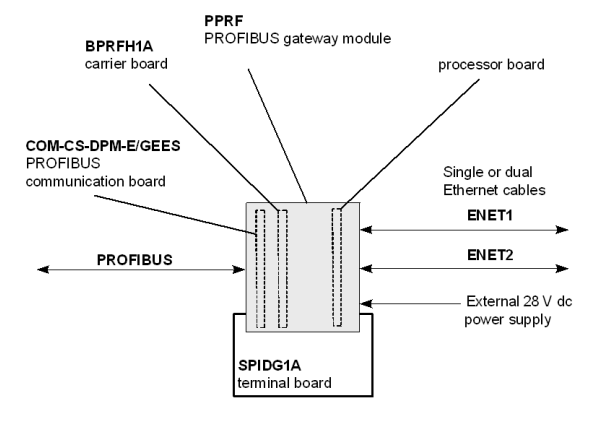

The IS220PPRFH1B PROFIBUS Master Gateway represents the evolution of the Mark VIe control system's fieldbus integration capability, delivering enhanced performance and expanded protocol support. As a PROFIBUS DP-V1 Class 1 Master, this I/O pack builds upon the foundation of its predecessor by incorporating advanced features that enable more sophisticated device management and data exchange capabilities. The IS220PPRFH1B serves as a critical integration point between the Mark VIe control environment and PROFIBUS DP networks, facilitating not only basic I/O mapping but also supporting complex acyclic communication and enhanced diagnostic functions.

This advanced gateway incorporates the BPPC processor board, which provides the computational foundation for handling the increased demands of modern industrial automation systems. The IS220PPRFH1B is specifically engineered to address the growing need for higher-speed data processing, improved device parameterization capabilities, and seamless integration with asset management systems through standardized technologies.

2. Enhanced System Architecture and Functional Capabilities

2.1 Advanced Protocol Support: DP-V1 Master Functionality

The IS220PPRFH1B's most significant advancement lies in its support for PROFIBUS DP-V1 functionality, which extends beyond the basic cyclic data exchange of DP-V0:

Acyclic Data Communication: Enables parameterization, configuration, and diagnostic data exchange outside the regular cyclic process data communication stream. This allows for reading and writing of detailed device parameters without interrupting real-time control processes.

Alarm Handling Mechanisms: Supports sophisticated alarm management with confirmed and unconfirmed alarm services, providing more reliable notification of device status changes and fault conditions.

Extended Device Identification: Facilitates comprehensive device identification and management through enhanced read and write services, enabling better asset tracking and maintenance planning.

2.2 FDT/DTM Technology Integration

The IS220PPRFH1B leverages Field Device Tool (FDT) technology to provide unprecedented access to device-level intelligence:

Device Type Manager (DTM) Support: Enables the use of manufacturer-specific DTMs through GE's PROFIBUS Communication DTM, allowing for detailed device configuration, calibration, and diagnostics directly from engineering workstations.

Asset Management Integration: Through coordination with the Device Manager Gateway, the IS220PPRFH1B enables remote management of PROFIBUS DP-V1 devices from any FDT frame application, supporting centralized asset management strategies.

Unified Engineering Environment: Eliminates the need for manufacturer-specific configuration tools by providing a standardized interface for all PROFIBUS devices with certified DTMs.

2.3 Enhanced Redundancy and System Availability

Building upon the HotBackup capability, the IS220PPRFH1B introduces refinements that improve system reliability:

Intelligent Switchover Logic: Enhanced algorithms for detecting master failures and initiating switchover procedures, ensuring minimal disruption to process operations.

State Synchronization Improvements: More sophisticated mechanisms for maintaining configuration and operational state synchronization between active and backup masters.

Extended Diagnostic Coverage: Comprehensive monitoring of both PROFIBUS network health and the redundancy communication path between paired IS220PPRFH1B modules.

3. Hardware Architecture and Performance Enhancements

3.1 Processor and Memory Advancements

The IS220PPRFH1B incorporates significant hardware improvements that enable its advanced functionality:

BPPC Processor Board: Provides enhanced processing power to handle the computational demands of DP-V1 communications and faster frame rates.

