The IS230STTCH2A is a compact and advanced Simplex Thermocouple Input Terminal Board, designed for the Mark VIe control system to connect and condition field thermocouple signals. As a member of the STTC series, it is characterized by its removable Euro-style terminal blocks, which greatly simplify field wiring and maintenance. This terminal board supports 12 independent thermocouple input channels, capable of handling various international standard thermocouple types. It conditions the weak millivolt-level signals and reliably transmits them to the paired PTCC or YTCC I/O Pack for high-precision analog-to-digital conversion and data processing.

The IS230STTCH2A employs a DIN-rail or panel mounting method, offering the advantages of small size and high integration, making it ideal for control cabinet applications with space constraints. Its design incorporates the core signal conditioning and cold junction compensation technology of the larger TBTC terminal board, while providing modular wiring convenience, making it an ideal interface device for achieving highly reliable temperature monitoring.

II. Key Features & Functions

1. High-Density Modular Structure

Compact Design: Optimized layout, effectively saving space inside the control cabinet.

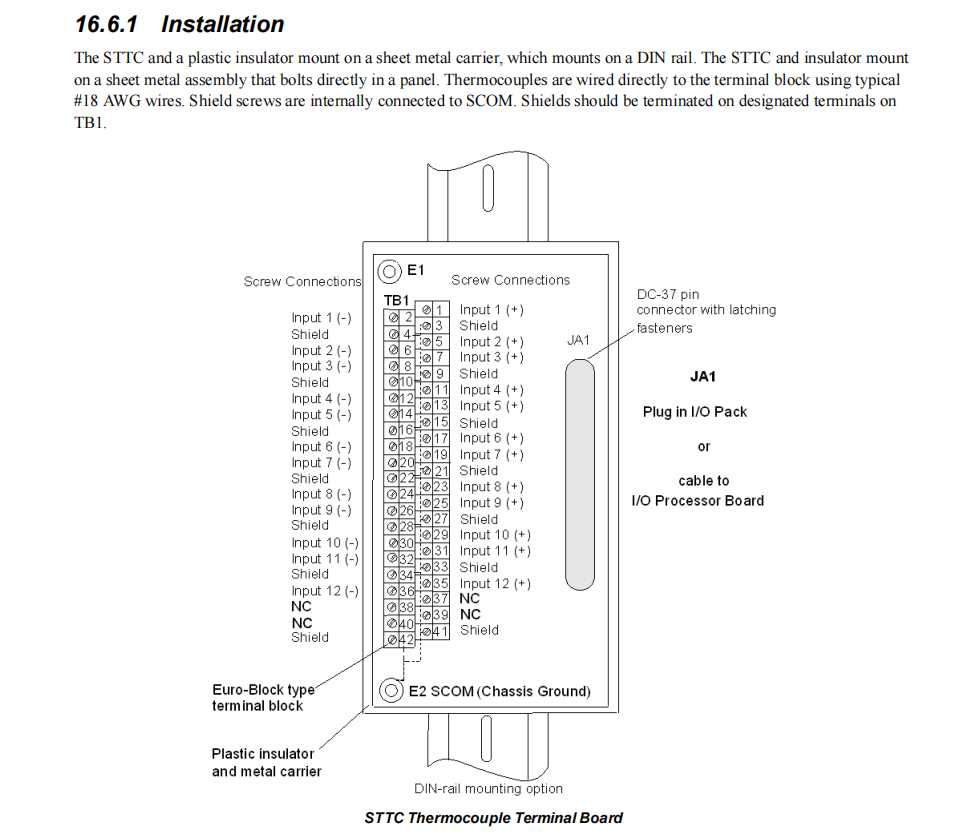

Removable Terminal Blocks: Uses 42-pin removable Euro-style terminal blocks, supporting quick wiring and replacement without handling the entire terminal board, significantly improving maintenance efficiency. In contrast, the IS230STTCH1A has fixed terminal blocks.

