The VM600 CPUM Mk2 is a core component of VM product line for the VM600 Mk2 (second generation) rack-based monitoring system. It serves as a rack controller and communication interface module paired with the IOCN Mk2. As a key part of the second-generation VM600 system, the CPUM Mk2 offers significant improvements over the first-generation CPUM module in terms of hardware architecture, processing capabilities, communication features, and system integration.

The CPUM Mk2 and IOCN Mk2 modules together form a complete module pair, providing system control, data communication gateway, and signal interface functions for the VM600 Mk2 system. Designed for demanding industrial environments, this module is widely used in rotating machinery protection and condition monitoring systems in power generation, oil and gas, and other industries.

Key Differences Between CPUM Mk2 and CPUM

1 Hardware Architecture Differences

| Feature | CPUM (First Generation) | CPUM Mk2 (Second Generation) |

| Module Width | Double-width (occupies 2 slots) | Single-width (occupies 1 slot) |

| Processor | AMD Geode™ LX800 500MHz | Upgraded processor (specific model not disclosed) |

| Memory | 256MB DRAM | Enhanced memory configuration |

| Module Structure | Carrier board + PC/104 modular design | Integrated design |

2 Communication Capability Differences

| Communication Feature | CPUM (First Generation) | CPUM Mk2 (Second Generation) |

| System Ethernet | 10/100BASE-TX (max 100Mbps) | 10/100/1000BASE-T(X) (max 1Gbps) |

| Fieldbus Support | Modbus RTU/TCP, PROFINET | Modbus TCP, PROFIBUS DP |

| Serial Interfaces | Up to 3 RS-232/RS-422/RS-485 | 2 RS-485 (supporting PROFIBUS DP) |

| Redundancy Support | Limited support | Full rack-level redundancy support |

3 Processing Capability Differences

The CPUM Mk2 shows significant improvements in data processing capabilities:

Mathematical processing functions: The Mk2 version adds a more powerful mathematical processing engine supporting more complex data processing algorithms

Data aggregation capability: Ability to process data from more modules simultaneously, improving system integration

Real-time performance: Faster processing speed and shorter response times

4 Compatibility Differences

Forward compatibility: CPUM Mk2 is not compatible with first-generation VM600 cards (such as MPC4/IOC4T and AMC8/IOC8T card pairs)

Backward compatibility: CPUM Mk2 is compatible with all VM600 Mk2 system racks (ABE04x) and later VM600 system racks with I²C interface

Software compatibility: CPUM Mk2 requires VibroSight® software for configuration, while the first-generation CPUM uses VM600 MPSx software

5 Functional Characteristic Differences

| Functional Feature | CPUM (First Generation) | CPUM Mk2 (Second Generation) |

| Front Panel Display | LCD display available | No display, relies on LED status indicators |

| Configuration Management | Supports MPC4/IOC4T and AMC8/IOC8T card pairs | Supports MPC4 Mk2 and XMV16 modules |

| Security Features | Basic security functions | Enhanced security functions meeting stricter standards |

| Diagnostic Functions | Basic diagnostic logging | Enhanced diagnostics and status monitoring |

6 Application Scope Differences

CPUM: Suitable for traditional VM600 systems, mainly for machinery protection applications

CPUM Mk2: Designed specifically for VM600 Mk2 systems, supporting both machinery protection and condition monitoring applications, suitable for broader monitoring scenarios

7 Redundancy Capability Differences

CPUM: Supports limited communication redundancy but cannot achieve true rack-level module redundancy

CPUM Mk2: Supports complete rack-level communication redundancy, allowing configuration of two modules for seamless switching

