The IS200STCIH2A is a member of the STCI (Simplex Contact Input) family of terminal boards used in GE's Mark VIe and Mark VIeS Control Systems. It is a compact terminal board specifically designed for discrete input signal acquisition, responsible for receiving dry contact signals from field devices (such as relay contacts, pushbuttons, switches) and conditioning and converting them into standardized signals recognizable by the control system.

A key feature of this terminal board is its pluggable Euro-style terminal blocks, which greatly simplify field wiring, maintenance, and replacement procedures, reducing downtime. The IS200STCIH2A is designed for Simplex system configurations, meaning it operates with a single PDIA or YDIA I/O pack, providing a cost-effective solution for applications requiring high reliability without redundant hardware architecture.

It is rated for a 24 V DC wetting voltage and supports up to 24 independent dry contact input channels. Built-in noise suppression and hardware filtering ensure stable and accurate signal acquisition even in harsh industrial electromagnetic environments.

2. Hardware Structure and Interfaces

2.1 Mechanical Structure

Compact Design: Dimensions of 15.9 cm (H) x 10.2 cm (W), making it ideal for installation in control cabinets with limited space.

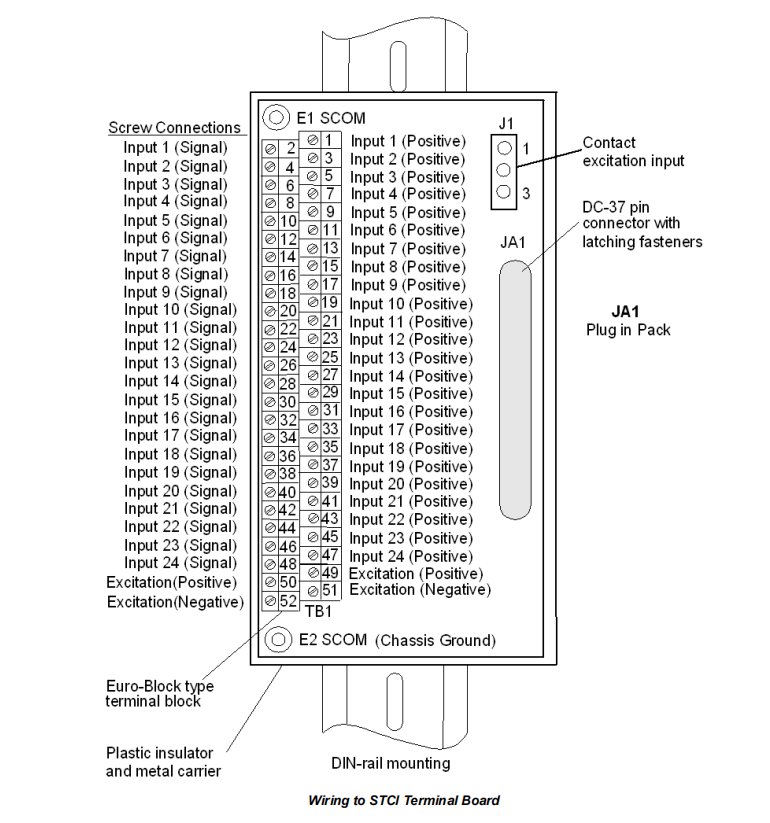

Mounting Method: Mounted via a plastic insulator onto a sheet metal carrier, which then snaps onto a standard DIN rail. Alternatively, it can be bolted into a cabinet using a sheet metal assembly.

Pluggable Terminal Blocks: This is a critical feature of the IS200STCIH2A. All wiring is connected to pluggable Euro-style terminal blocks. The entire block can be unplugged from the terminal board by loosening two screws, facilitating rapid wiring and maintenance without disturbing the terminal board itself or the I/O pack connection.

2.2 Electrical Interfaces

Power Input (J1): An external 24 V DC contact excitation power supply is connected via dedicated terminals (Terminals 50 and 51/52) on the terminal block. This supply provides the "wetting" voltage for the field dry contacts, with an allowable range of 18.5 to 32 V DC, and it is floating.

