The VM600 CPUM is a high-performance modular CPU card from VM product line, specifically designed for VM600 rack-based monitoring systems. Serving as the core control and communication unit of the system, the CPUM undertakes critical roles in rack management, data exchange, and communication coordination. It is suitable for medium to large rotating machinery protection and condition monitoring systems, widely used in power generation, oil and gas, metallurgy, and other industrial sectors, providing reliable, real-time monitoring and protection for critical equipment.

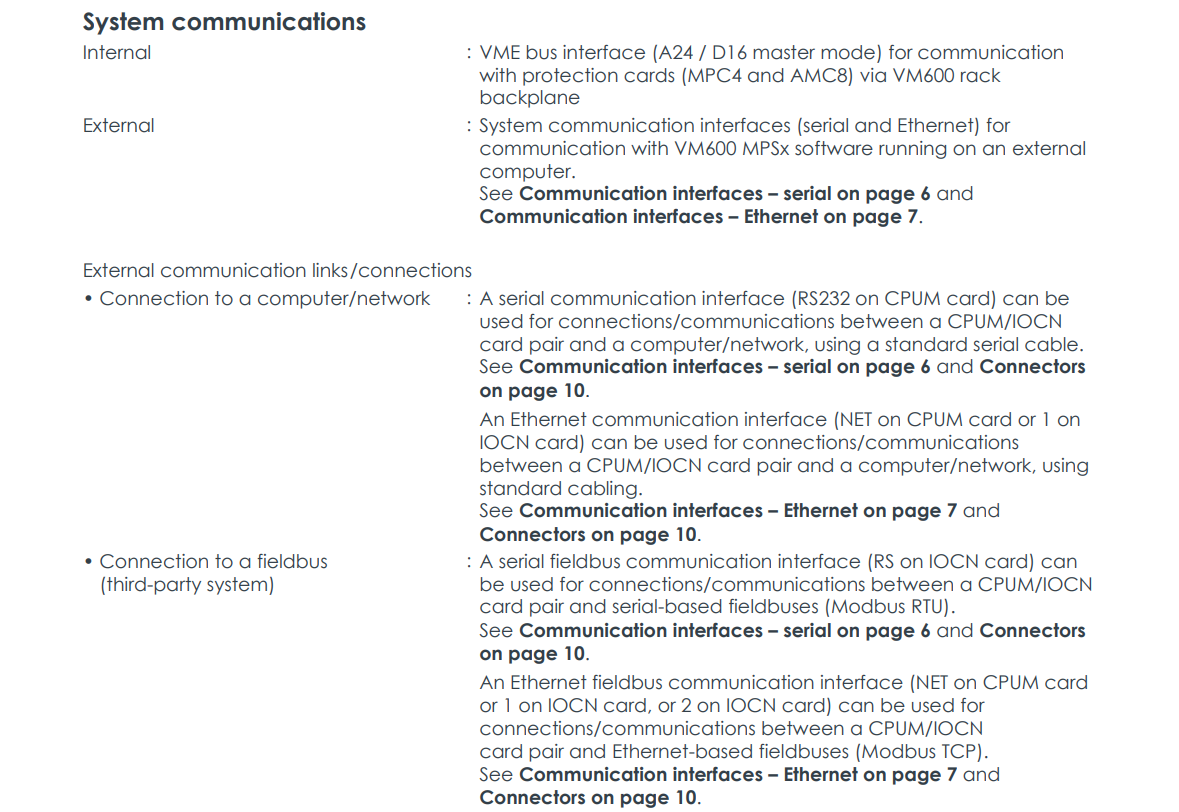

The CPUM card occupies a central position in the control layer of the VM600 system. Its main functions include rack management, data acquisition, protocol conversion, and communication coordination. It exchanges data with other monitoring cards in the rack (such as MPC4 and AMC8 protection cards) via the VME bus, while communicating with external computers (running VM600 MPSx software) or third-party systems (such as DCS or PLC) through Ethernet or serial interfaces. The CPUM can operate independently or be paired with an IOCN input/output card to expand communication interfaces and enhance the system's anti-interference capability.

