The 3500/50M Tachometer Module is a high-performance, dual-channel machinery condition monitoring module developed by Bently Nevada, designed for monitoring rotational speed, acceleration, and direction of rotating equipment. This module accepts input signals from proximity probes or magnetic pickups, enabling real-time calculation of shaft rotational speed, rotor acceleration, and rotation direction. It utilizes user-programmable alarm setpoints to implement intelligent alarm management. The 3500/50M module offers high configuration flexibility and supports multiple monitoring modes, making it suitable for critical equipment protection and condition monitoring across various industrial environments.

Integrated into the 3500 Monitoring System, the module works synergistically with other system modules to provide reliable machinery protection and early warning functions. Its design complies with numerous international standards and carries hazardous area certifications, making it applicable for high-risk industries such as marine, oil & gas, power generation, and chemicals.

2. Key Features

2.1 Dual-Channel Input Support

The 3500/50M module features two independent channels that can simultaneously accept signals from two types of sensors:

Proximity Probes: Suitable for high-precision speed measurement, supporting low to high-speed ranges.

Magnetic Pickups: Suitable for medium to high-speed monitoring, but not recommended for reverse rotation or zero-speed detection.

2.2 Multiple Monitoring Modes

Users can select the following operational modes via the 3500 Rack Configuration Software:

Speed Monitoring with Setpoint Alarming: Monitors speed in real-time and triggers alarms.

Speed Monitoring with Speed Band Alarming: Alarms when speed deviates outside a defined range.

Speed Monitoring with Zero Speed Notification: Detects whether equipment has stopped rotating.

Speed Monitoring with Rotor Acceleration Alarming: Monitors rotor acceleration to prevent overspeed risks.

Speed Monitoring with Reverse Rotation Notification: Detects if the shaft is rotating in reverse.

2.3 Peak Hold Function

The module includes a peak hold capability that records and stores:

2.4 Conditioned Keyphasor Signal Output

The 3500/50M module can provide conditioned Keyphasor signals to the 3500 rack backplane for use by other monitoring modules (e.g., vibration monitors). This eliminates the need for a separate Keyphasor module, saving rack space and cost.

2.5 Alarm Management

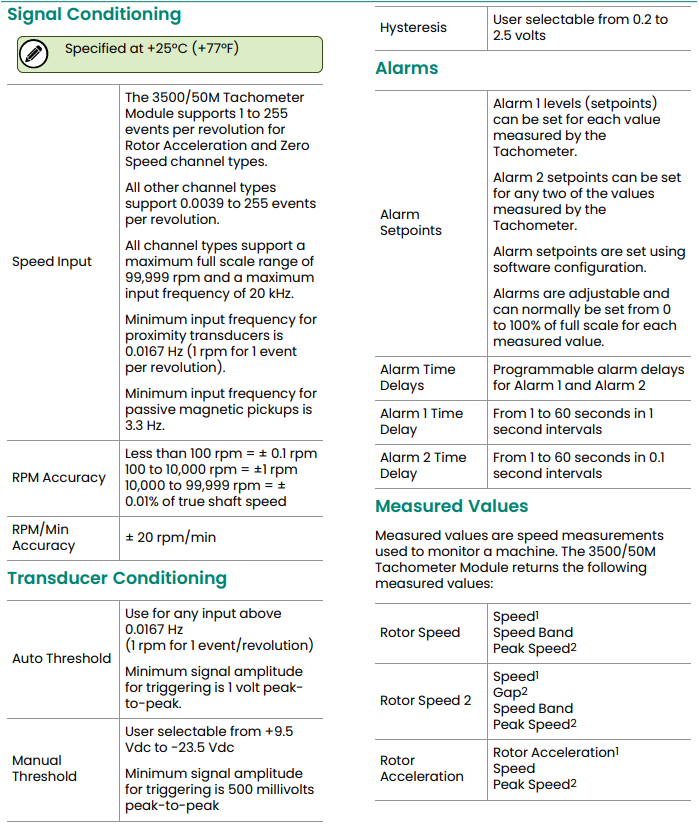

Two-Level Alarming: Alarm 1 and Alarm 2 can be set independently for different severity levels.

