| Basic Information | Product Model | CA202 (Standard Version, Non-Explosion Proof) | Meggitt vibro-meter Product Line |

| Ordering Number (PNR) | 144-202-000-225 | Standard Version, 11m Integral Cable |

| Sensing Principle | Piezoelectric Effect, Shear Mode | Symmetrical Polycrystalline Measuring Element |

| Output Type | Charge Output | Differential, 2-pole system, insulated from case |

| Signal Conditioning Requirement | Requires external charge amplifier/transmitter | Recommended to use IPC 70x series signal conditioners |

| Electrical & Performance Parameters | Sensitivity | 100 pC/g ± 5% | At 23°C ±5°C, 120 Hz, 5 g peak conditions |

| Dynamic Measurement Range | 0.01 g to 400 g (peak) | Random vibration |

| Overload Capacity (Spike) | Up to 500 g (peak) | Transient spike signals |

| Linearity | ±1% (0.01 to 20 g peak)

±2% (20 to 400 g peak) | Percentage of Full Scale |

| Transverse Sensitivity | ≤ 3% |

|

| Resonant Frequency (Mounted) | > 22 kHz (nominal) | Actual value is typically higher, depends on mounting stiffness |

| Frequency Response (±5%) | 0.5 Hz to 6000 Hz | Lower cutoff frequency depends on the high-pass filter setting of the charge amplifier used |

| Typical Deviation @ 8kHz | +10% | Deviation relative to flat frequency response |

| Internal Insulation Resistance | ≥ 1 x 10⁹ Ω (minimum) | Inside sensor |

| Capacitance (Nominal) | Sensor:

- Pole to Pole: 5000 pF

- Pole to Case: 10 pF

Cable (per meter):

- Pole to Pole: 105 pF/m

- Pole to Case: 210 pF/m | Cable capacitance adds to system total, must be considered during system calibration |

| Environmental & Durability Parameters | Operating Temperature Range | Sensor Body: -55°C to +260°C

Integral Cable: -55°C to +200°C | Continuous operating temperature |

| Short-Term Survival Temperature | Sensor Body: -70°C to +280°C

Integral Cable: -62°C to +250°C | Tolerance limit in non-operating state |

| Temperature Sensitivity Error | -55°C to +23°C: 0.25% / °C

+23°C to +260°C: 0.1% / °C | Rate of sensitivity change relative to 23°C (73°F) reference |

| Protection & Materials | Housing: Austenitic Stainless Steel (1.4441), hermetically welded.

Protection Hose: Heat-Resistant Stainless Steel (1.4541), hermetically welded.

Sealing: Resistant to 100% RH, water, steam, oil, salt spray, dust, fungus, etc. | Forms a leak-tight sealed assembly |

| Base Strain Sensitivity | 0.15 x 10⁻³ g / με | Equivalent acceleration error generated under 250 με peak-to-peak base strain |

| Shock Resistance | ≤ 1000 g (peak) | Half sine wave, 1 ms duration |

| Explosion Proof Certification | This Model (-225): Not Applicable.

Optional Models: Available in Ex ia IIC T6...T2 Ga (Intrinsic Safety) and Ex na IIC T6...T2 Gc (Non-Sparking) certified versions. | Hazardous area applications must use corresponding Ex-proof models |

| Mechanical & Physical Parameters | Housing Material | Austenitic Stainless Steel |

|

| Weight | Sensor (with base): Approx. 250 g

Cable (per unit length): Approx. 135 g/m |

|

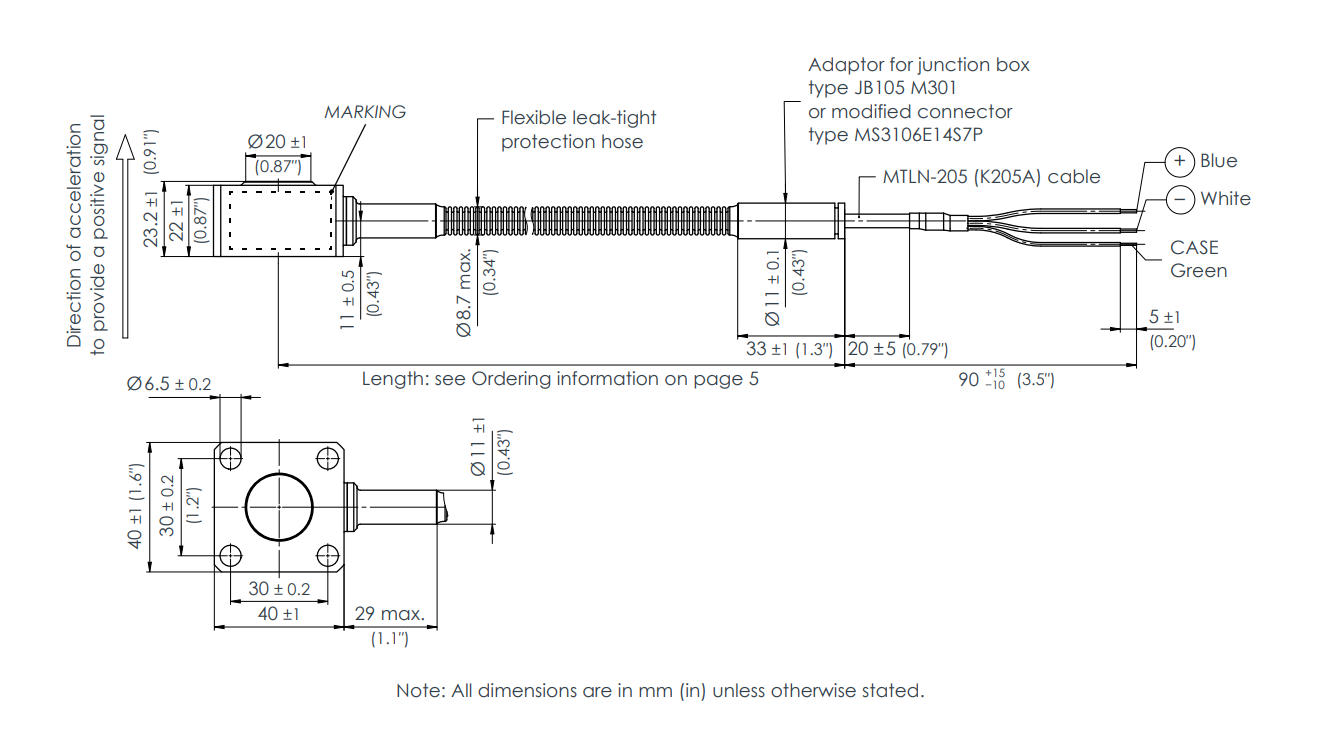

| Cable Length | 11 meters | Integral low-noise cable with stainless steel sleeve |

| Cable Type | 2-pole twisted and shielded cable | Outer layer is stainless steel flexible protection hose (BOA) |

| Mounting | 4 x M6 x 35 socket head cap screws, with 4 x M6 spring lock washers.

Mounting Torque: 15 N·m.

Note: Electrical insulation of mounting surface is not required. |

|

| Electrical Connection | Flying leads (stripped wire ends) at cable end | For direct connection to terminal blocks or signal conditioners |

| Calibration & Warranty | Factory Calibration | Dynamic calibration performed at 5 g peak, 120 Hz, 23°C. | Calibration data provided. No periodic field calibration required under normal operating conditions. |

| Compliance & Approvals | EMC: Complies with EN 61000-6-2, EN 61000-6-4

Safety: Complies with EN 61010-1

Environmental: RoHS (2011/65/EU) compliant

Regional: CE Marking, EAC Marking (Eurasian Union) |

|