The 3500/70M Reciprocating Impulse Velocity Monitor is a professional industrial-grade monitoring device under the 3500 Machinery Protection Systems, serving as a critical component of the 3500 machinery protection system. This single-slot module provides four-channel monitoring capability, specifically designed to monitor the crankcase and crosshead vibration of reciprocating compressors.

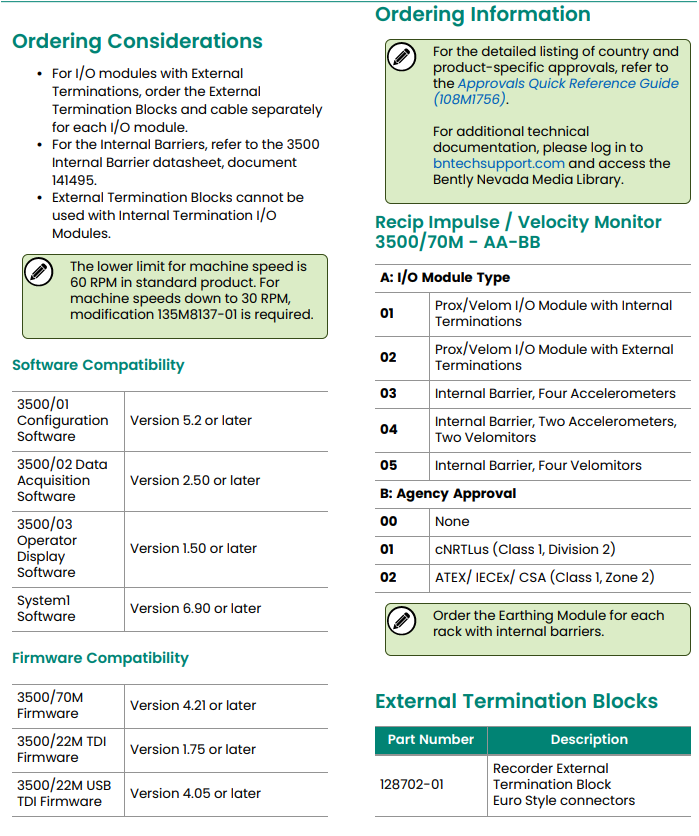

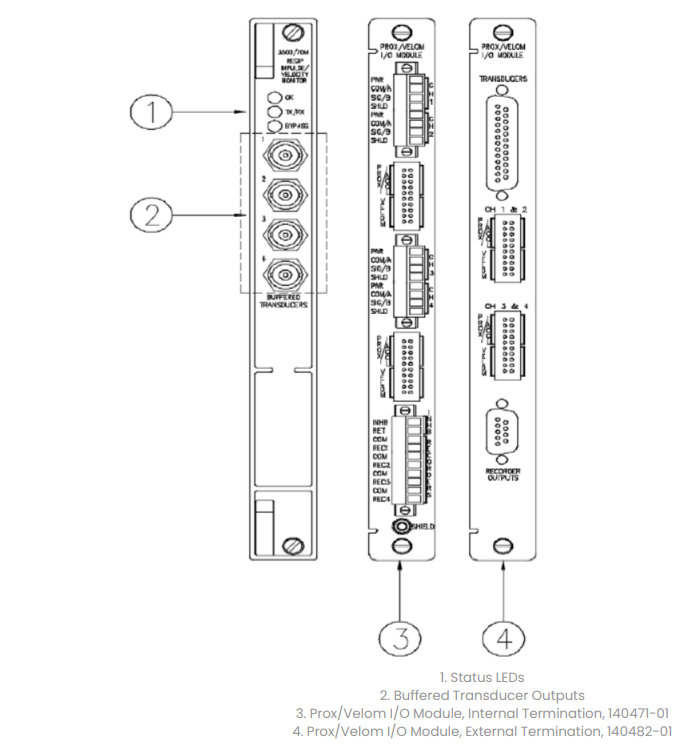

The 3500/70M consists of a fixed front module (P/N 176449-09) and five different types of rear I/O modules (see Ordering page for details). The 176449-09 can form a complete system when combined with any one of the rear I/O modules.