Mounting Flexibility: Supports two mainstream industrial mounting methods:

DIN-rail Mounting: Can be assembled with a plastic insulator and metal carrier, then snapped directly onto a standard DIN rail.

Panel Mounting: Can be bolted directly to a control cabinet backplate via a metal carrier assembly.

2. Extensive Signal Compatibility

3. Integrated Signal Conditioning & Protection

Noise Suppression: Each thermocouple input is equipped with a noise suppression circuit, effectively filtering out high-frequency electromagnetic interference from the field environment, ensuring signal purity.

Cold Junction Compensation: Features an onboard precision cold junction reference element to measure the ambient temperature at the terminal block connections (i.e., the cold junction temperature), providing critical compensation data for accurate thermocouple measurement.

Shield Grounding: Provides dedicated shield grounding terminals for connecting thermocouple shield wires, effectively suppressing common-mode noise and improving signal transmission quality.

4. Advanced Diagnostics & Identification

Electronic ID Recognition: The terminal board's JA1 connector integrates a read-only electronic ID chip storing the board's serial number, type, revision, and connector location. The I/O pack reads this information upon power-up and verifies it against the control system configuration. A mismatch triggers a hardware incompatibility fault, preventing misconfiguration.

Open Circuit Detection: The I/O pack injects a very small sense current into each thermocouple loop. If an open circuit occurs in the thermocouple or wiring, this current causes the input voltage to drift to a recognizable abnormal value (typically a very low negative voltage), which is detected by the system, triggering an alarm.

III. Detailed Working Principle

The IS230STTCH2A, serving as the interface between sensors and the control system, operates on a precise process of converting physical temperature signals into digital data understandable by the controller. This process involves signal connection, cold junction compensation, signal transmission, and system diagnostics.

1. Signal Path & Connection

Field Sensor Connection: Field thermocouples are connected via compensation cables to the IS230STTCH2A's removable Euro-style terminal blocks. Each thermocouple occupies two terminals: one for the signal positive and one for the signal negative/shield. The terminal board clearly marks the polarity for each channel.

Signal Routing: The weak millivolt signals generated by the thermocouples are routed through the terminal board's internal printed circuit board to the onboard noise suppression filter. This filter, typically an RC network, attenuates high-frequency noise.

Cold Junction Reference Point: All thermocouple connection terminals are physically located near the same cold junction reference element. This element (often a precision RTD or integrated circuit temperature sensor) accurately measures the temperature at the terminal block metal connections, which is the cold junction temperature for the thermocouple measurement.

2. Cold Junction Compensation Principle

This is a critical step in thermocouple measurement, performed collaboratively by the IS230STTCH2A and the I/O pack.

Root Cause: The thermoelectric potential generated by a thermocouple is a function of the temperature difference between its measuring junction (hot end) and reference junction (cold end). The cold junction temperature on the IS230STTCH2A is not constant (it's typically ambient temperature). Without compensation, changes in the cold junction temperature would be erroneously included in the hot end temperature measurement.

Compensation Mechanism:

a. Temperature Sensing: The cold junction reference element on the IS230STTCH2A continuously senses the cold junction temperature T_cold.

b. Signal Transmission: The electrical signal corresponding to this temperature is transmitted, along with the 12 thermocouple signals, via the DC-37 pin JA1 connector to the PTCC or YTCC I/O pack.

c. Software Calculation: The processor inside the I/O pack reads T_cold and, based on the configured thermocouple type, calculates the expected thermoelectric potential E_cold at that temperature using the type's standard reference tables or polynomials.

d. True EMF Calculation: The processor then adds the measured total EMF E_measured to E_cold to obtain the true EMF E_hot corresponding solely to the hot end temperature T_hot.

e. Temperature Conversion: Finally, using the reference tables again, it converts E_hot to the final hot end temperature T_hot.

This process effectively compensates for the influence of cold junction temperature variations. The cold junction compensation accuracy provided by the STTCH2A system is within ±1.1°C (±2°F).