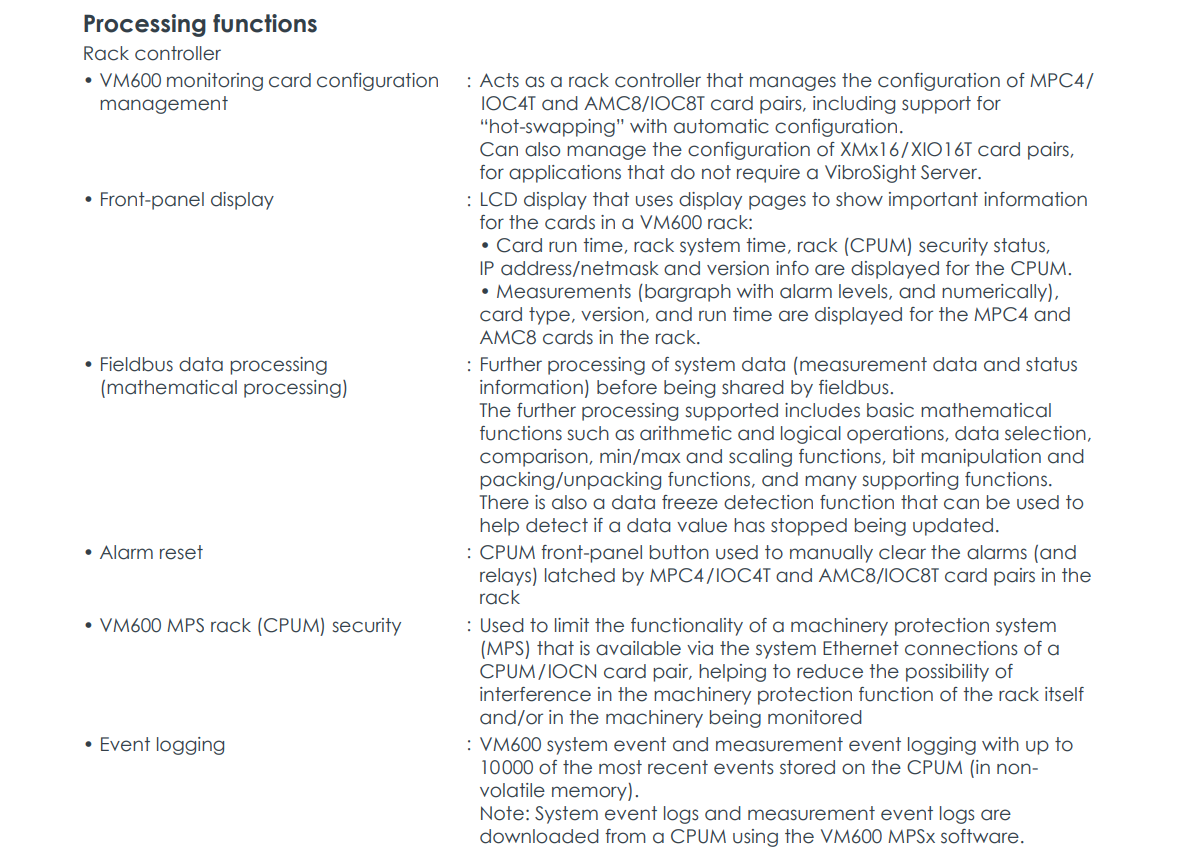

Key Features and Functions

Centralized Configuration and Hot-Swapping Support

The CPUM supports unified configuration and management of all monitoring cards in the rack through VM600 MPSx software, significantly simplifying system commissioning and maintenance processes. In conjunction with the VM600 backplane bus structure, the CPUM can automatically recognize newly inserted monitoring cards and load corresponding configurations, enabling true hot-swapping operation and greatly improving system availability and maintainability.

