The IS220PAOCH1B is a high-performance analog output module within the PAOC Analog Output Pack series, designed for GE's Mark Vle and Mark VleS control systems. Its core function is to accurately and reliably convert digital commands from the controller into standard 0-20 mA analog current signals, which are used to drive field devices such as valves, actuators, and variable frequency drives.

The IS220PAOCH1B module is equipped with the more advanced BPPC processor board, extending the operating temperature range and enhancing compatibility with the latest control software while retaining all the advantages of its predecessors. It integrates precision signal conversion circuitry, comprehensive diagnostic functions, and multiple safety protection mechanisms, specifically designed for high-precision control in demanding industrial environments. It is widely used in industries with high reliability requirements, such as power generation, oil and gas, and chemical processing.

Detailed Features

The IS220PAOCH1B module offers a series of advanced features designed to ensure long-term system stability and safe operation.

High-Precision Analog Current Output

Channel Configuration: Provides 8 fully independent and electrically isolated analog output channels, supporting flexible system configuration.

Signal Standard: Each channel outputs the industry-standard 0-20 mA current signal, with strong drive capability, capable of driving loads up to 900 Ω with a compliance voltage of 18 V, suitable for long-distance transmission and various load requirements.

Exceptional Accuracy: Guarantees an output accuracy within ±0.5% over the entire specified operating temperature and load range. Under room temperature (25°C) and typical load (500Ω) conditions, accuracy can reach ±0.25%, meeting the most stringent precision control applications.

Dual Redundant Network Communication

The module features two RJ-45 Ethernet ports (ENET1 and ENET2) on its side, allowing connection to redundant control network architectures.

This design ensures maximum communication reliability. If the primary communication path (typically ENET1 connected to the R controller) fails, the module can seamlessly switch to the redundant path (ENET2), ensuring uninterrupted transmission of control commands and significantly improving system availability.

Real-Time Current Feedback Monitoring

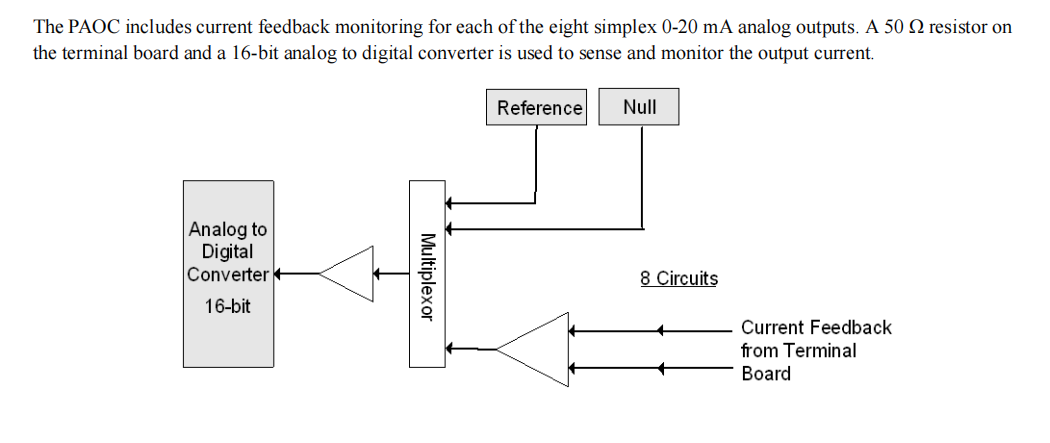

The module can perform real-time, simultaneous sampling and measurement of the output current for each channel. This is achieved using a 50 Ω high-precision sense resistor on the terminal board, which converts the current signal into a voltage signal, subsequently digitized by a dedicated 16-bit Analog-to-Digital Converter (ADC) inside the module.

The system continuously compares the commanded current value with the feedback current value, forming a closed-loop diagnostic. This is the core method for detecting the health of the output circuit, identifying wire breaks, short circuits, or hardware failures.

