The VM600 IOCN Mk2 is an important component of VM product line for the VM600 Mk2 (second generation) rack-based monitoring system. It serves as the matching input/output and communication interface module for the CPUM Mk2 rack controller module. The IOCN Mk2 and CPUM Mk2 together form a complete module pair, providing system control, data communication gateway, and signal interface functions for the VM600 Mk2 system.

Designed for industrial environments, this module is widely used in rotating machinery protection and condition monitoring systems in power generation, oil and gas, and other industries. As a second-generation product, the IOCN Mk2 offers significant improvements over the first-generation IOCN module in terms of hardware architecture, communication performance, system integration, and reliability.

Key Differences Between IOCN Mk2 and IOCN

1. Hardware Architecture Differences

| Feature | IOCN (First Generation) | IOCN Mk2 (Second Generation) |

| Module Width | Single-width | Single-width |

| Matching Controller | CPUM (double-width) | CPUM Mk2 (single-width) |

| Total Slot Occupation | 3 slots (CPUM double-width + IOCN single-width) | 2 slots (CPUM Mk2 single-width + IOCN Mk2 single-width) |

| Module Structure | Basic interface functions | Enhanced interface functions |

2. Communication Capability Differences

| Communication Feature | IOCN (First Generation) | IOCN Mk2 (Second Generation) |

| System Ethernet | 10/100BASE-TX (max 100Mbps) | 10/100/1000BASE-T(X) (max 1Gbps) |

| Fieldbus Support | Modbus RTU/TCP, PROFINET | Modbus TCP, PROFIBUS DP |

| Serial Interfaces | Up to 3 RS-232/RS-422/RS-485 | 2 RS-485 (supporting PROFIBUS DP) |

| Redundancy Support | Limited support | Complete module-level and rack-level redundancy support |

3. Performance Improvements

The IOCN Mk2 shows significant improvements in communication performance:

Transmission speed: Ethernet interfaces upgraded from Fast Ethernet to Gigabit Ethernet, 10x faster transmission speed

Processing capability: Support for higher-speed fieldbus communication (PROFIBUS DP up to 12Mbps)

Response time: Faster signal transmission and processing speed, shorter system response time

4. Compatibility Differences

Forward compatibility: IOCN Mk2 is only compatible with VM600 Mk2 systems, not compatible with first-generation VM600 cards

Backward compatibility: IOCN Mk2 is compatible with all VM600 Mk2 system racks

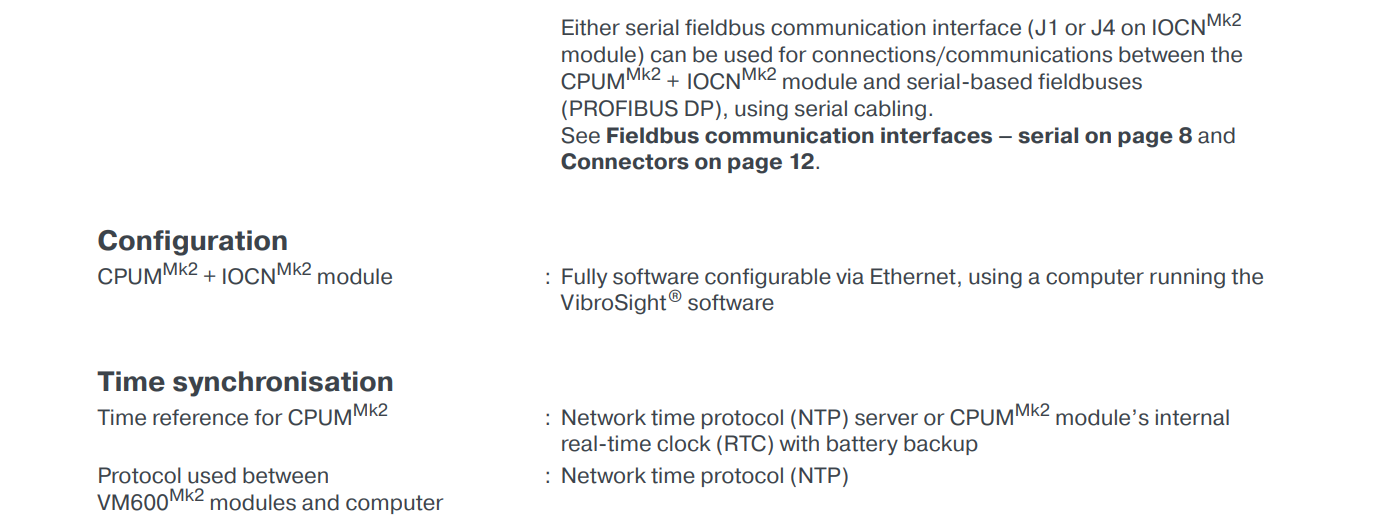

Software compatibility: IOCN Mk2 requires VibroSight software for configuration

5. Functional Characteristic Differences

| Functional Feature | IOCN (First Generation) | IOCN Mk2 (Second Generation) |

| Isolation Performance | Basic isolation protection | Enhanced isolation protection with higher isolation voltage |

| Diagnostic Functions | Basic status indication | Enhanced diagnostics and status monitoring |

| Configuration Management | Hardware configuration using jumpers | Full software configuration, no jumpers required |

| Redundancy Functions | Limited redundancy support | Complete redundancy support, supporting complex configurations |

6. Application Scope Differences

IOCN: Suitable for traditional VM600 systems, mainly for machinery protection applications

IOCN Mk2: Designed specifically for VM600 Mk2 systems, supporting broader application scenarios and higher performance requirements