Powerful Communication Gateway Functionality

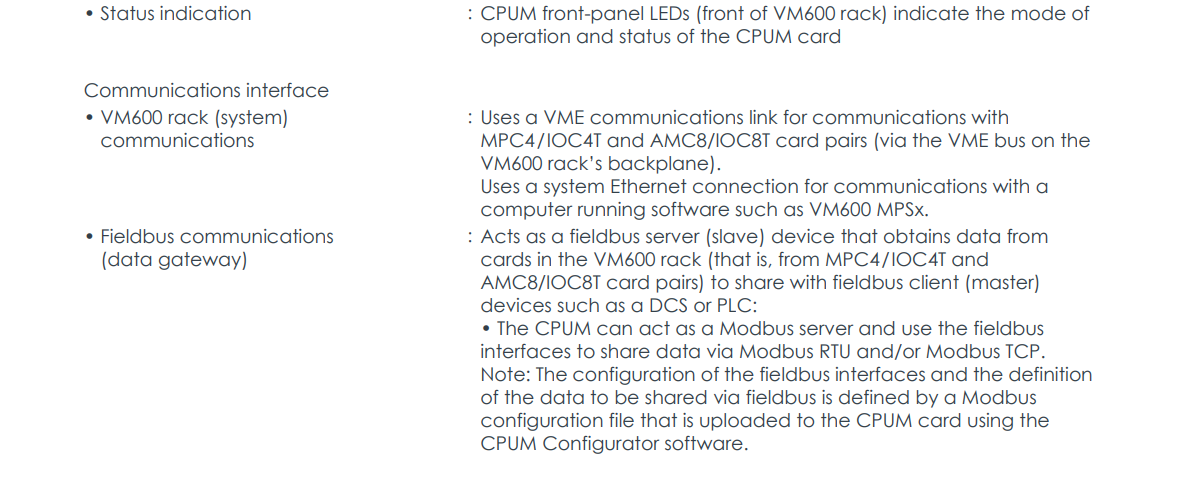

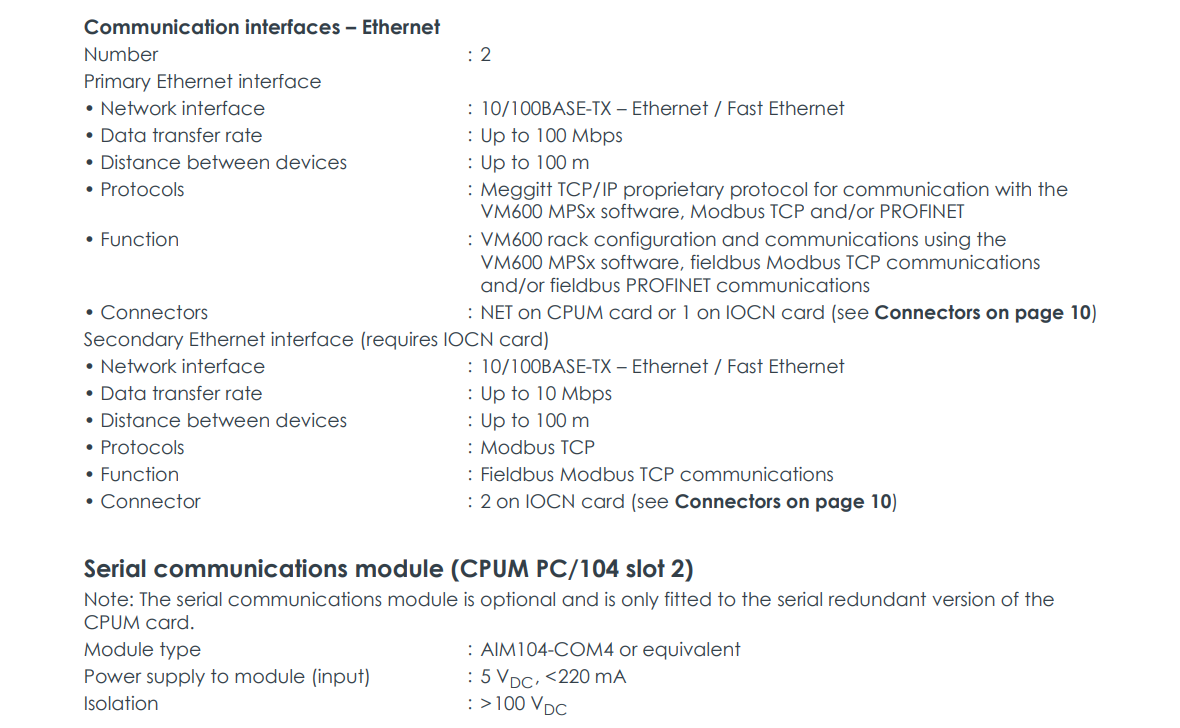

The CPUM provides multiple industrial standard communication interfaces:

2 Ethernet interfaces (10/100BASE-TX), supporting Modbus TCP, PROFINET, and Meggitt proprietary protocols

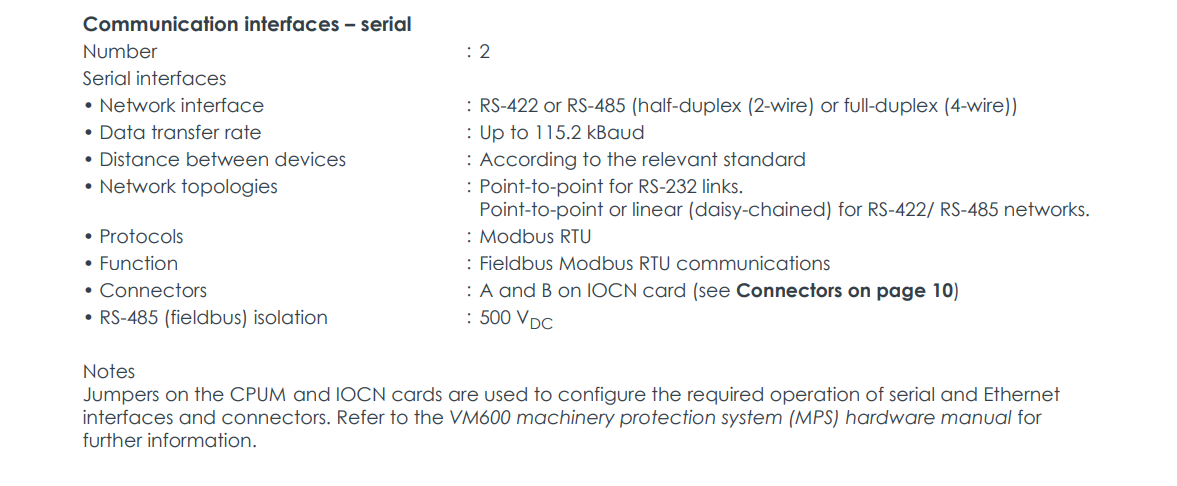

2 serial interfaces, supporting RS-232/RS-422/RS-485 standards and Modbus RTU protocol

Support for redundant communication configuration, enhancing system reliability through primary/backup communication links

These interfaces enable the CPUM to act as a data gateway, transmitting monitoring data from the rack to upper-level monitoring systems in real time.

