| Product Identification | Model | CA202 (Explosion-Proof Intrinsic Safety Ex ia) | Meggitt vibro-meter Product Line |

| Ordering Number (PNR) | 144-202-000-105 | Key Identifier: Ex ia Explosion-Proof Version, 3m Cable |

| Explosion Protection Type | Intrinsic Safety “ia” | Permitted for use in Zone 0, 1, 2 (Gas) |

| Equipment Protection Level (EPL) | Ga (for Gas Atmospheres) | Provides a very high level of protection |

| Electrical Output | Charge Signal | Differential output, 2-wire, insulated from case, Intrinsically Safe |

| Associated Apparatus Requirement | Must be connected to a certified intrinsic safety barrier (e.g., Meggitt GSI series) or an IS-rated charge amplifier located in a safe area. | Forms a complete Intrinsic Safety loop |

| Performance Parameters | Sensitivity (Nominal) | 100 pC/g | At 23°C, 120Hz, 5g conditions |

| Sensitivity Tolerance | ±5% |

|

| Measurement Range | 0.01 to 400 g (peak) |

|

| Overload Protection (Transient) | Up to 500 g (peak) |

|

| Linearity | ±1% (0.01-20g peak)

±2% (20-400g peak) |

|

| Transverse Sensitivity Ratio | ≤ 3% |

|

| Mounted Resonant Frequency | > 22 kHz (typical) |

|

| Frequency Response (±5%) | 0.5 Hz to 6000 Hz |

|

| Insulation Resistance (Internal) | ≥ 1 x 10⁹ Ω | Signal terminal to case, minimum |

| Capacitance | Sensor Body (Ci):

Pole-Pole: ~5000 pF

Pole-Case: ~10 pF

Cable Distributed Capacitance (Cc, per meter):

Pole-Pole: ~105 pF/m

Pole-Case: ~210 pF/m | Ci and Cc are critical parameters for Intrinsic Safety loop calculation and must match the barrier parameters. |

| Environmental, Ex-Proof & Construction | Ambient Temperature (Ta) | Sensor Head: -55°C to +260°C

Integral Cable: -55°C to +200°C | Note: Ambient temperature affects the temperature class (T-Code). |

| Temperature Class (T-Code) | T6 to T2 (depending on ambient temperature Ta) | T6: Ta ≤ 85°C, T5: Ta ≤ 100°C, T4: Ta ≤ 135°C, T3: Ta ≤ 200°C, T2: Ta ≤ 260°C |

| Construction & Materials | Housing/Hose: Stainless Steel, hermetically welded

Sealing: Resistant to moisture, water, oil, corrosion. |

|

| Equipment Category/Zone | II 1G (per ATEX) | Suitable for Gas Atmospheres Zone 0, 1, 2 |

| Gas Group | IIC | Includes hydrogen, acetylene, etc. |

| Ex Marking (Example) | Ex ia IIC T6...T2 Ga |

|

| Primary Ex Certifications | ATEX: LCIE 02 ATEX 6179 X

IECEx: IECEx LCI 10.0018X

North America: cCSAus 70004630 (Class I, Div 2 & Zone 2, AEx na)

UK UKEX: CML 22 UKEX 2746 X

Russia: EA3C RU C-CH.AA07.B.03042/21 | The "X" marking indicates special conditions for safe use which must be strictly followed as per certificate annex. |

