The IS220PDOAH1A is a Discrete Output I/O module used in GE's Mark VIe and Mark VIeS Control Systems, representing a specific hardware version within the PDOA series. This module is primarily used in industrial automation and control systems to enable remote control and status monitoring of relay devices. The IS220PDOAH1A module incorporates a BPPB processor board, providing robust signal processing and communication capabilities, making it suitable for high-reliability industrial applications such as gas turbines, steam turbines, wind power generation, and process control.

The module connects to the control system network (IONet) via dual Ethernet interfaces, supporting redundant network communication to ensure high data availability. Its output channels can control up to 12 relays and include comprehensive functions such as relay driving, status feedback, fuse monitoring, and self-diagnostics, meeting the configuration requirements for both Simplex and TMR (Triple Modular Redundant) systems.

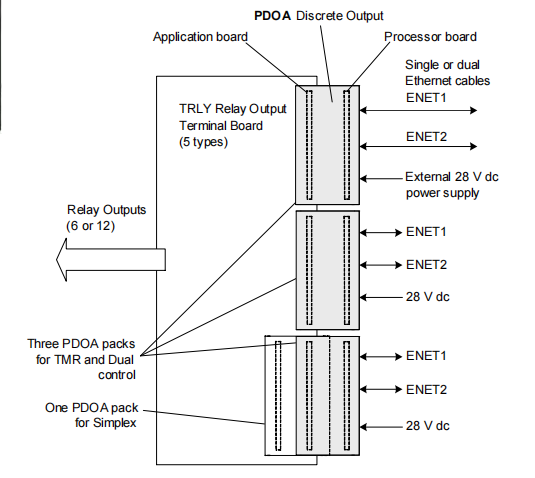

2. Hardware Structure and Interfaces

2.1 Module Composition

The IS220PDOAH1A module consists of two core printed circuit boards:

BPPB Processor Board: Responsible for communication protocol handling, logic control, self-diagnostics, and data reporting.

Acquisition Board: Dedicated to driving discrete output signals and acquiring feedback, providing functions like level shifting, current monitoring, and relay driving.

2.2 External Interfaces

DC-37 Pin Connector: Located on the underside of the module, used for direct connection to relay terminal boards (e.g., TRLY series).

Dual RJ-45 Ethernet Ports (ENET1, ENET2): Support redundant network connections. ENET1 is typically connected to the primary controller network.

3-pin External Power Input: Accepts 28 V DC power to supply the module and the terminal board.

2.3 Mechanical Structure

3. Functions and Operating Principles

3.1 Relay Command Signal Output

The IS220PDOAH1A receives command signals via Ethernet from the controller and outputs relay drive signals through its internal acquisition board. Each output channel uses an open-collector transistor circuit with current monitoring capability to detect whether the relay has picked up correctly and is connected to a load. When an output is activated:

The corresponding yellow status indicator (LEDs 1–12) illuminates.

The current monitor circuit detects load current, and the feedback signal becomes TRUE.

If no current is detected, the indicator remains off, the feedback is FALSE, and the system can identify an output fault.

3.2 Output Enable Control

During initial power-up, all outputs are automatically disabled until the following self-tests are completed:

An Enable Line activates the outputs only after all conditions are met, ensuring relays remain de-energized during system initialization to prevent misoperation.

3.3 Monitor Inputs and Feedback Processing

The IS220PDOAH1A features 15 inverting level-shifting monitor input circuits used to acquire the following feedback signals:

Additionally, the module supports feedback multiplexing control, allowing it to read two sets of 15 signals from the terminal board via a control line for comprehensive monitoring of complex terminal board states.

3.4 Sequence of Events (SOE) Recording

Each relay channel can be configured to generate an SOE record upon a state change, used for fault analysis and system behavior tracing. It is recommended to prioritize using relay feedback signals (rather than output commands) as the SOE source for improved accuracy.

3.5 Power Load Unbalance (PLU) Function

This function is specific to GE industrial applications and requires coordination with a PGEN module to monitor power load status and prevent system faults caused by load imbalance. Detailed descriptions can be found in the GEH-6721_Vol_III manual.

4. Compatibility and System Configuration

4.1 Compatible Terminal Boards

The IS220PDOAH1A supports various relay output terminal boards, including:

| Terminal Board Model | Simplex | TMR | Notes |

| TRLYH1B, S1B | Yes | Yes | Electromechanical, with coil sensing |

| TRLYH1C | No | Yes | Electromechanical, with contact sensing |

| TRLYH2C | Yes | Yes |

|

| TRLYH1D, S1D | No | Yes | With solenoid integrity sensing |

| TRLYH1E, 2E, 3E | No | Yes | Solid-State Relays |

Note: Simplex systems use 1 PDOA module; TMR systems use 3 modules.

4.2 Software and Firmware Requirements

Supports the ControlST software suite V04.04 and later

Configuration, parameter setting, and diagnostics can be performed using the ToolboxST application

5. Installation and Wiring

Installation Steps:

Mount the Terminal Board: Securely install the selected relay terminal board.

Plug in the PDOA Module: Insert the module directly into the terminal board's DC-37 connector.

Mechanically Secure: Use the threaded studs adjacent to the Ethernet ports to secure the module to the mounting bracket.

Connect Network:

Apply Power: Plug in the 28 V DC power connector. The module has soft-start capability, so power does not need to be removed before connection.

Software Configuration: Use ToolboxST to configure module parameters such as relay enable, SOE recording, and fuse diagnostics.

6. Diagnostics and Status Indication

6.1 Self-Diagnostic Functions

The IS220PDOAH1A continuously performs the following self-checks during operation:

Power supply monitoring

Processor and memory checks

Ethernet communication status

Comparison between relay command and feedback states

Verification of terminal board electronic ID

Fuse status reading

6.2 Status Indicators

Yellow LEDs 1–12: Indicate whether each relay output is commanded to energize.

Processor LEDs: Display module communication, power, fault, and other statuses (refer to Common Module documentation).

6.3 Common Alarms and Handling

| Alarm Code | Description | Recommended Action |

| 33-129 | Signal Voting Mismatch (TMR systems) | Check R/S/T module configuration, power, network, mounting |

| 130-141 | Relay Circuit Fuse(s) Blown | Check fuses, terminal board power, configuration, connections |

| 143-154 | Relay Coil State does not match Command | Check output circuit, load, terminal board power |

| 155-166 | NO Contact Voltage disagrees with Command | Check external voltage, terminal board config/connections |

| 191 | TRLY_F Board configured for Simplex error | Change redundancy configuration to TMR in ToolboxST |