The IS220PVIBH1A is a Vibration Monitor I/O Module designed for GE's Mark VIe control system. It is specifically used for vibration and position monitoring of rotating machinery such as industrial gas turbines, steam turbines, compressors, and generators. This module integrates data acquisition, signal conditioning, digital processing, and communication functions. It can connect to various types of sensors to enable real-time monitoring and protection of equipment operational status. The IS220PVIBH1A is an early version of the PVIB series, later superseded by the PVIBH1B, but remains widely used in many existing systems.

Key Features

1 Support for Multiple Sensor Types

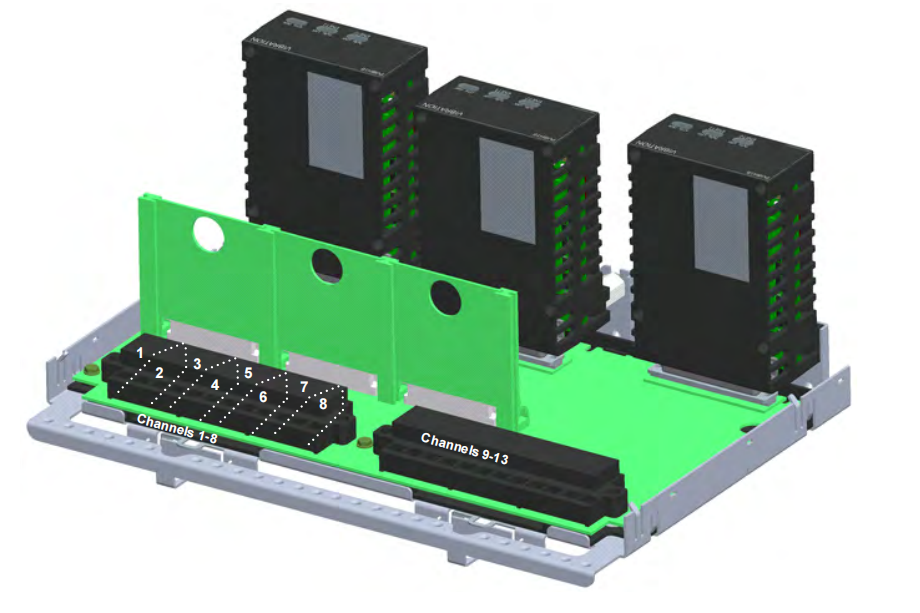

The IS220PVIBH1A supports up to 13 sensor input channels, which can be flexibly configured for the following sensor types:

Proximitor: Used to measure shaft vibration displacement and position.

Seismic Sensor: Used to measure vibration velocity on bearing housings or machine casings.

Velomitor: Used for structural vibration measurement.

Accelerometer: Suitable for aero-derivative gas turbines.

Keyphasor: Provides shaft rotational speed and phase reference signals.

2 Vibration Parameter Measurement

Gap Value (DC Component): Represents the average distance between the probe tip and the shaft surface.

Peak-to-Peak Vibration (AC Component): Represents the amplitude of shaft vibration.

1X and 2X Vibration Vectors: Analysis of vibration components synchronized with the Keyphasor signal, used to identify faults like unbalance or misalignment.

3 Rotational Speed and Phase Measurement

Using the Keyphasor input, the module calculates shaft rotational speed (RPM) and vibration phase angle, providing critical data for fault diagnosis.

4 System Limits Monitoring

Users can set high/low alarm thresholds. The module continuously monitors vibration or position signals and outputs a Boolean signal if a limit is exceeded. It supports both latching and non-latching modes for easy integration into control logic.

5 TMR (Triple Modular Redundancy) Support

The IS220PVIBH1A supports a triple-redundant configuration where three modules operate in parallel. A voting mechanism enhances system reliability, making it suitable for high-safety integrity applications.

6 Buffered Outputs

When used with the TVBAH2A terminal board, it provides buffered output signals for connection to third-party monitoring systems (e.g., Bently Nevada 3500).

Working Principle

1 Signal Conditioning and Acquisition

Each input channel is equipped with a differential amplifier, programmable gain, and bias adjustment circuitry to ensure the signal is within the optimal range before Analog-to-Digital Conversion. The module uses a 14-bit ADC for sampling, ensuring high-precision data acquisition.

2 Digital Signal Processing

Filtering: Includes low-pass filtering (for Gap values), high-pass filtering (to remove DC bias), and band-pass filtering (for extracting specific vibration frequencies).

Peak Detection: Employs a windowed peak detection algorithm that dynamically adjusts the scan period based on shaft speed to calculate vibration amplitude.

Tracking Filters: Extract the 1X and 2X vibration components synchronous with the shaft speed for phase and amplitude analysis.

3 Keyphasor Processing

The Keyphasor signal is used for:

Calculating shaft rotational speed (RPM).

Providing a phase reference for vibration analysis.

Switching to a median filter mode at low speeds to improve signal clarity.

4 Communication and Diagnostics

Communicates with the Mark VIe controller via dual Ethernet ports (ENET1/ENET2), supporting frame periods of 10 ms or slower.

Incorporates comprehensive self-diagnostics, including power supply monitoring, ADC calibration, open circuit detection, and limit violation alarms.

Application Scenarios

The IS220PVIBH1A is widely used in the following areas:

Heavy-Duty Gas Turbines (HDGT): Monitoring shaft vibration, eccentricity, axial displacement, etc.

Power Generation Sets: Vibration monitoring for generator and turbine bearings.

Compressors and Pumps: Vibration protection for driver equipment in the oil and gas industry.