Front Panel Display and Operation Interface

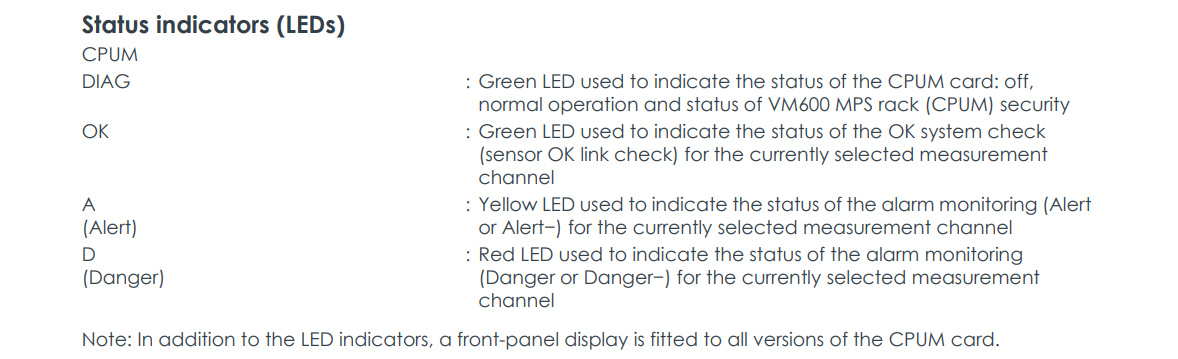

The CPUM features an LCD display and operation buttons on its front panel, enabling real-time display of:

Measurement values and alarm status of currently selected channels

System operational status and communication status

Alarm limits and bar graph displays

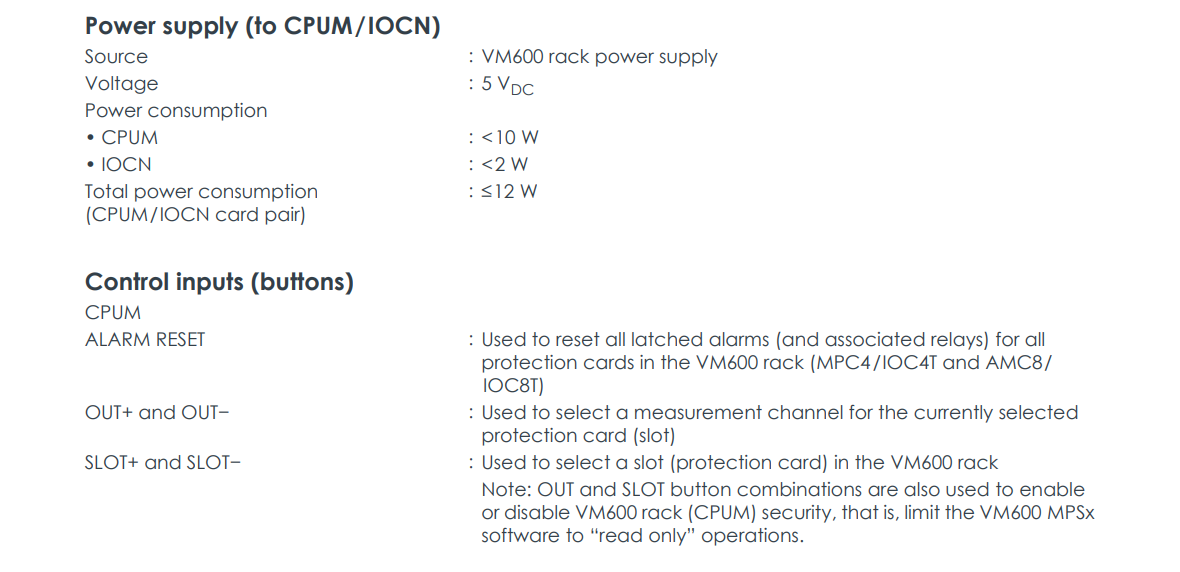

Using the front panel SLOT± and OUT± buttons, operators can easily browse information from different slots and channels. A dedicated ALARM RESET button allows one-key reset of all latched alarm states of protection cards in the rack.

System Security and Event Logging

The CPUM provides multi-level security protection mechanisms:

Hardware access lock (CPUM access lock) prevents unauthorized physical operations

Software password validation (MPSx password validation) restricts configuration modification privileges

The system automatically logs operational events and measurement events, storing up to 10,000 event records, providing complete historical data for system maintenance and fault diagnosis.