Output Safety Disable (Suicide Relay)

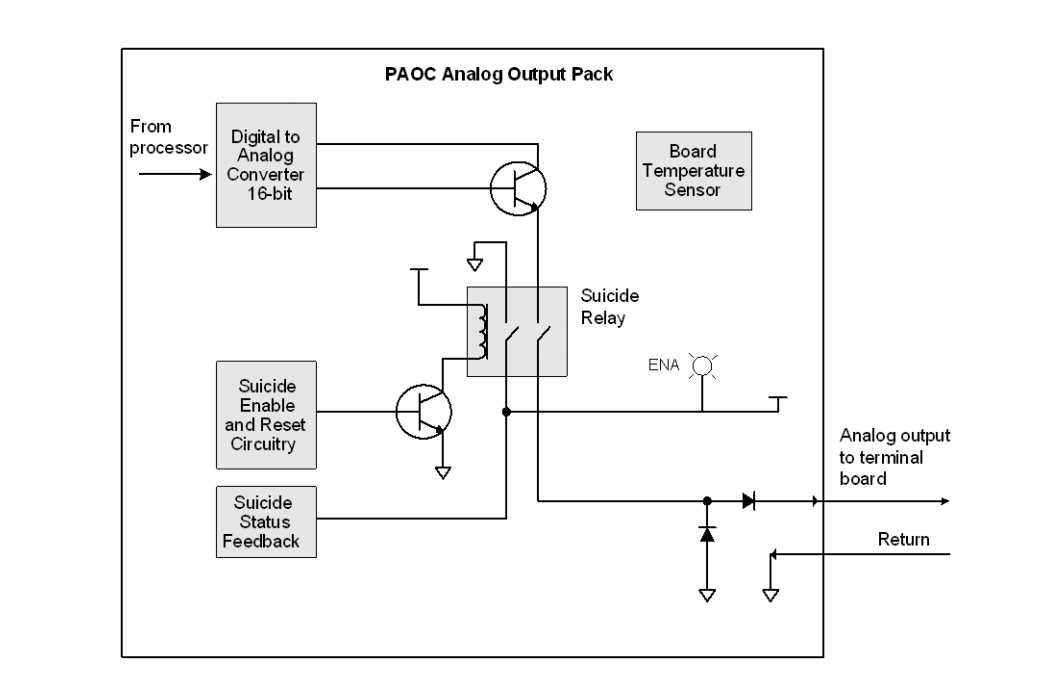

Each output channel is wired in series with a normally-open mechanical relay, known as the "Suicide Relay."

Upon detection of a critical fault, such as output current abnormally exceeding 30 mA, permanent communication loss, or internal hardware self-test failure, the relay is activated immediately, physically disconnecting that output channel from the field load. This function serves as the ultimate robust defense against dangerous equipment actions caused by erroneous signals, representing an inherently safe design.

Comprehensive Self-Diagnostics and Status Monitoring

Power-Up Self-Test: Automatically tests the integrity of RAM, Flash memory, Ethernet ports, and core processor hardware upon startup.

Continuous Health Monitoring: Uninterruptedly monitors the status of the internal +15V and -15V analog circuit power supplies to ensure power quality.

Hardware Identity Verification: Reads and verifies the electronic IDs of the processor board, acquisition board, and terminal board to ensure all hardware components are compatible and matched.

Communication Status Indication: Provides a clear "LINK_OK" status signal, allowing the control system to intuitively understand the communication link status with the module.

Temperature Monitoring: A built-in temperature sensor monitors the module's internal temperature in real-time, providing data for thermal management and overtemperature warnings.

Relay Status Feedback: Reports the actual position (energized/de-energized) of each suicide relay in real-time, ensuring its action matches the control command.

Configurable Offline Output Behavior

Power Down Mode (PwrDownMode): Activates the suicide relay, disconnecting the output circuit, and forces the current output to zero. This is the highest safety level mode.

Hold Last Value Mode (HoldLastVal): Maintains the output at the last valid command value received before communication was lost, suitable for scenarios requiring process stability.

Output Predefined Value Mode (Output_Value): Drives the output to a user-predefined safe value, e.g., returning a valve to a safe position.

