The SR511 is a high-performance 24 V/5 V switched-mode power supply (SMPS) voltage regulator module, specifically designed for the controller subsystem (Controller Subrack) of ABB's Advant® Controller 450 and Advant Controller 400 series industrial control systems. This module is a critical component in the core power distribution network of the control system, responsible for converting unstable 24 V DC input voltage into highly stable and clean 5 V and 2.1 V DC voltages, providing reliable, high-quality operating power for all electronic modules within the controller subsystem (e.g., processor modules, communication modules).

The SR511 embodies the high standards of industrial-grade power supply design, featuring core characteristics such as high-power output (35A), high-efficiency conversion, n+1 redundancy support, comprehensive status monitoring and diagnostics, and support for online hot-swap maintenance. Its design aims to meet the stringent industrial environment requirements for power system high reliability, high availability, and ease of maintenance, making it a cornerstone for building stable and robust Advant OCS control systems.

Core Functions in Detail

1. Efficient, High-Capacity DC Voltage Conversion

The core function of the SR511 is to efficiently convert 24 V DC power from the system's main power supply (provided via power distribution units) into the standard voltages required by electronic circuits.

5 V Main Output: Provides a stable voltage rated at 5.15 V (adjustable), with a maximum continuous output current of up to 35 A (excluding current from the 2.1 V output), sufficient to power all high-power digital circuits, processors, and memory modules within the controller subsystem.

2.1 V Auxiliary Output: Provides a stable voltage rated at 2.1 V, specifically designed to supply termination bias voltage for the parallel bus (Futurebus+) on the controller subsystem backplane, ensuring the integrity and stability of high-speed bus signal transmission.

High-Efficiency Conversion: Utilizes switch-mode power supply technology with a typical efficiency as high as 70%, effectively reducing energy loss and the module's own heat generation, thereby improving the overall energy efficiency and thermal management performance of the system.

2. Comprehensive n+1 Redundant Power Supply Architecture Support

The SR511 is designed specifically for building redundant power supply systems and is key to achieving high availability in control systems.

Parallel Current-Sharing Operation: The outputs (5V and 2.1V) of multiple SR511 modules can be directly connected in parallel to jointly power the backplane bus. The load current is automatically shared among all parallel-connected modules.

Achieving n+1 Redundancy: In a typical Advant Controller 450 configuration, the controller subsystem is equipped with two SR511 modules. During normal operation, both modules share the load (n=1). If one module fails, the other can immediately take over the full load (+1), ensuring uninterrupted power supply to the subsystem and continuous system operation.

Dual 24 V Inputs: The module supports connection to two independent 24 V power supply networks (24 V A and 24 V B), providing redundancy on the input side, further enhancing the reliability of the power supply chain.

3. Comprehensive Status Monitoring and Diagnostic Indication

The module front provides clear and intuitive LED indicators for maintenance personnel to quickly assess its operating status:

5 V (Green): Illuminates when the 5 V output voltage is normal or in an overvoltage state (but not undervoltage). This is the primary indicator of normal module operation.

2 V (Green): Illuminates when the 2.1 V output voltage is normal or in an overvoltage state (but not undervoltage).

F (Red, Fault): Illuminates when the module detects an undervoltage or overvoltage fault. This is an alarm signal requiring immediate attention.

Built-in Monitoring Logic: The module contains monitoring logic circuitry. When the module is operating normally, it grounds a signal output terminal through a 100-ohm resistor via a semiconductor switch. If the module fails or is missing, this signal terminal remains open. This signal can be read by higher-level system monitoring modules (e.g., TC520) for centralized alarming and system status display.

4. Advanced Protection and Safety Features

To ensure system safety and prevent damage to the module itself, the SR511 incorporates multiple protection mechanisms:

Output Overvoltage Protection (OVP): Activates when the 5 V output voltage exceeds a safe threshold (typically 6.3 V via electronic circuitry; with an additional Zener clamp protection of ~7 V as backup), preventing high voltage from damaging subsequent connected expensive electronic modules.