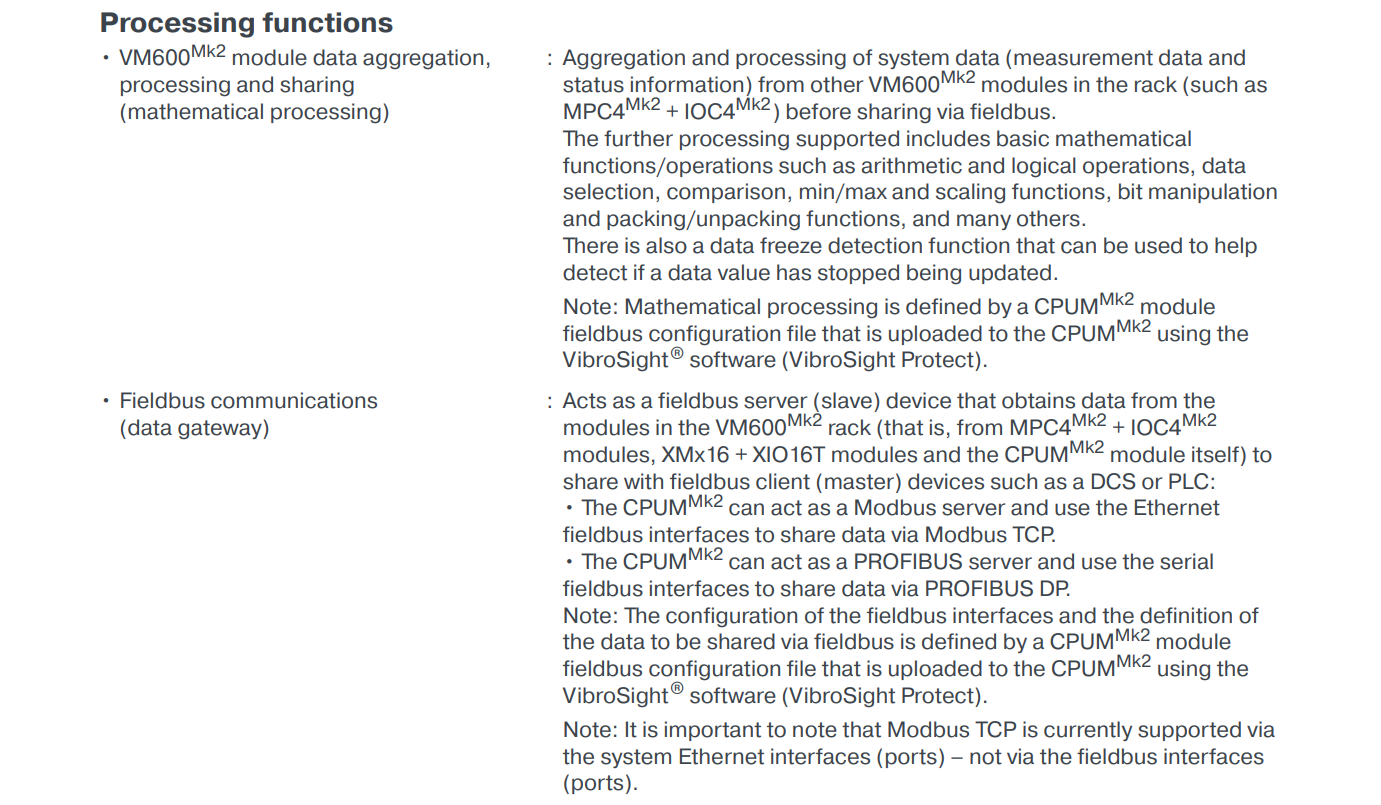

Key Features and Functions

1 Data Processing and Aggregation Capabilities

The CPUM Mk2 features powerful data aggregation and processing capabilities, enabling it to collect measurement data and status information from other VM600 Mk2 modules (such as MPC4 Mk2) within the rack and perform mathematical processing. Supported processing functions include:

Arithmetic and logical operations

Data selection and comparison functions

Minimum/maximum and scaling functions

Bit manipulation and packing/unpacking functions

Data freeze detection function

2 Communication Interface Functions

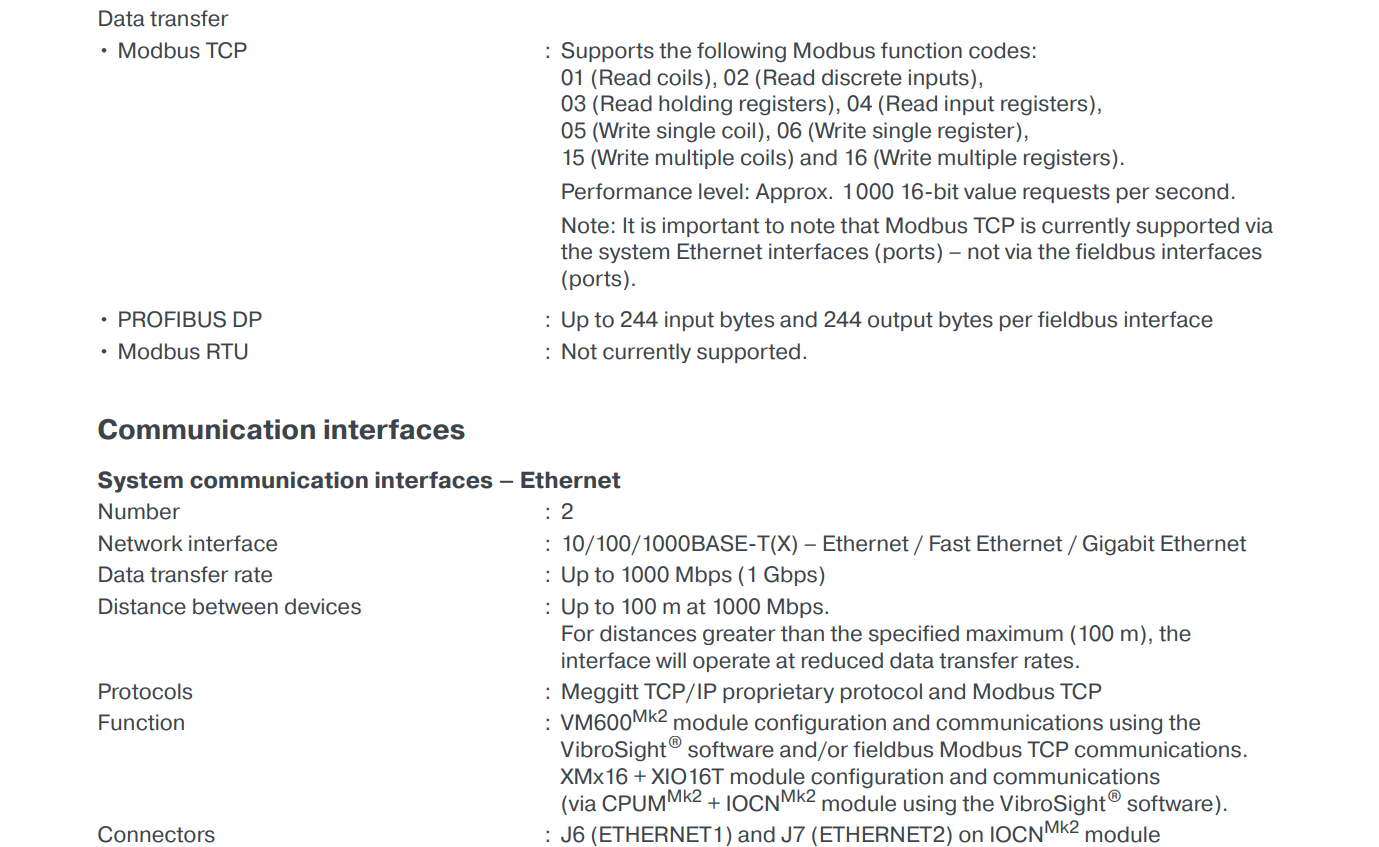