High-Reliability Design

Utilizes industrial-grade AMD Geode™ LX800 500MHz processor

Equipped with 256MB DRAM memory

Runs on QNX real-time operating system

Operating temperature range: -20°C to 65°C

Supports dual Ethernet redundancy and serial communication redundancy

Detailed Working Principle

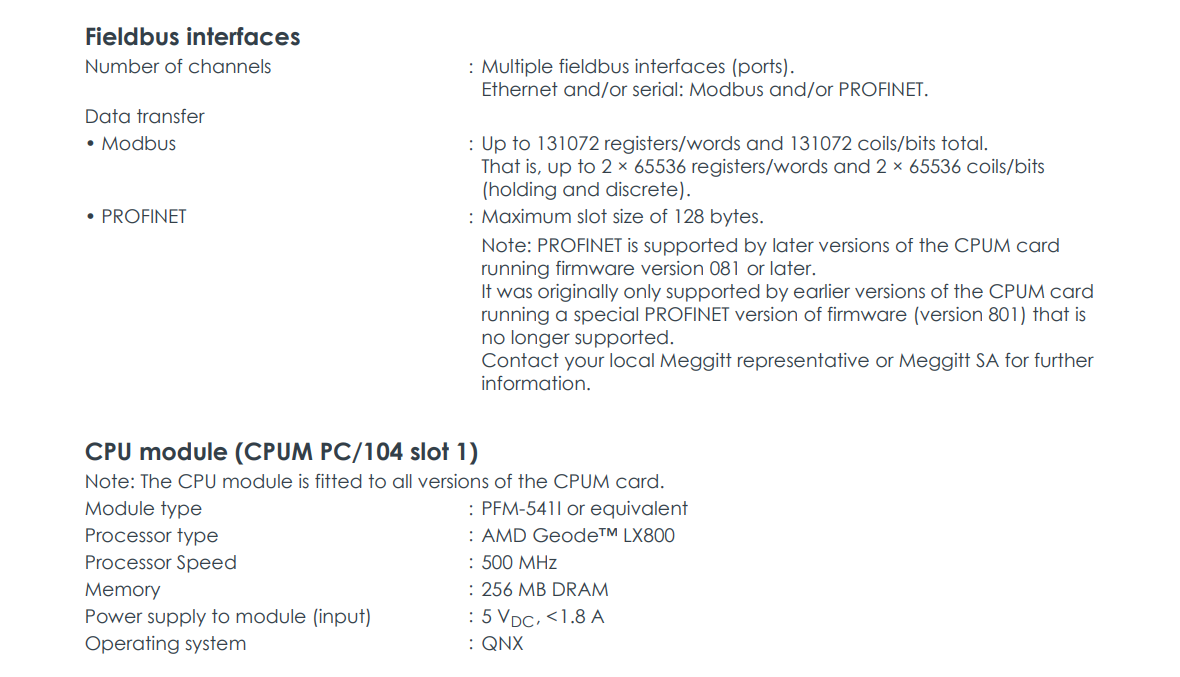

The CPUM adopts an advanced modular design concept. Its core is an embedded system based on PC/104 architecture. The card main body is a carrier board providing two PC/104 expansion slots. The first slot accommodates a standard CPU module, while the second slot can optionally accommodate a serial communication module to expand additional serial ports.

Data Processing Mechanism:

The CPUM exchanges data with other monitoring cards in the rack through the VME bus. It periodically reads output data from various monitoring cards (including vibration values, temperature, pressure, and other parameters) and performs necessary format conversion and alarm judgment. For XMx16 series monitoring cards connected via Ethernet, the CPUM obtains data through TCP/IP protocol.

Communication Protocol Processing:

As the communication hub of the system, the CPUM implements multi-level protocol conversion functions. It converts internal data formats into standard industrial protocol formats (such as Modbus register mapping), enabling external systems to access data in familiar ways. For example, vibration velocity values are mapped to specific Modbus holding registers, allowing DCS systems to obtain real-time data by regularly reading these registers.

