The VM600 RLC16 Relay Card is a key optional component from VM product line, specifically designed for the VM600 series of machinery protection systems and condition and performance monitoring systems. Its primary function is to expand the system's relay output capability. When the four built-in relays on the system's main input/output card (IOC4T) are insufficient for complex application requirements, the RLC16 provides substantial additional relay resources, serving as core hardware for building high-reliability, multi-loop interlock protection logic.

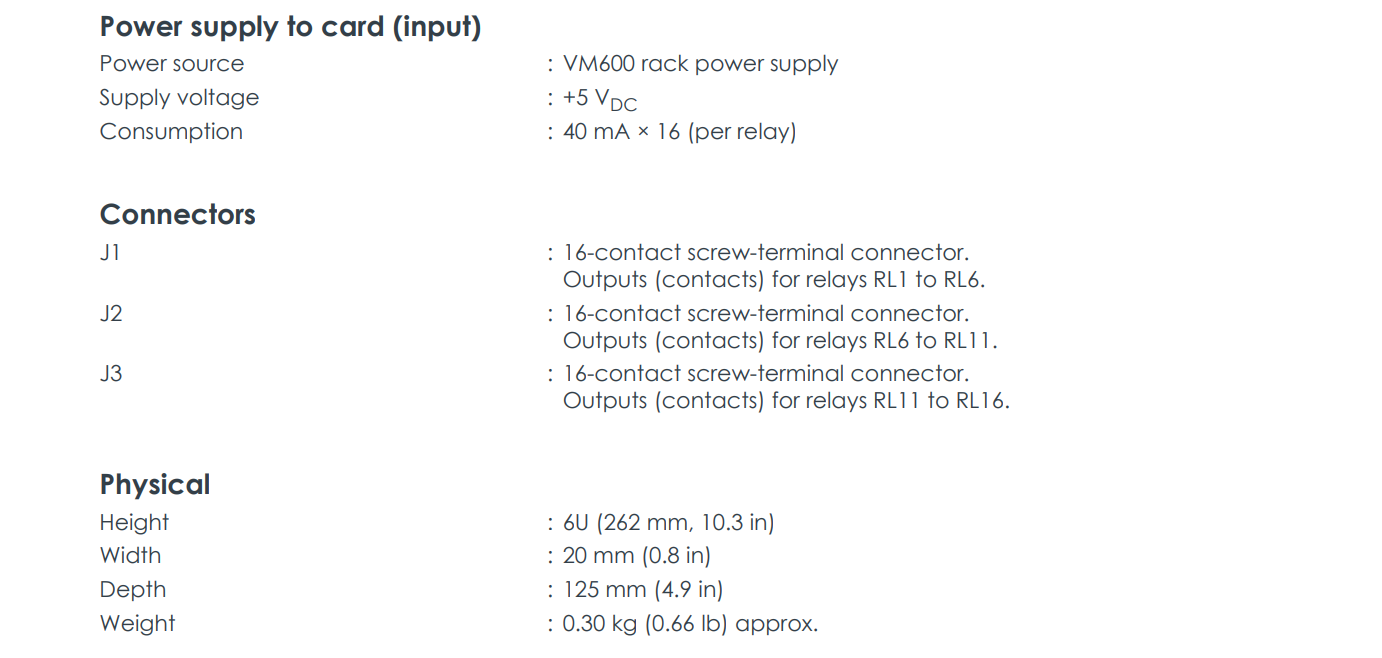

The RLC16 is a relay output card based on screw-terminal connectors. Its core feature is providing 16 high-quality relays, each equipped with Change-Over Contacts. The card features a standardized 6U height design, installed at the rear of a VM600 rack (ABE04x or ABE056) and connected directly to the rack's backplane via a single connector, offering high integration and easy installation.

A standout advantage of this card is its support for live insertion and removal (hot-swappable). This allows for the safe installation or replacement of the card while the system remains powered and operational, significantly enhancing system availability and maintenance convenience. Furthermore, its relay drive logic can be flexibly configured via jumpers to Normally Energized (NE) or Normally De-energized (NDE) mode, adapting to different safety logic designs and fail-safe requirements.

The RLC16 is designed to comply with European EMC and other relevant standards, possessing excellent electrical characteristics such as low contact resistance, low capacitance, and high current-carrying capacity, ensuring long-term stability and reliability in harsh industrial environments. It is widely used in protection systems for various types of rotating machinery to drive critical external circuits for alarms, shutdowns, and sequential control.

