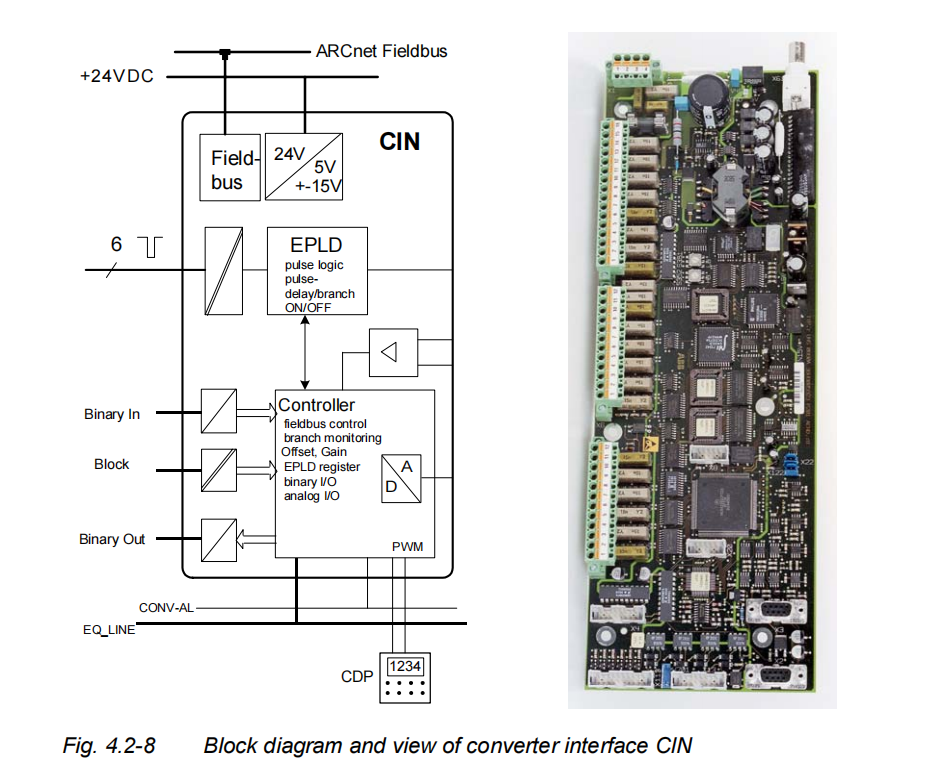

The UNS 0880a-P (abbreviated as CIN, Converter Interface) is a key component in the ABB UNITROL® 5000 excitation system. As a converter interface board, it is responsible for the control, monitoring, and protection functions of the power converter bridge. The CIN board communicates with the main control board (COB) via the ARCnet fieldbus, enabling distributed control logic and ensuring the reliable operation of the power converters. This interface board is suitable for various industrial and power application scenarios, especially in synchronous motor excitation systems requiring high reliability, redundant configuration, and precise current control.

II. Key Functions

1. Distributed Control and Monitoring

As the local control unit for the power converters, the CIN board executes control logic related to the converter bridge, including:

Fan Control and Airflow Monitoring: Ensures effective heat dissipation for power devices.

Temperature Monitoring: Real-time monitoring of critical components via KTY10 temperature sensors.

Automatic Fault Isolation: Automatically disables the corresponding converter bridge upon detecting an abnormality, preventing fault propagation.

2. Firing Pulse Generation and Transmission

The CIN receives firing pulse signals from the COB board (transmitted via a ribbon cable) and generates high-frequency firing pulse chains suitable for the Gate Driver Interface (GDI).

Features electrically isolated firing pulse detection, ensuring safety isolation between the control and power sections.

3. Automatic Current Sharing Control

The CIN supports active current balancing regulation during parallel operation of multiple converter bridges.

Connects all CIN boards via an "equalization line" to compare the current deviation of each individual branch from the average value and achieve dynamic current balance by finely adjusting the firing pulse delay for each bridge.