Signal Inputs: Provides 24 pairs of input terminals. Each input uses two terminals:

Positive (+): e.g., Positive for Input 1 is Terminal 1.

Signal/Return (-): e.g., Return for Input 1 is Terminal 2.

The terminal block accepts wires up to #18 AWG.

System Interface (JA1): A DC-37 pin connector for directly plugging in a PDIA or YDIA I/O pack. This connector carries all 24 input signals, the ID recognition signal, relay coil power, and the feedback multiplex command.

Shielding and Grounding:

SCOM: Connected to chassis ground via screw terminals E1 and E2, providing a grounding point for signal shields.

It is recommended to terminate cable shields on a separate grounding bar for optimal noise immunity.

3. Functionality and Operating Principles

The functionality of the IS200STCIH2A terminal board extends far beyond a simple wiring junction. It serves as the first line of defense for signal conditioning and system protection. Its operating principle involves multiple layers of precise processing.

3.1 Signal Conditioning and Acquisition Chain

The journey of a signal from the field to the control system begins at the IS200STCIH2A:

Wetting Voltage Provision: The externally provided 24 V DC excitation power enters the terminal board. This voltage is distributed to each input channel, providing a potential difference across the field dry contact connected between the positive and return terminals. The circuit conducts when the contact is closed and is open when the contact is open.

Noise Suppression and Surge Protection: Before the signal proceeds to subsequent circuits, each input channel is equipped with a noise suppression circuit. This circuit is specifically designed to suppress high-frequency noise and withstand voltage surges. Industrial environments are filled with electromagnetic interference generated by motors, variable frequency drives, etc., which can couple into signals via long cables, causing false "ghost" readings. The noise suppression circuit effectively filters out these interferences, ensuring only genuine contact status signals are passed. Simultaneously, the surge protection function can withstand transient high voltages from lightning strikes or inductive load switching, protecting the sensitive downstream electronics.

Hardware Filtering: After noise suppression, the signal passes through a fixed 4 millisecond hardware filter. This filter further smoothens the signal, eliminating rapid on/off transitions that may be caused by contact bounce. Mechanical contacts often produce a series of fast, unstable physical rebounds at the moment of closure or opening, causing electrical signal glitches. The 4ms hardware filter effectively ignores these brief bounces, ensuring the I/O pack acquires a clean, stable status signal, significantly improving input reliability.

Signal Transmission to the I/O Pack: The 24 discrete voltage signals, conditioned as described above, are transmitted in parallel via the DC-37 connector to the PDIA or YDIA I/O pack plugged into it.

3.2 Further Processing inside the I/O Pack (Collaboration with the Terminal Board)

After receiving signals from the IS200STCIH2A, the I/O pack performs a second stage of processing. While this functionality resides within the I/O pack, it is closely related to the terminal board's design:

Optical Isolation: On the acquisition board of the PDIA/YDIA pack, each input signal passes through an opto-isolator. This is key to achieving system electrical isolation. The opto-coupler completely separates the input circuit on the terminal board side from the control logic side. This isolation can withstand voltages up to 1500 V, effectively preventing voltage spikes, ground potential differences, or fault high voltages from the field side from entering the control system core, thereby protecting the controller from damage and improving the overall system's noise immunity and safety. It is important to note that the input channels are not isolated from each other at the terminal board and I/O pack level (group isolation).

Variable Threshold Comparison and Status Determination: Each input channel has a voltage comparator circuit. Its decision threshold is not fixed but is dynamically derived from the wetting voltage provided by the terminal board. In standard applications, this threshold is set to 50% of the wetting voltage. For example, with a 24V wetting voltage, the threshold is approximately 12V. When a field contact closes, the voltage on the return line is pulled high, close to the wetting voltage, exceeding the threshold, and the comparator outputs a high level, interpreted as "1" (ON). When the contact opens, the return line voltage is low (often via a pull-down resistor), falling below the threshold, and the comparator outputs a low level, interpreted as "0" (OFF). This design allows the input circuit to adapt to different wetting voltage levels.

