The IS200TDBTH6A represents the high-voltage variant within the TDBT series of discrete input/output terminal boards, engineered specifically for demanding industrial applications requiring operation at elevated DC voltage levels. Designed for integration with Mark VIe and Mark VIeS control systems employing Triple Modular Redundancy (TMR) architecture, this terminal board delivers robust performance in environments where standard 24V systems prove inadequate. The IS200TDBTH6A maintains the same mechanical footprint and modular philosophy as other TDBT boards while offering distinct electrical characteristics tailored for high-voltage applications across power generation, transmission, and heavy industrial sectors.

2. Technical Specifications & Key Features

2.1 Electrical Characteristics

Input Channels: 24 group-isolated dry contact inputs

Nominal Wetting Voltage: 125V DC (operational range: 100-145V DC)

Input Current Consumption: 2.55mA (first 21 circuits), 10mA (circuits 22-24)

Relay Outputs: 12 Form-C relay contacts

Maximum Load Ratings:

0.6A at 125V DC

1.2A at 48V DC

3.15A at 24V DC

3.15A at 120/240V AC

AC Voltage Rejection: 60V RMS at 125V DC wetting voltage

Response Time: ≤25ms (both ON and OFF operations)

2.2 Physical Configuration

Terminal Blocks: Euro-style pluggable connectors

Wire Compatibility: #24 - #12 AWG

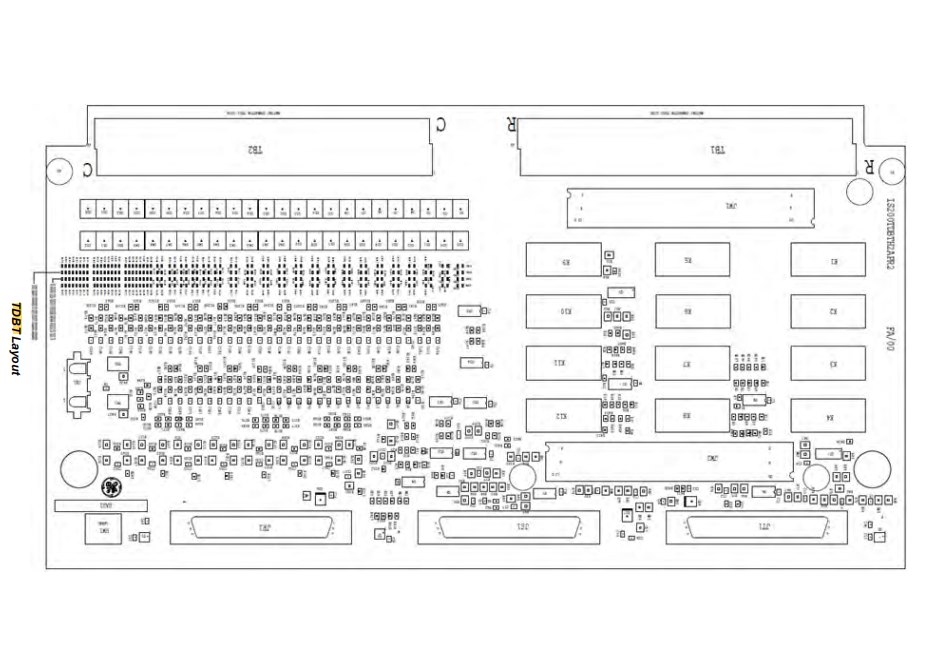

Board Dimensions: 17.8cm × 33.02cm (7.0" × 13.0")

Mounting Options: DIN rail or panel mounting with metal carrier

Contact Material: Silver-nickel alloy for extended electrical life

2.3 System Integration

PDIO Connectivity: Three D-type connectors (JR1, JS1, JT1) for triple-redundant communication