As the core component of the reciprocating compressor solutions package, this module accepts input signals from seismic transducers, conditions the signals to obtain vibration measurements, and compares the conditioned signals with user-programmable alarm setpoints. Users can program each channel through the 3500 Rack Configuration Software to achieve four different monitoring functions: Impulse Acceleration, Acceleration, Reciprocating Velocity, and Low-Frequency Reciprocating Velocity.

Features & Functions

1. Multi-Channel Monitoring Configuration

Provides 4 completely independent monitoring channels, supporting multiple monitoring functions.

Channels are configured in pairs (Channels 1-2 and Channels 3-4), enabling the simultaneous execution of two different monitoring functions.

Each channel can be programmed independently, allowing flexible monitoring scheme configuration.

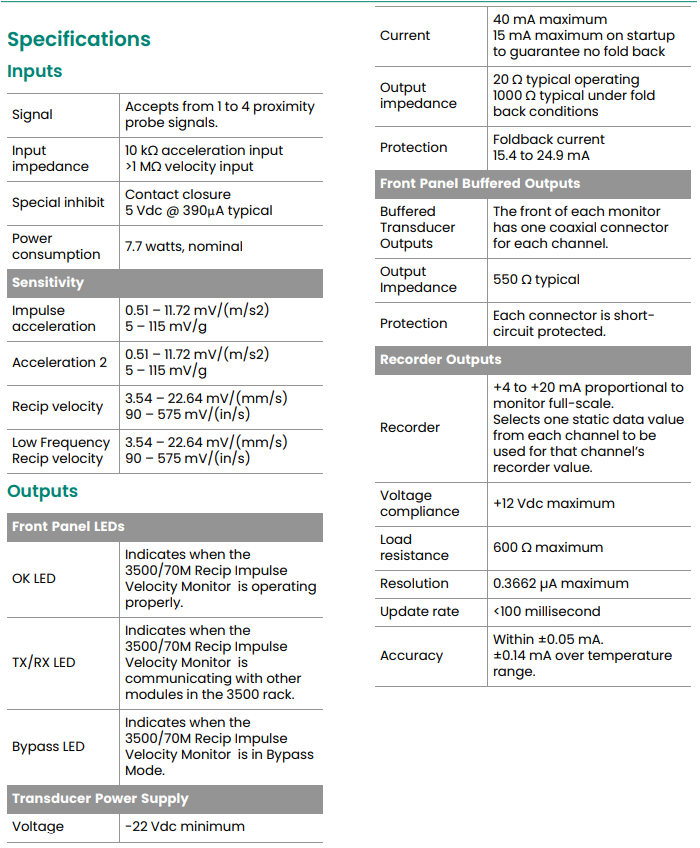

Supports seismic transducer input with input impedance up to 10 kΩ (acceleration) and >1 MΩ (velocity).

2. Four Professional Measurement Functions

Impulse Acceleration Monitoring

Measurement range: 0.51–11.72 mV/(m/s²) or 5–115 mV/g

Band selection: 0-359° (1° resolution)

Band duration: 1-360° (1° resolution)