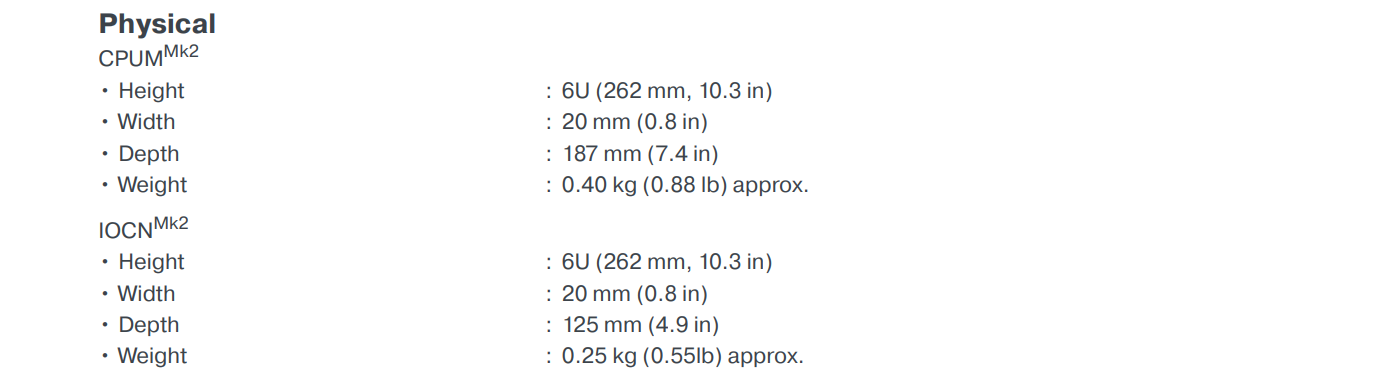

7. Physical Characteristic Differences

| Physical Feature | IOCN (First Generation) | IOCN Mk2 (Second Generation) |

| Dimensions | 6U height, 20mm width, 125mm depth | 6U height, 20mm width, 125mm depth |

| Weight | Approximately 0.25kg | Approximately 0.25kg |

| Connectors | Various types (D-sub, RJ45, RJ12) | Optimized connector layout supporting higher speeds |

