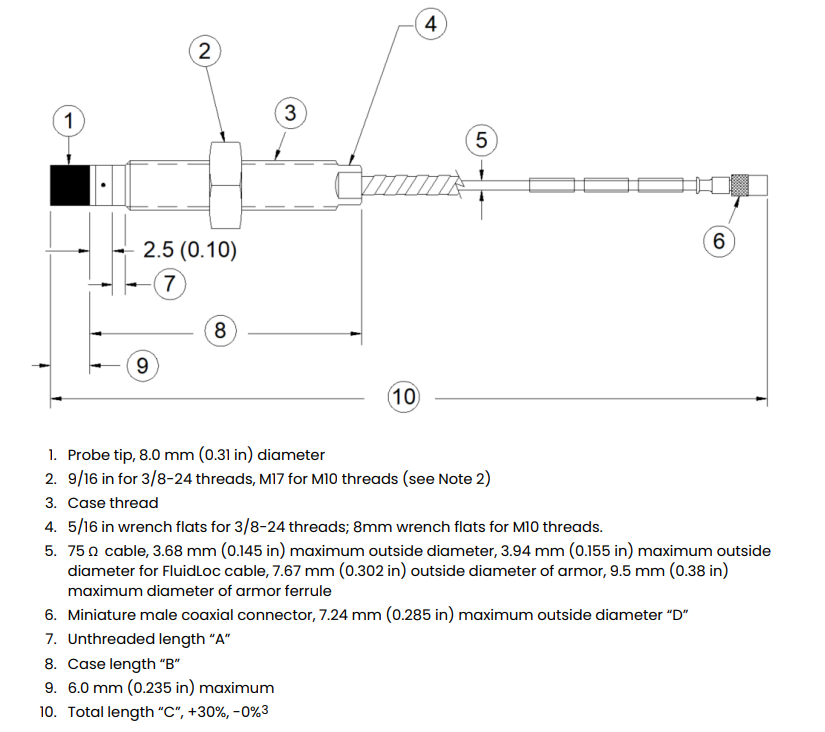

330104 is a probe model under the 3300 XL 8mm Proximity Transducer System. This probe features M10x1 threads and is armored. (M10x1 is a metric fine thread with a 10 mm major diameter and a 1 mm pitch, an ISO standard commonly found on European and Asian equipment).

The main differences between this model and the 330101 are:

Different thread style.

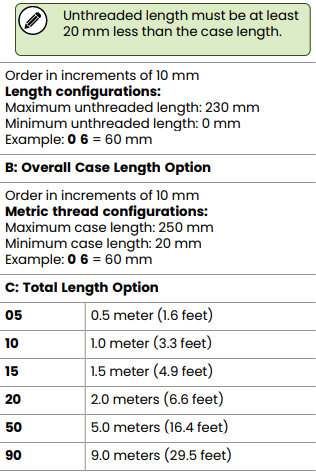

This model does not have a 3-meter length option.

This model is equipped with armor.