Output Overcurrent/Current Limiting Protection: The 5 V output features current limiting (typical value 43 A, including the 2.1 V load). In case of an abnormal short circuit or overload, the module limits the output current to prevent damage due to overload.

Input Overcurrent Protection: Each 24 V input terminal is recommended to be protected externally by a maximum 30 A fuse.

Over-Temperature Protection: The 2.1 V output circuit features linear temperature protection. When the module temperature is too high, the 2.1 V output current automatically decreases linearly to avoid permanent damage from overheating.

5. Support for Online Hot-Swap Maintenance (Live Replacement)

This is a key design advantage of the SR511, greatly facilitating system maintenance and reducing unscheduled downtime.

In a redundant configuration, when one SR511 module fails or requires preventive maintenance, maintenance personnel can directly remove the faulty module from the subrack without cutting power or affecting the normal operation of the controller.

Replacement Process: When inserting a new module, it must be pushed in slowly. Once the module begins initializing (observed by the green "5V" and "2V" LEDs illuminating, and the red "F" LED remaining off), pause briefly, then fully insert and secure it. During this process, the other normally operating module carries the entire load, ensuring no interruption in power supply to the modules within the controller.

This feature avoids the need to shut down the entire controller or part of the system to replace a single power module, which is critical for industrial processes requiring 24/7 continuous operation.

6. Modular and Standardized Integration

Standard Subrack Installation: The SR511 is designed as a standard 6 SU (Subrack Unit) height, 12 mp (mounting point) width pluggable module. It is directly inserted into a designated slot at the front of the controller subrack (e.g., RF533), connecting to the power bus and monitoring signal lines via the subrack backplane connectors.

Unified Management: As part of the Advant OCS hardware module ecosystem, its status can be monitored through system software, and its replacement procedures follow the unified maintenance protocols for controller hardware.

Working Principles in Detail

1. Basic Principles of Switched-Mode Power Conversion

The SR511 employs high-frequency switching regulation technology, offering advantages such as high efficiency, small size, and low heat generation compared to traditional linear regulators. Its core workflow is as follows:

Input Filtering: 24 V DC from the subrack backplane (24 V A and/or 24 V B) first enters the input filtering circuit to remove noise and interference from the upstream power source.

High-Frequency Switching and Transformation: The core is a power switch (e.g., MOSFET) driven by a control circuit. The control circuit rapidly turns this switch on and off at a high frequency (typically tens to hundreds of kHz) cyclically.

Energy Storage and Transfer: When the switch is on, the input voltage is applied across an inductor (and/or transformer), storing electrical energy in the form of a magnetic field, causing the current to rise linearly. When the switch turns off, the inductor's polarity reverses to maintain current, and the stored magnetic energy is released through a freewheeling diode to the output capacitor, converting back to electrical energy.

Pulse Width Modulation (PWM): The control circuit monitors the output voltage and compares it with an internal precise reference voltage. If the output voltage is low, it increases the switch's on-time within a cycle (i.e., increases the "duty cycle"), storing more energy in the inductor to raise the average output voltage; conversely, it reduces the duty cycle. This method of stabilizing output voltage by adjusting pulse width is called PWM control.

Output Filtering and Regulation: The pulsating voltage after switching transformation is then smoothed by an LC filter composed of inductors and capacitors, ultimately yielding stable 5 V and 2.1 V DC outputs with very low ripple voltage (typically <10 mV).

2. Principles of Redundancy and Parallel Current Sharing

"OR" Logic Power Supply: The two 24 V inputs are connected internally in an "OR" logic configuration; the module can operate as long as one input is normal.

Direct Output Parallel Connection: The 5 V and 2.1 V output terminals of all SR511 modules are directly connected together via the subrack backplane's power plane. Since each module's output voltage is precisely regulated to nearly the same value (e.g., 5.15V), according to Ohm's Law, they automatically share the total load current connected to this power plane.

Load Balancing: The internal feedback control loop of the module gives it a slight "droop" characteristic, meaning the output voltage decreases slightly as output current increases. This characteristic aids in achieving natural current balancing among parallel modules, preventing any single module from carrying an excessive load.

