The IS220YAICS1A is a critical component within GE's Mark VIeS control system, belonging to the YAIC series of Analog Input/Output modules. This module is designed to provide high-precision, highly reliable analog signal processing capabilities in demanding industrial environments, widely used in critical sectors such as power generation, process automation, and heavy machinery control. As a safety-rated I/O module, the YAICS1A acts as a bridge connecting the controller with field analog devices (such as sensors, transmitters, and actuators).

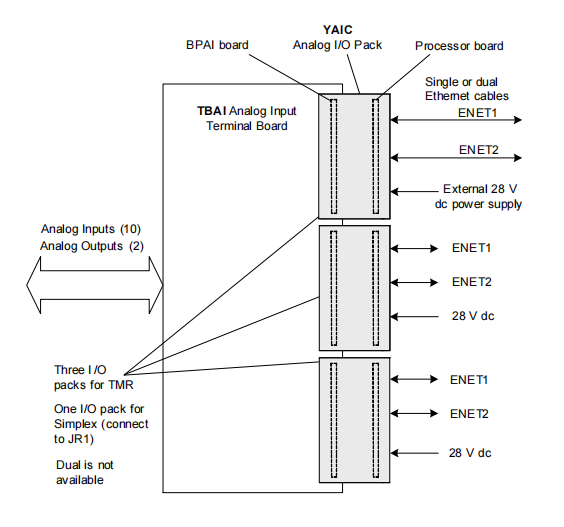

The core function of the IS220YAICS1A module is to process multi-channel analog signals, including voltage and current inputs, and to provide current outputs. It supports Simplex and Triple Modular Redundant (TMR) configurations to meet the safety and availability requirements of different applications. The module exchanges data with the upper-level controller via dual Ethernet interfaces and integrates comprehensive self-diagnostics and status monitoring functions to ensure system integrity and operational safety.

2. Key Features

1. Multi-Channel Analog Signal Input

The IS220YAICS1A module provides 10 analog input channels with high configuration flexibility.

Channels 1 through 8 can be individually configured for the following modes:

Channels 9 and 10 are dedicated to current input, configurable as:

2. High-Precision Analog Signal Output

The module integrates 2 independent 0-20 mA analog current outputs.

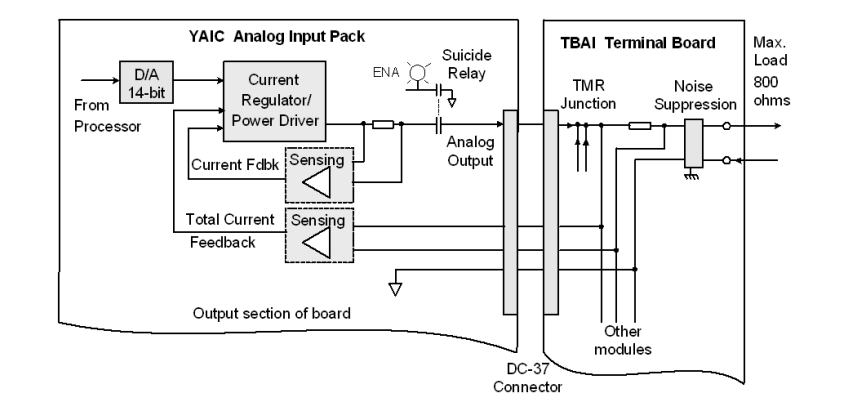

Each output features 18 V compliance voltage and can drive a maximum load of 800 Ω.

The output channels support load sharing in TMR systems, where three redundant modules work together to provide a single, stable output.

3. Flexible Interface and Network Redundancy

Equipped with dual RJ-45 Ethernet interfaces (ENET1, ENET2), supporting redundant network communication.

ENET1 is typically the primary communication interface connected to the R controller network, with ENET2 serving as the backup.

The module can operate normally on either network port, ensuring uninterrupted communication if one network path fails.

4. Comprehensive Diagnostics and Status Monitoring

The module performs Power-On Self-Test (POST), including memory, Ethernet port, and processor hardware checks.

Continuously monitors internal power supply status (+5V, ±15V).

Performs Hardware Limit Checking and System Limit Checking on analog inputs; out-of-limit signals are marked invalid and trigger alarms.

Performs command value vs. feedback value comparison for analog outputs to verify the health of the Digital-to-Analog Converter (DAC) and output circuitry.

Monitors the status of the output "Suicide" relays, ensuring their action matches the command.

5. Signal Conditioning and Noise Immunity

All analog input channels are processed through a passive low-pass filter with a cutoff frequency of 75.15 Hz (500 rad/s), effectively suppressing high-frequency noise.

Provides a configurable software digital filter with selectable cutoff frequencies (0.75 Hz, 1.5 Hz, 3 Hz, 6 Hz, 12 Hz) to further optimize signal quality.

Features excellent Common-Mode Rejection Ratio (CMRR):

3. Working Principle

1. Analog Input Signal Processing Chain

The processing of analog input signals is a precise, multi-stage process ensuring accurate and reliable data acquisition:

Signal Access and Conditioning: Analog signals from field sensors or transmitters are accessed via the Terminal Board. For current inputs (e.g., 4-20 mA), the terminal board incorporates a precision 250 Ω burden resistor, converting the current signal to a voltage signal (1-5 V) for module acquisition. Voltage signals are directly connected.

Filtering: The converted voltage signal first passes through a single-pole passive low-pass filter with a corner frequency of 75.15 Hz. This hardware filter is the first line of defense against field Electromagnetic Interference (EMI) and Radio Frequency Interference (RFI).