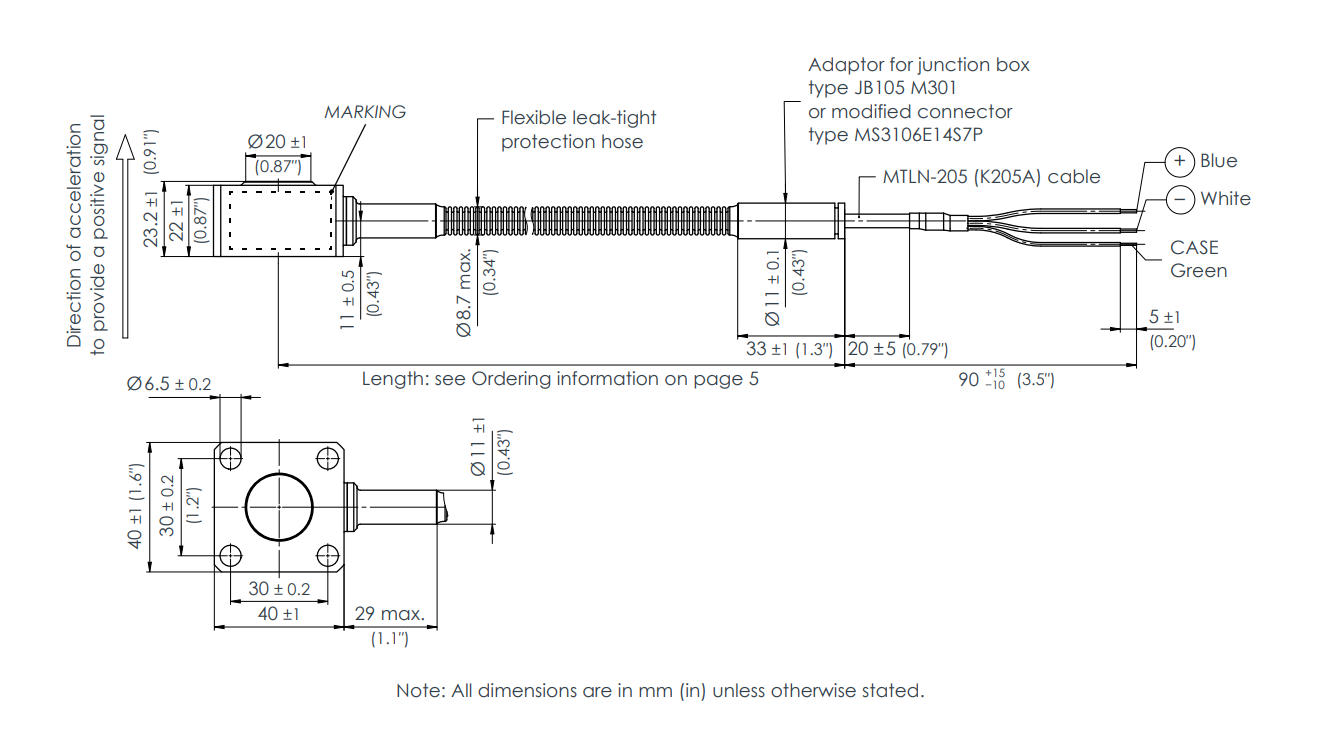

| Physical & Mounting | Material | Stainless Steel |

|

| Weight | Sensor: Approx. 250 grams

Cable: Approx. 135 grams/meter |

|

| Cable Length | 3 meters | Suitable for typical hazardous area wiring to a junction box |

| Cable Construction | Twisted-pair shielded low-noise cable, sheathed in stainless steel flexible braided hose |

|

| Mounting | 4 x M6 x 35 socket head cap screws, with 4 x M6 spring lock washers

Mounting Torque: 15 N·m

Note: Electrical insulation of mounting surface is not required. |

|

| Electrical Interface | Flying leads (stripped wire cores) at cable end | For Intrinsic Safety loop connection; use appropriate terminals. |

| Safety Parameters (Typical, refer to certificate) | Maximum Input Voltage (Ui) | e.g., 30 Vdc | Maximum voltage that can be applied from safe area |

| Maximum Input Current (Ii) | e.g., 100 mA |

|

| Maximum Input Power (Pi) | e.g., 0.75 W |

|

| Internal Capacitance (Ci) | See "Capacitance" row |

|

| Internal Inductance (Li) | Negligible (≤1 µH) |

|

| Permitted Cable Parameters | Max. Cable Capacitance (Cc): Determined by barrier parameter calculation

Max. Cable Inductance (Lc): Determined by barrier parameter calculation | Loop calculation is mandatory to ensure total stored energy is safe. |

| Quality & Compliance | Factory Calibration | Dynamic calibration performed at 5g peak, 120Hz, 23°C. |

|

| Other Compliance | EMC: EN 61000-6-2, -6-4

Electrical Safety: EN 61010-1

Environmental: RoHS Compliant |

|