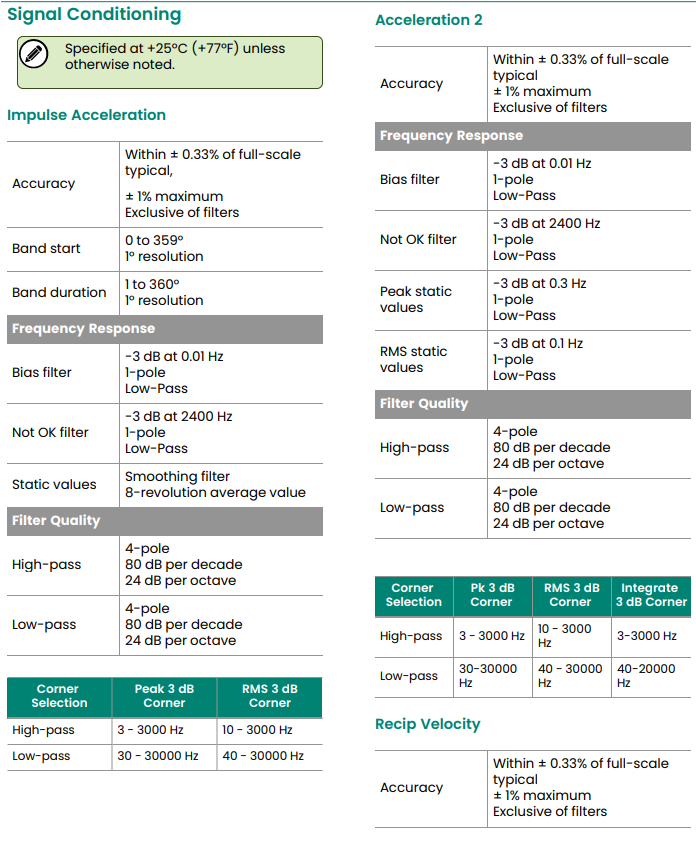

Utilizes an 8-revolution average smoothing filter

Acceleration Monitoring

Measurement range is the same as Impulse Acceleration.

Provides Peak and RMS static value outputs.

Supports 3-3000 Hz high-pass filtering and 30-30000 Hz low-pass filtering.

Reciprocating Velocity Monitoring

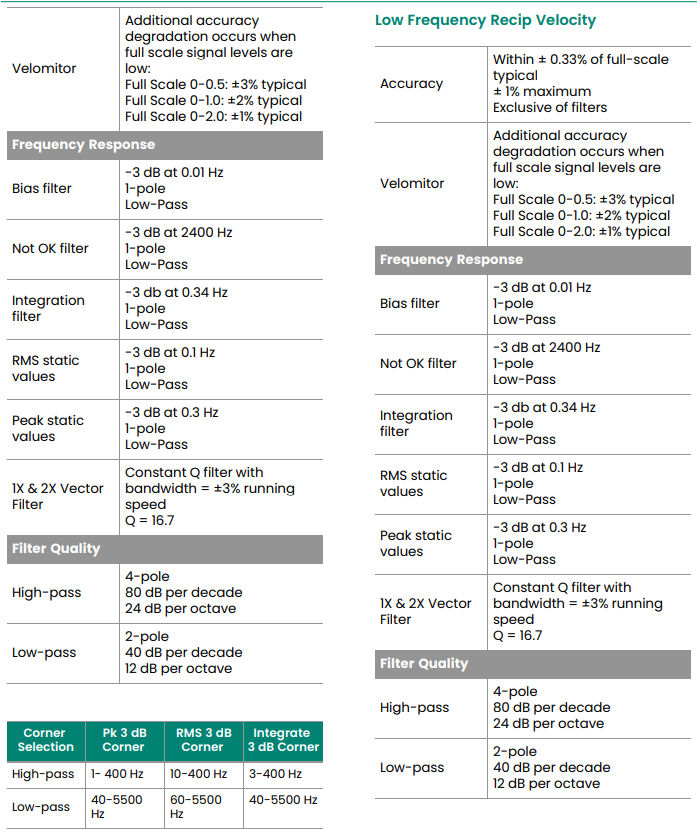

Sensitivity: 3.54–22.64 mV/(mm/s) or 90–575 mV/(in/s)

Integration filter: -3 dB @ 0.34 Hz

Provides 1X and 2X vector filtering with a bandwidth of ±3% of running speed.

Low-Frequency Reciprocating Velocity Monitoring

Particularly suitable for low-speed operating conditions.

