The IS220PTCCH1A is a critical component within GE's Mark VIe and Mark VIeS control systems, specifically engineered as a PTCC Thermocouple Input I/O pack. Its primary function is to serve as a precise and reliable interface for acquiring temperature data from a wide array of thermocouple sensors deployed in industrial environments, such as gas and steam turbines. The module is tasked with the crucial job of converting the minute millivolt (mV) signals generated by these thermocouples into high-integrity, high-precision digital data for the control system.

Unlike general-purpose communication modules, the IS220PTCCH1A is a specialized analog input device designed for mission-critical temperature monitoring. Its core value lies in delivering an end-to-end solution for analog signal management, which includes signal conditioning, analog-to-digital conversion, linearization, cold junction compensation, and comprehensive diagnostics. By seamlessly integrating with the Mark VIe controller via the IONet, the module acts as a dependable node in a distributed temperature acquisition network, providing the accurate and reliable data essential for equipment protection, operational control, and performance optimization.

The model number IS220PTCCH1A specifically denotes that it incorporates a BPPB processor board and its acquisition board hardware is calibrated to support a defined subset of thermocouple types.

2. Hardware Architecture and Signal Path

The hardware design of the IS220PTCCH1A is optimized for the accurate measurement of low-level analog signals, comprising two main subsystems:

General-Purpose Processor Board (BPPB): Acting as the module's "brain," the BPPB processor manages communication with the IONet, oversees module operation, processes digitized data from the acquisition board, executes complex linearization algorithms, performs cold junction compensation, and runs continuous self-diagnostic routines.

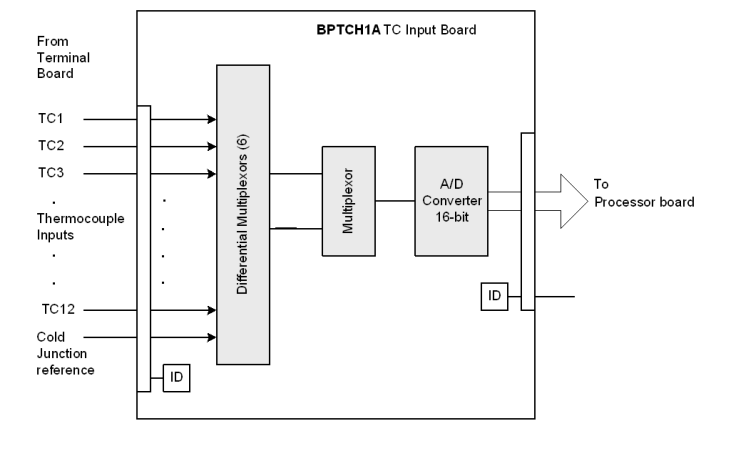

Dedicated Thermocouple Acquisition Board (BPTC): This is the unique, precision analog front-end of the PTCC module. It contains the critical circuitry required for high-accuracy measurement, including multiplexers, filters, and the analog-to-digital converter.

The module's signal path and physical interfaces are as follows:

3. Core Functions and Precision Measurement Principles

The functionality of the IS220PTCCH1A extends far beyond simple signal conversion, encompassing a complete and reliable temperature measurement chain.

3.1 High-Precision Analog Signal Acquisition Chain

This is the physical foundation for accurate measurement. The principle can be summarized in the following steps:

Signal Access and Multiplexing: The weak mV signals from the 12 field-mounted thermocouples are connected to the acquisition board via the terminal board. Internally, the board first manages these signals through six differential multiplexers. This differential input design effectively suppresses common-mode noise.

Signal Digitization: The selected signal is then routed through a main multiplexer to a high-precision 16-bit Analog-to-Digital Converter (ADC). This ADC samples each input at a rate of up to 120 Hz, meaning each thermocouple channel is measured 120 times per second, ensuring the capture of rapid temperature transients.

Filtering and Noise Immunity: The module employs a dual-filtering mechanism combining hardware and firmware filters. Coupled with a configurable system frequency (50/60 Hz), the module delivers exceptional Common-Mode Rejection (110 dB) and Normal-Mode Rejection (80 dB), effectively eliminating common power-line interference and other electrical noise to ensure signal integrity in harsh industrial environments.

3.2 Thermocouple Linearization and Engineering Value Conversion

The relationship between temperature and millivolt output in a thermocouple is non-linear. A core intelligent function of the IS220PTCCH1A module is its on-board execution of linearization algorithms.