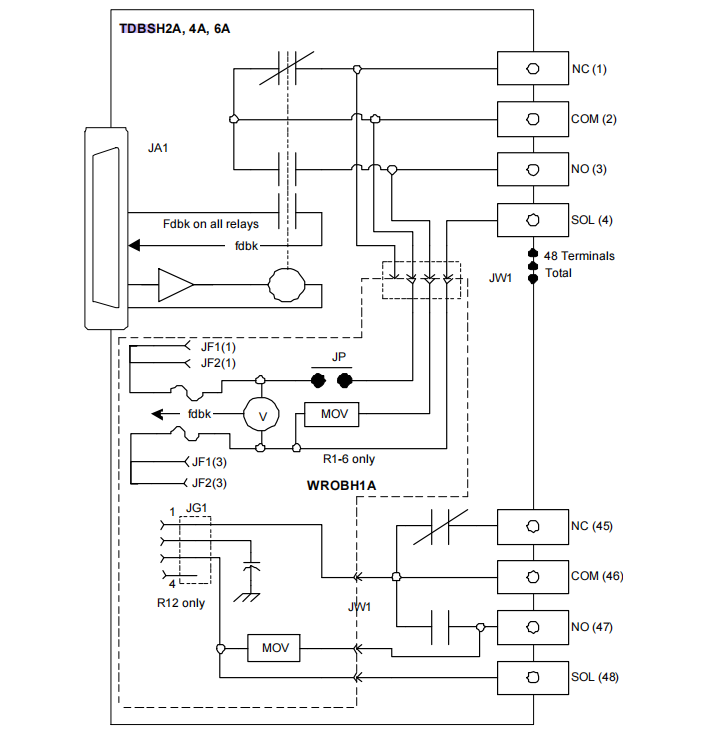

Option Board Support: Compatible with WROBH1A for enhanced relay functionality

Environmental Compliance: Designed for industrial environments with enhanced noise immunity

3. Operational Principles

3.1 High-Voltage Input Circuit Operation

The IS200TDBTH6A's input section employs specialized conditioning circuitry capable of handling the extended voltage range of 100-145V DC. Unlike lower-voltage variants, the input protection network incorporates enhanced transient voltage suppression and reinforced isolation barriers to withstand the higher potential differences encountered in high-voltage applications. The input threshold detection is calibrated at 50% of the applied wetting voltage (approximately 62.5V for nominal operation), providing reliable state detection even with significant voltage drops across long field wiring runs.

The current limiting strategy employs precision resistors that maintain consistent current levels across the specified voltage range, ensuring stable operation while protecting both field devices and internal circuitry. The hardware filtering (4ms time constant) is optimized to reject industrial noise typical in high-voltage environments, particularly effective against the 60V RMS AC interference specified in the rejection rating.

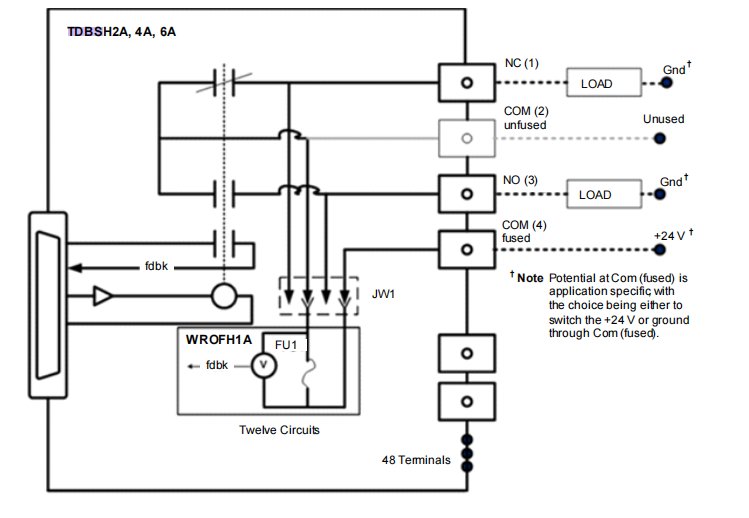

3.2 Relay Output Section

The relay output circuitry in the IS200TDBTH6A shares the same mechanical platform as other TDBT variants but utilizes contact materials and arc suppression techniques specifically engineered for high-voltage DC interruption. The relays incorporate magnetic blow-out configurations and specially designed contact gaps to safely extinguish arcs generated when breaking inductive DC loads at 125V. The MOV (Metal Oxide Varistor) suppression devices across NO contacts are rated for higher energy absorption compared to lower-voltage variants, providing enhanced protection against voltage transients.

