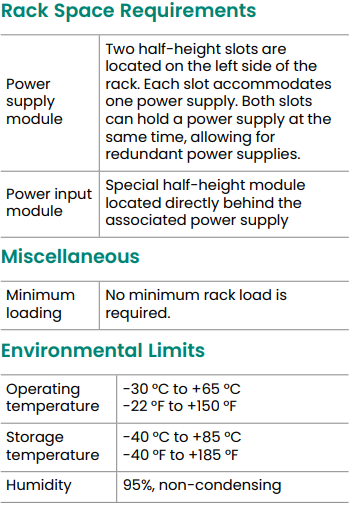

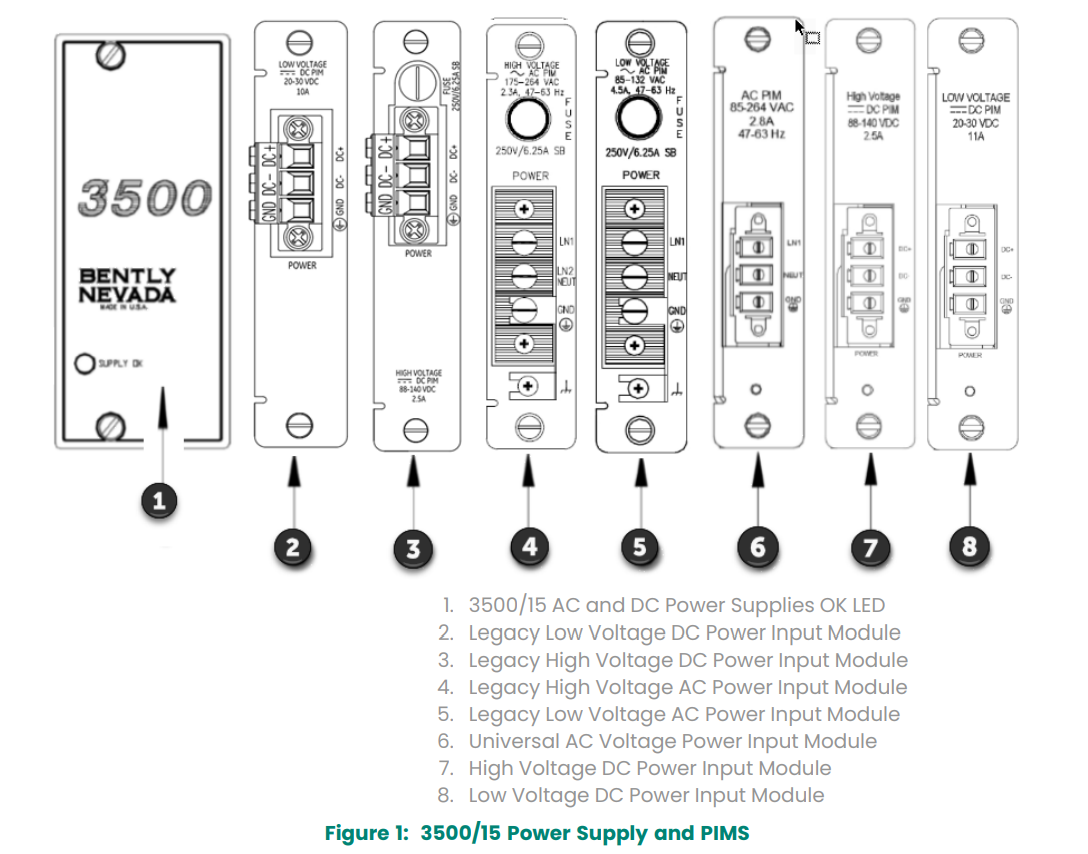

The 3500/15 AC and DC Power Supplies are the core power units for the Bently Nevada 3500 Series Machinery Condition Monitoring System. As half-height modules, they must be installed in the designated slots on the left side of the 3500 rack. A single rack can be configured with one or two power supply modules, supporting any combination of AC and DC types, with either single supply capable of powering a fully loaded rack.

The design philosophy of this power supply series centers on high reliability and redundancy, aiming to provide uninterrupted, clean, and stable power for critical machinery protection systems, ensuring continuous and stable operation in harsh industrial environments. When two power supply modules are installed in a rack, the unit in the lower slot acts as the primary supply, and the unit in the upper slot acts as the backup supply. This redundant design means that the rack's operation will not be disrupted while installing or removing either power supply module, as long as the other is functioning normally, enabling online maintenance and hot-swapping capabilities.

