| Product Identification | Full Model | CA202 (Standard Industrial Version, 20m Integral Cable) | Ordering Part Number: 144-202-000-236 |

| Sensing Principle | Shear-mode piezoelectric effect, High-impedance charge output | Internal sensing element fully electrically isolated from metal housing, provides symmetrical differential charge signal, inherently resistant to common-mode interference. |

| Output Signal Form | Charge Signal (Unit: pC/g) | Raw output. Must be converted to low-impedance voltage or 4-20mA current signal by a compatible charge amplifier (e.g., vibro-meter® IPC series). |

| Electrical Performance | Charge Sensitivity | 100 pC/g ±5% | Calibrated at 23°C, 120Hz, 5g peak sinusoidal vibration. The basis for system gain setting. |

| Linear Operating Range | 0.01 g to 400 g (peak) | Within this range, the output is in strict proportion to the input acceleration, with non-linearity error ≤ ±1%. |

| Transient Overload Capacity | 500 g (peak) | Capable of withstanding occasional high shocks without causing permanent performance degradation or damage. |

| Frequency Response (±5%) | 0.5 Hz to 6000 Hz | Amplitude flat zone. The actual system lower frequency limit is determined by the charge amplifier's high-pass filter. |

| Resonant Frequency | > 22 kHz (nominal) | Sensor's first-order natural frequency, far above the operating bandwidth, ensuring flat and accurate phase and amplitude response within the operating band. |

| Transverse Sensitivity Ratio | ≤ 3% | Ratio of maximum transverse axis sensitivity to main sensitivity axis sensitivity. A low value ensures low sensitivity to vibrations in non-measurement directions. |

| Insulation Resistance | ≥ 1 x 10^9 Ω | Measured between sensor pins (@ 50 V DC). High impedance is key to preventing charge signal leakage and maintaining high signal-to-noise ratio. |

| Distributed Capacitance | Sensor Body: ~5000 pF pin-to-pin; ~10 pF pin-to-case

Integral Cable (per meter, typical): ~105 pF core-to-core; ~210 pF core-to-shield | Critical Parameter. Total capacitance for 20m cable is approx. ~7100 pF (core-to-core). This value must be provided to the charge amplifier for accurate setting of its feedback capacitance to determine the overall sensitivity (mV/g) of the entire measurement chain. |

| Environmental & Mechanical Characteristics | Continuous Operating Temp. | Sensing Head: -55°C to +260°C

Integral Cable & Sheath: -55°C to +200°C | Defines the environmental temperature limits within which the sensor can operate safely and reliably long-term. Sensing head can be mounted on high-temperature equipment surfaces. |

| Short-Term Survival Temp. | Sensing Head: -70°C to +280°C

Integral Cable: -62°C to +250°C | Permissible short-term exposure to extreme temperatures, e.g., during equipment start-up, shutdown, or abnormal conditions, without causing permanent damage. |

| Sensitivity Temperature Coefficient | -55°C to +23°C range: +0.25% / °C

+23°C to +260°C range: +0.10% / °C | Describes how sensitivity changes with temperature. In highly demanding measurements, software compensation can be applied based on measured temperature. |

| Mechanical Shock Resistance | 1000 g (peak) | Half-sine wave, 1ms pulse width. Indicates the sensor can withstand severe shocks during installation, transportation, or equipment anomalies. |

| Base Strain Sensitivity | 0.15 x 10^-3 g/με | Spurious signal output generated when the sensor mounting surface deforms. This value is extremely low and negligible in most applications. |

| Housing Material & Process | Austenitic Stainless Steel (1.4441, equivalent to 316L), laser/TIG welded fully perimeter sealed. | Provides excellent mechanical strength, corrosion resistance, and long-term sealing. Welding process guarantees hermeticity. |

| Cable Sheath Material | Heat-Resistant Stainless Steel Braided Armor (1.4541) | Provides high flexibility, abrasion resistance, and crush resistance, protecting the internal low-noise cable and welded to the sensor as one. |

| Overall Protection | Fully welded hermetic encapsulation, dustproof, waterproof, oil-proof, resistant to general industrial chemical media. | Suitable for the most demanding industrial environments, but explicitly not suitable for explosive atmospheres. |

| Physical & Mounting Characteristics | Weight | Sensing Head: approx. 250 g

Integral Cable: approx. 135 g/m | Total weight for 20m cable approx. 2.95 kg. Its weight impact on supporting structures must be considered during installation. |