Threshold Clamping and Undervoltage Detection: To prevent the input circuit from entering an indeterminate state if the wetting voltage is accidentally lost or drops significantly, the system implements two important protection mechanisms:

Threshold Clamping: Even if the wetting voltage drops to zero, the input threshold is clamped to 13% of the nominal rated voltage. This ensures that all inputs are forced to indicate "OFF" in the event of excitation power loss, which is a fail-safe design.

Undervoltage Detection: If the wetting voltage drops below 40% of its nominal value, the I/O pack detects this condition and reports an "Excitation Voltage not valid" diagnostic alarm to the control system, alerting maintenance personnel to check the power supply.

Status Indication: The I/O pack is equipped with a yellow status LED indicator for each input. When an input is determined to be in the "ON" (picked up) state, the corresponding LED illuminates, providing intuitive visual feedback for field debugging and troubleshooting.

3.3 Input Current Characteristics and Load Design

The IS200STCIH2A's input circuits have specific current consumption characteristics, which are important for power supply selection and understanding its operation:

First 21 Inputs (Channels 1-21): Each consumes approximately 2.5 mA of current when the contact is closed. This corresponds to an internal current-limiting resistor of about 10 kΩ.

Last 3 Inputs (Channels 22-24): Each consumes approximately 9.9 mA of current when the contact is closed. This corresponds to an internal current-limiting resistor of about 2.40 kΩ.

The last three channels are designed with higher drive capability to better interface with loads such as remote solid-state output electronics.

3.4 Diagnostics and Self-Verification

The IS200STCIH2A works in concert with the I/O pack to implement advanced diagnostic functions, which are crucial for high-availability systems:

Periodic Self-Test: The I/O pack performs an automatic diagnostic test every four seconds. In this mode, it sequentially forces the comparator threshold for each input high and then low and checks whether the opto-coupler's response matches the expectation. If the opto-coupler for a particular input does not respond or responds incorrectly, it indicates a hardware failure within that input channel (possibly the comparator or opto-coupler), and the system generates a "Contact Input [#] not responding to self-test mode" alarm (Alarm Code 56-79).

Electronic ID Verification: The IS200STCIH2A terminal board's DC-37 connector contains an embedded read-only electronic ID chip. When the I/O pack is plugged in, it immediately reads the information from this chip, including: terminal board serial number, board type, and revision number. The I/O pack compares the read information with the hardware information pre-configured in the ControlST Toolbox. If a mismatch is found (e.g., wrong terminal board type or revision), it immediately generates a "hardware incompatibility" fault, preventing the system from operating under an incorrect configuration and ensuring hardware traceability and configuration accuracy.

Excitation Voltage Monitoring: As mentioned earlier, the I/O pack continuously monitors the wetting voltage from the terminal board. Once an undervoltage condition is detected, it triggers a diagnostic alarm (Alarm Code 240: "Excitation Voltage not valid, Contact Inputs not valid").

4. Installation and Configuration Key Points

4.1 Installation Steps

Mount the Terminal Board: Securely mount the IS200STCIH2A with its plastic insulator onto the DIN rail or sheet metal bracket.

Wiring:

Connect the external 24 V DC excitation power to Terminals 50 (+) and 51/52 (-).

Connect the 24 field dry contacts to their respective positive and return terminals.

Connect the SCOM grounding screws (E1, E2) to chassis ground.

Install the I/O Pack: Directly and vertically plug the PDIA or YDIA I/O pack into the terminal board's DC-37 connector (JA1).

Mechanically Secure: Use the threaded studs adjacent to the I/O pack's Ethernet ports to slide it into the terminal board's specific mounting bracket and tighten. Adjust the bracket position to ensure no side-force is applied to the DC-37 connector.

Connect Network and Power: Plug in one or two Ethernet cables to the I/O pack and connect the 28 V DC pack operating power.

4.2 Software Configuration

Use the ToolboxST software to configure the associated PDIA or YDIA pack. Relevant parameters include:

ContactInput: Mark used channels as "Used".

SignalInvert: Choose to Normal or Invert the input logic.

SeqOfEvents: Whether to record contact state transitions in the sequence of events.

SignalFilter: Option to add additional software digital filtering (0, 10, 20, 50, 100 ms) on top of the hardware filter.