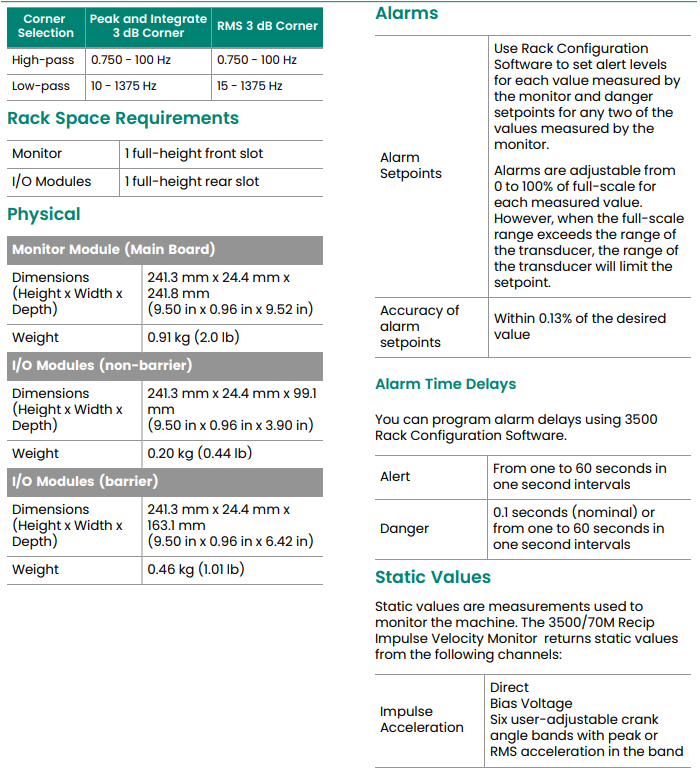

High-pass filter range: 0.750-100 Hz

Low-pass filter range: 10-1375 Hz

Minimum machine speed can reach 30 RPM (requires specific modification).

3. Advanced Signal Processing Capability

Filter Characteristics: 4-pole high-pass filter (80 dB/decade) and 2-pole/4-pole low-pass filter.

Bias Filter: -3 dB @ 0.01 Hz, effectively eliminates DC component.

Not OK Filter: -3 dB @ 2400 Hz, provides anti-aliasing protection.

Vector Filter: Constant Q value filtering, Q=16.7, bandwidth is ±3% of running speed.

4. Programmable Alarm Function

Each channel supports Alert setpoints.

Danger setpoints can be configured for any two static values.

Alarm setpoint accuracy is as high as 0.13%.

Adjustable alarm delay: Alert: 1-60 seconds (1-second increments); Danger: 0.1 seconds or 1-60 seconds (1-second increments).

Alarm range: 0-100% of full scale, limited by the transducer's range.

5. Comprehensive Output Capability

Recorder Output

4-20 mA analog output, proportional to full scale.

Maximum load resistance: 600 Ω

Voltage compliance: +12 Vdc

Resolution: 0.3662 μA

Update rate: <100 milliseconds

Accuracy: ±0.05 mA (ambient temperature), ±0.14 mA (full temperature range)

Buffered Transducer Output

6. Transducer Power Supply Capability

Output voltage: ≥22 Vdc

Maximum current: 40 mA

Starting current: ≤15 mA (guarantees no foldback)

Output impedance: 20 Ω (normal operation), 1000 Ω (foldback condition)

Foldback protection: 15.4-24.9 mA

Working Principle

1. Signal Acquisition and Input Processing

Sensor signals are accessed through dedicated I/O modules. Acceleration signals are received via a 10 kΩ impedance input circuit, and velocity signals are received via a >1 MΩ high-impedance input circuit, ensuring accurate signal acquisition. The module provides a stable excitation power supply for the transducers: output voltage ≥22 Vdc, maximum current 40 mA, and features foldback protection (15.4-24.9 mA), ensuring reliable operation for various transducer types.