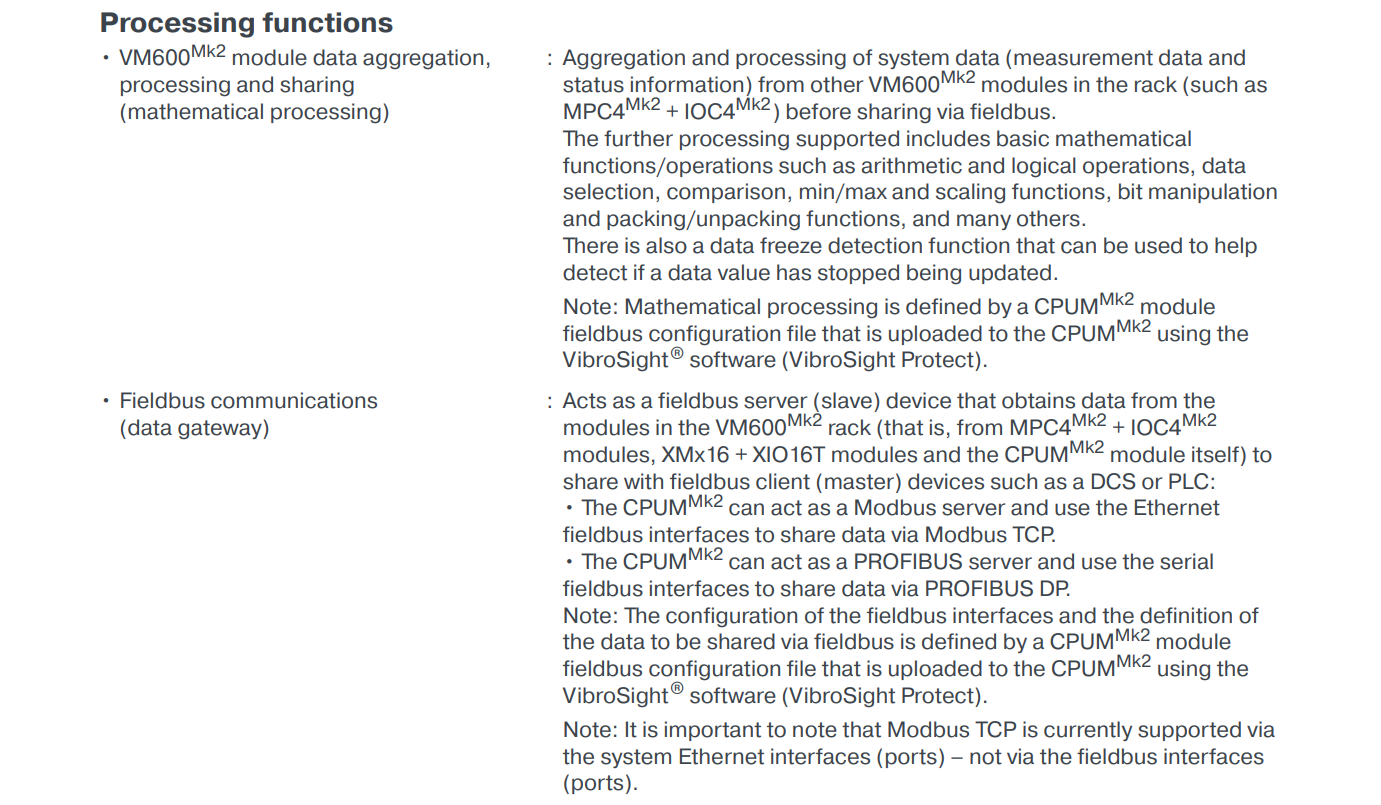

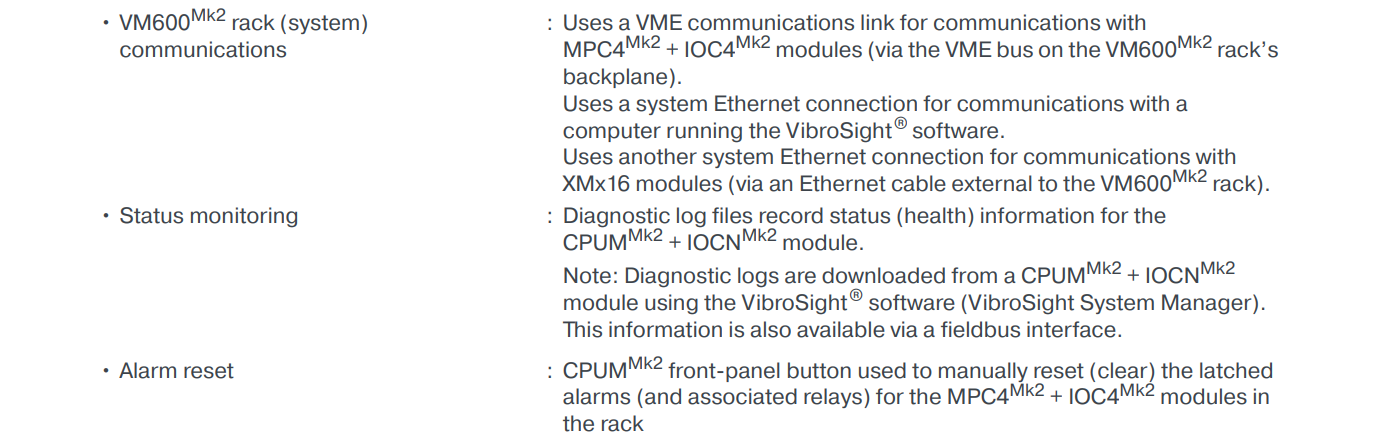

Key Features and Functions

1. Communication Interface Functions

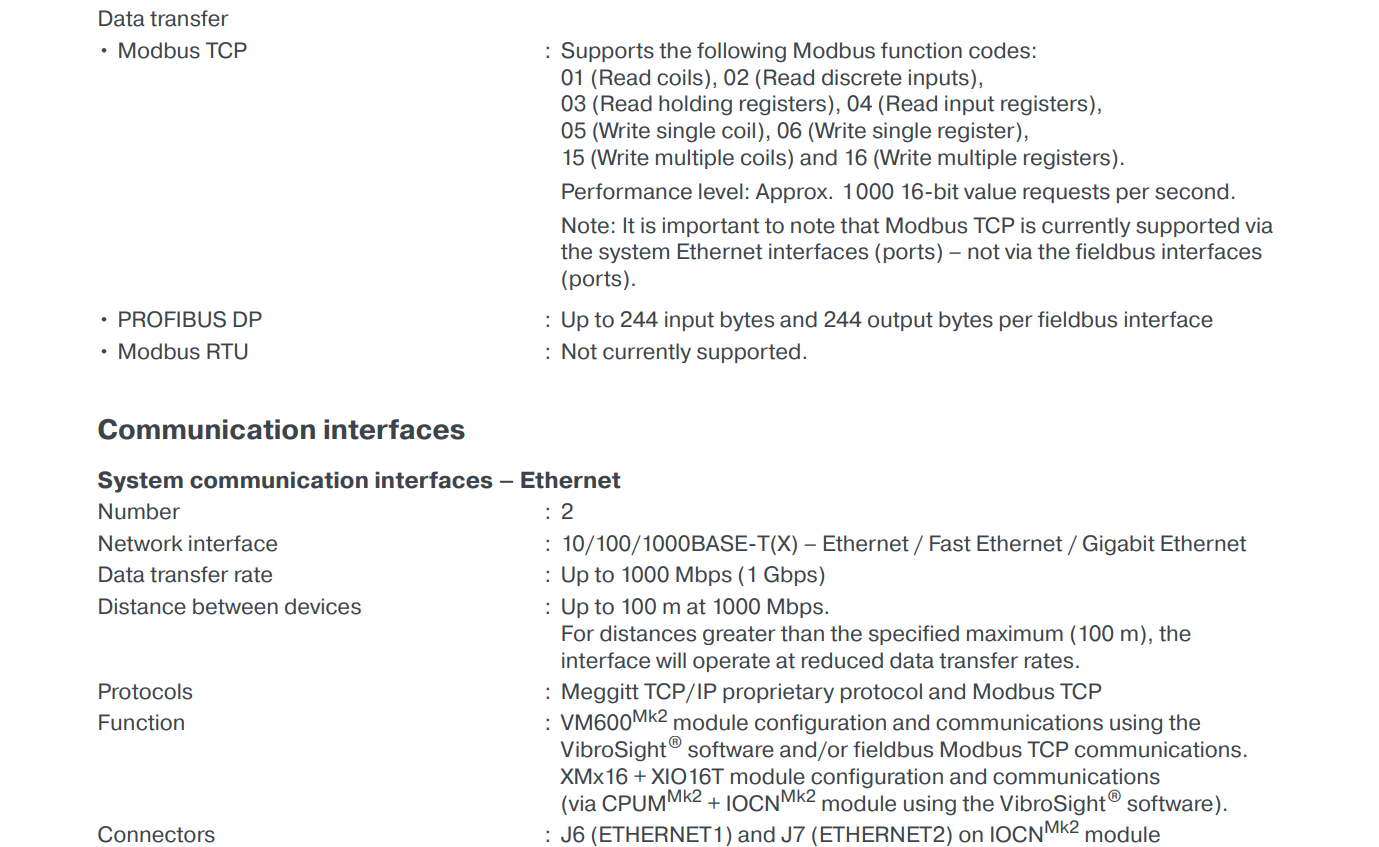

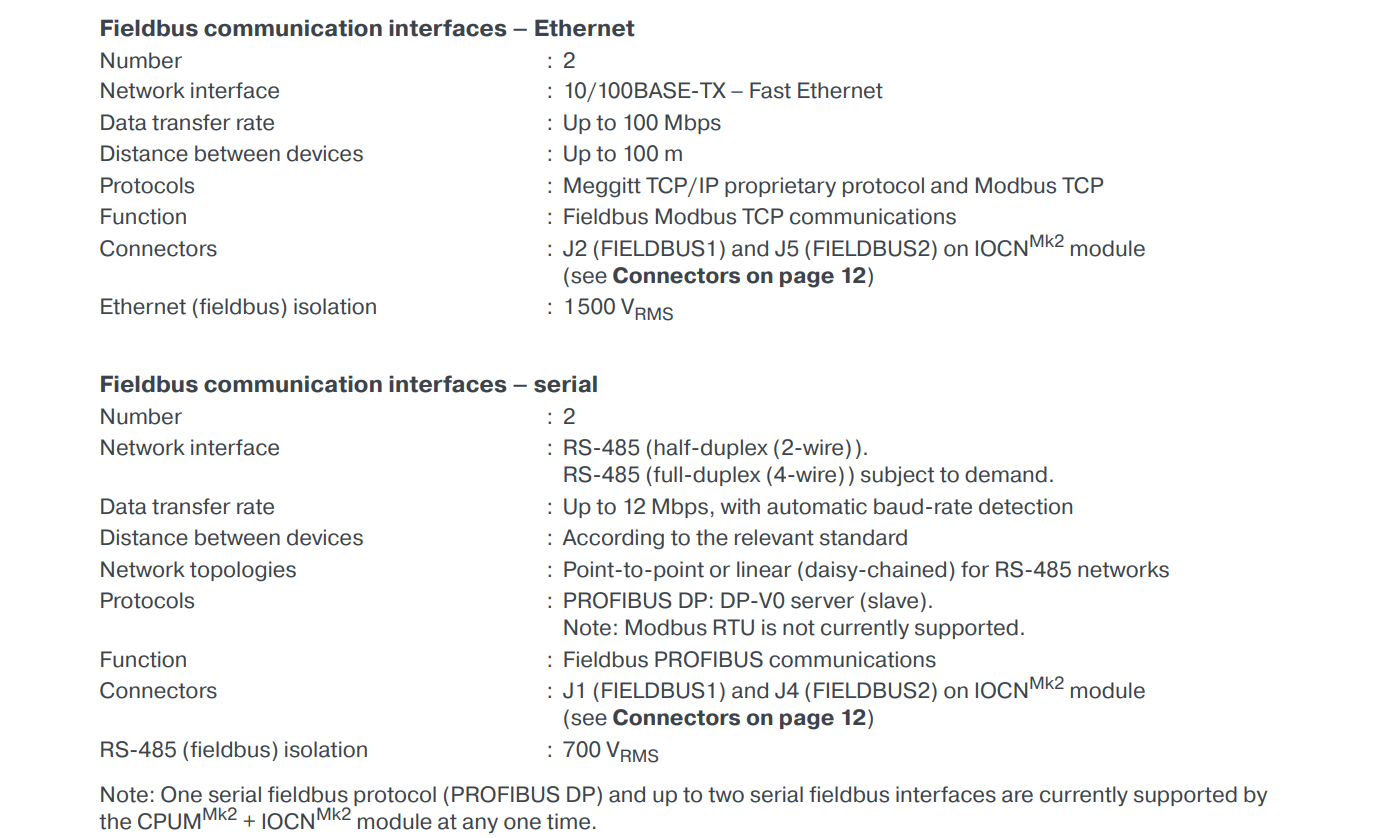

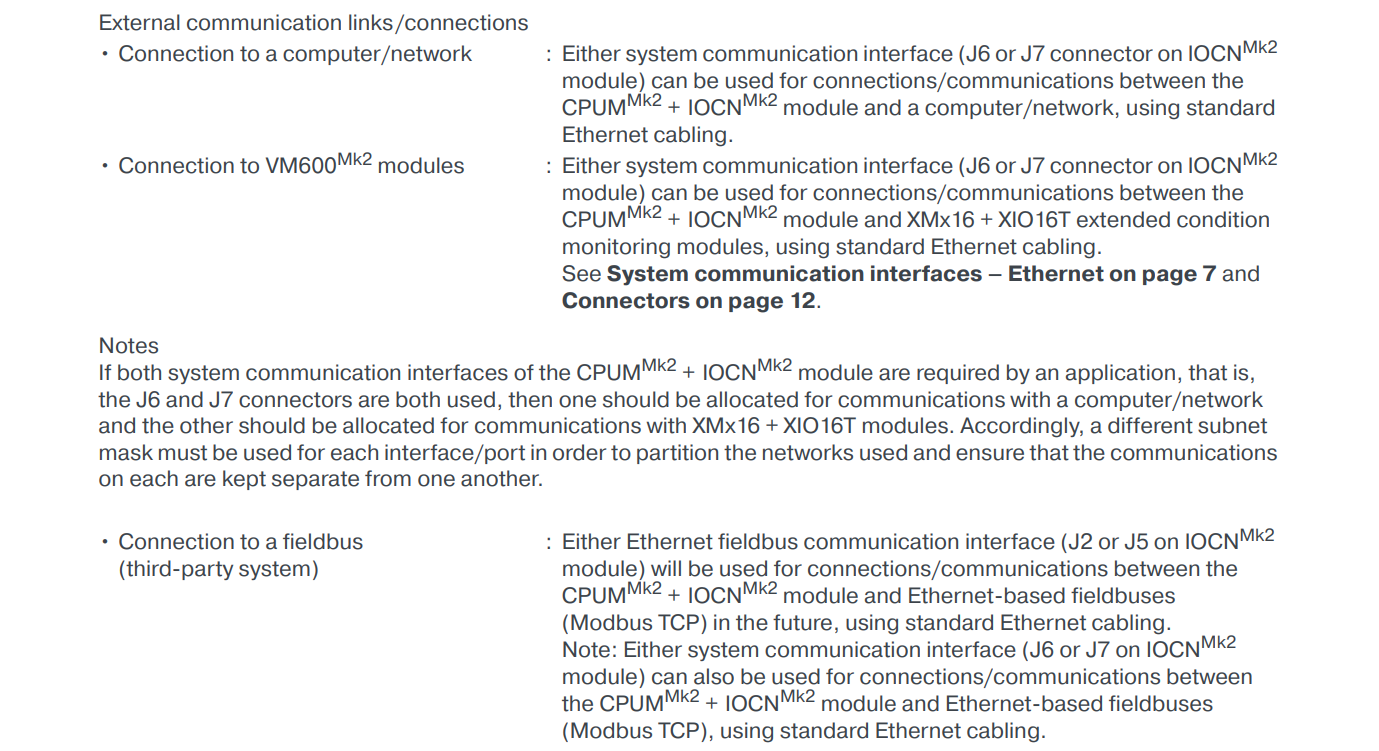

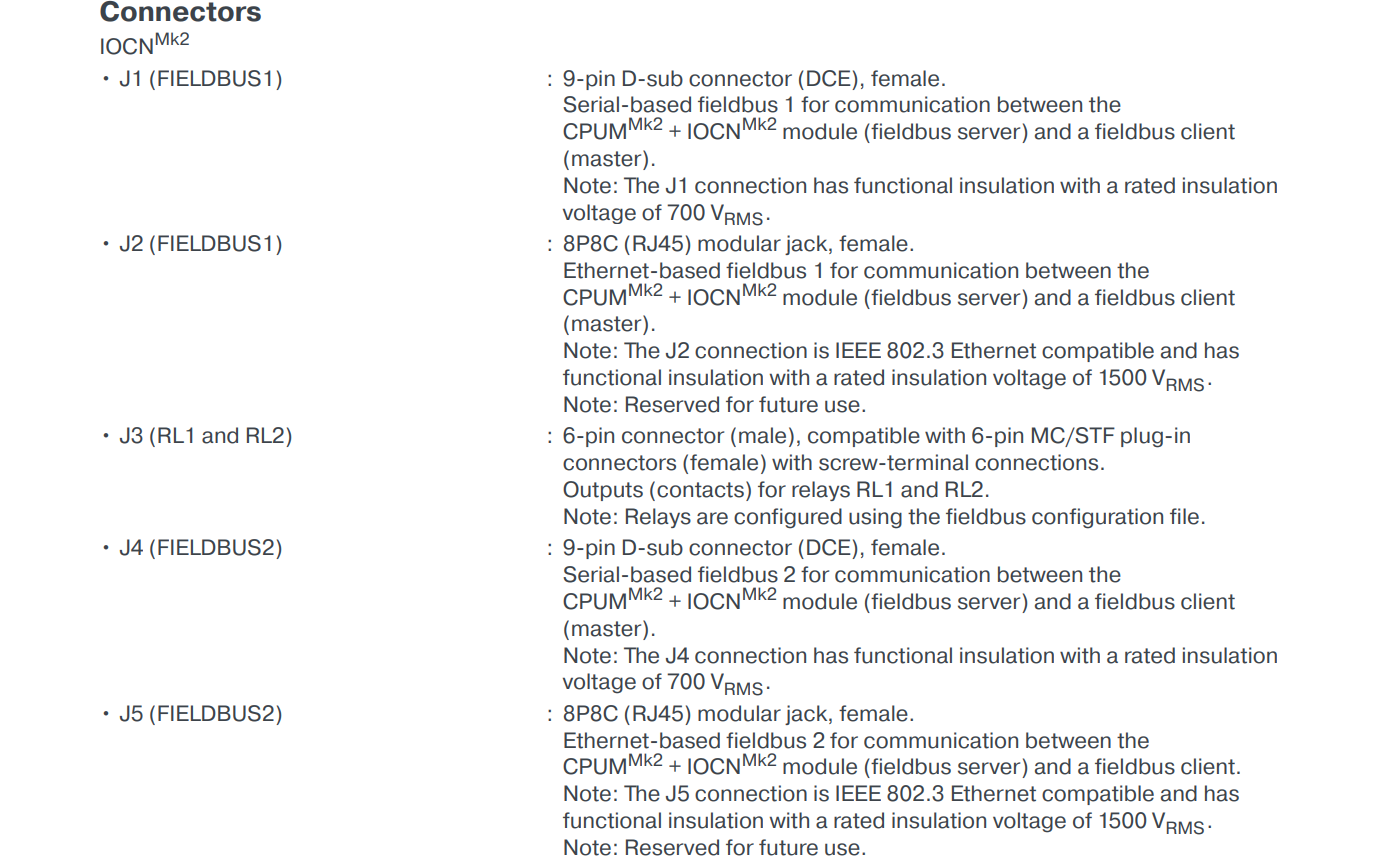

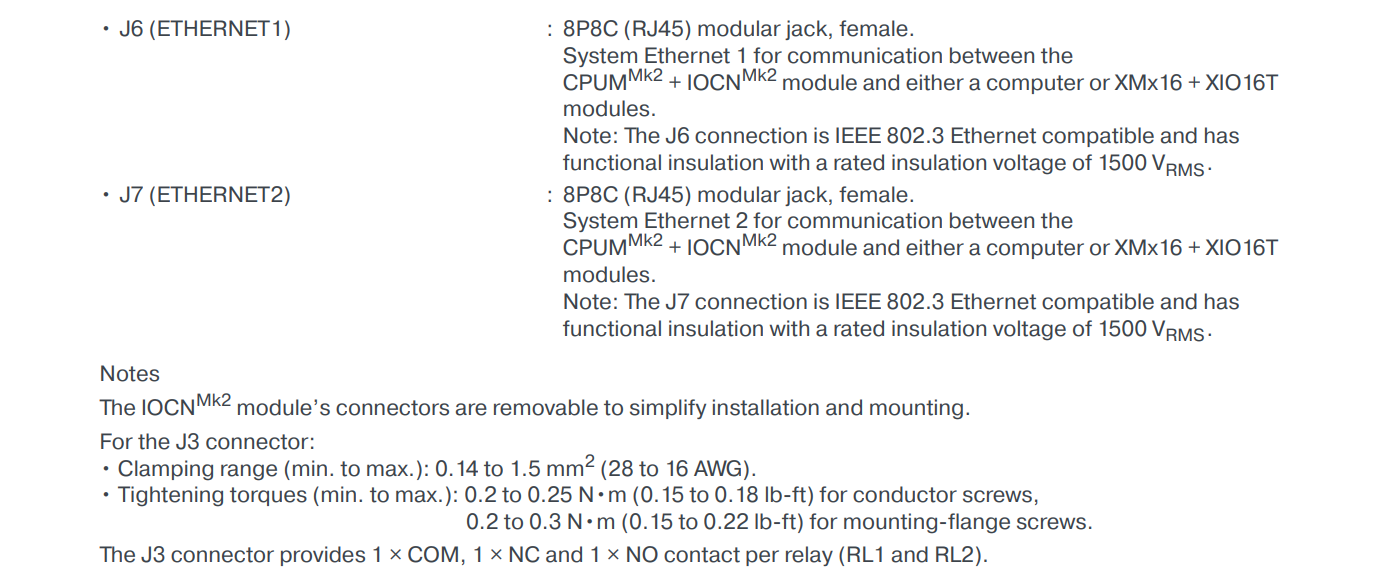