Expanded Flash Memory: Features 4096K x 8 bits of Flash memory, substantially larger than previous versions, accommodating more complex firmware and extensive configuration data for large-scale PROFIBUS networks.

Optimized Memory Architecture: Improved memory management for handling the increased data volumes associated with high-speed PROFIBUS networks and extensive I/O configurations.

3.2 Communication Performance Specifications

The IS220PPRFH1B delivers superior performance characteristics that distinguish it from earlier versions:

Extended Frame Rate Support: Operates at frame periods of 10, 20, 40, 80, 160, and 320 ms, with 10 ms capability being exclusive to the H1B version for high-speed applications.

Enhanced Data Throughput: Supports larger I/O configurations at faster frame rates, enabling more responsive control loops and higher data acquisition rates.

Improved PROFIBUS Network Utilization: Advanced scheduling algorithms optimize PROFIBUS token rotation and data exchange timing, maximizing network efficiency.

4. Advanced Operational Principles

4.1 Dual-Mode Communication Architecture

The IS220PPRFH1B operates through a sophisticated dual-mode communication architecture:

Cyclic Process Data Exchange: Maintains high-performance cyclic exchange of process data with PROFIBUS slaves, ensuring deterministic real-time control performance.

Acyclic Service Channel: Operates parallel acyclic communication channels for device configuration, parameterization, and extended diagnostics without impacting cyclic process data performance.

Dynamic Bandwidth Allocation: Intelligently manages PROFIBUS network bandwidth between cyclic and acyclic communications based on system demands and priorities.

4.2 Advanced Data Management

The IS220PPRFH1B implements sophisticated data handling mechanisms:

Configurable Data Processing: Supports flexible data type conversions and scaling operations within the I/O pack, reducing controller processing load.

Enhanced Input Filtering: Provides advanced filtering options for analog and digital inputs, improving signal quality and reliability.

Intelligent Data Validation: Implements comprehensive data validation checks with configurable response actions for detected anomalies.

4.3 Sophisticated Network Management

The IS220PPRFH1B incorporates advanced PROFIBUS network management capabilities:

Dynamic Slave Management: Supports automatic detection and configuration of slave devices in certain operating modes.

Network Diagnostics Enhancement: Provides detailed network performance statistics and communication quality indicators for proactive maintenance.

Configurable Retry Strategies: Implements sophisticated retry mechanisms for failed communications with configurable attempt limits and timeout values.

5. Configuration and Commissioning Enhancements

5.1 Advanced Parameterization Capabilities

The IS220PPRFH1B supports extensive parameterization options that enable fine-tuning of system behavior:

ProfiClearMode Configuration: Allows selective enabling/disabling of CLEAR mode behavior when IONet communication is lost, providing flexibility in fail-safe strategy implementation.

Extended Diagnostic Control: SetDiagOnExtDiag parameter enables precise control over diagnostic presence annunciation, allowing users to focus on critical device monitoring.

Performance Optimization Parameters: Numerous configurable parameters for optimizing data exchange timing, buffer management, and communication scheduling.

5.2 Enhanced ToolboxST Integration

The IS220PPRFH1B benefits from improved integration with the ToolboxST engineering environment:

Streamlined Device Configuration: Enhanced wizards and templates for rapid configuration of complex PROFIBUS device networks.

Advanced Diagnostics Visualization: Improved diagnostic display and analysis tools within the Component Editor for faster troubleshooting.

Configuration Validation Tools: Enhanced pre-download configuration checks and validation routines to prevent configuration errors.

6. Advanced Diagnostic and Monitoring Capabilities

6.1 Comprehensive Health Monitoring

The IS220PPRFH1B implements an extensive health monitoring system:

Multi-level Diagnostic Hierarchy: Implements a structured diagnostic approach covering module, network, and device-level health indicators.

Predictive Maintenance Support: Through analysis of communication statistics and device performance trends, supports predictive maintenance strategies.