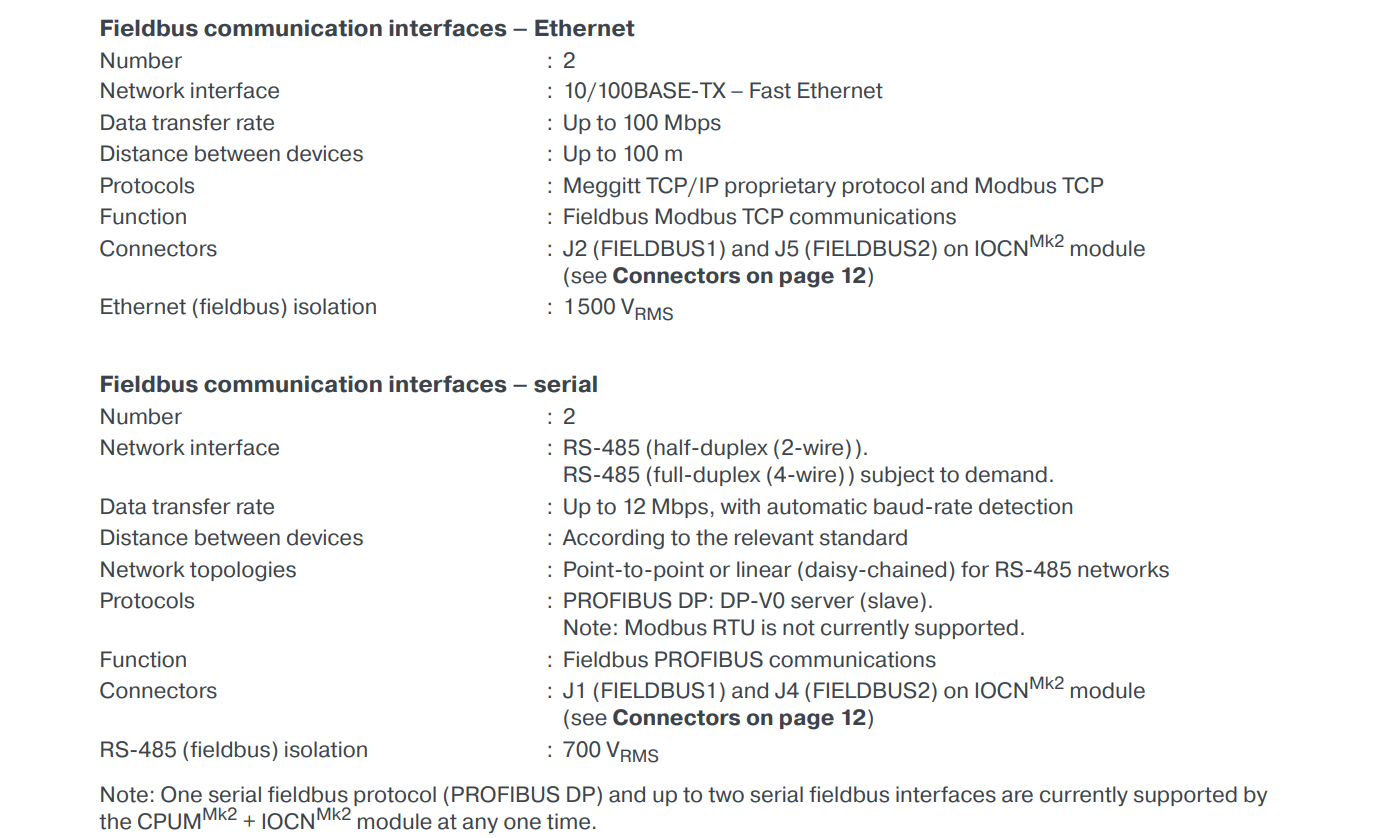

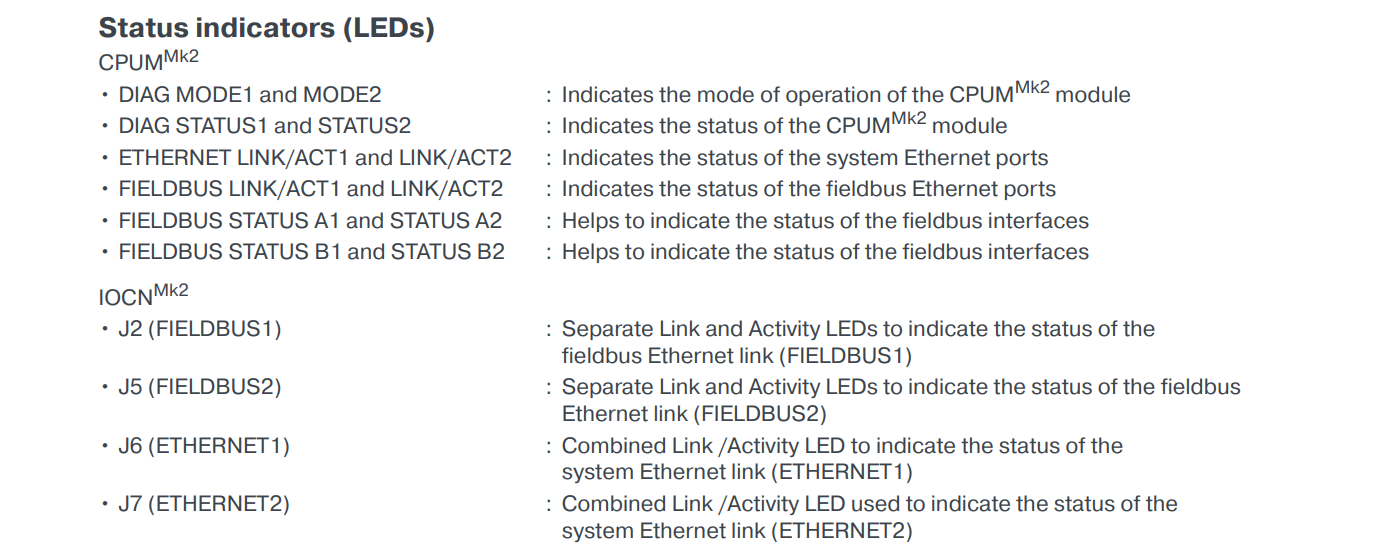

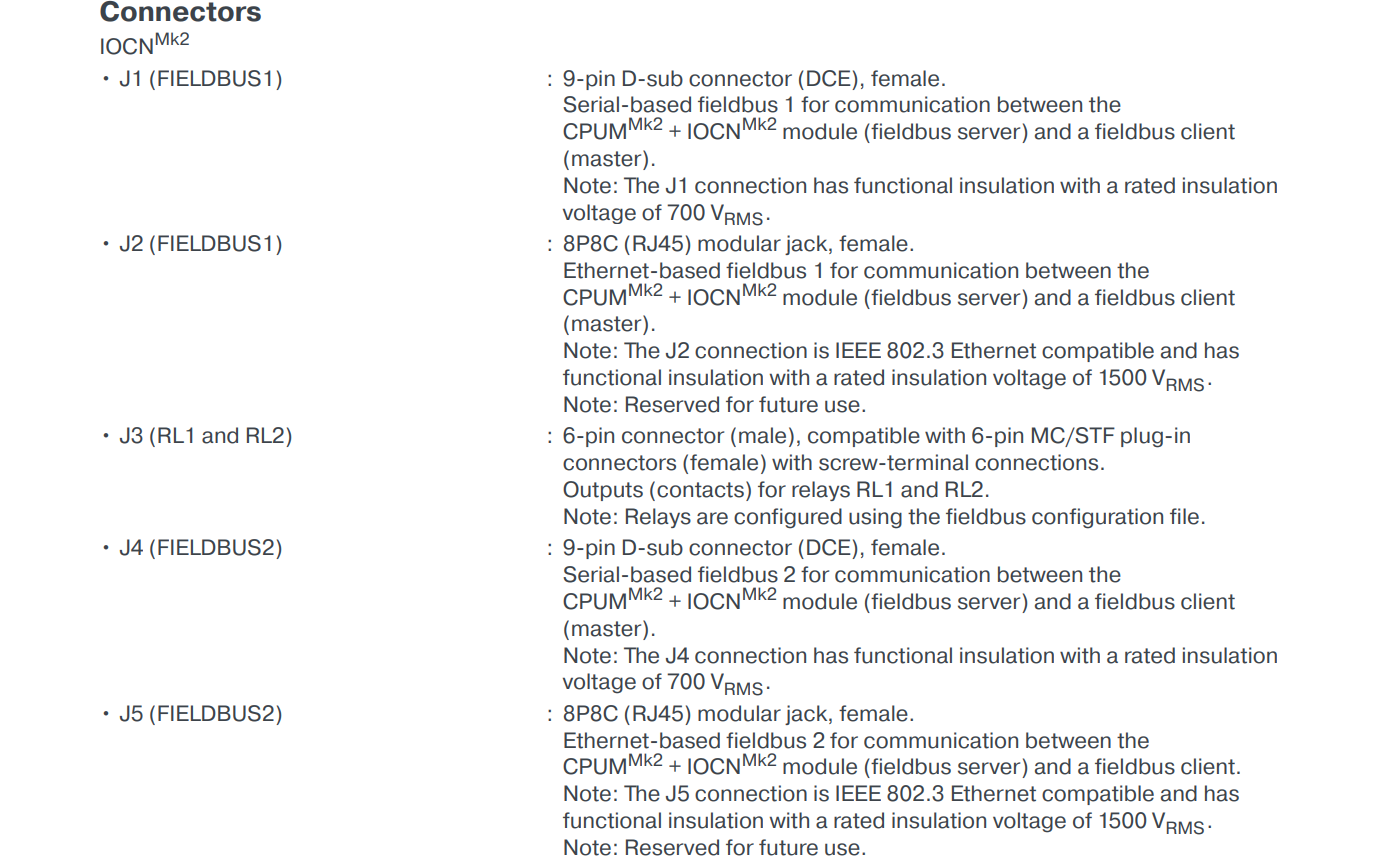

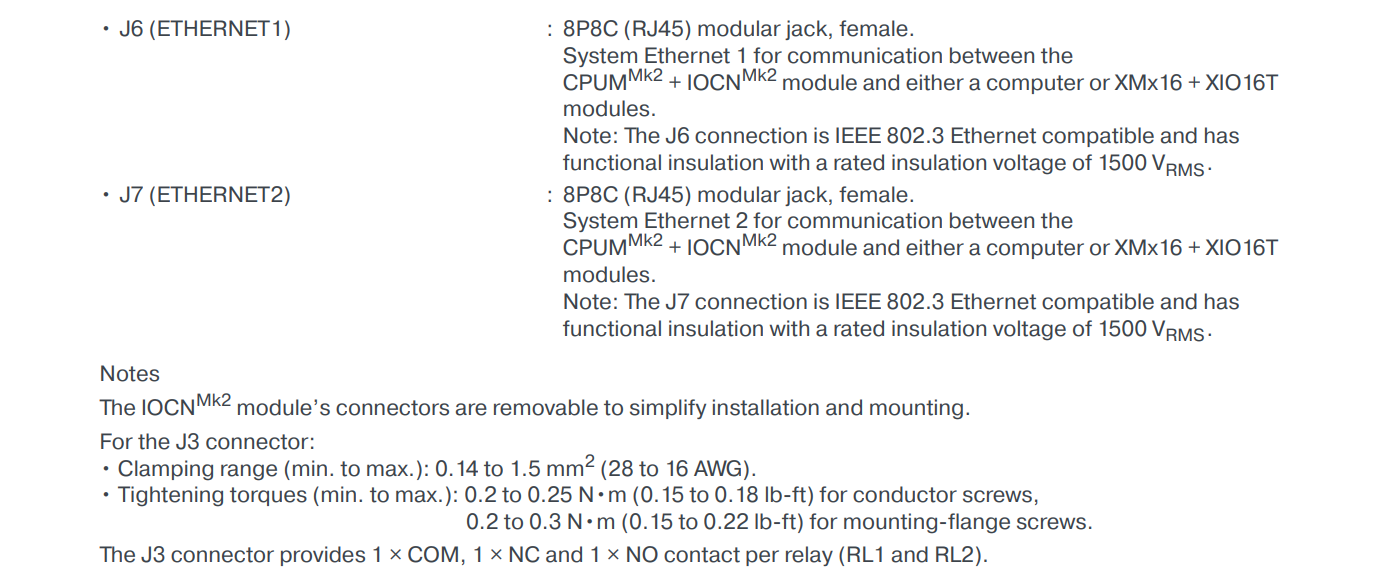

The CPUM Mk2 provides multiple communication interfaces supporting system Ethernet and fieldbus communication:

System Ethernet interfaces: Two 10/100/1000BASE-T(X) Ethernet ports supporting gigabit communication

Fieldbus interfaces: Support for Modbus TCP and PROFIBUS DP protocols

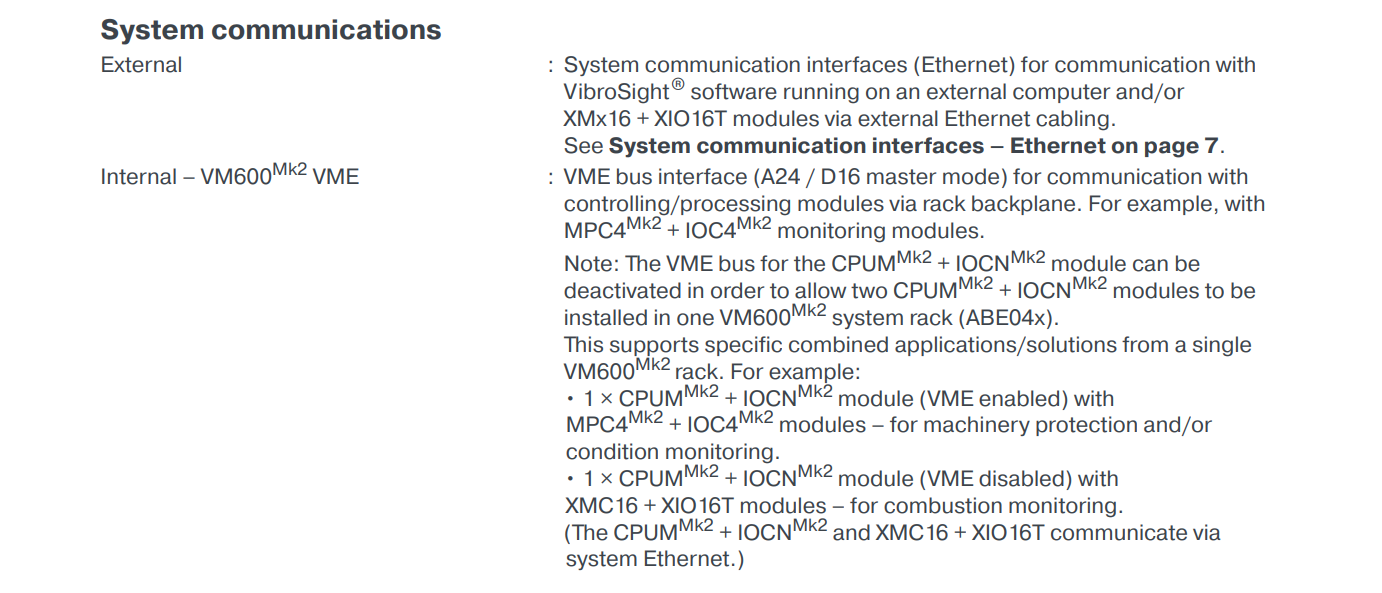

Internal rack communication: Communication with processing modules such as MPC4 Mk2 via VME bus