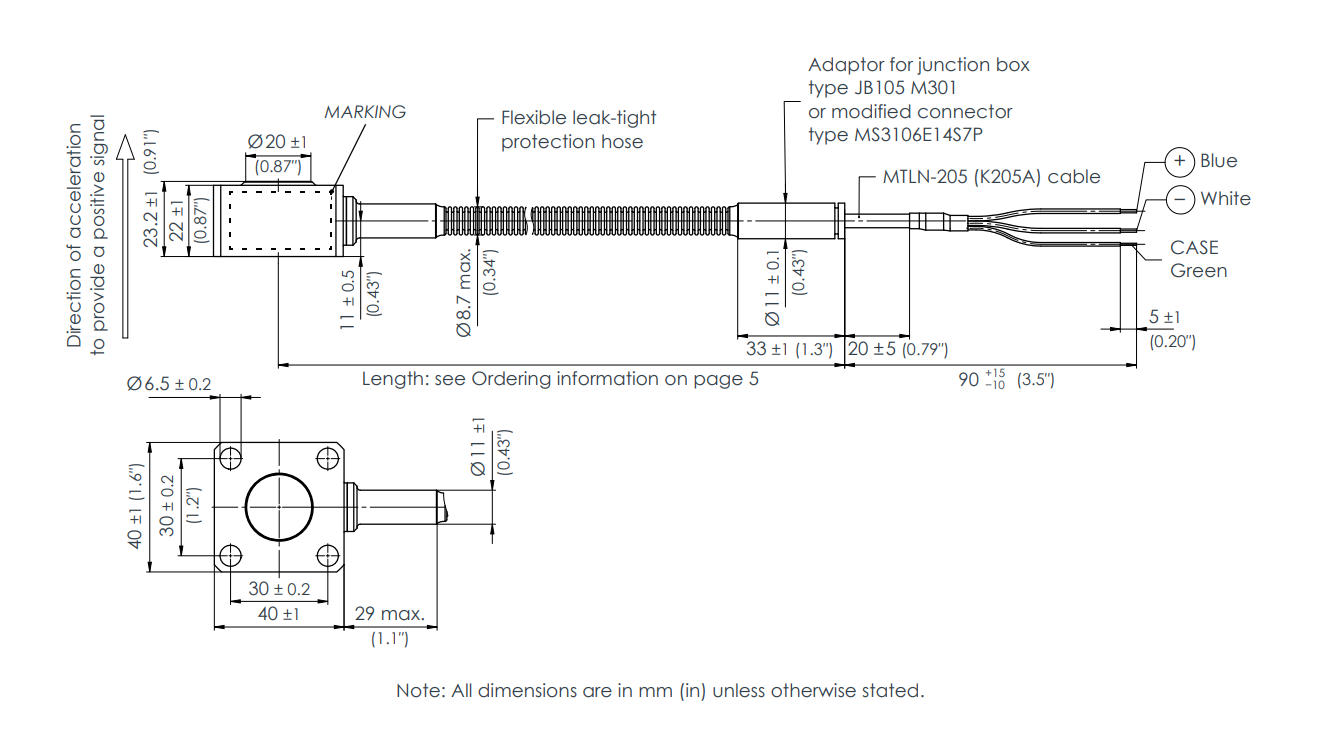

| Mounting Interface | Four-hole flange mount, thru-hole Ø6.6 mm, for M6 bolts. | Standard mounting method providing firm mechanical coupling, ensuring high-frequency vibration transfer efficiency. |

| Recommended Mounting Hardware | M6 x 35 Socket Head Cap Screws, M6 Spring Lock Washers, optional thread-locking compound. | Spring washers prevent loosening; locking compound for high-vibration environments. |

| Maximum Mounting Torque | 15 N·m | Critical Installation Parameter. Must use a torque wrench and tighten in a crisscross pattern stepwise to ensure even force distribution on the mounting surface and avoid base deformation affecting performance. |

| Total Cable Length | 20 meters | Defined configuration for Model 236. Supplied as an inseparable unit ex-factory; field shortening or splicing is strictly prohibited. |

| Cable Termination | Flying leads (typically red and white cores plus shield braid). | For direct connection to terminal blocks or special connectors, providing flexible field wiring options. |

| Certifications & Compliance | General Safety Certification | CE Marking | Complies with EU Directives 2014/30/EU (EMC) and 2014/35/EU (LVD), permitting sale in the EU market. |

| Electromagnetic Compatibility | Complies with EN 61000-6-2:2005 (Immunity for Industrial Environments)

Complies with EN 61000-6-4:2007+A1:2011 (Emission for Industrial Environments) | Ensures normal operation in typical industrial electromagnetic environments and that its own emissions do not interfere with other equipment. |

| Electrical Safety | Complies with EN 61010-1:2010 | Meets basic safety requirements for measurement and control equipment. |

| Environmental Compliance | Complies with EU RoHS Directive (2011/65/EU) recast. | Restricts the use of hazardous substances like lead, mercury, and cadmium, complying with environmental regulations. |

| Factory Calibration | Sensor and 20m cable dynamically calibrated as a complete unit (5g, 120Hz). | Calibration certificate provided includes actual sensitivity, capacitance, etc. Calibration values already incorporate the influence of the 20m cable and can be used directly by the customer. |

| Explosion-Proof Certification | None | This is a Standard Industrial Version, not certified for any explosion-proof use. It is strictly prohibited for use in hazardous areas (Zone 0/1/2) where explosive risks exist, such as in petroleum, chemical, natural gas, or mining industries. |