Principle: The module's processor contains stored temperature-millivolt characteristic curves (look-up tables) compliant with international standards for supported thermocouple types (E, J, K, S, T). After the ADC acquires the raw millivolt data, the processor references the curve corresponding to the user-configured ThermCpType parameter for that channel (e.g., Type K, Type S) and performs a real-time calculation to convert the mV value directly into its corresponding temperature value (°C or °F).

Advantage: Performing linearization at the I/O pack level reduces the computational load on the main controller and transmits engineering values directly over the network, enhancing overall system efficiency.

3.3 Cold Junction Compensation Technology

This is a critical element in thermocouple measurement. According to thermoelectric principle, the voltage generated is a function of the temperature difference between the measuring junction (hot end) and the reference junction (cold end). Fluctuations in the cold end temperature will directly introduce measurement error.

Principle: The IS220PTCCH1A module measures the temperature at the terminal block (the cold end) in real-time via an integrated cold junction compensation sensor on its connected terminal board.

Compensation Calculation: The module calculates the final temperature using the formula: E(Measuring Junction, 0°C) = E(Measuring Junction, Cold Junction) + E(Cold Junction, 0°C). It uses the measured cold junction temperature and standard thermocouple reference data to compute a compensation value, which is added to the measured thermoelectric voltage. This yields the true voltage referenced to 0°C, which is then linearized to produce an accurate measurement junction temperature.

High Accuracy and Fault Tolerance:

The cold junction temperature measurement accuracy is 1.1°C (2°F) over its operating range.

The module performs system limit checks on the cold junction signal. If the sensor fails (e.g., open circuit, short circuit, or reading outside the hard-coded range of -50 to 85°C), the module marks it unhealthy and automatically switches to using a CJBackup value provided by the controller, ensuring system continuity.

3.4 Comprehensive Diagnostics and Protection Mechanisms

The IS220PTCCH1A incorporates multiple layers of diagnostics to ensure data credibility.

Hardware Limit Check: Circuits on the acquisition board continuously monitor the input millivolt signals. If any channel's input voltage exceeds the IS220PTCCH1A's hardware range of -8 mV to 45 mV, that channel is immediately removed from the active scan list. This prevents a faulty signal from affecting measurements on other channels or the ADC's operation.

System (Software) Limit Check: Users can configure high and low system limits (SysLimit1, SysLimit2) for each thermocouple channel. When the temperature value exceeds these preset boundaries, the module sets a corresponding Boolean status point (e.g., SysLim1TC01), which can be used in the controller logic to trigger alarms or protective shutdowns. These limits can be configured as latching or non-latching.

Self-Diagnostics: The module executes a comprehensive suite of power-up self-tests (RAM, Flash, Ethernet ports, processor hardware). During operation, it continuously monitors internal power supply status (PS18V_PTCC, PS28V_PTCC) and verifies the electronic ID information from the terminal board, acquisition board, and processor board to ensure hardware compatibility.

3.5 Flexible System Configuration Capability

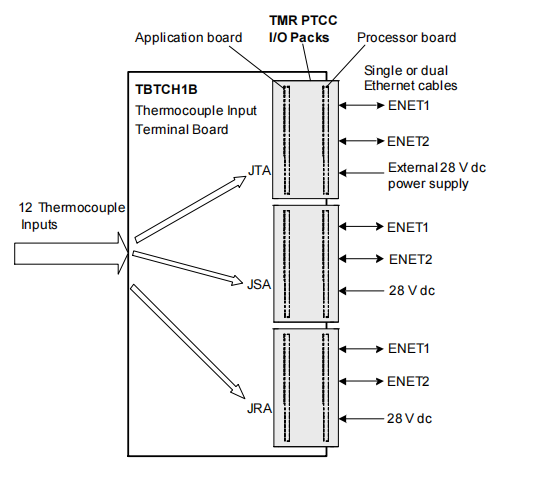

The IS220PTCCH1A supports various system architectures to meet different availability requirements:

4. Configuration and Data Handling

Using the ToolboxST software, engineers can meticulously configure the IS220PTCCH1A:

Channel Configuration: Select thermocouple type (ThermCpType) or set to 'Unused' for each channel, set display units (ThermCpUnit), and enable a 2 Hz low-pass filter (LowPassFlitr).

Limit Setting: Configure two independent system limits for each thermocouple and cold junction sensor, including limit value, enable/disable, latching mode, and check type (≥ or ≤).

Data Handling: The linearized and cold-junction-compensated temperature values are directly mapped as FLOATs into the controller's signal space. Simultaneously, health status bits, limit alarm statuses, and other diagnostic data for each channel and the cold junction are output. All these signals are readily available for use in the controller's application logic.