Programmable Alarm Delays: Alarm 1 delay is configurable from 1 to 60 seconds; Alarm 2 delay from 0.1 to 60 seconds, helping to prevent false alarms.

Flexible Setpoints: Alarm values can typically be set from 0% to 100% of the full-scale range for each measured value, accommodating different equipment requirements.

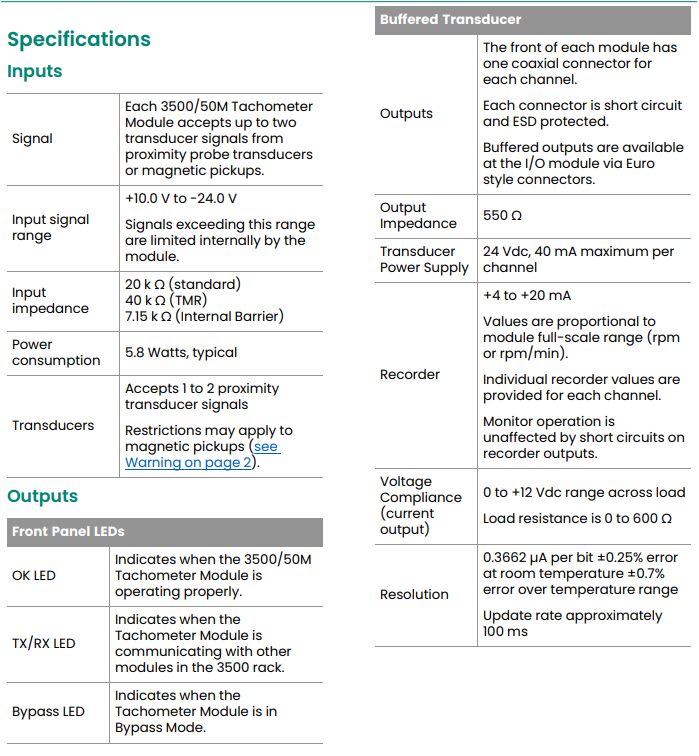

2.6 Analog Output & Recorder Interface

The module provides a 4–20 mA analog output suitable for data loggers, chart recorders, or display devices. Output impedance is 550 Ω, with a voltage compliance range of 0–12 Vdc and a maximum load resistance of 600 Ω.

2.7 Status Indication & Communication

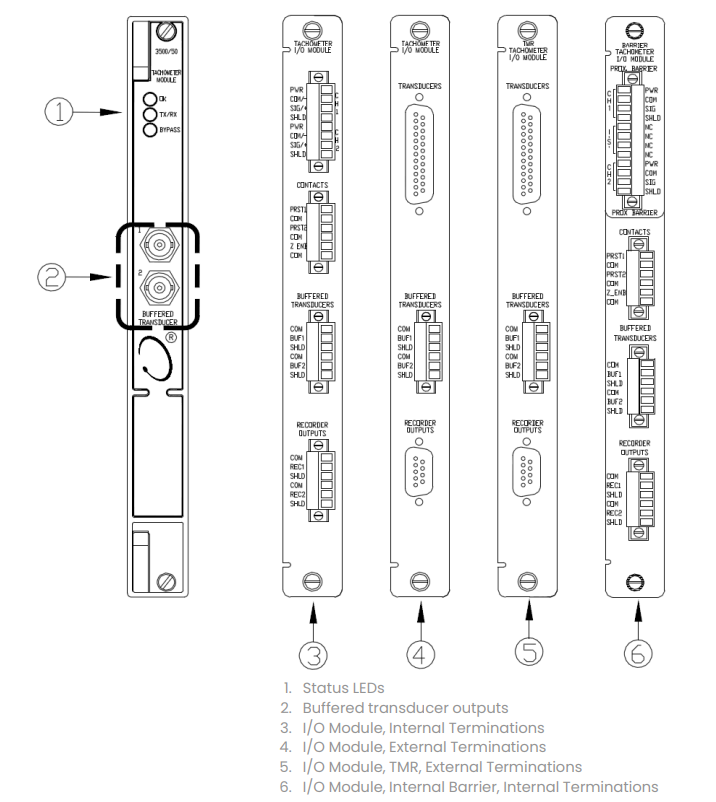

The front panel features three-color LED indicators:

OK LED: Indicates normal module operation.

