The 3500/62 Process Variable Monitor is a high-performance, multi-functional industrial-grade process variable monitoring device under the 3500 Machinery Protection Systems, serving as a critical component of the 3500 Machinery Protection System. It is specifically designed for the continuous monitoring and protection of process parameters essential to the operation of critical mechanical equipment. These parameters include, but are not limited to, pressure, flow, level, temperature (via transmitters), and other physical quantities that can be converted into standard electrical signals.

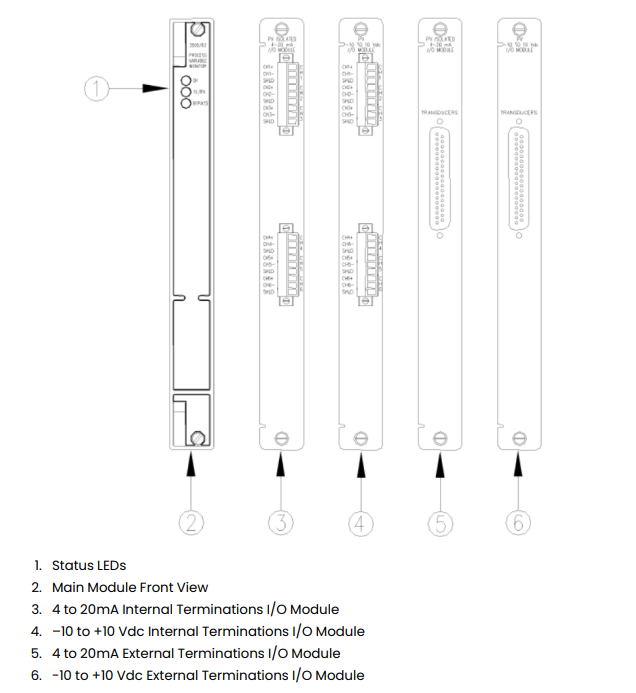

The 3500/62 consists of a fixed front module (P/N 163179-03) and five different types of rear I/O modules (see the Ordering page for details). The 163179-03 can form a complete system when combined with any one of the rear I/O modules.

The 3500/62 module provides six channels of analog signal monitoring, capable of accepting +4 to +20 mA current signals or -10 Vdc to +10 Vdc voltage signals. Its core functionalities include high-precision signal conditioning, user-programmable alarm settings, comprehensive front-panel status indication, and backplane communication. It continuously compares monitored parameters against configured alarm setpoints to drive alarms for machinery protection and provides vital machine information for both operations and maintenance personnel.

Users can flexibly configure each channel for current or voltage measurement using the dedicated 3500 Rack Configuration Software. The module offers I/O modules for three signal input scenarios: ±10 Vdc, isolated 4-20 mA, and 4-20 mA with intrinsically safe Zener barriers, catering to different industrial environments and safety requirements.

Features & Functions

1. Multi-Channel Flexible Input

Provides 6 completely independent monitoring channels, supporting industry-standard analog signal inputs.

Voltage input range: -10 Vdc to +10 Vdc; Current input range: +4 to +20 mA.

Offers three I/O module options:

±10 Vdc Module: Suitable for directly connecting devices outputting voltage signals.

Isolated 4-20 mA Module: Provides 500 Vdc channel-to-channel isolation, effectively suppressing ground loop interference.

4-20 mA Module with Internal Barriers: Designed for hazardous areas, features built-in intrinsically safe Zener barriers, and can supply +24 Vdc @ 250 mA isolated power to field transmitters, meeting explosion-proof certification requirements such as ATEX, IECEx, and CSA.

2. High-Precision Signal Conditioning and Measurement

Utilizes a high-performance analog front end with a measurement accuracy of ±0.33% of full-scale (FS) (typical).

Input impedance is optimized for different signal types: 1 MΩ for voltage input, 50 Ω for current input.

Supports mapping the input signal span to a maximum of 20,000 engineering units, providing precise engineering value readings.

The internal transmitter power supply is protected by a 250 mA fast-blow fuse, ensuring safe and reliable power delivery.

3. Programmable Alarm Function

Each channel supports independent setting of dual alarm thresholds: "Alert" and "Danger", accommodating both over and under process variable alarms.

Alarm setpoint accuracy is as high as 0.13%, and setpoints can be freely defined within the scaled range.

Features adjustable alarm delays: Alert delay: 1-60 seconds (1-second increments); Danger delay: 1-60 seconds (0.5-second increments), effectively filtering out transient interference signals and preventing false alarms.

4. Status Indication and Communication

The front panel is equipped with tri-color LED status indicators:

OK (Green): Indicates normal module operation.

TX/RX (Green): Indicates module communication status.

Bypass (Yellow): Indicates bypass mode is active.

Facilitates real-time data exchange with the Framework Interface Module (FIM) via the 3500 backplane, uploading process variable values, alarm statuses, and module health information, enabling highly integrated system monitoring.

5. Support for Triple Modular Redundant (TMR) Configuration

Although TMR units are no longer available for sale, the module design supports TMR configuration.