When deployed with the WROBH1A option board, the first six relays receive fused power distribution with both positive and negative leg fusing, critical for floating high-voltage DC systems. The fuse feedback circuitry employs voltage-dividing networks to provide compatible signaling to the PDIO modules despite the higher operating voltages.

3.3 Redundancy Implementation

The IS200TDBTH6A implements triple redundancy through parallel processing across three independent PDIO modules, each maintaining separate communication paths to the R, S, and T controllers. The board's ID devices store specific information about the high-voltage configuration, enabling the control system to apply appropriate scaling and monitoring parameters. Diagnostic feedback for both input and output sections is fanned out to all three PDIO modules, maintaining system integrity even during single-failure scenarios.

4. Comparative Analysis: IS200TDBTH6A vs. IS200TDBTH2A

4.1 Voltage Compatibility & Application Scope

The primary distinction between IS200TDBTH6A and IS200TDBTH2A lies in their operational voltage ranges. While the IS200TDBTH2A is optimized for standard 24V DC industrial systems (16-32V DC range), the IS200TDBTH6A addresses the niche requirements of high-voltage applications with its 100-145V DC capability. This fundamental difference dictates their deployment across various industries:

IS200TDBTH2A: Predominantly used in manufacturing automation, process control, and machinery applications where 24V DC represents the standard control voltage

IS200TDBTH6A: Essential in power generation facilities, electrical substations, railway systems, and industrial processes where 125V DC control systems are prevalent

4.2 Electrical Design Variations

The IS200TDBTH6A incorporates several design adaptations to accommodate high-voltage operation:

Input Current Limiting: The IS200TDBTH6A employs higher-wattage current limiting resistors to dissipate the increased power generated at 125V operation (approximately 319mW per circuit versus 60mW in the TDBTH2A)

Isolation Enhancement: Reinforced isolation barriers and increased creepage distances between circuits ensure safe operation at the higher voltage potential

Component Ratings: All voltage-dependent components (capacitors, suppression devices, optoisolators) are specified for 125V DC service versus 24V DC in the TDBTH2A

Wetting Voltage Configuration: Unlike the TDBTH2A's parallel-connected wetting voltage terminals, the TDBTH6A may require individual current limiting in certain configurations to prevent excessive power dissipation

4.3 Performance Characteristics

Load Switching Capability: The IS200TDBTH6A's relay contacts are rated for lower current at high voltage (0.6A at 125V DC) compared to the IS200TDBTH2A's 3.15A at 24V DC, reflecting the different arc suppression requirements

Noise Immunity: The IS200TDBTH6A provides significantly higher AC noise rejection (60V RMS versus 12V RMS for IS200TDBTH2A), essential in electrically noisy high-voltage environments

Power Management: The IS200TDBTH6A requires consideration of higher power dissipation in the input circuits, potentially affecting thermal management in high-density installations

4.4 System Integration Considerations

Installation of IS200TDBTH6A necessitates additional safety precautions due to the higher operating voltages. Wiring practices must account for the increased potential, including proper spacing, insulation, and labeling. While both models share identical mechanical dimensions and mounting configurations, the IS200TDBTH6A typically requires more stringent compliance with electrical codes governing high-voltage control circuits.

5. Application Engineering

The IS200TDBTH6A finds particular utility in applications where control signals must traverse long distances, as the higher voltage minimizes voltage drop issues. It's also indispensable in environments where 125V DC represents the established standard, such as in legacy electrical systems or specific industrial processes. The board's enhanced noise immunity makes it suitable for installation in close proximity to variable frequency drives, high-power switching equipment, and electrical substations where electromagnetic interference would compromise lower-voltage systems.