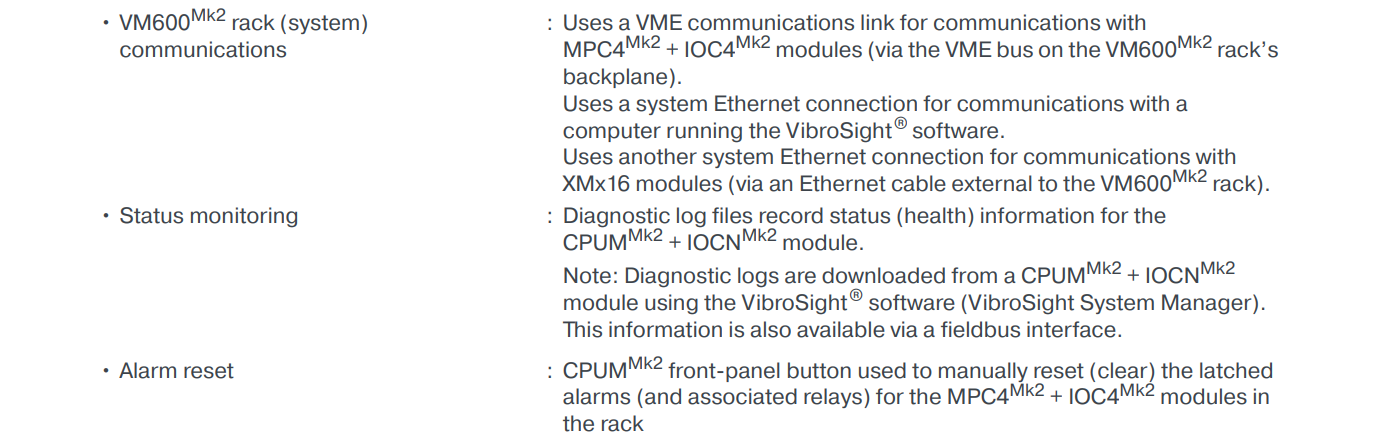

3 Rack Control Functions

Configuration management support for XMV16/XIO16T modules (without requiring VibroSight Server)

Front panel alarm reset (AR) button to clear latched alarms from all MPC4 Mk2 modules in the rack

System status monitoring and diagnostic logging

4 Redundancy Configuration Support

Supports rack-level communication redundancy, allowing installation of two CPUM Mk2 + IOCN Mk2 modules in the same VM600 Mk2 system rack for true redundant configuration. If the master module fails, the subordinate module can automatically take over within 200ms.

5 Security Features

Front panel security key lock enables/disables VM600 Mk2 rack security, restricting access to machinery protection system functions via system Ethernet connections, complying with international security/critical infrastructure regulations.

Working Principle

1 System Architecture and Data Flow

The CPUM Mk2 serves as the core controller of the VM600 Mk2 system, exchanging data with other system components in multiple ways:

Data acquisition level:

Acquisition of machinery protection data from MPC4 Mk2 + IOC4 Mk2 modules via VME bus

Acquisition of condition monitoring data from XMx16 + XIO16T modules via system Ethernet connections

Collection of self-status information through internal monitoring circuits

Data processing level:

The CPUM Mk2 utilizes an advanced mathematical processing engine to perform real-time processing of collected raw data. The processing is defined by a fieldbus configuration file uploaded via VibroSight® software, including data normalization, unit conversion, limit comparison, and logical operations.

Data output level:

Processed data is output through the following channels:

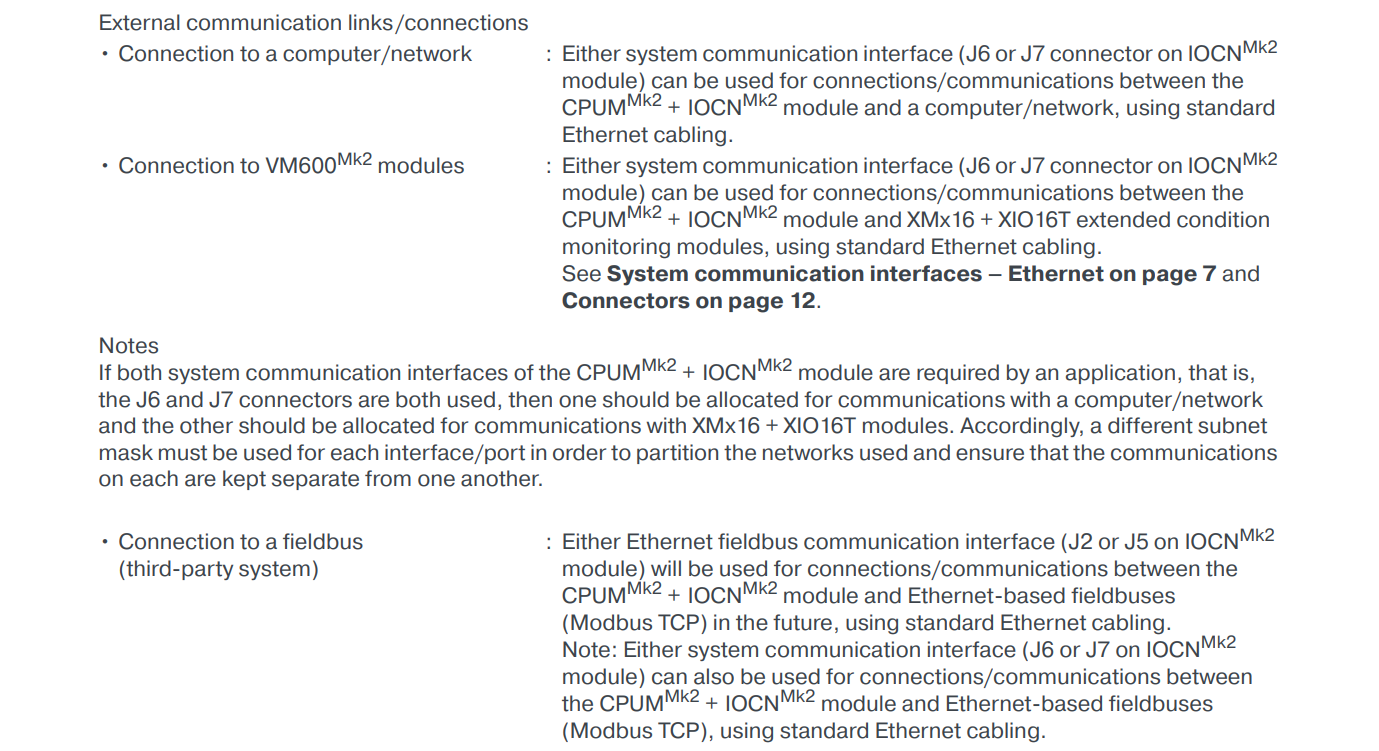

Transmission to third-party systems (such as DCS or PLC) via fieldbus interfaces (Modbus TCP or PROFIBUS DP)

Transfer to VibroSight software for display and analysis via system Ethernet interfaces