3. Collaborative Operation with the I/O Pack

The IS230STTCH2A itself does not perform analog-to-digital conversion; it is a passive signal conditioning and interface unit.

Signal Aggregation: The filtered 12 thermocouple analog signals, 1 cold junction compensation signal, and the electronic ID signal are aggregated through the JA1 connector.

Connection to I/O Pack: The PTCC or YTCC I/O pack is plugged directly onto the IS230STTCH2A's JA1 connector or connected via a cable with a DC-37 connector.

Precision Measurement: Inside the I/O pack:

Excitation: The I/O pack provides a stable excitation supply for the cold junction reference element on the IS230STTCH2A.

Multiplexing: A high-precision differential multiplexer sequentially selects each of the 12 thermocouple signals and the cold junction signal.

A/D Conversion: The selected analog signal is fed into a 16-bit high-resolution Σ-Δ ADC for sampling and conversion, at a rate of up to 120 samples per second per channel.

Digital Filtering & Linearization: The converted digital values are further processed by hardware and software digital filters to suppress power line noise. Subsequently, the processor performs linearization calculations based on the cold junction compensation principle and thermocouple characteristics, ultimately yielding accurate temperature values in engineering units.

Data Upload: The computed 12 temperature values, cold junction temperature, and device status information are transmitted in real-time to the Mark VIe controller via IONet Ethernet.

4. Diagnostics & Protection Mechanisms Detailed

Hardware Limit Check: The I/O pack firmware presets hard upper and lower millivolt limits for each thermocouple type. This check occurs immediately after ADC conversion. If a channel's signal exceeds this range, the system deems it invalid and automatically removes the channel from the scan list, preventing one faulty channel from affecting others. Simultaneously, a "Thermocouple Input Voltage Exceeds HW Limit" alarm is triggered.

Open Circuit Detection Principle: The I/O pack injects a tiny bias current into each thermocouple signal line via a high-value resistor. In a normal loop, this current's effect is negligible. But when the thermocouple is open, this current cannot form a loop and accumulates at the ADC input, producing a significant voltage offset. The system detects this specific abnormal voltage pattern and determines that the thermocouple is open, triggering the corresponding alarm.

Electronic ID Verification: This is a key error-proofing mechanism. Each time the system powers up or the pack resets, the PTCC/YTCC reads the IS230STTCH2A's electronic ID via a dedicated communication line. It compares the read information with the expected hardware information in the ControlST configuration. If a model mismatch, incompatible revision, or serial number discrepancy is found, it immediately generates a hardware incompatibility fault, preventing system operation and thus avoiding potential production incidents or equipment damage caused by using incorrect spare parts.

IV. Installation Guide

1. Mechanical Installation

Assembly: Assemble the IS230STTCH2A terminal board with the accompanying plastic insulator.

Mount on Carrier: Mount the assembled unit onto the provided metal carrier.

Final Mounting:

DIN-rail Mounting: Snap the entire carrier onto a standard DIN rail until it locks.

Panel Mounting: Use screws through the mounting holes on the carrier to fix the entire assembly directly to the control cabinet backplate.

Grounding: Use wires to reliably connect the E1 and E2 ground screw points on the carrier to the cabinet safety ground.

2. Electrical Connection

Thermocouple Wiring: Connect the field thermocouple compensation cables to the corresponding positive and negative terminals according to the markings on the terminal block. It is recommended to use #18 AWG shielded twisted pair cables.

Shield Handling: Connect the cable shields to the dedicated shield grounding terminals on the terminal block.

Connect I/O Pack: Plug the PTCC or YTCC I/O pack directly into the IS230STTCH2A's JA1 connector, ensuring the latching mechanisms on both sides engage securely. Alternatively, use a pre-fabricated cable with a DC-37 connector to link the terminal board to a remotely mounted I/O pack.

3. System Power-Up and Verification

After completing all connections, power up the system. Use the ToolboxST software to check if the I/O pack correctly recognizes the IS230STTCH2A terminal board's electronic ID and confirm that all thermocouple channel statuses are normal and readings are accurate.