2. Key Features and Detailed Functional Principles

2.1 Core Function: Power Conversion and Distribution

The fundamental function of the 3500/15 power supply module is to convert and stabilize various wide-range input industrial voltages into the precise DC operating voltages required by other modules within the 3500 rack. It acts as the "heart" of the entire monitoring system, providing energy for all data processing, signal acquisition, and protection logic circuits.

2.2 Key Characteristic: Redundant Power Supply and Trouble-Free Maintenance

Primary-Backup Redundancy Mode: In a dual-power configuration, the system automatically recognizes the primary-backup relationship. The primary supply handles the full load, while the backup remains on standby, continuously monitoring the primary's output. If the primary supply fails or its voltage deviates from the allowable range, the backup supply seamlessly takes over, ensuring uninterrupted rack operation.

Hot-Swappability: This feature is key to achieving high availability. Maintenance personnel can directly remove a faulty power supply module or insert a new replacement module without system downtime. This significantly reduces unplanned downtime, which is crucial for continuous process industries.

2.3 Input Voltage Ranges and Compatibility

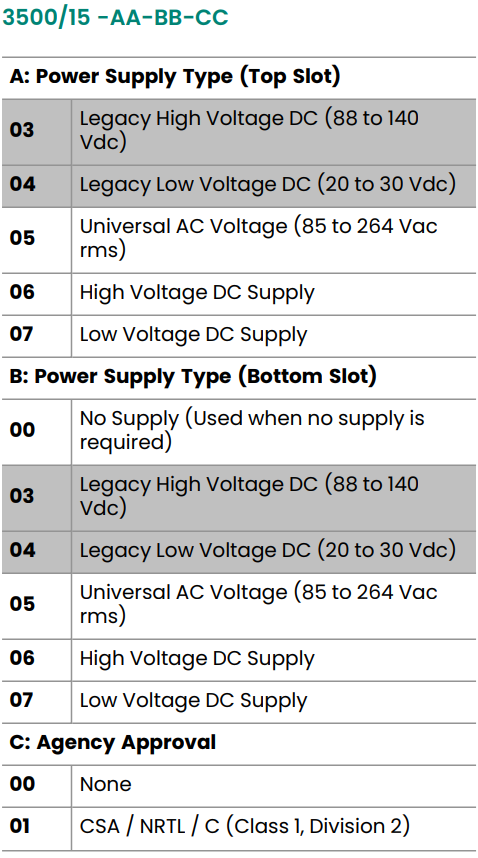

The 3500/15 series offers three main power supply options to adapt to different field power conditions worldwide and strictly distinguishes between new models and legacy models for compatibility:

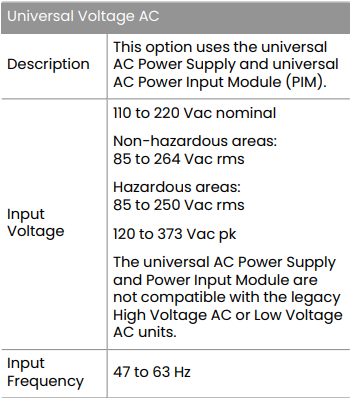

a) Universal AC Power Supply

Input Voltage: 85 to 264 Vac RMS in non-hazardous areas; 85 to 250 Vac RMS in hazardous areas. This covers globally common standard voltages like 110Vac, 120Vac, 220Vac, 230Vac, etc., eliminating the need for region-specific power modules.

Input Frequency: 47 to 63 Hz, compatible with both 50Hz and 60Hz power grids.

Key Note: The Universal AC Power Supply Module and its associated Power Input Module are NOT compatible with the legacy High Voltage AC or Low Voltage AC units. Matching new modules must be used during upgrades or replacements.

b) High Voltage DC Power Supply

Input Voltage: 88 to 140 Vdc. This voltage level is common in industrial DC control panels, UPS systems, or specific DC grids.

Application Scenarios: Often used in situations demanding extremely high power supply reliability, such as power plants and substations, which typically have stable DC control power sources.

c) Low Voltage DC Power Supply

Input Voltage: 20 to 30 Vdc. This is the most common DC supply level, typically sourced from 24Vdc industrial power supplies or battery systems.

Application Scenarios: Widely used in OEM equipment, mobile equipment, or industrial environments powered by standard PLC DC power sources.

Important Note: The High Voltage and Low Voltage DC Power Supplies and their associated Power Input Modules are also NOT compatible with the legacy models of the same type. Model compatibility must be confirmed when ordering or replacing.