Working Principle

The working principle of the RLC16 relay card exemplifies the complete chain from logical command to physical action in industrial control. Its core function involves receiving software commands from the VM600 system monitoring cards (e.g., MPC4) and driving the relays to actuate via hardware circuits, ultimately controlling external circuits through the contacts. Its workflow and internal mechanisms are detailed below:

1. Command Reception and Signal Path

The core of the VM600 system (e.g., CPUM or CPUR controller) continuously runs protection logic and algorithms. When monitored parameters (such as vibration, displacement, speed) exceed preset alarm or trip thresholds, the system software generates a corresponding logical control command. This command is transmitted via the VM600 rack's backplane bus. The backplane provides high-speed, reliable data and power connections between cards.

The RLC16 card receives these commands from the controller via its sole backplane connector. The card's receiving circuitry decodes the commands, identifying the specific relay channel (RL1 to RL16) that needs to be operated and the desired action state (close or open).

2. Relay Drive Circuit and Logic Configuration

The decoded commands are sent to an array of Open-Collector Drivers. Each relay corresponds to an independent driver. The driver's role is to provide a software-controlled, active-low signal to energize the relay coil.

The RLC16 provides a crucial user-configurable option: Relay Drive Logic Selection. This is achieved via Jumpers on the card:

Normally De-energized (NDE) Mode: When the jumper is set to NDE, an active driver output (low level) energizes the relay coil, causing the contact state to change (Normally Open contacts close, Normally Closed contacts open). When the driver output is inactive (high level) or the card loses power, the coil de-energizes, and the relay returns to its initial "de-energized" state. This mode is typically used for "fail-safe" design, meaning the relay state reverts to a predetermined safe state (e.g., trip circuit open) upon system power loss or failure.

Normally Energized (NE) Mode: When the jumper is set to NE, the logic is inverted. The driver needs to continuously output an active signal (low level) to keep the coil energized, thereby maintaining the relay in its "normal operation" state. Once the driver output becomes inactive (high level) or the card loses power, the coil de-energizes, and the relay actuates. This mode is suitable for applications requiring the relay to remain engaged for extended periods.

This flexible jumper selection allows system integrators to configure each RLC16 card according to the end-user's safety philosophy and specific control logic, without changing external wiring or software logic.

3. Relay Actuation and Load Control

When the driver's output energizes the relay coil, the magnetic field generated by the coil pulls the armature, moving the mechanical structure to switch the state of the change-over contacts. Each relay provides one set of change-over contacts, including one Common (COM), one Normally Closed (NC) contact, and one Normally Open (NO) contact.

These contacts are brought out to the external world via three screw-terminal connectors (J1, J2, J3) at the rear of the card. Users can connect the power circuit of field devices that need to be controlled (e.g., alarm horns, shutdown solenoids, indicator lights, PLC digital input points) in series with these contacts.