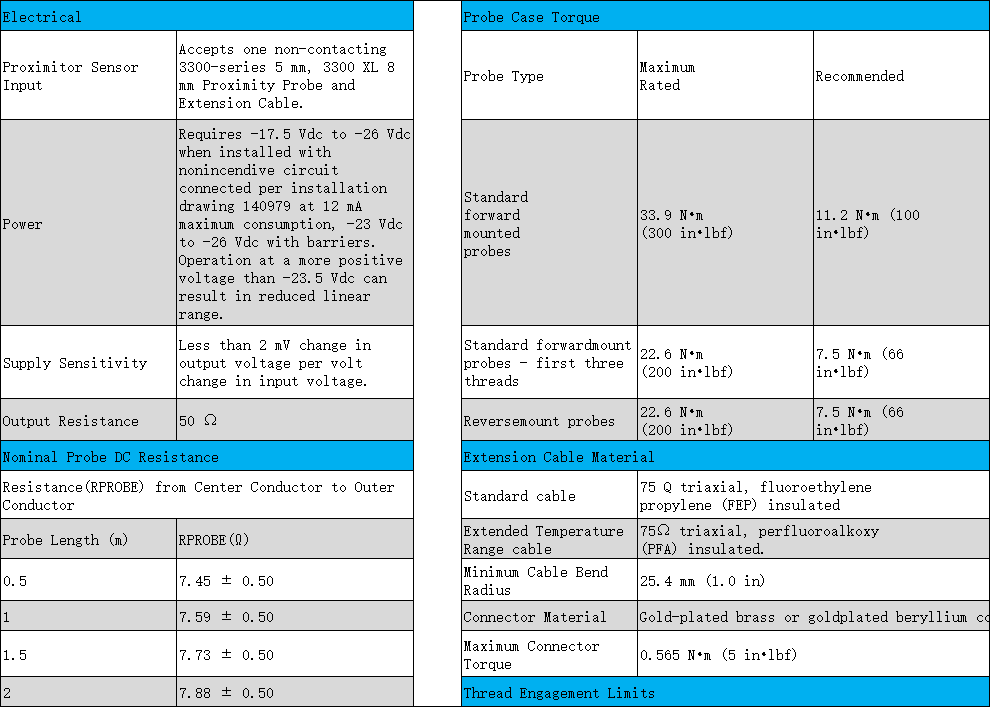

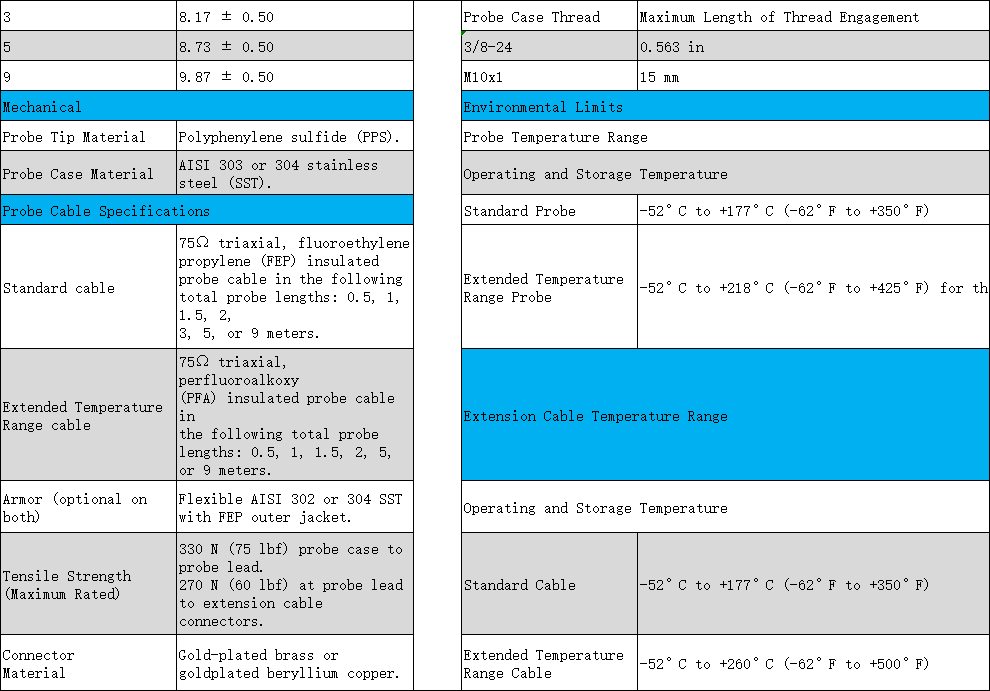

This probe is primarily used for vibration and position measurement on fluid-film bearing machinery, as well as for Keyphasor reference and speed measurement. It fully complies with the American Petroleum Institute (API) 670 standard regarding mechanical configuration, linear range, accuracy, and temperature stability. It remains backward compatible and interchangeable with corresponding components from non-XL 3300 Series 5 mm and 8 mm systems.

The probe cable incorporates the patented CableLoc® design, which provides a pull-off resistance of 330 N (75 lbf), ensuring a more secure connection between the cable and the probe tip. Cables with the optional FluidLoc® feature can also be ordered. This option prevents oil and other fluids from migrating along the inside of the cable out of the machine.

Notes:

One-meter systems do not use extension cables.

Mixing model 330104 with corresponding components from non-3300 XL Series 5 mm and 8 mm systems will limit the overall system performance to the specifications of the non-3300 XL 5 mm and 8 mm transducer systems.

3300 Series 5 mm probes feature a smaller physical package; however, they do not reduce side-clearance or probe spacing requirements compared to 8 mm probes. The 5 mm probes are intended for use where physical (not electrical) constraints prevent the use of an 8 mm probe. If your application requires a narrow side-view probe, use the 3300 NSv eddy current sensor system.

8 mm probes feature a thicker probe coil package housed in a molded PPS plastic probe tip. This construction makes the probe more robust. The larger probe body diameter also contributes to a more rugged housing. It is recommended to use an 8 mm probe wherever possible to provide maximum robustness against physical damage.

We provide a one-year warranty for all genuine new products. Shipping will be carried out via DHL / FEDEX / TNT / UPS or other methods. If you have any questions prior to purchasing this specific item, please contact us.