2.4 Protection Mechanisms

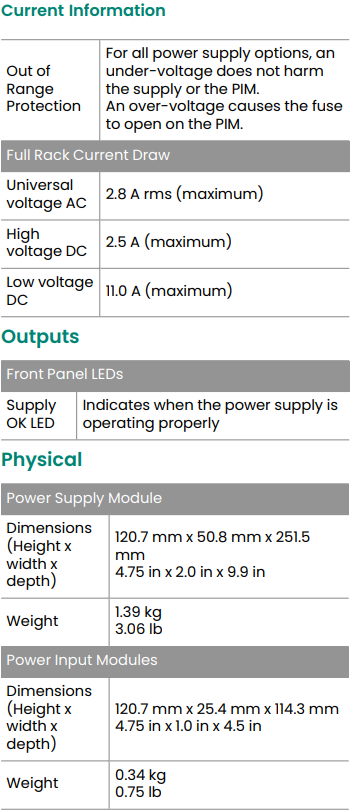

Overvoltage and Undervoltage Protection:

Undervoltage Protection: If the input voltage falls below the normal operating range, the power supply module ceases output. However, the undervoltage condition itself does not damage the supply or the PIM. This prevents the module from operating under inefficient or unstable voltage conditions.

Overvoltage Protection: If the input voltage exceeds the safe threshold, the fuse on the Power Input Module will blow, cutting off the input circuit and effectively protecting the subsequent power supply module and the entire rack's expensive electronic equipment from high-voltage surges.

Fuses: Different PIM models use fuses of specific ratings (e.g., the Universal AC PIM uses a 120M3877 fast-blow fuse). These serve as reliable, sacrificial physical protection barriers, blowing in case of an overvoltage fault.

2.5 Status Indication and Monitoring

Each 3500/15 power supply module features a "Supply OK" LED indicator on the front panel, providing users with immediate status feedback:

Illuminated: Indicates the power supply module is operating normally and outputting power within specifications.

Off: Indicates the power supply module is not powered, has failed, or has an abnormal output.

In a dual-power configuration, maintenance personnel can quickly assess the status of both primary and backup supplies by observing the indicators on both modules.

2.6 Power Output and Load Capacity

The power supply modules are designed to meet the power demands of a fully loaded 3500 rack. The maximum input current draw for different input types is as follows:

Universal AC Power Supply: 2.8 A RMS (max)

High Voltage DC Power Supply: 2.5 A (max)

Low Voltage DC Power Supply: 11.0 A (max) (Requires higher current due to the lower voltage to deliver equivalent power).

The system requires no minimum load; the power supply modules operate stably even under light load conditions when only a few modules are installed in the rack.

3. Mechanical Structure and Installation

Power Supply Module:

Power Input Module:

Dimensions: 120.7 mm H x 25.4 mm W x 114.3 mm D

Weight: 0.34 kg

Installation: The PIM is a special half-height module installed directly behind its corresponding Power Supply Module. It is responsible for receiving the external power cable and delivering power via an internal connector to the front power supply module for conversion. This front-back corresponding design ensures simple and reliable connection.

4. Environmental Suitability

The 3500/15 power supply modules are designed for harsh industrial environments:

Operating Temperature: -30°C to +65°C

Storage Temperature: -40°C to +85°C

Humidity: 95%, non-condensing

This wide temperature range allows installation in various environments, from outdoor arctic locations to high-temperature factory floors.

5. Compliance and Certifications

The power supply modules comply with numerous international standards and certifications, ensuring safety and electromagnetic compatibility:

FCC Part 15: Prevents harmful electromagnetic interference.

EMC Directive 2014/30/EU: Conforms to immunity and emission standards for industrial environments.

Low Voltage Directive 2014/35/EU: Conforms to electrical safety standards.

RoHS Directive 2011/65/EU: Restriction of Hazardous Substances.

Maritime Classifications: Includes DNV GL and ABS, suitable for ships and offshore installations.

Hazardous Area Approvals:

Suitable for Class I, Zone 2 and Class I, Division 2 hazardous areas.

Certified for Temperature Class T4, with an ambient temperature range of -20°C to +65°C.

6. Application Scenarios

The 3500/15 power supply module is the foundation of the Bently Nevada 3500 system, widely used across all industries that rely on this system for monitoring critical rotating equipment, including:

Power Generation: Steam turbines, gas turbines, hydro turbines, generators.

Oil & Gas: Pipeline compressors, offshore platform pumps, gas turbines.

Chemical & Metallurgical: Large compressors, blowers, critical pumps.

Marine Industry: Main propulsion turbines, gearboxes, large auxiliary machinery.