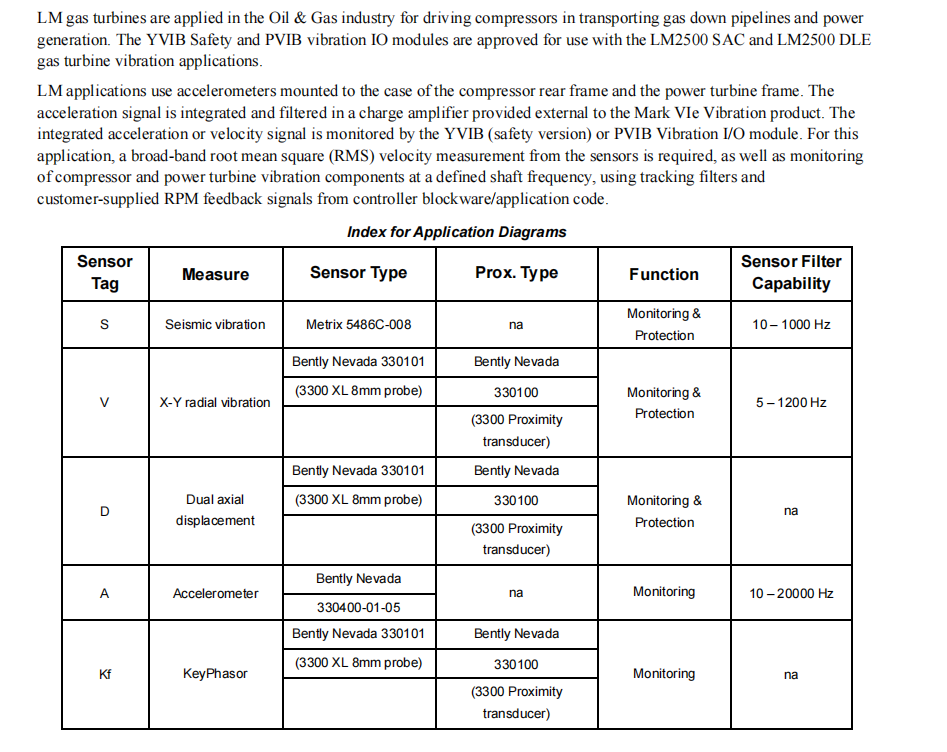

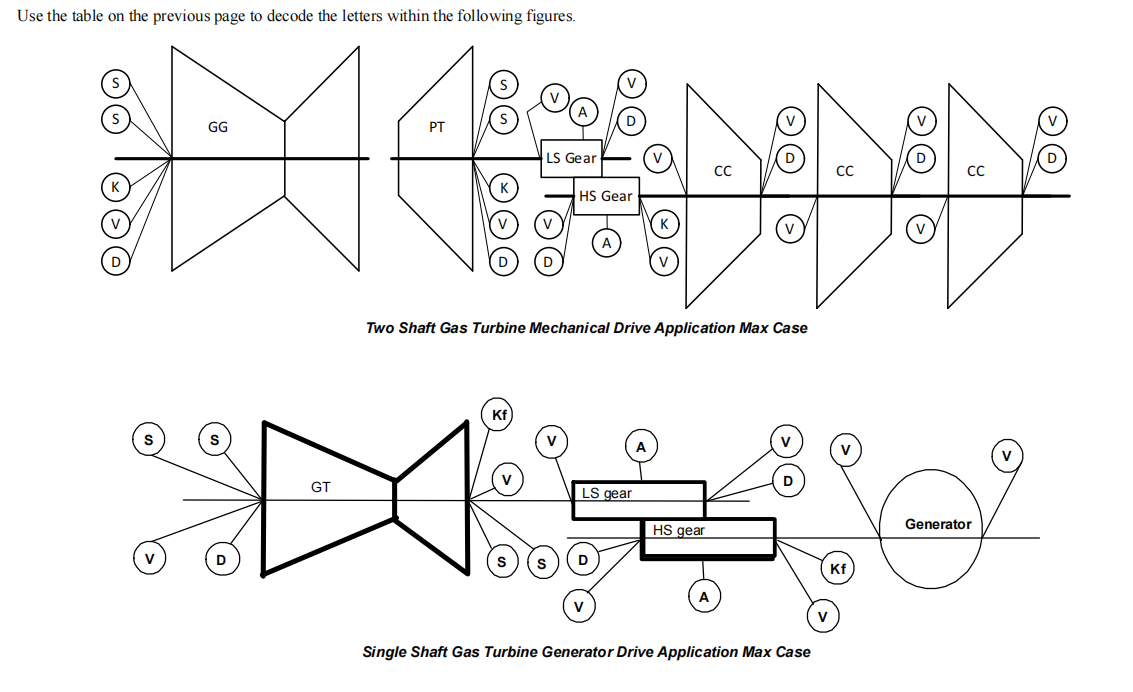

Aero-Derivative Gas Turbines (LM Series): Such as LM2500, LM6000, supporting accelerometers and dynamic pressure sensors.

Configuration and Tools

Configuration is performed using GE's ToolboxST software, including:

Sensor type selection.

Gain and bias settings.

Filter parameter adjustment.

System limits configuration.

Fault diagnosis and log viewing.

Important Notes

Enhanced Mode Not Supported: The PVIBH1A cannot use the enhanced features available on the PVIBH1B (e.g., RMS calculation, CDM sensor support).

Firmware Upgrade: It is recommended to upgrade to firmware version V5.01 or later during an outage to enable online replacement capability.

Mixed TMR Configuration: If used in a TMR set with PVIBH1B modules, Enhanced Mode cannot be enabled, and some configurations may require manual adjustment.