Multiplexing and Scaling: The 10 input signals are sequentially selected by an Analog Multiplexer (MUX). The signal then enters a programmable gain amplifier, where it is scaled appropriately based on the configured input type (±5V, ±10V, 4-20mA corresponding to 1-5V) to match the input range of the Analog-to-Digital Converter (ADC).

Analog-to-Digital Conversion (ADC): The scaled signal is digitized by a 16-bit high-precision ADC. The 16-bit resolution means it can divide the full-scale signal into 65,536 discrete levels, providing extremely high measurement accuracy and the ability to resolve minute signal changes.

Data Delivery: The digitized data is read by the processor and sent to the controller via Ethernet for closed-loop control, logic operations, or Human-Machine Interface (HMI) display.

2. Analog Output Signal Generation Chain

The generation of analog outputs is a closed-loop control process ensuring precise and stable output current:

Command Reception and Digital-to-Analog Conversion: The controller sends output commands via Ethernet. The module's internal processor sends this digital command to a 14-bit resolution Digital-to-Analog Converter (DAC). The DAC produces a reference voltage proportional to the command value.

Current Regulation and Driving: This reference voltage drives a precision current regulator/power driver circuit to generate the required 0-20 mA output current.

Closed-Loop Feedback and Health Diagnostics: The accuracy of the output current is ensured by a closed-loop system:

Internal Current Sensing: The module measures the current output by itself internally.

External Total Current Sensing: On the TBAI terminal board, a precision sense resistor measures the total current flowing through the load. In a TMR system, this is the sum of the output currents from the three redundant YAIC modules.

Comparison and Verification: The module continuously compares the DAC reference voltage, the internally sensed current, and the external total current feedback. Any significant discrepancy triggers a diagnostic alarm, indicating a potential hardware fault.

3. TMR Output Redundancy and "Suicide" Relay Mechanism

In TMR applications, the analog output functionality of the IS220YAICS1A demonstrates its high-reliability design:

Load Sharing: Three redundant YAIC modules jointly drive the same load. Their current regulators are designed to automatically share the load current. For example, if a 12 mA output is required, each module will contribute approximately 4 mA.

Fault Isolation ("Suicide" Relay): Each analog output channel is equipped with a Normally Open mechanical relay, known as a "Suicide" relay. When the module detects a permanent fault in its own output circuit through internal diagnostics (like the current comparison mentioned above) or voting logic, it proactively opens this relay.

Ensuring System Integrity: Once the relay opens, the faulty module's output circuit is completely physically isolated from the load loop. The remaining two healthy modules immediately detect the change in total load and automatically readjust their outputs to maintain the total current at the commanded value, enabling fault-tolerant operation. The system can continue functioning without requiring a shutdown. The status (open/closed) of this relay is indicated by a feedback signal and accompanied by a panel LED.

4. Power Management and Initialization

The module receives external 28 V DC power via a 3-pin connector on its side.

Incorporates a soft-start circuit that effectively suppresses inrush current during power-up, allowing hot swapping for easier maintenance.

Upon power-up, all outputs remain disabled until the self-test sequence is completed, ensuring the system cannot cause maloperation before it is ready.

4. System Integration and Configuration

1. Compatibility

Processor Board: IS220YAICS1A incorporates the BPPB processor board.

Firmware and Software: Compatible with firmware version V04.06, supported by the ControlST software suite V04.06 and later.

Terminal Board Compatibility:

Redundancy Configuration Rules:

All three YAIC modules in a TMR set must be of the same hardware model (YAICS1A); mixing YAICS1A and YAICS1B is not allowed.

Simplex systems use 1 module, TMR systems use 3 modules.

2. Installation Procedure

Securely mount the selected terminal board (TBAIS1C or STAIS#A) onto the baseplate.

Align the YAIC module directly and plug it into the terminal board's DC-37 interface.

Use the threaded studs adjacent to the Ethernet ports to slide the module into and secure it to the terminal board-specific mounting bracket. Adjust the bracket position to ensure no side force is applied to the DC-37 connector.

Connect one or two Ethernet cables. Standard practice is to connect ENET1 to the primary (R) controller network.

Connect the 3-pin 28 V DC power connector on the side.

Use the ToolboxST engineering software to configure the module and download parameters.

3. Key Configuration Parameters (via ToolboxST)

Input Configuration:

InputType: Select the signal type for each channel (e.g., 4-20 mA, ±5V).

Low_Input/High_Input & Low_Value/High_Value: Set the analog signal range and linear scaling to engineering units.

InputFilter: Select the cutoff frequency for the software digital filter.

SysLimitEnab/SysLimit: Enable and set system alarm high/low limits.

DiagHighEnab/DiagLowEnab: Enable hardware wire-break/short-circuit diagnostics for 4-20 mA signals.

Output Configuration:

Output_MA: Select 0-20 mA output.

OutputState: Define behavior when communication with the controller is lost (e.g., Hold Last Value, Output Safe Value, De-energize Output).

TMR_Suicide: Enable the "Suicide" relay function in TMR applications.

TMR_SuicideLimit: Set the load-sharing deviation threshold that triggers the "suicide" action.

5. Diagnostics and Maintenance

The IS220YAICS1A module provides hierarchical diagnostic information, accessible and troubleshootable via the ToolboxST software and panel LEDs:

All diagnostic alarms can be configured for latching mode and can be reset via the RSTDIAG signal in the controller logic once the fault is cleared.