In this configuration, three modules are installed side-by-side, employing voting logic to process alarms and outputs. This ensures that a failure of any single module will not cause a system false shutdown, significantly enhancing the safety and availability of critical applications.

Working Principle

1. Signal Input and Conditioning

Process variable signals are接入 (accessed) through the rear I/O module.

Voltage signals enter a high-impedance measurement circuit directly, while current signals are converted to voltage signals via a precision sampling resistor.

Isolated modules use optocoupler or magnetic coupling isolation technology to provide 500 Vdc electrical isolation, effectively suppressing common-mode interference.

Barrier modules limit energy through Zener safety barriers to achieve intrinsic safety.

The conditioned signals are converted into digital quantities by a high-precision Analog-to-Digital Converter (ADC).

2. Scaling and Engineering Value Calculation

Users define the input signal type and range for each channel using the 3500 Configuration Software.

The module's processor, typically a 32-bit DSP, performs linear mapping calculations to convert digital values into engineering unit values.

The mapping algorithm uses floating-point arithmetic to ensure conversion accuracy.

The engineering value update rate reaches 100ms, meeting real-time monitoring requirements.

The entire process requires no field calibration, greatly simplifying the commissioning process.

3. Alarm Logic Processing

Real-time engineering values are compared against preset setpoints, employing digital filtering techniques to eliminate signal jitter.

Delay timers use an independent clock source to ensure timing accuracy.

Alarm statuses are transmitted to the system framework via backplane communication, triggering relay outputs.

Simultaneously supports alarm latching and manual reset functions, providing a complete alarm management solution.

4. Communication and Data Interaction

Utilizes a high-speed backplane bus protocol with a data transfer rate of up to 10Mbps.

Supports real-time uploading of process variable values, alarm statuses, delay statuses, and module health information for all channels.

Enables remote configuration and monitoring via the 3500 Configuration Software or FIM module supporting industrial protocols like Modbus TCP and OPC UA.

Employs a double-buffering mechanism for data storage, ensuring data transmission integrity and real-time performance.