The IOCN Mk2 module provides multiple communication interfaces supporting system Ethernet and fieldbus communication:

System Ethernet Interfaces:

Two 10/100/1000BASE-T(X) Ethernet ports (ETHERNET1 and ETHERNET2)

Support for gigabit communication (up to 1 Gbps)

Used for communication with VibroSight® software and XMx16 + XIO16T modules

Fieldbus Interfaces:

Two independent fieldbus ports (FIELDBUS1 and FIELDBUS2)

Each port contains one RS-485 serial interface and one Ethernet interface

Support for Modbus TCP and PROFIBUS DP protocols

Support for simultaneous operation of dual fieldbuses, enabling communication redundancy

2. Signal Protection Functions

Provides electromagnetic interference (EMI) and surge protection for all input signals

Complies with electromagnetic compatibility (EMC) standards

RS-485 interface isolation voltage: 700 Vrms

Ethernet interface isolation voltage: 1500 Vrms

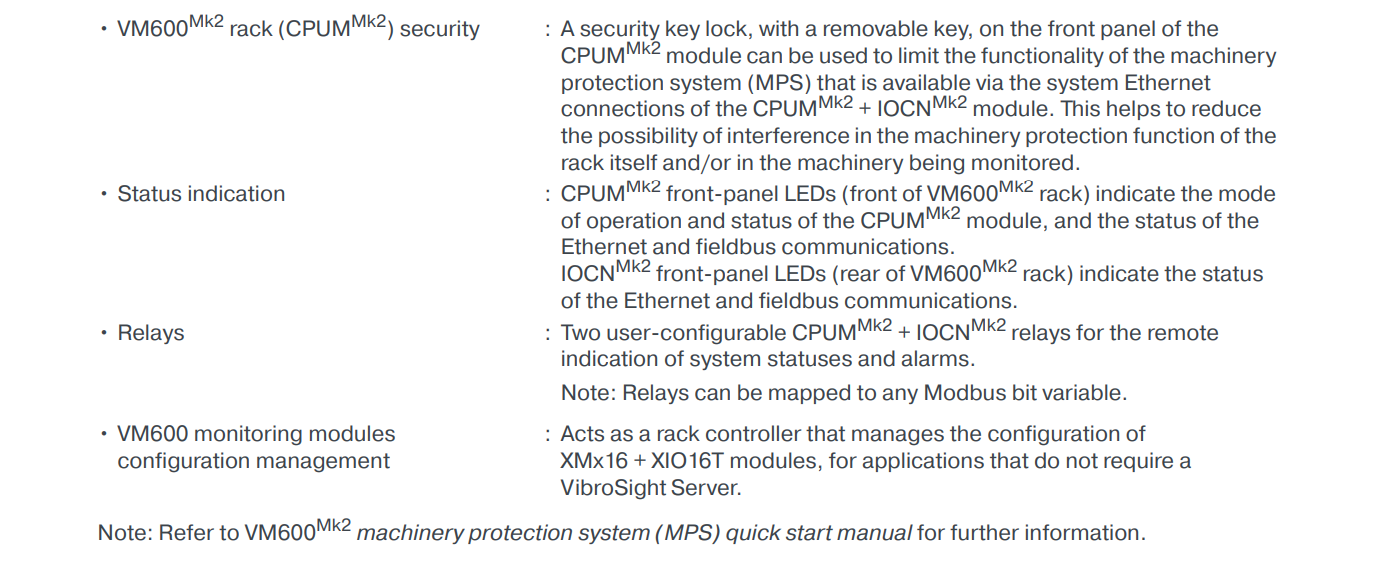

3. Relay Output Functions

Two user-configurable relays (RL1 and RL2)

