The UCSCS2A controller is a core component of GE's Mark VIeS Safety Control System, belonging to the UCSCS2x controller series. This controller is specifically designed to implement functional safety loops, achieving Safety Integrity Level (SIL) 2 and SIL 3 capabilities, making it suitable for industrial control scenarios with extremely high requirements for safety and reliability. The UCSCS2A controller utilizes a dual-core processor architecture and runs on the QNX Neutrino real-time operating system (RTOS), ensuring stable and real-time response even under high-load conditions.

As part of the Mark VIeS Safety system, the UCSCS2A is primarily intended for professional users knowledgeable in Safety Instrumented Systems (SIS) to perform critical safety functions and mitigate risks in industrial processes. The controller and its supporting distributed I/O modules are specifically programmed and certified for safety control use, complying with the IEC 61508 international functional safety standard, ensuring its reliability and compliance in safety-critical applications.

The UCSCS2A controller is supported starting from ControlST software suite version V07.02 and offers multiple redundancy configuration capabilities, including Simplex, Dual, and Triple Modular Redundant (TMR), meeting the availability and reliability requirements of various application scenarios.

II. System Functions and Features (Expanded Version)

The UCSCS2A controller is more than just a hardware platform; it is a complete control system solution that integrates advanced safety concepts, redundant architectures, and powerful communication capabilities. Its core functions and features are elaborated below:

1. Top-Tier Safety Control Capabilities

The core of the UCSCS2A lies in its functional safety characteristics. It is specifically designed to execute Safety Instrumented Functions (SIFs), capable of achieving SIL 2 and SIL 3 Safety Integrity Levels. This means the controller can significantly reduce residual risks in industrial processes, preventing hazardous events or mitigating their consequences.

Compliance and Certification: Its hardware and software are rigorously designed, developed, and certified in accordance with the IEC 61508 international functional safety standard. This globally recognized foundational standard ensures the controller's reliability and predictability throughout its entire lifecycle.

Application Scenarios: Typical applications include:

Emergency Shutdown Systems (ESD): Safely and orderly shutting down equipment upon detection of hazardous conditions.

Fire & Gas Detection and Protection Systems (F&G): Interfacing with fire and combustible gas detectors to trigger fire suppression and isolation procedures.

Process Safety Interlocks: Ensuring production processes follow established safety sequences to prevent misoperation.

Mechanical Equipment Protection: Monitoring and protecting critical parameters like overspeed, vibration, and axial displacement for large rotating equipment such as turbines and compressors to prevent mechanical damage.

2. Flexible High-Availability Redundancy Architecture

To meet the availability requirements of different applications, the UCSCS2A supports multiple redundancy configurations, ensuring system operation continues even in the event of single or multiple point failures.

Simplex Configuration: A single controller executes all control functions. Suitable for applications where safety functions are relatively independent or where availability requirements are less extreme.

Dual Configuration: Two controllers run in parallel, forming a "Hot Backup" system. Both controllers synchronously process the same input data and execute the same logic. If the primary controller fails, the backup controller can seamlessly switch to the primary role within a very short time, ensuring continuous system operation and significantly improving availability.

Triple Modular Redundancy (TMR) Configuration: This is the highest level of redundancy, using three controllers running simultaneously. The system uses a "majority voting" mechanism to arbitrate outputs. Even if one controller fails, the system can continue operating based on the correct outputs from the other two controllers without any interruption. The TMR architecture completely eliminates the controller as a single point of failure, making it ideal for the highest safety-grade applications such as nuclear power plants and critical pipeline compressor stations.

3. High-Efficiency and Reliable IONet Communication Network

The UCSCS2A communicates with distributed I/O modules via IONet, a dedicated, high-performance industrial Ethernet network. IONet is the backbone of the Mark control system and offers significant advantages:

Dedicated Network: IONet is a private network that only supports GE Mark series I/O modules and controllers. This closed nature prevents interference and attacks from external networks or unauthorized devices, enhancing system determinism and security.

High-Precision Clock Synchronization: It employs the IEEE 1588 Precision Time Protocol (PTP), synchronizing the clocks of all controllers and I/O modules in the network to within ±100 microseconds. This extremely high level of timing consistency is crucial for precise sequence of event recording for post-incident analysis and for high-precision control loops.

No Single Point of Input Loss Architecture: In redundant configurations, all I/O networks are connected to every controller simultaneously. This means each controller independently receives all input data. This architecture ensures that even if one controller is powered down for maintenance or due to failure, no application input data is lost, guaranteeing data integrity and control continuity at the hardware level.