Real-Time Control Function:

The CPUM runs on the QNX real-time operating system, ensuring rapid response to system events. It continuously monitors the status of each monitoring card, and any abnormal conditions (such as card failure, communication timeout, or alarm triggering) are immediately detected and processed. The front panel human-machine interaction functions (button scanning, LCD display driving, LED status indication) are also processed in real time by the CPUM, ensuring timely operational response.

System Management Function:

The CPUM is responsible for configuration management and operational monitoring of the entire rack. It stores configuration information for all monitoring cards and automatically loads corresponding configurations during system startup or card replacement. The event management system continuously records system operational status, providing maintenance personnel with complete system operational history.

Redundancy and Fault Tolerance Mechanisms:

The CPUM supports multiple redundant configuration methods. In terms of communication, it supports automatic switching between primary and backup Ethernet and serial links. In terms of system security, dual protection mechanisms through both hardware and software ensure the security of system configuration.

Hardware Architecture and Performance Parameters

Processor System:

Main processor: AMD Geode™ LX800, 500MHz

Memory: 256MB DRAM

Storage: On-board Flash memory for system programs and configuration storage

Operating system: QNX real-time operating system

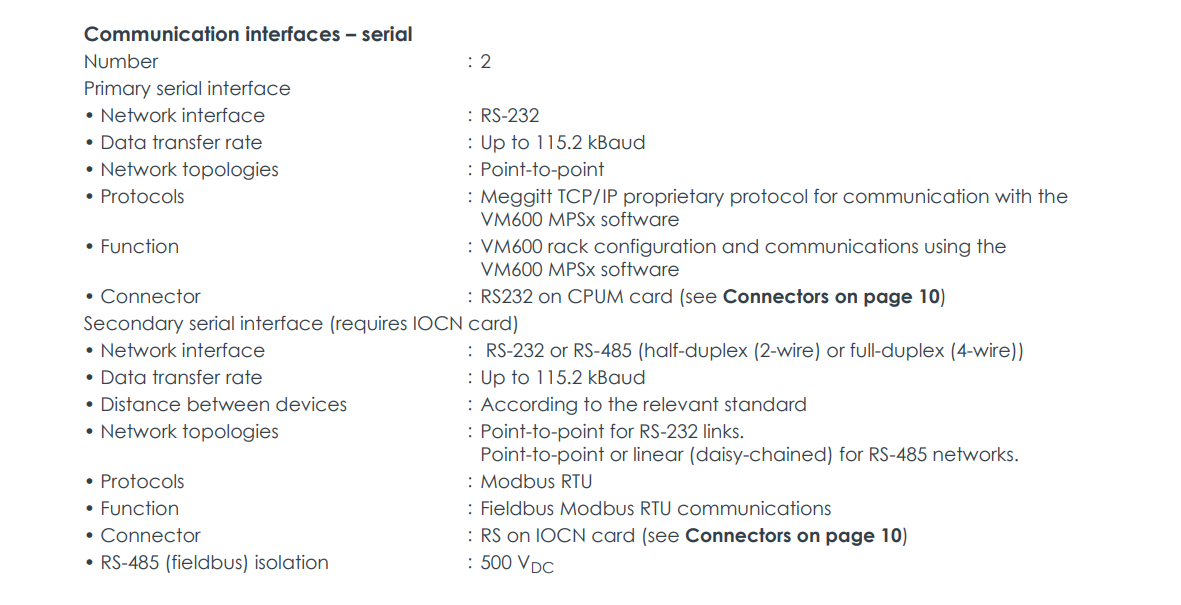

Communication Interfaces:

Primary Ethernet interface: 10/100BASE-TX, supporting Modbus TCP, PROFINET

Secondary Ethernet interface: 10/100BASE-TX, supporting Modbus TCP

Primary serial interface: RS-232, up to 115.2kbps

Secondary serial interface: RS-232/RS-485, up to 115.2kbps

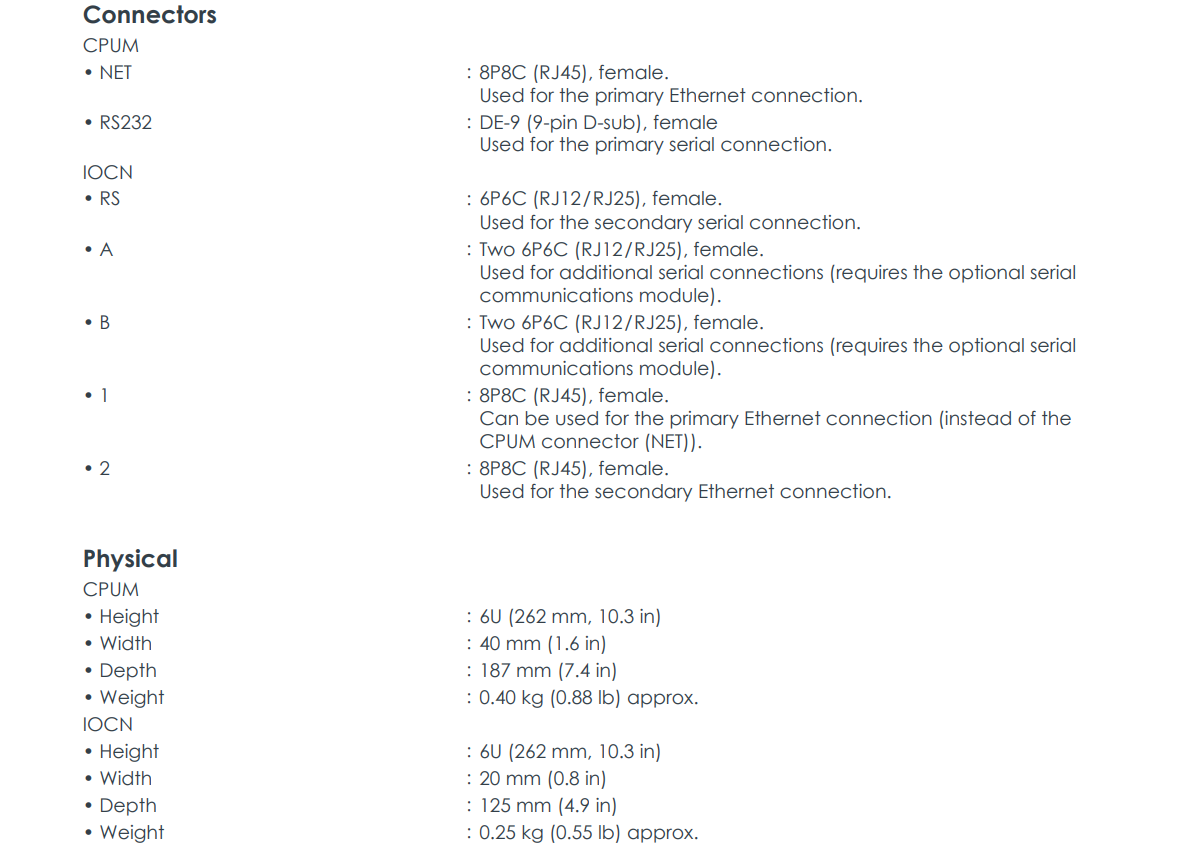

Physical Characteristics:

Card dimensions: 6U height (262mm) × 40mm width × 187mm depth

Weight: Approximately 0.40kg

Power requirements: 5VDC, <10W

Installation method: Front slot of VM600 rack (occupying two slots)

Typical Application Scenarios

Power Plant Turbine Unit Monitoring

In large power plants, the CPUM serves as the core of the VM600 system, continuously monitoring critical parameters of turbines such as vibration, displacement, and speed, and transmitting data to the plant's main control system via Modbus TCP.

Oil and Gas Compressor Monitoring

In compressor station applications, the CPUM uploads vibration trends and spectrum data to the control system via PROFINET or Modbus RTU networks, providing data support for predictive maintenance.

Large Water Pump Unit Protection

Used for large water pump units in hydraulic engineering projects, providing real-time monitoring of operational status to ensure equipment safety.