Single-pole double-throw (SPDT / Form C) type

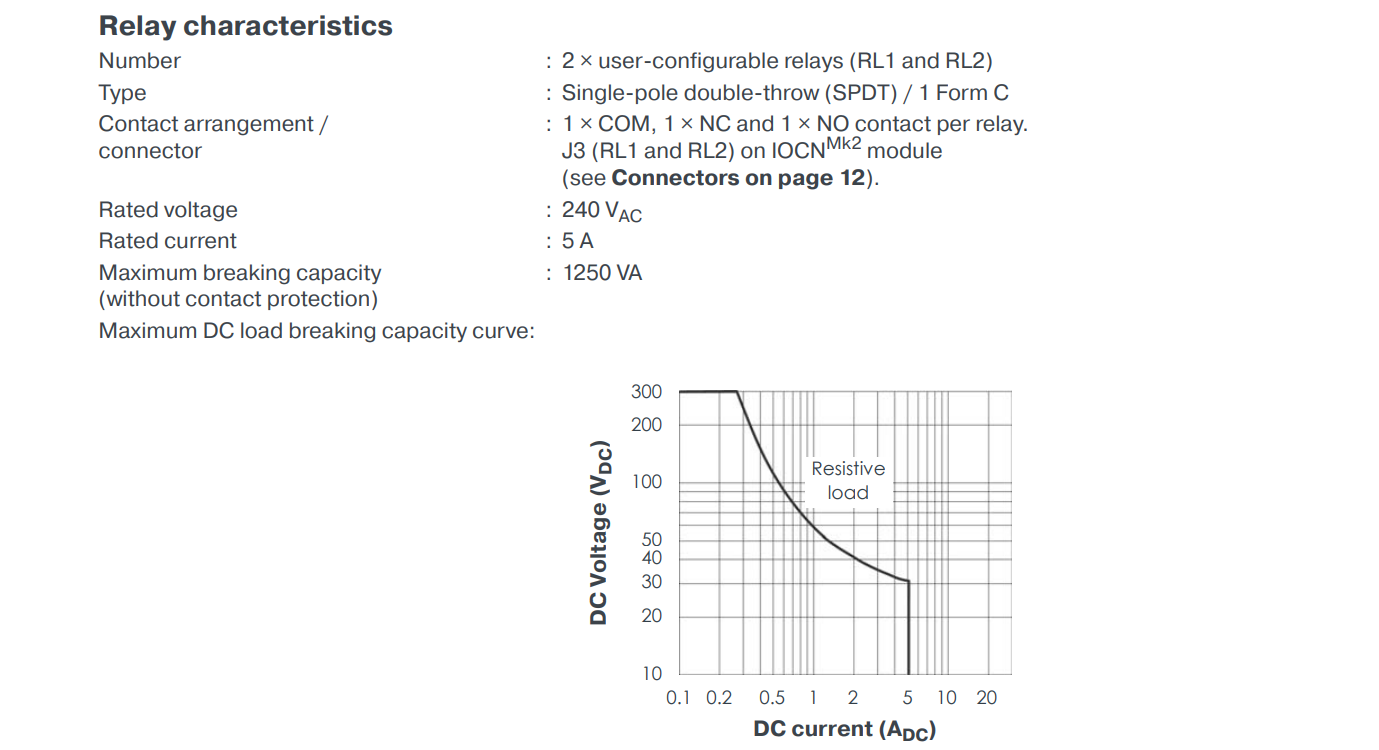

Rated voltage: 240 VAC, rated current: 5 A

Can be mapped via Modbus bit variables for remote indication of system status and alarm information

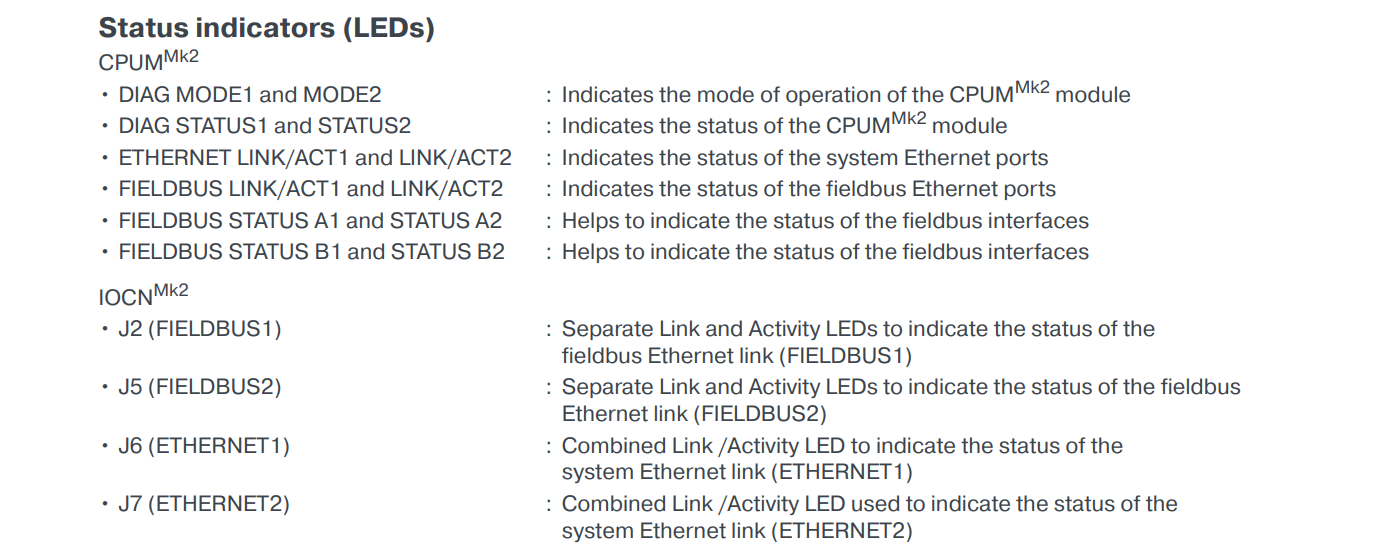

4. Status Indication Functions

Front panel equipped with multiple LED indicators

Displays system Ethernet and fieldbus communication status

Provides link and activity status indications

5. Hot-Swapping Support

Supports module hot-swapping functionality

System automatically recognizes and reconfigures, improving system availability and maintenance efficiency