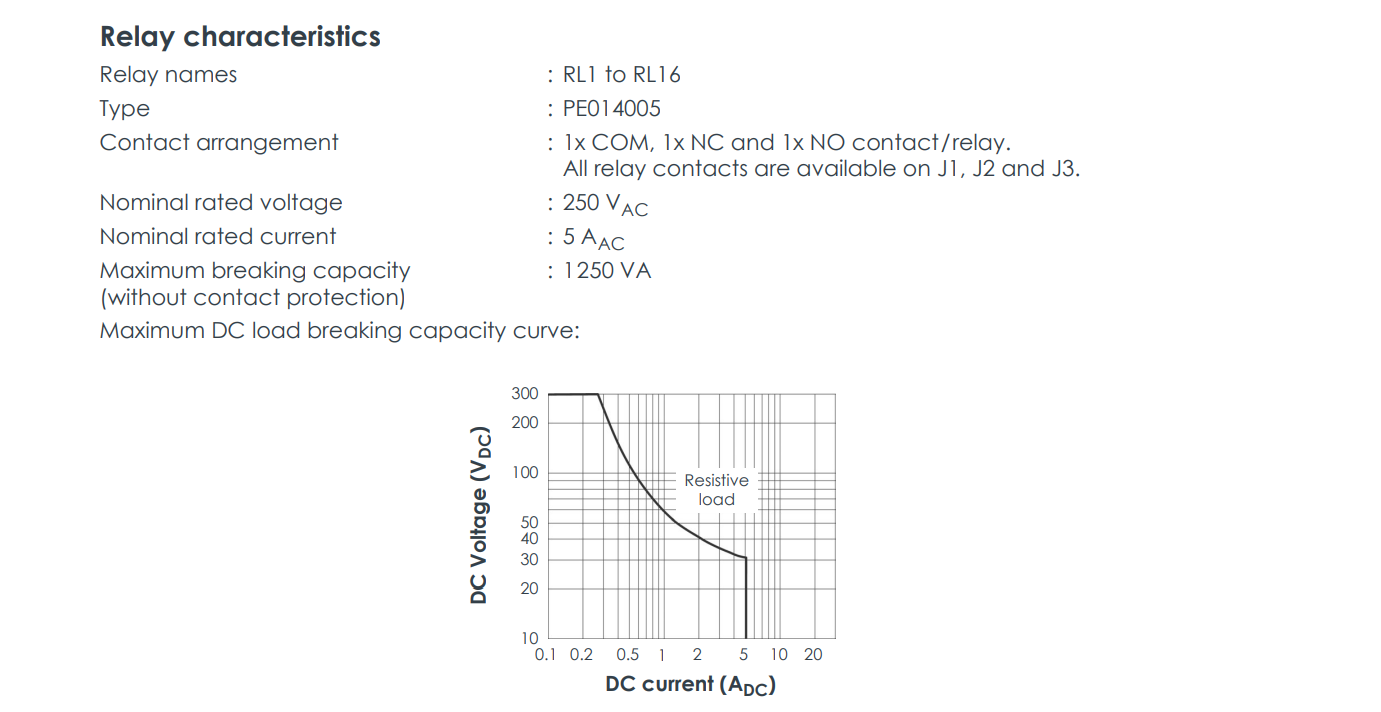

The actuation of the contacts directly controls the opening and closing of the external load circuit. The relays used in the RLC16 have strong load capacity, rated for 250 VAC / 5 AAC, with a maximum breaking capacity of 1250 VA. This means it can directly drive many industrial devices without requiring intermediate relays for secondary conversion. Its low contact resistance ensures minimal voltage drop during conduction, while low capacitance is beneficial for maintaining signal integrity when switching signal circuits.

4. Power Supply and Safety Features

The RLC16 card itself is powered by the VM600 rack power supply via the backplane, providing +5 VDC operating power. This power is primarily used for the card's logic circuitry and relay drivers. It is important to note that the drive power for the relay coils is also supplied from the backplane, but its switching is ultimately controlled by the open-collector drivers.