4. Powerful Real-Time Operating System and Software Ecosystem

The UCSCS2A runs on the proven QNX Neutrino Real-Time Operating System. The key difference between an RTOS and a general-purpose OS is its "predictability" and "determinism," meaning it can respond to external events within strictly defined time constraints, which is indispensable for safety control.

Its applications are developed, debugged, and maintained through GE's unified ControlST software suite. This suite provides a complete toolchain:

Programming Languages:

Control Block Language: A graphical programming language that builds complex control logic by dragging and dropping pre-defined function blocks (e.g., PID controllers, timers, logic gates), making it easy to understand and maintain.

Relay Ladder Diagram: A familiar ladder logic format, particularly well-suited for describing discrete logic and interlock conditions, favored by electrical engineers.

Rich Data Type Support: Supports everything from simple Boolean values to complex 64-bit floating-point numbers, catering to various industrial measurement and control needs, ensuring speed and precision in data processing.

Integrated Engineering Environment: All tasks—from hardware configuration, logic programming, simulation testing, to online debugging and diagnostics—are performed within the unified ToolboxST environment. This greatly improves engineering efficiency and reduces lifecycle costs.

Through the close integration of these four functional characteristics, the UCSCS2A controller provides a safe, reliable, flexible, and efficient control foundation for modern industry.

III. Installation and Maintenance Requirements

1. Installation Environment

Mounting Method: Vertical mounting to ensure unobstructed airflow through the cooling fins.