Working Principle

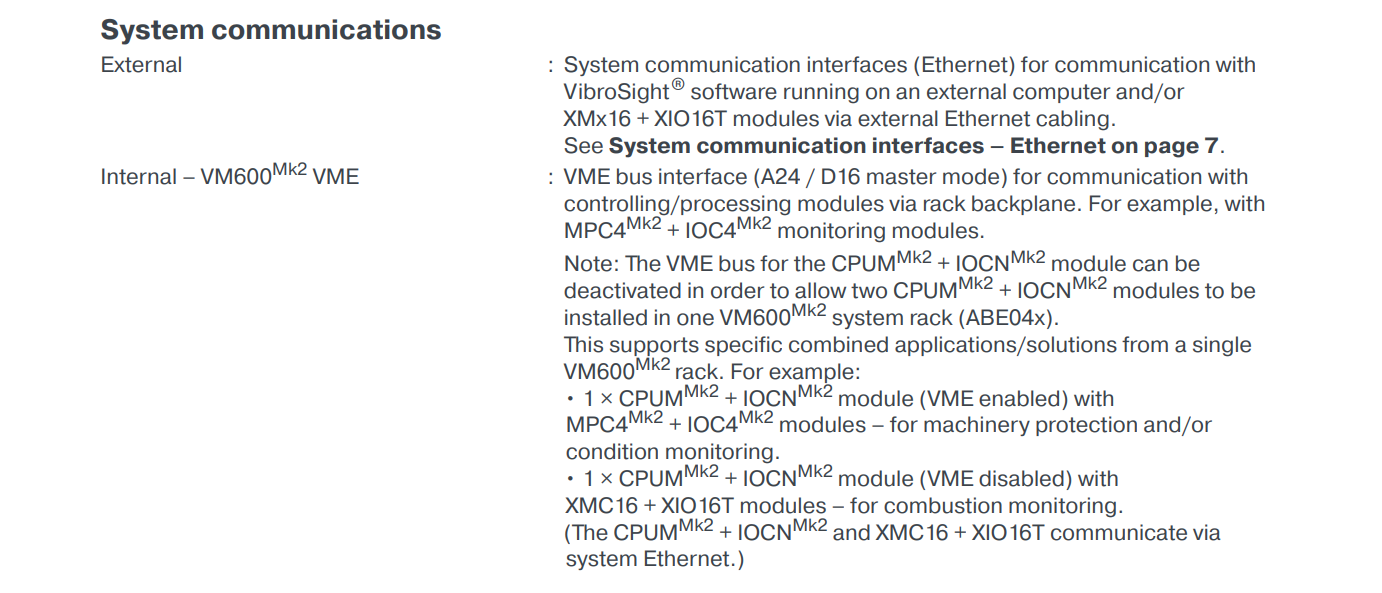

1. System Architecture and Role Positioning

The IOCN Mk2 module serves as a signal and communication interface extension for the CPUM Mk2, exchanging data with the CPUM Mk2 via the VM600 Mk2 rack backplane. Its main roles include:

Communication Interface Role:

Provides physical connection interfaces, converting CPUM Mk2's logical communication functions into actual physical signals

Manages all external communication connections, including system Ethernet and fieldbus interfaces

Provides electrical isolation and protection, ensuring stable system operation in harsh industrial environments

Signal Interface Role:

Provides relay output interfaces, converting system status and alarm information into dry contact signals

Manages electrical characteristic matching and protection for all input and output signals

2. Data Flow Processing

The data processing flow of the IOCN Mk2 in the system is as follows:

Data Reception Path:

Receives control commands and data requests from external devices (such as DCS, PLC) via fieldbus

Receives configuration and monitoring commands from VibroSight software via system Ethernet

Converts these signals into formats suitable for backplane transmission and passes them to the CPUM Mk2 for processing

Data Transmission Path:

Receives processed data and status information from the CPUM Mk2

Transmits data to third-party systems via fieldbus interfaces

Sends data to monitoring software via system Ethernet interfaces

Outputs specific status information through relays based on configuration

3. Electrical Isolation Mechanism

The IOCN Mk2 employs a multi-level electrical isolation design:

Fieldbus interfaces use magnetic or optical isolation technology

System Ethernet interfaces use transformer isolation

Relay outputs use physical isolation

All interfaces meet the isolation requirements of relevant safety standards

4. Redundancy Working Mechanism

When configured in redundancy mode, two IOCN Mk2 modules work collaboratively:

Interfaces of both master and slave modules are simultaneously activated, providing redundant communication paths

Automatic link status detection enables seamless switching

Supports complex communication configurations to meet high availability requirements

Technical Specifications Summary

Power Requirements: Powered by VM600 RPS6U rack power supply, 5VDC, maximum power consumption 1W

Operating Temperature: 0°C to 65°C (depending on relay load)

Communication Interfaces: 2 system Ethernet (10/100/1000BASE-T), 2 fieldbus ports

Isolation Voltage: RS-485 interface 700Vrms, Ethernet interface 1500Vrms

Compliance Standards: CE, EN 61010-1, EN 61326-3-1, RoHS, etc.

Application Scenarios

The IOCN Mk2 module is suitable for the following scenarios:

Vibration protection and condition monitoring systems for turbines (steam, gas, hydro) in power plants

Monitoring of rotating machinery such as compressors, pumps, and fans in the oil and gas industry

Critical applications requiring high availability and redundant configurations

Integration with control systems such as DCS and PLC for data sharing and linked control