2. Signal Conditioning and Filtering Processing

Input signals first undergo pre-amplification and impedance matching before entering multi-stage filtering. The Bias Filter (-3 dB @ 0.01 Hz) effectively eliminates the DC component, and the Not OK Filter (-3 dB @ 2400 Hz) provides anti-aliasing protection. The module offers four filtering mode choices, utilizing a 4-pole design providing 80 dB/decade roll-off characteristics. The unique Vector Filter uses a constant Q value design (Q=16.7) with a bandwidth of ±3% of the running speed, effectively extracting 1X and 2X vibration components.

3. Measured Value and Static Value Calculation

Depending on the configured monitoring function, the module uses different algorithms to process signals:

Impulse Acceleration: Calculates peak or RMS acceleration values within user-adjustable crank angle bands, using 8-revolution average smoothing.

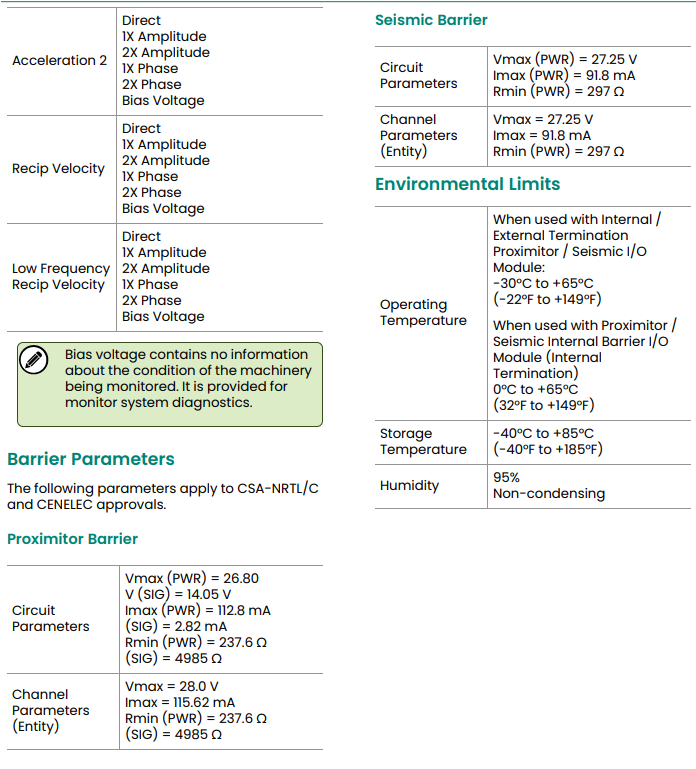

Acceleration: Provides various static values such as Direct Bias Voltage, 1X Amplitude, 2X Amplitude, 1X Phase, 2X Phase.

Reciprocating Velocity: Converts acceleration signals to velocity signals through integration processing (-3 dB @ 0.34 Hz), providing 1X and 2X component analysis.

Low-Frequency Reciprocating Velocity: Optimizes low-frequency response characteristics, supports 0.75-100 Hz high-pass filtering, and is suitable for low-speed operating conditions.

4. Alarm Processing Logic

The processed signals are compared in real-time with user-preset alarm setpoints. The system uses digital filtering technology to eliminate signal jitter, ensuring comparison accuracy. Alarm delay timers use an independent clock source for precise timing control. Alert and Danger alarms use different delay step accuracies (1-second and 0.1-second), balancing response speed and anti-interference capability. Alarm status is transmitted via backplane communication to the system framework, triggering corresponding relay actions and event logging.

5. Output Signal Generation

The module provides multiple output signals: Buffered transducer output provides an isolated signal with 550 Ω impedance via front-panel coaxial connectors; Recorder output generates a 4-20 mA analog signal via a high-precision DAC, with an update rate of <100 ms ensuring real-time performance. All output circuits feature short-circuit protection, ensuring the normal operation of the primary monitoring function is unaffected under abnormal conditions.