4. Digital and Analog I/O Interface

10 Digital Inputs: For receiving external status signals (e.g., circuit breaker status, fault signals).

8 Digital Outputs: 24VDC outputs for controlling peripherals such as relays and indicator lights.

2 Analog Inputs: For signal acquisition from KTY10 temperature sensors.

5. Conduction Status Monitoring

III. Working Principle

1. System Architecture and Communication Mechanism

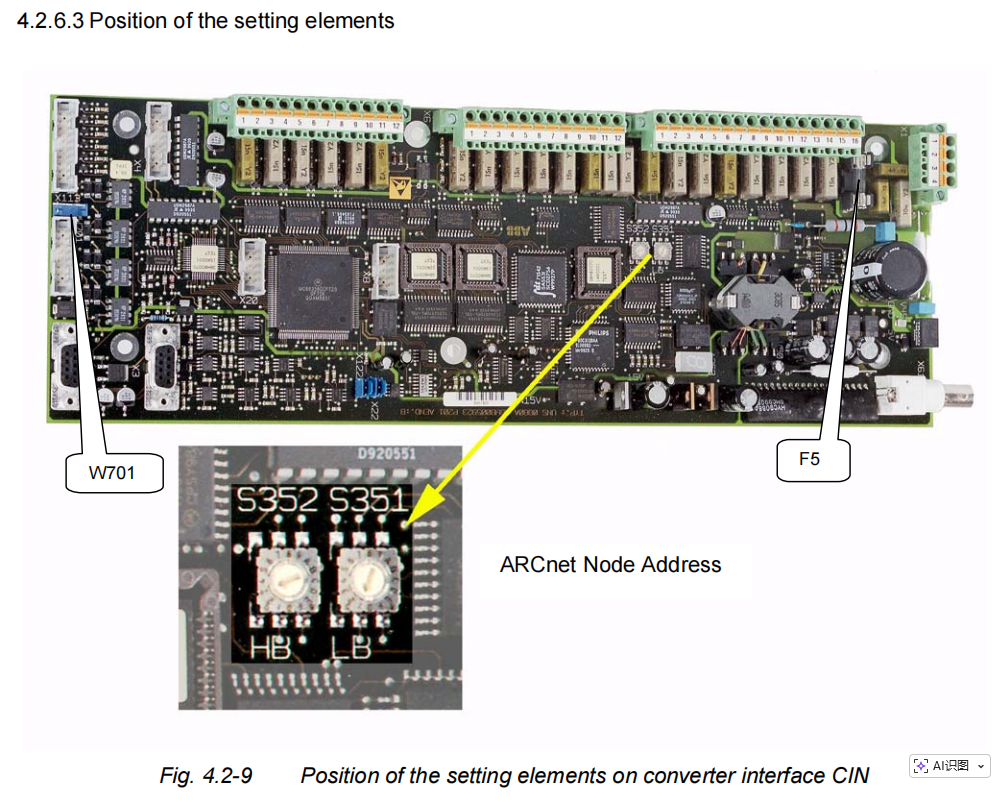

The CIN board acts as a distributed node in the UNITROL 5000 system, exchanging data with the COB main control board via the ARCnet fieldbus. ARCnet uses a coaxial cable as the transmission medium, offering high noise immunity and real-time performance. The node address of the CIN is set using Hex rotary switches or DIL slider switches, ensuring a unique identity for each device on the bus.

2. Firing Pulse Processing Flow

The COB board generates the original firing pulse signals, which are transmitted to the CIN via a ribbon cable.

The EPLD (Erasable Programmable Logic Device) inside the CIN performs logical processing, delay adjustment, and branch control on the pulses.

The processed pulse signals are optically isolated and then output to the GDI board, ultimately driving the power thyristors.

3. Current Balancing Principle

In multi-bridge parallel systems, the CIN collects current signals from each bridge via the "equalization line" and calculates the average current value. If a bridge's current deviates from the average, the CIN adjusts that bridge's firing pulse delay time to bring its output current back into balance. This closed-loop regulation mechanism effectively prevents current imbalance caused by differences in device parameters.

4. Fault Detection and Protection Mechanism

The CIN features comprehensive fault detection functions, including:

Overtemperature: Real-time monitoring via KTY10 sensors; protection is triggered upon exceeding limits.

Fan Fault: Monitors fan operation status; alarms or blocks in case of abnormality.

Bridge Arm Conduction Failure: Detects output current via Hall sensors; immediately blocks the bridge if an anomaly is found.

5. Software Parameter Configuration

Most CIN functions are configured via software parameters set using the CMT or SPT tools on the COB board, including:

Current balancing coefficients

Temperature alarm thresholds

Digital I/O function mapping

Firing pulse parameters

6. Hardware Configuration and Jumper Settings

The CIN board supports multiple converter configuration modes, set via jumper W701:

| Configuration Mode | Description | Jumper Setting |

| E (Economic) | Single bridge operation | Conv.1: 1-2 |

| S (Standard) | (n-1) redundancy operation | All Bridges: 1-2 |

| T (Twin) | 1+1 full redundancy | Conv.1: 1-2, Conv.2: 1-3 |

| N (Negative Bridge) | Four-quadrant operation | Antiparallel Neg. Conv.: 1-3 |

IV. Technical Features

High Reliability: Distributed control architecture localizes faults, preventing impact on overall system operation.

Flexible Configuration: Supports various converter topologies and redundancy modes.

Real-time Communication: Based on the ARCnet bus, offering low communication delay and strong noise immunity.

Intelligent Current Sharing: Dynamically adjusts the current of each bridge, improving overall system efficiency and reliability.

Comprehensive Monitoring: Covers multiple dimensions including temperature, fans, current, and conduction status.

Ease of Maintenance: Intuitive status display via the CDP panel supports remote parameter adjustment.