The IS220PTCCH1B represents an advanced iteration within the GE Mark VIeS distributed I/O portfolio, engineered specifically for high-fidelity thermocouple signal acquisition. This module functions as a critical data gateway, transforming analog temperature measurements from diverse thermocouple types into deterministic, engineering-unit data for the control network. Its design is optimized for integration into modern control architectures where data integrity, operational resilience in extended temperature ranges, and compatibility with contemporary software platforms are paramount. The PTCCH1B is particularly suited for applications demanding robust performance in harsh plant environments, from turbine exhaust monitoring to critical bearing temperature measurements, where its enhanced specifications ensure long-term measurement stability and system reliability.

2. Advanced Hardware Architecture and Component Synergy

The IS220PTCCH1B's hardware configuration is designed for superior performance and longevity, building upon a foundation of enhanced computational power and precision analog design.

High-Performance Processor Board (BPPC): The defining core of the IS220PTCCH1B is its integration of the BPPC processor board. This advanced processor provides increased computational resources necessary for executing complex linearization algorithms for multiple thermocouple types, managing high-speed data communication over the IONet, and running sophisticated diagnostic routines concurrently. Its operational compatibility is certified with ControlST® V04.06 and later, ensuring alignment with the latest system features and cybersecurity protocols.

Precision Acquisition Board (BPTC): This board is a masterpiece of analog signal conditioning, tailored for the microvolt-level signals inherent to thermocouple technology. It incorporates high-stability components and advanced filtering circuits to ensure signal purity before digitization.

Robust Physical Interfacing:

Deterministic Network Uplink: The dual, auto-sensing RJ-45 Ethernet ports provide a fault-tolerant data pipeline to the IONet. The module's firmware seamlessly manages network redundancy, ensuring uninterrupted data flow critical for real-time control and protection logic.

High-Integrity Field Downlink: The module interfaces with the terminal board via a DC-37 pin connector, a robust interface designed for vibration-resistant environments. This connection is engineered to maintain signal integrity for the low-level analog inputs.

Service-Oriented Design: The inclusion of hot-swappable power with soft-start and tool-less mechanical securing via threaded studs underscores a design philosophy focused on maximizing system uptime and simplifying maintenance procedures.

3. Core Functional Capabilities and Operational Principles

The operational intelligence of the IS220PTCCH1B is manifested through its sophisticated signal management, diagnostic depth, and configuration flexibility.

3.1 High-Fidelity Signal Acquisition and Digitization

The module's principle of operation begins with exceptional signal integrity. The acquisition board employs a multi-stage process:

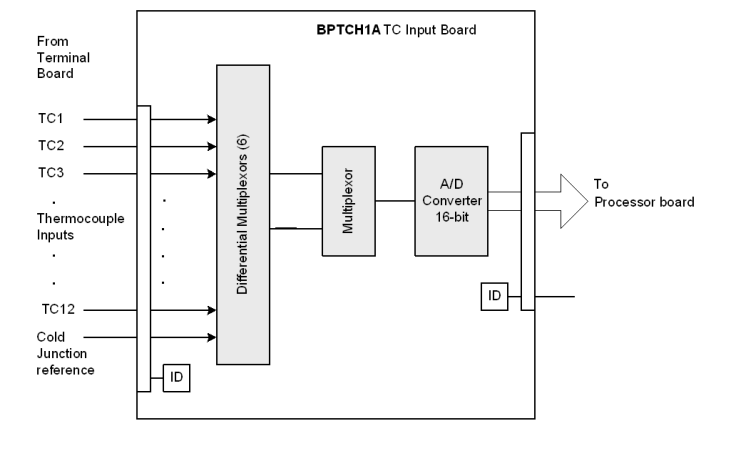

Differential Multiplexing and Conditioning: Each of the 12 channels is processed through high-impedance, differential amplifiers. This configuration inherently rejects common-mode noise, a critical capability in electrically noisy industrial settings. The signals are then routed through a precision multiplexer.

High-Speed, High-Resolution Digitization: The conditioned signal is fed to a 16-bit analog-to-digital converter (ADC) that operates at a sampling rate of up to 120 Hz per channel. This high scan rate is not for data output but for oversampling, a technique that, combined with advanced digital filtering in the BPPC processor, significantly enhances the signal-to-noise ratio and the effective resolution of the measurement, ensuring that the final datapoint is both accurate and stable.

3.2 Intelligent Signal Linearization and Compensation

The module transcends basic conversion by embedding the intelligence required to deliver true temperature values.

On-Board Polynomial Linearization: The BPPC processor executes complex polynomial algorithms or high-resolution lookup tables that conform to international standards (IEC 60584) for each supported thermocouple type (E, J, K, S, T). This real-time mathematical conversion from millivolts to temperature (°C or °F) occurs within the module, offloading this computational burden from the main controller and ensuring timestamp consistency for all channels.

Precision Cold Junction Referencing: Accurate thermocouple measurement requires knowledge of the temperature at the connection point (cold junction). The PTCCH1B utilizes a high-accuracy temperature sensor embedded in its terminal board. This reference measurement is integrated into the thermocouple calculation with a precision of ±1.1°C (±2.0°F), effectively correcting for ambient temperature shifts at the I/O panel. The module continuously monitors the health of this sensor and can seamlessly utilize a controller-provided backup value (CJBackup) in the rare event of a sensor failure.