Fault Isolation: When a module fails (e.g., no output or severely abnormal output voltage), its internal protection circuits and reverse-blocking diodes (or control mechanisms) prevent it from drawing current from the bus or pulling down the bus voltage, effectively "isolating" it from the system without affecting the operation of other normal modules.

3. Principles of Voltage Regulation and Monitoring

Precision Reference Source: The module uses a highly temperature-stable voltage reference source (e.g., bandgap reference) as the regulation target.

Feedback Sampling Network: A high-precision resistor divider network samples the actual 5 V output voltage, producing a low-voltage signal proportional to the output.

Error Amplifier: The sampled signal is compared with the reference voltage, and their difference (error voltage) is amplified.

PWM Controller: The output of the error amplifier is fed into a PWM controller chip, which adjusts the pulse width driving the power switch based on the magnitude of the error signal, forming a closed-loop negative feedback control system that ultimately locks the output voltage at the set value.

Monitoring Logic: An independent monitoring circuit continuously monitors input voltage, output voltage, and internal module temperature. If any parameter exceeds a preset safe window, the logic circuit changes the state of the "Fault" signal output (open) and illuminates the red "F" LED. Simultaneously, undervoltage or overvoltage events are fed back to the PWM controller, triggering protective actions.

4. Principles of Thermal Management and Heat Dissipation

High Efficiency Reduces Heat Generation: 70% high conversion efficiency means only a small portion of input power (~30%) is dissipated as heat, fundamentally reducing temperature rise.

Aluminum Housing for Heat Dissipation: The module's metal housing acts as a heat sink, conducting heat from internal power semiconductor devices to the surface.

Forced Air Convection: Within the controller cabinet, a fan unit (e.g., RCS27) typically provides continuous forced cooling airflow across the surfaces of the SR511 and other modules, carrying heat out of the cabinet to ensure operation within the rated ambient temperature range.

Linear Thermal Protection for 2.1 V Output: This output may use linear regulation or post-regulation. When excessive temperature is detected, its drive capability is actively reduced, a self-protection mechanism to prevent thermal runaway.

5. Integration Principle within the Advant Controller 450 System

The SR511 does not operate in isolation but is deeply integrated into the controller's power architecture:

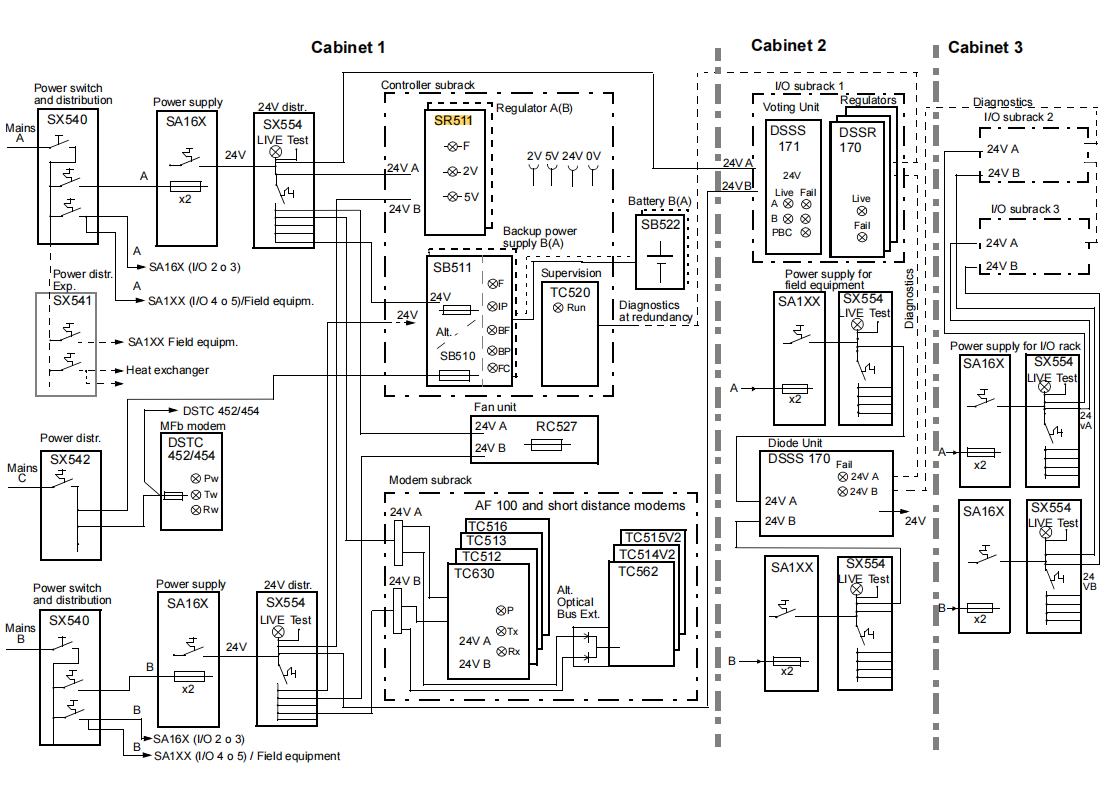

Power Chain: External AC or DC mains power is converted to 24 V DC via power switch/distribution units (SX5xx) and power supply units (SA1xx or SD150), then distributed to the controller subrack via 24 V distribution units (SX554).

Backplane Power Supply: 24 V power enters the power layer of the subrack backplane. When the SR511 module is inserted, its input terminals connect to the backplane's 24 V layer, and its output terminals connect to the backplane's 5 V and 2.1 V power layers.

Load Connection: All modules within the subrack—the processor module (PM511), communication modules (e.g., CI531, CI541), submodule carriers (SC520), etc.—draw power directly from the backplane's 5 V/2.1 V power layers via their backplane connectors.

System Monitoring: The SR511's "Fault" signal is connected via the backplane's monitoring bus to the system status monitoring module (TC520). The TC520 aggregates the status of all critical components (power, fans, etc.) and provides a global health view for operators and maintenance personnel via the "Run/Alarm" relay and system status display screens.

Installation and Maintenance Instructions

Installation

The SR511 is installed in a designated slot at the front of the controller subrack (e.g., 12-slot subrack RF533). During installation, align the module with the subrack guides, slide it in smoothly until it fully engages with the backplane connectors, then secure it to the subrack using the screws on the module's front panel.

Replacement (Online Hot-Swap in Redundant Configuration)

Preparation: Verify the system is in redundant operation with both SR511 modules functioning normally (green LEDs on).

Removing the Faulty Module: Loosen the fixing screws on the handles of the module to be replaced. Firmly grip both handles and decisively, steadily extract the module from the subrack.

Checking the New Module: Confirm the new module's version number meets or exceeds system requirements.

Installing the New Module: Carefully insert the new module along the guides. Critical Step: Push slowly. When the module begins power-up initialization (observed by the green "5V" and "2V" LEDs illuminating, and the red "F" LED remaining off), pause briefly, then continue to push it fully in until it is tightly connected to the backplane.

Securing: Tighten the fixing screws on the handles.

Verification: Check that all indicator lights on the new module show normal status (5V green, 2V green, F off). The system monitoring screen should show no related alarms.

Preventive Maintenance

Regular Inspection: During routine system maintenance, visually inspect the LED status of the SR511 modules.

Cleaning: With power off, use dry compressed air to clean dust accumulation from the module's heat sink fins.

Spare Parts: Ensure spare parts of the same model are stored in anti-static packaging.

Typical Application Scenarios

The SR511 voltage regulator module is specifically applied in the following scenarios:

ABB Advant Controller 450 controller's standard configuration, serving as the core power supply for its controller subsystem.

Advant Controller 400 series platforms requiring equivalent power and reliability levels.

Any industrial control or automation project utilizing the Advant controller subrack architecture that requires highly reliable, redundant, hot-swappable 5V/2.1V power supplies.