Technical Specifications

| Parameter | Specification |

| Monitoring Channels | 4 channels, configured in pairs |

| Input Signal | Seismic transducer signal |

| Input Impedance | Acceleration: 10 kΩ; Velocity: >1 MΩ |

| Measurement Functions | Impulse Acceleration, Acceleration, Reciprocating Velocity, Low-Frequency Reciprocating Velocity |

| Sensitivity | Acceleration: 0.51–11.72 mV/(m/s²); Velocity: 3.54–22.64 mV/(mm/s) |

| Filter Characteristics | 4-pole high-pass (80 dB/dec), 2/4-pole low-pass, Vector filtering (Q=16.7) |

| Recorder Output | 4-20 mA, load capability 0-600 Ω |

| Buffered Output Impedance | 550 Ω |

| Transducer Power Supply | ≥22 Vdc, 40 mA max, with foldback protection |

| Alarm Accuracy | ±0.13% of setpoint value |

| Alarm Delay | Alert: 1-60s (1s increments); Danger: 0.1s or 1-60s (1s increments) |

| Operating Temperature | -30°C to +65°C (Standard modules), 0°C to +65°C (Barrier modules) |

| Power Consumption | 7.7 W (typical) |

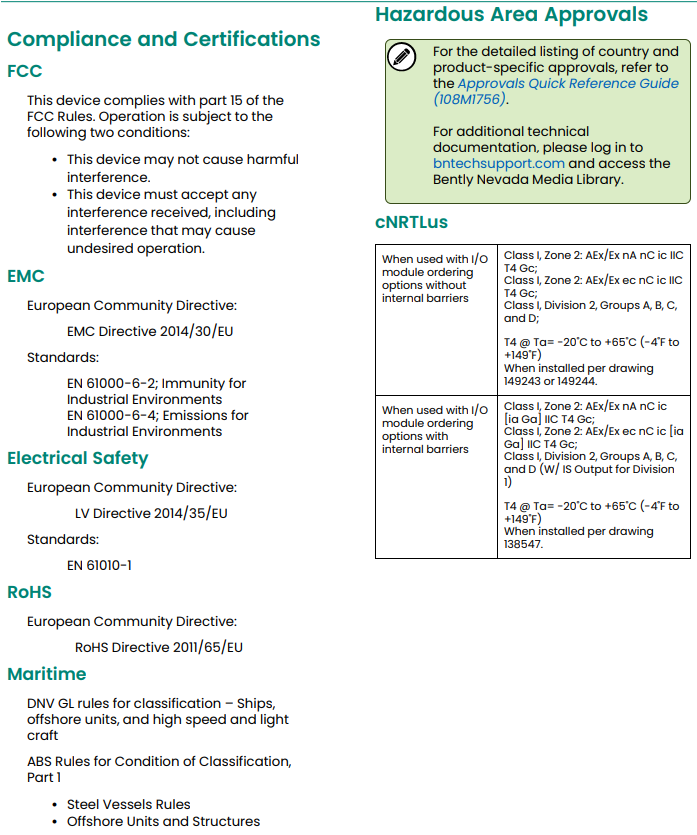

| Safety Certifications | ATEX, IECEx, CSA, CE, FCC, RoHS, DNV GL, ABS |

Application Scenarios

The 3500/70M Reciprocating Impulse Velocity Monitor is particularly suitable for the following industrial scenarios:

Reciprocating Compressor Monitoring: Crankcase vibration monitoring, crosshead vibration analysis, connecting rod motion status assessment.

Low-Speed Rotating Machinery: Vibration monitoring for large compressors, low-speed engines, reciprocating pumps.

Process Compressors: Mechanical condition monitoring for synthesis gas compressors, recycle gas compressors, natural gas compressors.

Critical Equipment Protection: Important mechanical equipment requiring precise vibration analysis and early fault warning.

Predictive Maintenance: Equipment health assessment and maintenance planning based on vibration trend analysis.