Detailed Performance Metrics: Provides comprehensive performance data including communication load, error rates, and response time statistics.

6.2 Enhanced LED Indication System

The IS220PPRFH1B features an advanced LED indication system that provides detailed status information:

Multi-state Visual Feedback: LEDs provide clear indication of operational states, fault conditions, and communication status through various flashing patterns and colors.

Quick Status Assessment: The intuitive LED patterns enable rapid field assessment of module health and network status without requiring connection to engineering tools.

Detailed Fault Indication: Specific LED sequences indicate particular fault conditions, accelerating initial troubleshooting efforts.

7. Comparative Analysis: IS220PPRFH1B vs. IS220PPRFH1A

The IS220PPRFH1B represents a significant evolutionary step from the IS220PPRFH1A, with enhancements that address the demands of modern industrial automation systems:

7.1 Protocol and Functional Capabilities

| Feature | IS220PPRFH1B | IS220PPRFH1A |

| PROFIBUS Protocol Support | DP-V0 and DP-V1 Class 1 Master | DP-V0 Class 1 Master only |

| Acyclic Communication | Supported for parameterization and diagnostics | Not supported |

| Alarm Handling | Advanced DP-V1 alarm services with confirmation | Basic diagnostic reporting only |

| FDT/DTM Technology | Full support through GE's PROFIBUS Communication DTM | Not supported |

| Device Management | Remote device management via Device Manager Gateway | Limited to basic configuration |

7.2 Performance and Operational Characteristics

| Characteristic | IS220PPRFH1B | IS220PPRFH1A |

| Frame Period Support | 10, 20, 40, 80, 160, 320 ms | 20, 40, 80, 160, 320 ms |

| 10 ms Frame Operation | Fully supported and recommended for high-speed applications | Not supported (20 ms possible but not recommended) |

| Processor Board | BPPC processor with enhanced capabilities | BPPB processor |

| Flash Memory | 4096K x 8 bits for complex configurations | 512K x 8 bits |

| I/O Capacity at 10/20 ms | Up to 1664 points at 20 ms frame rate | Limited capacity at 20 ms (not recommended) |

| Data Throughput | Higher throughput at faster frame rates | Limited throughput at faster rates |

7.3 Configuration and Maintenance Features

| Aspect | IS220PPRFH1B | IS220PPRFH1A |

| Device Parameterization | Online parameterization via DP-V1 acyclic services | Requires bus stop for configuration changes |

| Diagnostic Capabilities | Extended diagnostics with detailed device information | Standard PROFIBUS diagnostics only |

| Asset Management | Integrated asset management through FDT/DTM | Basic device identification |

| Configuration Flexibility | Advanced parameters for fine-tuning network behavior | Basic configuration options |

7.4 Application Suitability and Migration Considerations

The IS220PPRFH1B is particularly advantageous for:

New installations requiring high-speed data acquisition and control

Systems with complex PROFIBUS devices that benefit from DP-V1 services

Applications demanding advanced device management and asset management integration

Environments where reduced engineering effort through FDT/DTM technology is valuable

For existing IS220PPRFH1A installations, migration to PPRFH1B provides:

Enhanced performance through support of faster frame rates

Reduced maintenance effort through advanced diagnostic and device management capabilities

Future-proofing through support of modern PROFIBUS features and technologies

Improved system availability through enhanced redundancy and diagnostic features

7.5 Technical Superiority and Operational Benefits

The IS220PPRFH1B demonstrates clear technical superiority through:

Approximately 60% larger I/O capacity at comparable frame rates

Support for 10 ms frame periods enabling higher-speed control applications

Advanced communication capabilities through DP-V1 protocol support

Modern device integration through FDT/DTM technology

Enhanced engineering efficiency through improved configuration and diagnostic tools

The operational benefits include reduced commissioning time, improved maintenance efficiency, enhanced system performance, and better integration with modern industrial automation architectures. These advantages make the IS220PPRFH1B the preferred choice for new projects and system upgrades where optimal performance and modern feature sets are required.