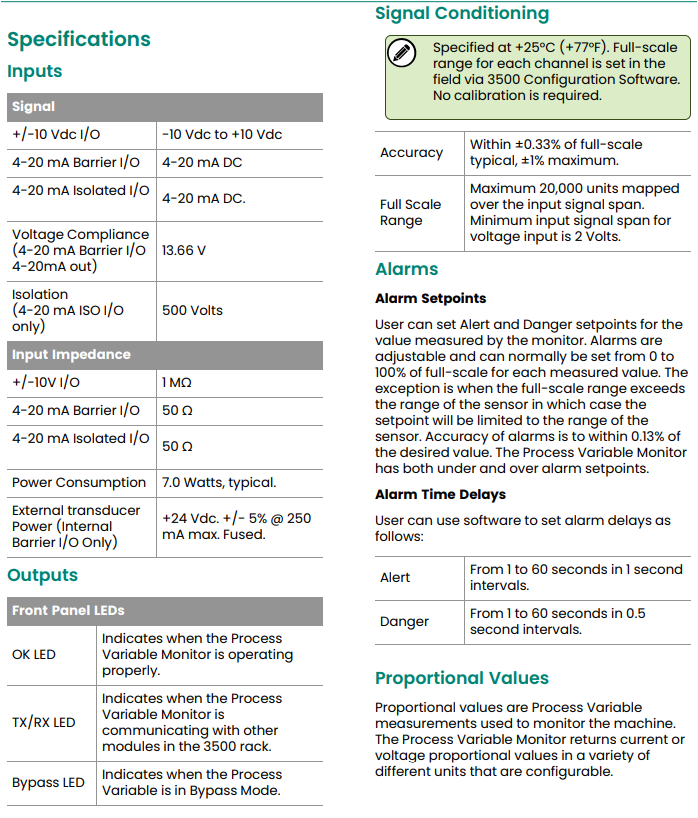

Technical Specifications

| Parameter | Specification |

| Input Channels | 6 independent channels |

| Signal Types | -10 to +10 Vdc, +4 to +20 mA |

| Input Impedance | Voltage: 1 MΩ, Current: 50 Ω |

| Measurement Accuracy | ±0.33% FS (typical) |

| Engineering Range | Max 20,000 units |

| Alarm Accuracy | ±0.13% of setpoint value |

| Alarm Delay | Alert: 1-60s (1s increments), Danger: 1-60s (0.5s increments) |

| Isolation Voltage | 500 Vdc (Isolated modules) |

| Transmitter Power | +24 Vdc ±5%, 250 mA max (Barrier modules) |

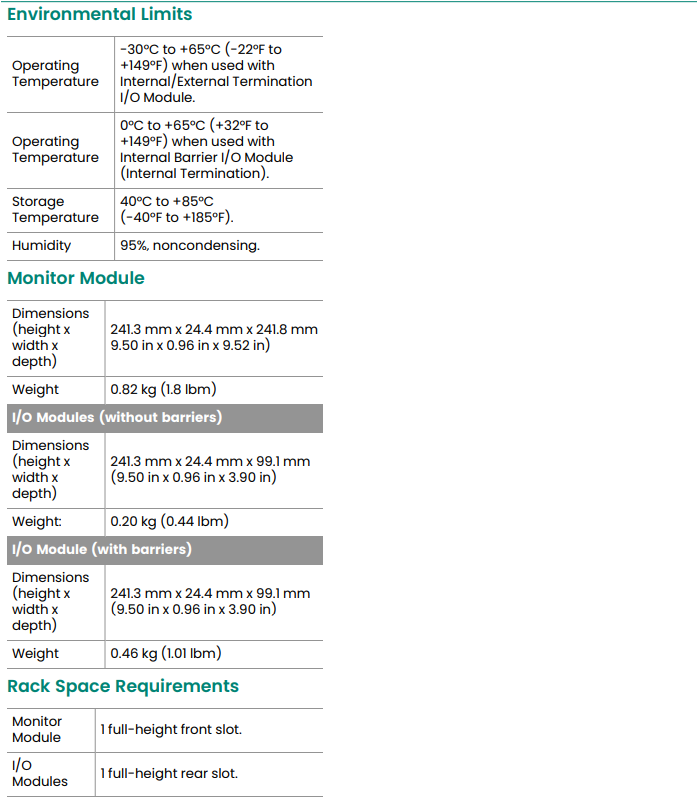

| Operating Temperature | -30 to +65°C (Standard modules), 0 to +65°C (Barrier modules) |

| Power Consumption | 7.0 W (typical) |

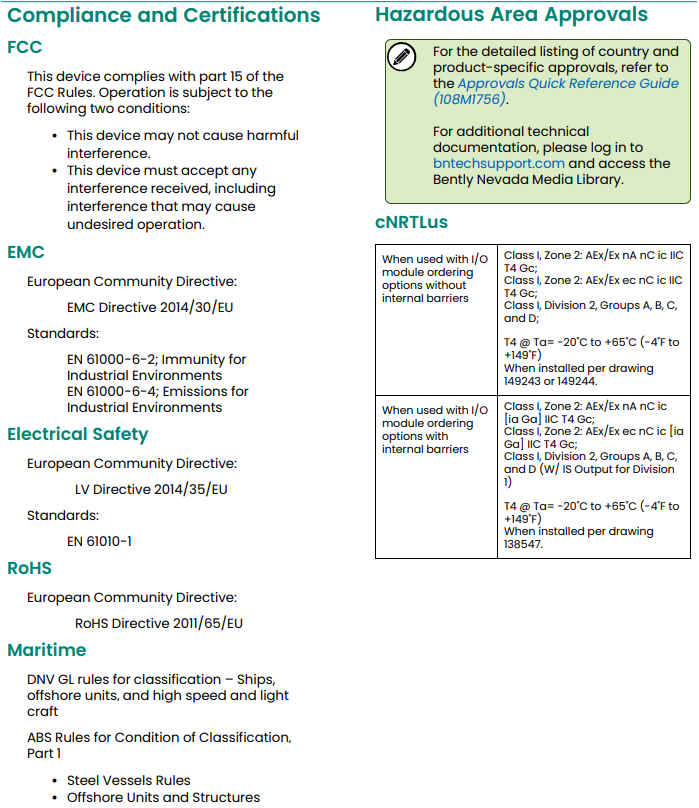

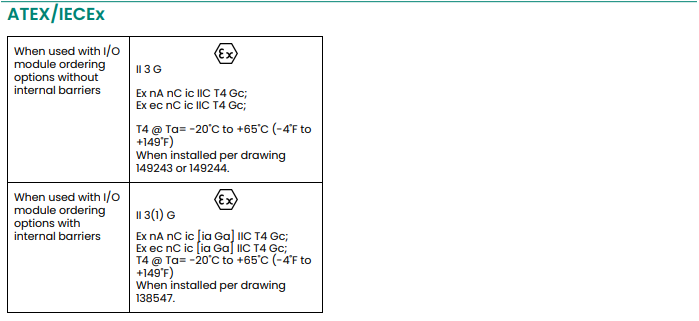

| Safety Certifications | ATEX, IECEx, CSA, CE, FCC, RoHS |

Application Scenarios

The 3500/62 Process Variable Module is highly suitable for monitoring and protecting critical parameters in the following industrial scenarios due to its high reliability, precision, and versatility:

Compressor Set Monitoring: Monitoring interstage pressures, lube oil pressure, fuel gas pressure, seal gas differential pressure, etc.

Pump and Fan Monitoring: Monitoring inlet/outlet pressure, flow, differential pressure, bearing lube oil pressure, etc.

Steam Turbine Monitoring: Monitoring steam pressure, bearing lube oil pressure, hydraulic oil pressure, etc.

Process Vessels and Reactors: Monitoring level, pressure, flow, etc.

Utility Systems: Monitoring cooling water pressure, instrument air pressure, etc.

Any application requiring the integration of standard analog signals (4-20 mA, ±10V) into a machinery protection system or for highly reliable monitoring.