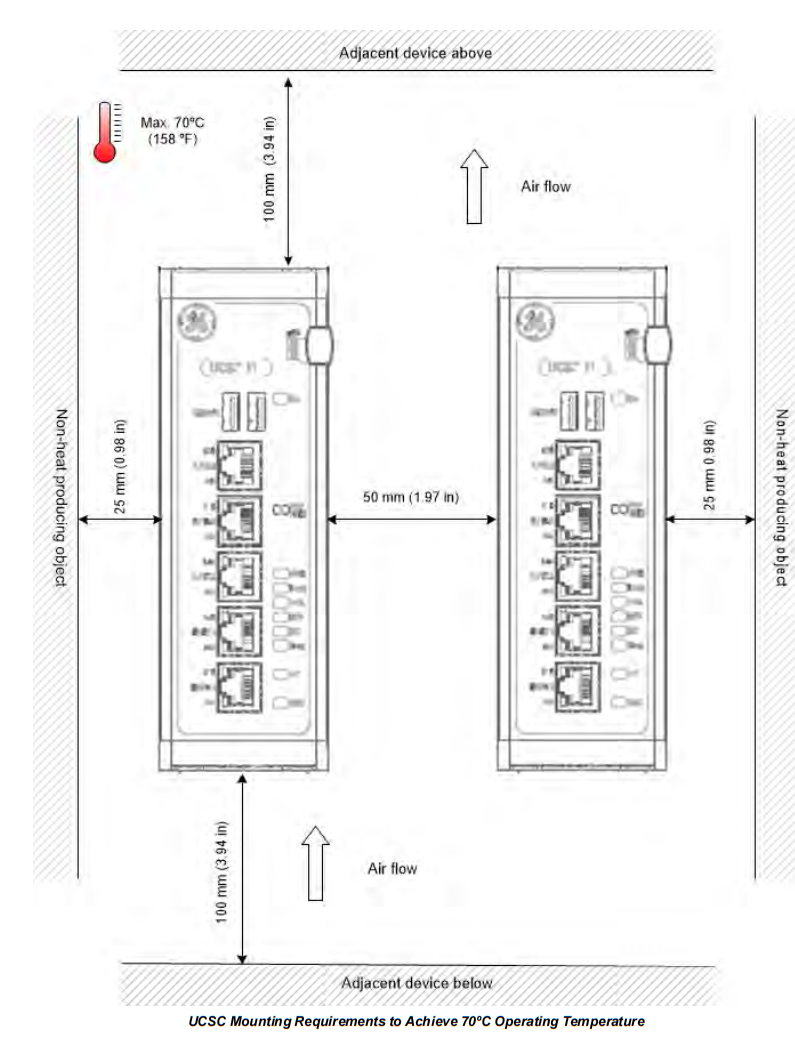

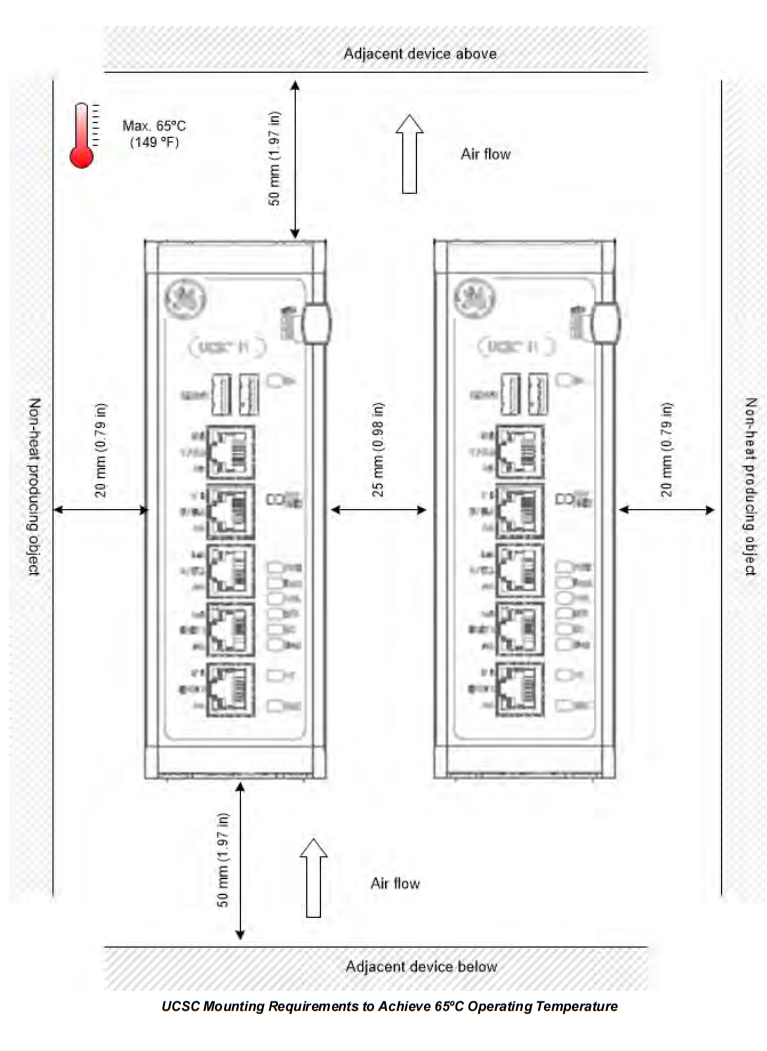

Air Gap Requirements:

Temperature Monitoring Point: The ambient temperature measured 25 mm from any point on the UCSC surface must not exceed 70°C.

2. Power and Wiring

Power Connector: 3-pin Phoenix Contact plug (Model MC 1,5/3-STF-3,81).

Pinout:

Wire Gauge: Supports 28 to 16 AWG wires.

Screw Torque: 0.23 Nm (2 in-lb).

3. Maintenance and Replacement

The UCSCS2A controller supports field replacement. The procedure is as follows:

Disconnect the power connector and all communication cables.

Loosen the mounting screws and remove the old controller.

Install the new controller and reconnect all cables.

Perform the "Controller Restore" procedure to load the configuration.

Use the ToolboxST application to download the software and commission the system.

IV. LED Status Indicators

The UCSCS2A controller front panel features multiple LED indicators for real-time status monitoring:

Link/Act LEDs: Indicate network connection and data activity status.

ONL LED: Solid green indicates the controller is online and running the application.

DC LED: Solid green indicates this controller is the designated controller (always on for Simplex configurations).

Diag LED: Flashing red indicates an active diagnostic alarm.

OT LED: Solid amber indicates the temperature of internal components exceeds the recommended limit.

VDC LED: Indicates power status (Green/Amber/Red/Flashing).

V. Safety and Certifications

The UCSCS2A controller has passed multiple international safety and electromagnetic compatibility (EMC) certifications, including:

North American Safety for Hazardous Locations: Suitable for Class I Div. 2 Groups A, B, C, D.

ATEX Certification: For European explosive atmospheres.

CE Marking: Complies with the EU EMC Directive.

RoHS Compliance: Complies with the EU Restriction of Hazardous Substances directive.

China RoHS: Complies with China's "Management Methods for the Restriction of the Use of Hazardous Substances in Electrical and Electronic Products".

VI. Typical Application Scenarios

The UCSCS2A controller is widely used in the following industrial sectors:

Oil & Gas Production and Processing: Wellhead control, compressor package protection, fire and gas detection.

Power Generation: Gas turbines, steam turbines, wind turbine converters, excitation control systems.

Chemical and Process Industries: Reactor safety shutdown, pressure protection, temperature interlocks.

Mechanical Equipment Protection: Vibration monitoring, overspeed protection, and axial displacement monitoring for rotating equipment.