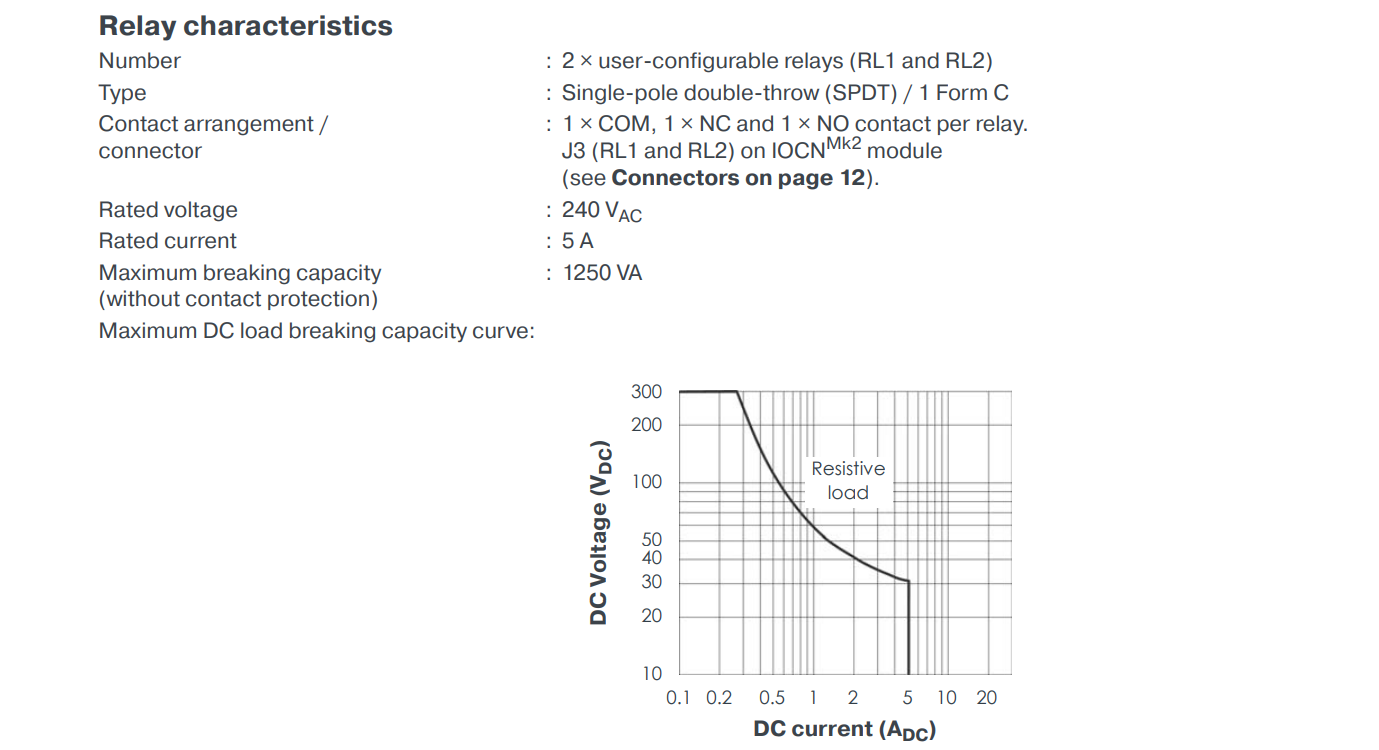

Provision of system status and alarm indications through relay outputs

2 Communication Protocol Implementation

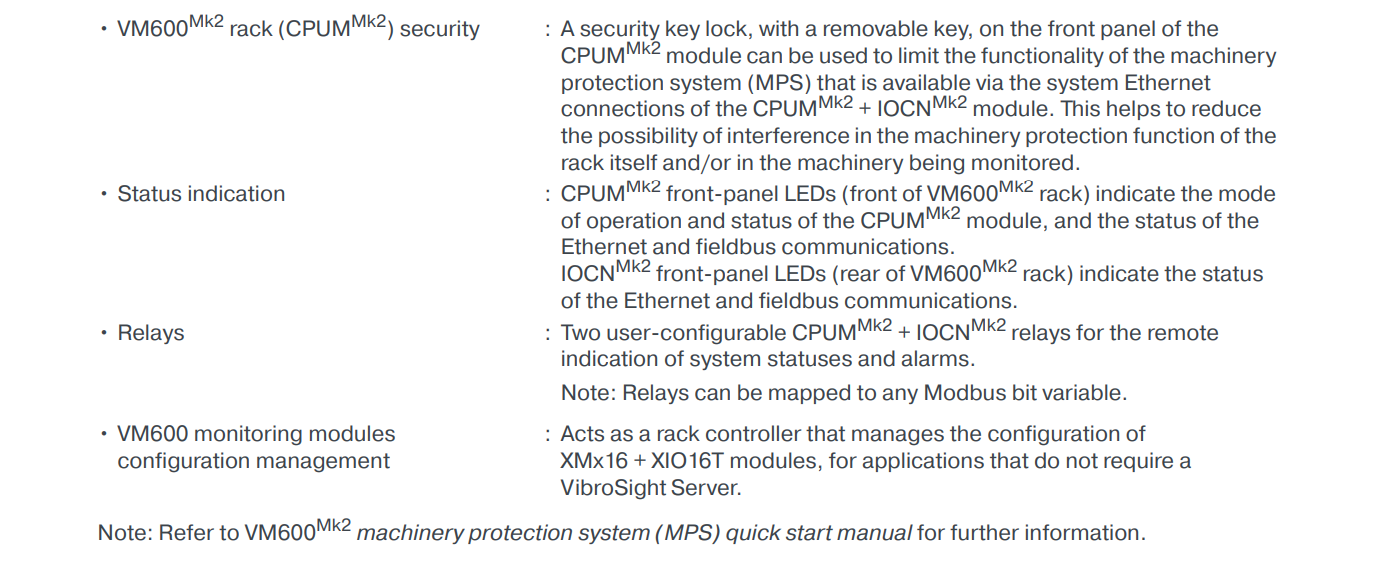

The CPUM Mk2 supports multiple industrial standard communication protocols:

Modbus TCP: Operates as a slave device, supporting up to 131,072 registers and coils

PROFIBUS DP: Operates as a DP-V0 slave, supporting up to 244 input and output bytes per interface

Meggit proprietary protocol: Used for communication with VibroSight software

3 Redundancy Working Mechanism

When configured in redundancy mode, two CPUM Mk2 modules work collaboratively:

The master module communicates with processing modules via the VME bus to obtain measurement data and status information

The subordinate module receives copies of all information sent by the master module

Both modules process and generate fieldbus communication data based on the same source data

If the master module fails, the subordinate module automatically takes over with a maximum switchover time of 200ms

4 Security Mechanism

The CPUM Mk2's security functions are implemented through multiple levels:

Hardware security: Enabled/disabled via the front panel security key lock

Software security: Password authentication and access control through VibroSight® software

Communication security: Restriction of specific system operations, such as configuration uploads and Modbus command transmission

Technical Specifications Summary

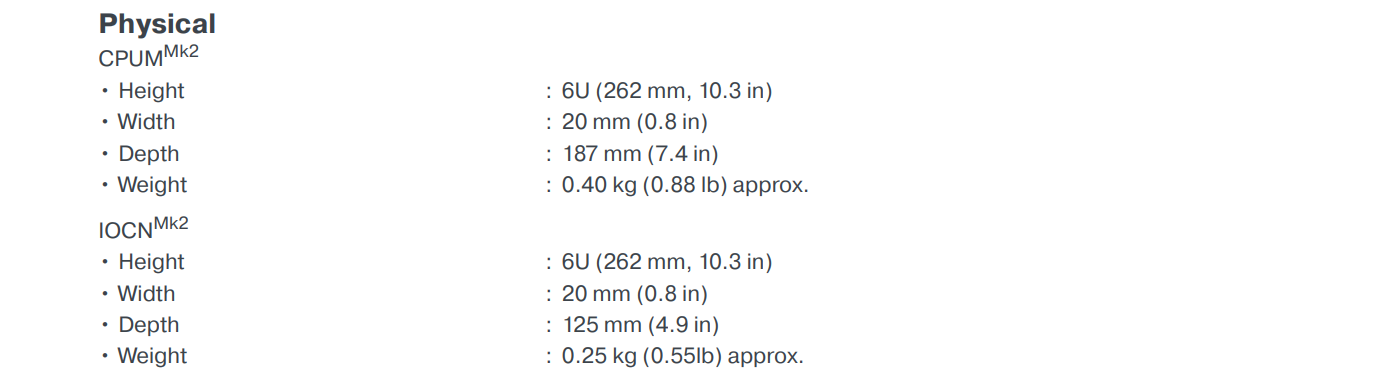

Power Requirements: Powered by VM600 RPS6U rack power supply, 5VDC, maximum power consumption 7.5W

Operating Temperature: 0°C to 65°C (depending on relay load)

Communication Interfaces: 2 system Ethernet (10/100/1000BASE-T), 2 fieldbus ports

Compliance Standards: CE, EN 61010-1, EN 61326-3-1, RoHS, etc.

Application Scenarios

The CPUM Mk2 module is suitable for the following scenarios:

Vibration protection and condition monitoring of turbines (steam, gas, hydro) in power plants

Monitoring of rotating machinery such as compressors, pumps, and fans in the oil and gas industry

Critical applications requiring high availability and redundant configurations

Integration with control systems such as DCS and PLC for data sharing and linked control