3.3 Comprehensive Diagnostic and Fault Management System

The IS220PTCCH1B is engineered for predictability and fault awareness, featuring a multi-layered diagnostic architecture:

Proactive Hardware Envelope Monitoring: The analog front-end continuously scrutinizes each input against predefined hardware limits (-8mV to +45mV). An input breaching these limits is automatically and instantly removed from the active scan list. This proactive isolation prevents a single faulty channel, such as one with a grounded or broken element introducing noise, from compromising the integrity of the ADC or the readings from adjacent channels.

Application-Aware System Limit Checking: Beyond hardware limits, users can configure two fully independent software-based system limits per channel. These limits, which can be set in engineering units, are instrumental in implementing operational alarms and protective shutdowns. The logic for these limits is processed within the module, generating discrete status bits (SysLim1TCxx, SysLim2TCxx) that can be directly used by the controller's application code, enabling rapid response to abnormal process conditions.

Continuous Self-Monitoring: The module performs a power-on self-test (POST) and continuously verifies the health of its internal power rails (PS18V_PTCC, PS28V_PTCC), processor, and memory. It also validates the electronic identity of its constituent boards and the loaded application firmware, ensuring a perfectly matched and certified hardware-software set.

3.4 Flexible System Deployment Topologies

The module's design accommodates various criticality levels in control system architecture:

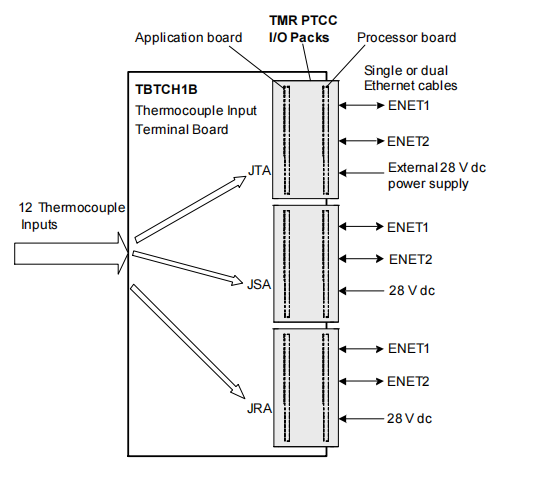

Simplex Configurations: A single IS220PTCCH1B module can service 12 thermocouples. For higher density, a second module can be added to compatible terminal boards (e.g., TBTCH1B at JRA & JTB) to support 24 inputs.

Fault-Tolerant TMR Configurations: In Triple Modular Redundant systems, three IS220PTCCH1B modules are deployed in parallel, each independently measuring the identical set of 12 thermocouples. The Mark VIeS controller performs a mid-value select or voting algorithm on the three independent readings. The IS220PTCCH1B supports this architecture with a TMR_DiffLimit parameter, which triggers a diagnostic alarm if the discrepancy between any two readings exceeds a user-defined threshold, flagging a potential sensor or module issue before it impacts the voted output.

4. Configuration and Data Handling

Configuration is centralized within the ToolboxST® software suite, allowing for granular control:

Parameterization: Engineers define the thermocouple type (ThermCpType), engineering units (ThermCpUnit), and filtering (LowPassFlitr) for each channel.

Limit Management: Two fully configurable system limits with individual enable, latching, and threshold settings allow for precise alarm setting.

Data Stream Output: The module publishes a rich dataset to the controller, including the primary temperature value (FLOAT), the health status of each channel and the cold junction, and the status of all configured system limits.

5. Detailed Comparison: IS220PTCCH1B vs. IS220PTCCH1A

While both the IS220PTCCH1B and IS220PTCCH1A provide 12-channel thermocouple input functionality, key technological and operational differentiators define their application domains and system compatibility.

| Feature | IS220PTCCH1B (PTCCH1B) | IS220PTCCH1A (PTCCH1A) |

| 1. Processor Board & Performance | BPPC. This represents a more advanced generation of processor, offering enhanced processing power and memory. This facilitates more complex on-board calculations and efficient handling of network traffic and diagnostics. | BPPB. The standard processor for the foundational PTCC implementation, providing reliable performance for core thermocouple input tasks. |

| 2. Firmware & System Compatibility | Mandates ControlST® V04.06 or later. This positions the PTCCH1B as the module for current and future system deployments, ensuring support for the latest software features and security updates. | Compatible with earlier versions of ControlST®, making it suitable for existing Mark VIe systems where a platform software upgrade is not planned. |

| 3. Environmental Robustness | Extended Operating Range: -40°C to +70°C. This wider temperature tolerance makes the PTCCH1B uniquely suited for installations in non-climate-controlled environments or geographical locations with extreme ambient conditions, enhancing its long-term reliability. | Standard Operating Range: -30°C to +65°C. Adequate for most controlled industrial settings but with less margin for extreme ambient exposure. |

| 4. Product Designation & Platform | Designated as IS420, indicating its native integration and optimization within the Mark VIeS system platform and its associated architecture. | Designated as IS220, reflecting its origin within the standard Mark VIe system platform. |

| 5. Functional Emphasis | The architecture emphasizes its role in high-integrity, fault-resilient systems, with a focus on advanced diagnostics and performance in challenging environments. | The design focuses on delivering robust and cost-effective core functionality for standard thermocouple input requirements. |