logging of pre-trigger (event) static data up to every 100 milliseconds and dynamic data every 1 second. Post-trigger (event) static data logging up to every 100 ms is also available for up to 1 hour.

6. Machine State Detection

Machine states such as full load (onload), overspeed, and transient are detected by checking reference speed against trigger levels. These states can be used by the software's machine operating conditions to control system behavior. Typically, higher density logging is available depending on machine operating conditions, configurable speed and time intervals, or any other process parameters.

7. Signal Sharing Mechanism

Within VM600 Mk2/VM600 racks, the XMV16 can use the Tacho bus to share tachometer input signals and the Raw bus to share dynamic input signals. Generally, in a VM600 Mk2 rack (ABE4x), the Raw bus is used to share dynamic input signals between processing modules, the Tacho bus is used to share tachometer (speed) input signals between processing modules, and the Open Collector (OC) bus is used by processing modules to drive relay modules, all within the same rack.

8. Communication & Data Transmission

The XMV16 module communicates with external computers running VibroSight® software via a Gigabit Ethernet interface. The system communication interface (ETHERNET connectors) can be used to establish connections/communications between the XMV16 + XIO16T module and computers/networks using standard Ethernet cables.

The module uses Network Time Protocol (NTP) for time synchronization, ensuring temporal consistency throughout the system. The front-panel ETHERNET connector supports transmission distances up to 100 meters (1000BASE-T compliant), while the rear-panel ETHERNET connector supports up to 60 meters (1000 Mbps). For distances exceeding specified maximums, the modules operate at reduced data transfer rates.

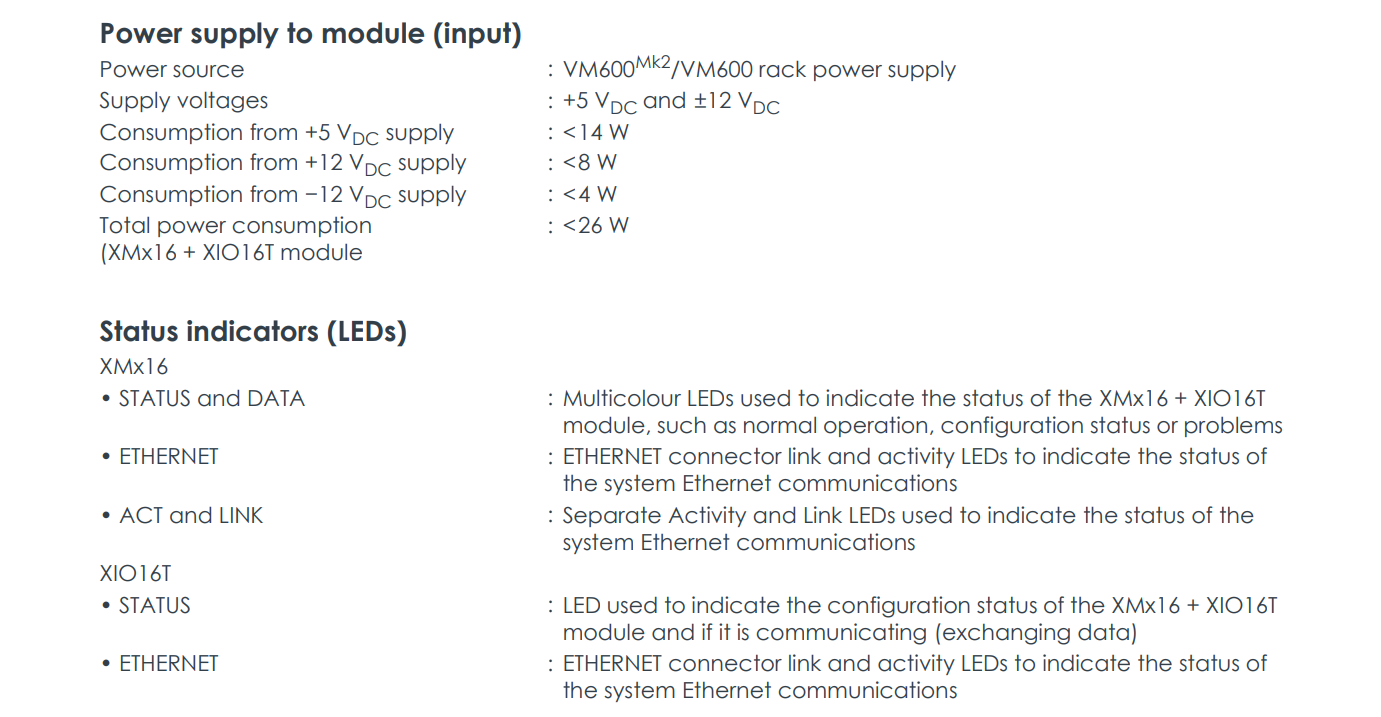

9. Configuration & Status Monitoring

The XMV16 + XIO16T module is fully software-configurable via Ethernet using a computer running VibroSight® software. The module provides multiple status indicators (LEDs): STATUS and DATA multicolor LEDs indicate the XMV16 + XIO16T module's status, such as normal operation, configuration status, or problems; ETHERNET connector link and activity LEDs indicate the status of system Ethernet communications.

10. Power Management & Thermal Design

The module receives operating power (+5 VDC and ±12 VDC) from the VM600 rack power supply. Power consumption is <14 W from the +5 VDC supply, <8 W from the +12 VDC supply, and <4 W from the -12 VDC supply, with total power consumption <26 W (XMV16 + XIO16T module). This efficient power design ensures stable module operation and low heat dissipation.

Applications

The VM600 XMV16 Extended Vibration Monitoring Module is ideally suited for the following application areas:

Rotor Dynamics Monitoring & Analysis: Vibration monitoring and rotor dynamics analysis for large rotating machinery such as steam turbines, gas turbines, and hydro turbines

Rolling Element Bearing Analysis: High-resolution spectrum analysis capability for early detection of rolling bearing fault characteristics

Hydro Air-Gap and Flux Monitoring: Supports air-gap monitoring and magnetic flux density monitoring applications for hydroelectric generators

Industrial Rotating Machinery Monitoring: Condition monitoring and fault diagnosis for industrial rotating machinery such as compressors, fans, pumps, and motors

Predictive Maintenance Systems: Serves as the core component of plant predictive maintenance systems, providing high-quality machine health data

Technical Specifications Summary

Dynamic Input Channels: 16 independent channels

Tachometer Input Channels: 4 independent channels

ADC Resolution: 24-bit

Maximum Sampling Rate: 98 kHz

Dynamic Input Range: -30 to +30 V (voltage), -25 to +25 mA (current)

Frequency Bandwidth: 0.10 Hz to 38 kHz (AC), DC to 1.0 Hz (DC)

Spectral Resolution: Up to 6400 lines

Signal-to-Noise Ratio: 115 dB (1 kHz bandwidth)

Communication Interface: Gigabit Ethernet (1000BASE-T)

Operating Temperature: 0 to 65°C (32 to 149°F)

Power Consumption: <26 W (XMV16 + XIO16T module)