Hot-Swappable and Soft-Start Capability

Supports installation or replacement without system power-down, greatly facilitating online system maintenance and expansion.

The built-in soft-start circuit effectively limits inrush current at power-on, protecting the module itself and the system power supply, thereby extending equipment lifespan.

Detailed Working Principles

The operation of the IS220PAOCH1B involves a precise closed-loop system that converts digital commands into physical signals while continuously performing self-verification and protection.

Signal Generation Chain: From Digital Bits to Analog Current

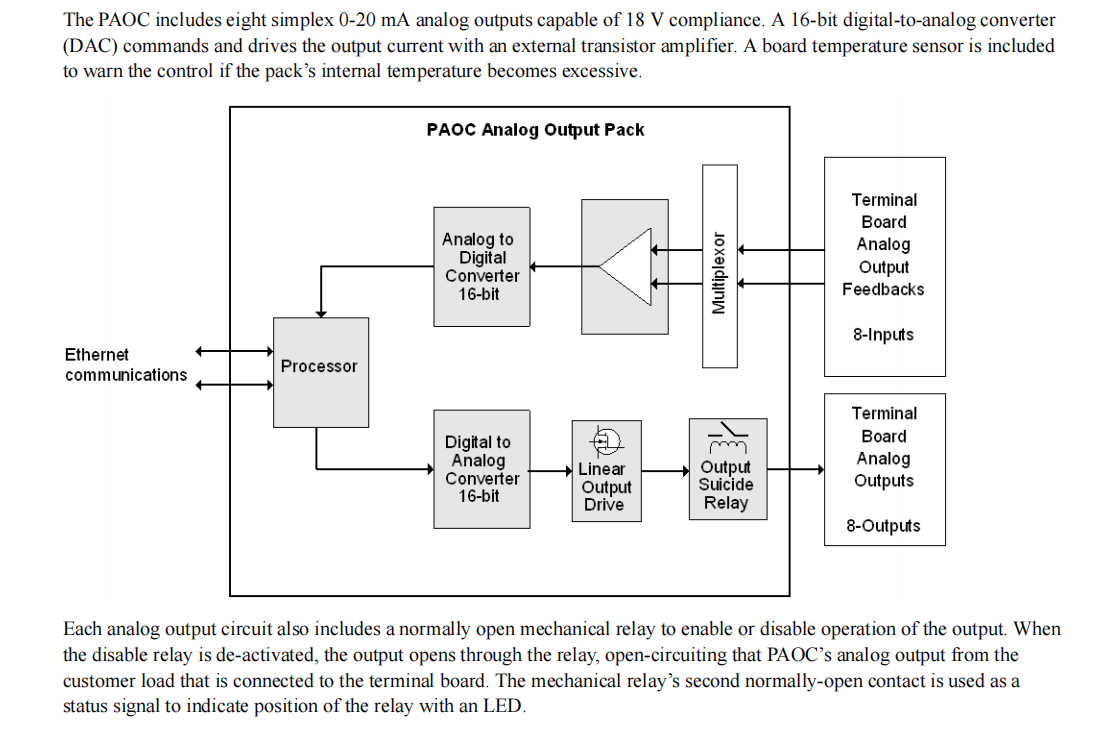

Step 1: Command Reception & Parsing: The main controller sends digital data packets containing target output information to the IS220PAOCH1B's BPPC processor via redundant Ethernet.

Step 2: Digital Command Processing: The processor parses the data and sends the precise digital value representing the target current to a high-performance 16-bit Digital-to-Analog Converter (DAC).

Step 3: Analog Reference Generation: The DAC converts the received digital code into an extremely stable and precise analog reference voltage signal.

Step 4: Power Amplification & Output: This reference voltage drives a linear power amplifier circuit based on external transistors, ultimately generating the required 0-20 mA constant current. This current is delivered to the terminal board via the bottom DC-37 pin connector and finally reaches the field load.

Feedback Monitoring Loop: Creating a Diagnostic Closed Loop

Step 1: Non-Intrusive Current Sampling: On the terminal board, a low-drift 50 Ω sense resistor is connected in series within each output loop. The current flowing through the load also passes through this resistor, generating a small voltage drop proportional to the current according to Ohm's Law.