TX/RX LED: Indicates communication status with other modules in the 3500 rack.

Bypass LED: Indicates the module is in Bypass Mode.

3. Detailed Working Principle

3.1 Signal Input & Conditioning

The 3500/50M module accepts voltage signals from proximity probes or magnetic pickups. The input signal range is –24 V to +10 V; signals exceeding this range are limited internally for protection. Module input impedance comes in three variants:

The module conditions the input signal using either Auto Threshold or Manual Threshold:

Auto Threshold: Used for signals with a frequency above 0.0167 Hz (equivalent to 1 rpm for 1 event/revolution). The minimum trigger signal amplitude is 1 V peak-to-peak.

Manual Threshold: Allows users to set the trigger threshold between +9.5 Vdc and –23.5 Vdc. The minimum trigger signal amplitude is 500 mV peak-to-peak.

3.2 Speed Calculation & Accuracy

The module calculates rotational speed based on the number of events per revolution (supporting 0.0039 to 255 events/rev for most channel types, and 1 to 255 for Rotor Acceleration and Zero Speed types). The maximum full-scale range is 99,999 rpm, with a maximum input frequency of 20 kHz. Speed accuracy is defined across three ranges:

3.3 Acceleration Monitoring

For rotor acceleration monitoring, the module supports 1 to 255 events per revolution, with an accuracy of ±20 rpm/min. The acceleration value is derived from the rate of change of speed, aiding in the prediction of abnormal behavior during equipment acceleration.

3.4 Direction Detection & Zero-Speed Determination

The module determines the direction of rotation by analyzing the phase or pulse sequence of the sensor signals.

Important Note: Magnetic pickups are not recommended for reverse rotation or zero-speed detection because the signal edges are not clean at low speeds, potentially leading to incorrect indications.

Zero-speed detection is based on whether the signal frequency falls below a set threshold, typically used to determine if the equipment has completely stopped.

3.5 Alarm Logic & Output

The module continuously compares real-time calculated parameters (speed, acceleration, direction, etc.) against user-defined alarm setpoints. If a parameter exceeds its set limit, the module triggers the corresponding alarm output. Alarm signals can be relayed to the control system via relays or communication interfaces.

3.6 Communication & Data Interface

The 3500/50M module communicates with the system via the 3500 rack backplane, interfacing with communication gateway modules (e.g., 3500/92) to upload measurement data to higher-level systems. The module supports industrial protocols like Modbus and OPC, enabling easy integration into DCS or SCADA systems.

4. Technical Characteristics

High-Precision Measurement:

Below 100 rpm: ±0.1 rpm

100-10,000 rpm: ±1 rpm

10,000-99,999 rpm: ±0.01% of true shaft speed

Acceleration accuracy: ±20 rpm/min

Wide Range Capability:

Maximum full scale: 99,999 rpm

Maximum input frequency: 20 kHz

Minimum input frequency for proximity probes: 0.0167 Hz (corresponding to 1 rpm for 1 event/revolution)

Minimum input frequency for magnetic pickups: 3.3 Hz

Flexible Input Configuration:

5. Environmental Adaptability:

6. Safety Certifications:

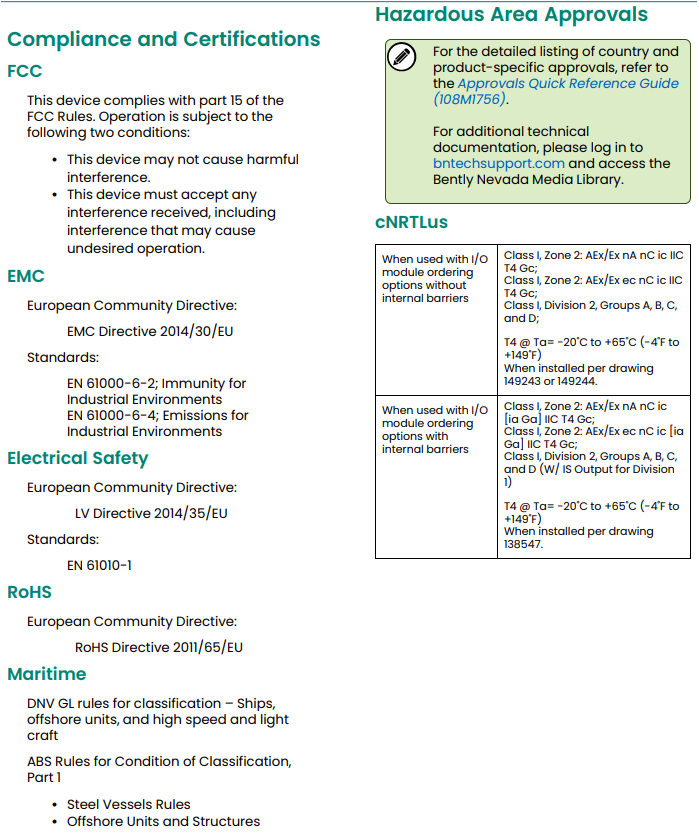

Complies with FCC, EMC, LV Directive, RoHS, ATEX, IECEx, CSA and other international standards

Suitable for hazardous areas (Class I, Division 2/Groups A,B,C,D or Class I, Zone 2)

7. Important Warning

It is important to note that the 3500/50M Tachometer Module must not be used independently or as a component of a speed control or overspeed protection system, as it does not provide protective redundancy or the response speed required for reliable operation as a speed control or overspeed protection system. The analog proportional output is suitable for data logging, chart recording, or display purposes only. Speed alert setpoints are suitable for annunciation purposes only.

For magnetic pickups: Do not use magnetic pickups for the reverse rotation option or zero speed option, otherwise false indications of rotation direction may occur. The transducers do not provide a clean edge for the detection circuit during low speeds.

8. Physical Characteristics

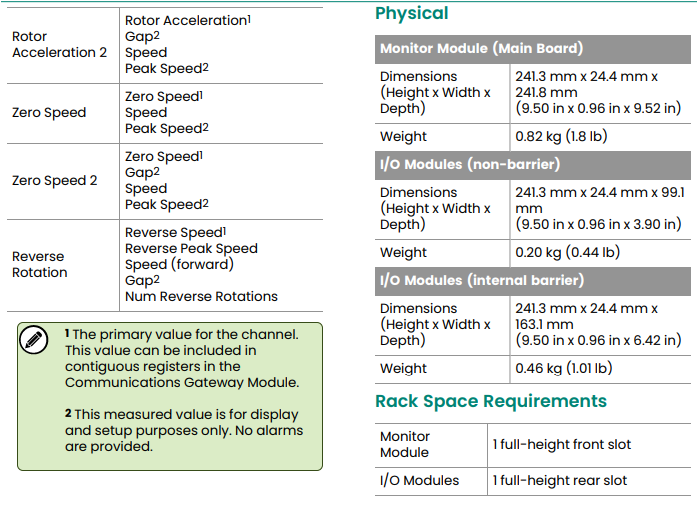

Monitor Module (Main Board):

Dimensions: 241.3 mm × 24.4 mm × 241.8 mm

Weight: 0.82 kg

I/O Modules:

Non-barrier version: 241.3 mm × 24.4 mm × 99.1 mm, weight 0.20 kg

Internal barrier version: 241.3 mm × 24.4 mm × 163.1 mm, weight 0.46 kg

Rack Space Requirements:

Monitor Module: Occupies 1 front slot

I/O Module: Occupies 1 rear slot

9. Applications

The 3500/50M Tachometer Module is specifically designed for rotating machinery in the following fields:

Power Plants: Speed monitoring and protection for steam turbines, gas turbines, and hydro turbines

Petrochemical Industry: Speed monitoring and overspeed protection for compressors and pumps

Metallurgical Industry: Speed monitoring for rolling mills and fans

Marine Propulsion: Speed and rotation direction monitoring for propulsion shaft systems

Industrial Drives: Speed monitoring for large motors and gearboxes