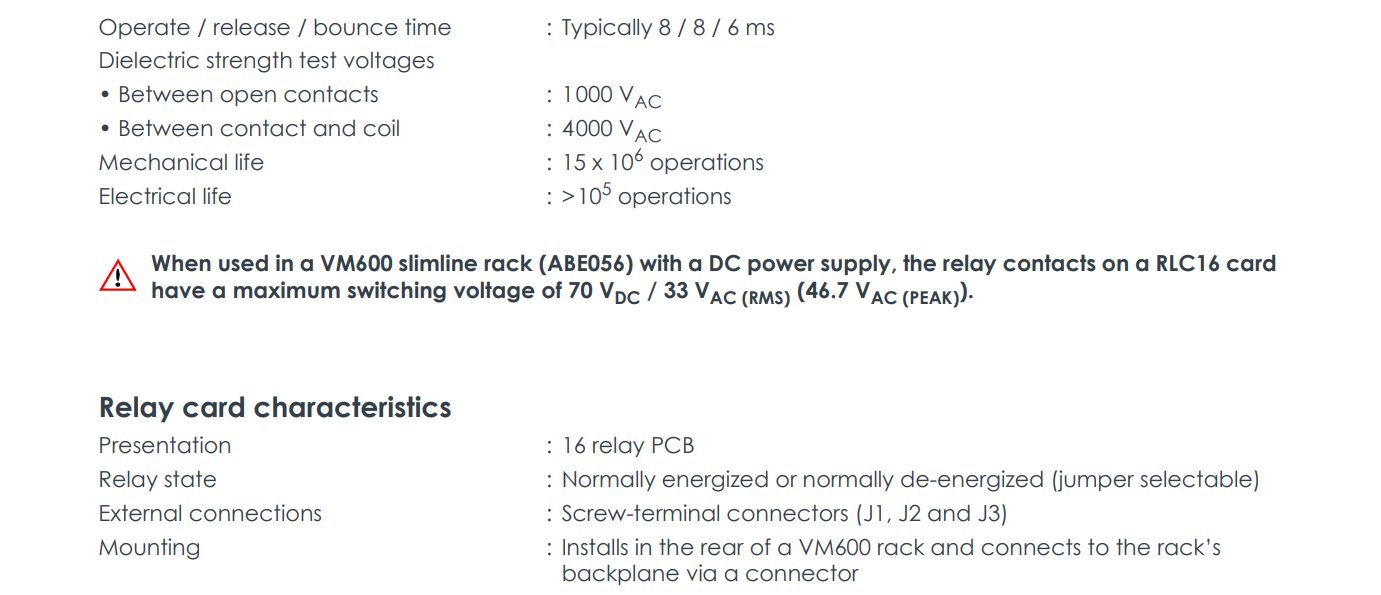

The relay contacts are highly electrically isolated from the internal coil circuit (4000 VAC), ensuring safety isolation between the low-voltage control side and the high-voltage load side, effectively preventing damage to the low-voltage control system from high-voltage intrusion. The contacts themselves can also withstand a 1000 VAC dielectric strength test.

5. Hot-Swap Mechanism

The "hot-swap" functionality is realized through careful electrical design. The card's connector utilizes a pin definition sequence that connects the ground first, followed by power and signals. When inserting the card, the ground pins make contact first, discharging any possible electrostatic discharge (ESD); then the power and signal pins connect, ensuring the card is stable within the rack before power is applied. The sequence is reversed during removal. This design prevents arcing and signal surges caused by live insertion/removal, protecting both the card and the backplane.

Core Features and Benefits

High-Density Relay Output: Provides 16 channels of high-quality relays, greatly expanding the VM600 system's external control capability.

Flexible Drive Logic: Jumpers allow selection of NE or NDE mode for all relays uniformly, adapting to different fail-safe design needs.

Change-Over Contacts: Each relay provides one set of COM, NC, NO contacts, offering flexible wiring options for various control logics.

Strong Load Capacity: Contacts rated for 250 VAC / 5A, maximum breaking capacity 1250 VA, capable of driving most industrial loads directly.

Hot-Swap Support: Allows for installation or maintenance while the system is running, greatly improving system availability and maintainability.

High-Reliability Electrical Characteristics: Low contact resistance, low capacitance, high isolation strength (4000 VAC between coil and contacts), ensuring long-term stable operation.

Convenient Connection Method: All contacts are accessible via three screw-terminal connectors (J1, J2, J3), ensuring secure and reliable wiring.

Comprehensive International Certifications: Complies with CE, EAC and other certification standards, meeting EMC (EN 61000-6-2, EN 61000-6-4), electrical safety (EN 61010-1), and other requirements.

Robust Environmental Adaptability: Operating temperature range from -25°C to +65°C, meeting typical industrial environment requirements.

Key Technical Specifications

Number of Relays: 16 (RL1 - RL16)

Contact Type: Change-Over (1 Form C), per relay: 1 COM, 1 NC, 1 NO

Contact Rating: 250 VAC, 5 AAC

Maximum Breaking Capacity: 1250 VA

Electrical Life: > 100,000 operations

Mechanical Life: 15 x 10^6 operations

Drive Logic: Software-controlled, open-collector output, jumper selectable NE or NDE

Connectors: 3 x 16-position screw-terminal connectors (J1, J2, J3)

Power Supply: +5 VDC (from rack backplate), consumption ~40 mA/relay

Operating Temperature: -25°C to +65°C

Dimensions (H x W x D): 6U (262 mm) x 20 mm x 125 mm

Installation: Rear of VM600 rack (ABE04x, ABE056)

Applications

The RLC16 relay card is primarily used in Machinery Protection Systems (MPS) as an actuator. Specific applications include, but are not limited to:

Alarm Indication: Driving audible and visual alarms to indicate equipment abnormalities.

Emergency Shutdown: Driving safety circuits to trigger unit trip shutdowns.

Sequential Control: Participating in the start/stop sequence logic control of equipment.

Status Indication: Driving indicator lights to display equipment status (e.g., running, stopped, fault).

Signal Relay: Forwarding system status signals to DCS, PLC, or other upper-level management systems.