Step 2: High-Precision Signal Digitization: This voltage signal is fed back into the module, conditioned (e.g., filtered, amplified), and then sampled by a 16-bit Analog-to-Digital Converter (ADC), converting it back into a digital value. This represents the digitized "actual output current."

Step 3: Real-Time Comparison & Alarm: The processor compares the feedback value read by the ADC with the command value sent to the DAC in real-time. If the deviation exceeds the percentage tolerance range set by the user via the D/A_ErrLimit parameter, the module immediately sets the corresponding diagnostic alarm (e.g., Alarms 46-53), indicating potential accuracy drift or hardware failure in that channel.

Safety Protection Mechanism: Decisive Response to Faults

The feedback loop detecting current consistently exceeding the 30 mA safety limit.

Internal diagnostic circuits detecting DAC or amplifier malfunction.

The processor receiving a forced disable command from the safety system.

This mechanism acts as an independent safety layer, triggered by conditions including but not limited to:

Protective Action Execution: Once conditions are met, the processor cuts off the current to the "Suicide Relay" coil. The relay, de-energized, returns to its normally open state, thereby physically completely disconnecting the output circuit, achieving the highest level of safety isolation. The status feedback provided by the relay's auxiliary contacts forms another status monitoring closed loop, ensuring the protective action is faithfully executed.

Thermal Management & Derating Strategy: Ensuring Long-Term Reliability

Heat Source: All 8 outputs of the module use linear amplification technology. Their power dissipation (P = I * V_drop) is significant, where V_drop is the output stage voltage drop (supply voltage minus load voltage). When driving low-impedance loads, V_drop is high, generating substantial heat inside the module.

Active Thermal Management: To ensure all electronic components operate within their safe junction temperature limits and prevent long-term performance degradation or damage due to overheating, the IS220PAOCH1B employs a scientific "thermal derating" strategy. This means that as the number of simultaneously active output channels increases, or the driven load impedance decreases, the maximum allowable ambient operating temperature for the module must be correspondingly reduced. The detailed derating table provided in the datasheet is an essential engineering guide that users must follow when designing the control cabinet cooling system to ensure the module enjoys a long service life in the intended application scenario.

4. Core Differences: IS220PAOCH1B vs. IS220PAOCH1A

Although the IS220PAOCH1B and IS220PAOCH1A are identical in basic functions, interfaces, and physical dimensions, they differ significantly in the following key aspects, which directly impact product selection and application scope.

| Comparison Item | IS220PAOCH1B | IS220PAOCH1A |

| Processor Board | BPPC | BPPB |

| Operating Temp Range | -40°C to +70°C

(Must follow derating guidelines) | -30°C to +65°C

(Must follow derating guidelines) |

| Thermal Derating Performance | Superior

Under the same number of active outputs and load conditions, it allows for a higher maximum ambient temperature inside the cabinet (Refer to derating table on Page 5). This means the IS220PAOCH1B can support denser output configurations or drive lower impedance loads in challenging thermal environments without performance limitation or alarms due to overheating. | Relatively Lower

Under the same conditions, its allowable maximum ambient temperature limits are lower than those of the IS220PAOCH1B, offering slightly less application flexibility. |

| Software Compatibility | Supported by the ControlST software suite V04.06 and later, enabling seamless integration with newer system platforms and features. | Compatible with older software versions, but may require verification or have functional limitations when upgrading to the latest system. |

| Target Application | Suitable for projects and upgrades involving harsher environments, more challenging cooling conditions, or plans to adopt the latest version of control system software. | Suitable for applications with relatively moderate environmental conditions and based on older versions of control system software. |

Summary of Differences: The IS220PAOCH1B can be considered an enhanced version of the IS220PAOCH1A, with its main advantages being a broader operating temperature range, superior thermal performance (derating capability), and better compatibility with future software systems. For new projects or applications demanding higher reliability and a longer lifecycle, the IS220PAOCH1B is the recommended choice.