The CA202 piezoelectric accelerometer is a high-performance industrial vibration sensor from the Vibro-Meter product line (now part of Meggitt Group), widely used for vibration monitoring and fault diagnosis in various rotating machinery, power equipment, and demanding industrial environments. Model 144-202-000-215 is the standard version equipped with a 6-meter integral cable, suitable for vibration monitoring tasks in non-explosive (non-hazardous) areas.

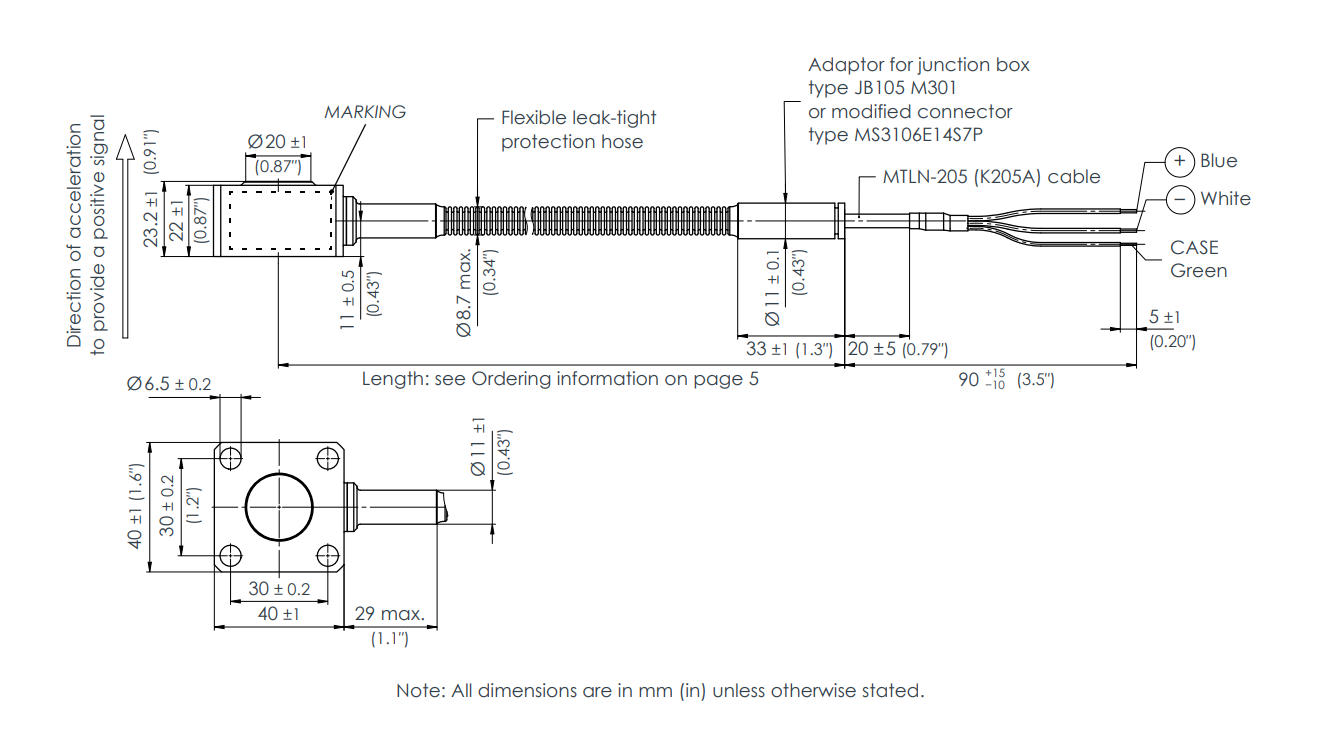

This sensor employs a symmetrical shear mode polycrystalline measuring element with internal case insulation and differential output. The housing is made of austenitic stainless steel and is hermetically welded, providing excellent mechanical strength, corrosion resistance, and long-term stability. The integral cable is protected by a flexible stainless steel sleeve and welded to the sensor housing, forming a sealed, leak-tight assembly that can withstand harsh industrial contaminants such as humidity, water, steam, oil, and salt-laden atmospheres.

The CA202 is designed for heavy-duty industrial vibration monitoring and measurement. Its high sensitivity, wide frequency response, broad operating temperature range, and excellent noise immunity make it a reliable front-end sensor for industrial equipment condition monitoring and predictive maintenance systems.

2. Key Features and Benefits

High Sensitivity: Provides a 100 pC/g high sensitivity for accurately capturing weak vibration signals.

Wide Frequency Response: Frequency response range from 0.5 Hz to 6000 Hz, covering the characteristic vibration frequencies of most industrial machinery.

Wide Operating Temperature Range: Sensor body operating temperature range from -55°C to +260°C, suitable for high or low-temperature environments.

Robust and Durable Design:

Housing made of Austenitic Stainless Steel (1.4441), hermetically welded.

Integral cable with Heat-Resistant Stainless Steel (1.4541) flexible protection hose, welded and sealed.

Overall structure is resistant to moisture, water, oil, salt spray, and adapts to harsh industrial environments.

Excellent Electrical Characteristics:

Internal Case Insulation effectively isolates ground loop interference.

Differential Charge Output provides strong common-mode noise rejection.

Very high internal insulation resistance (≥ 10⁹ Ω).

Easy Installation: Provides standard mounting holes. Electrical insulation of the mounting surface is not required.

Optional Safety Certifications: In addition to the standard version, Ex ia (intrinsically safe) and Ex na (non-sparking) certified versions are available for use in potentially explosive atmospheres (hazardous areas).

Long-Term Reliability: Dynamically calibrated at the factory. No subsequent calibration is required under normal operating conditions.

3. Application Areas

The CA202 piezoelectric accelerometer is designed for demanding industrial environments and is suitable for the following wide range of vibration monitoring applications:

Rotating Machinery / Driving Elements:

Rotating Machinery / Driven Elements:

Miscellaneous Applications:

Structural Vibration Monitoring (e.g., bridges, buildings, towers)

Loose Parts Monitoring in Rotating Machines

General Vibration Measurement and Condition Monitoring in Industrial Processes

Its high reliability and wide temperature capability make it particularly suitable for critical sectors such as Energy (power plants), Petrochemical, Heavy Manufacturing, Mining, and Marine Propulsion.

4. Installation and Connection Guidelines (Based on CAXXX Series General Manual)

Correct installation is crucial for ensuring measurement accuracy and sensor longevity. Below are key installation points for accelerometers like the CA202 with integral cable and separate signal conditioner.

1. Mounting Location Selection

Mount the sensor as close as possible to the bearings.

Ensure it is fixed to the most rigid part of the machine. Avoid mounting on housings or structures with low mechanical stiffness to prevent resonance distortion.

Refer to the relevant machine manufacturer's guidelines.

2. Mounting Surface Preparation (For models with base like CA201/CA202)

Prepare Surface: The mounting surface should be flat, clean, and perpendicular to the desired axis of sensitivity.

Precision Requirements: Surface flatness should be 0.01 mm, with a surface quality of approximately N7.

Drilling & Tapping: Based on mounting hole size (typically M6), drill 4.8 mm holes to a depth of 20 mm, and tap M6 threads to a depth of 14 mm.

Cleaning: Remove all debris and oils.

3. Sensor Mounting

Components: Prepare four M6x35 socket head cap screws and four M6 single-coil spring lock washers.

Locking: It is recommended to apply a medium-strength thread-locking compound like LOCTITE 241 to the screws to prevent loosening due to vibration.

Mounting: Align the sensor, place washers, and insert screws.

Torque Control: Using a torque wrench, cross-tighten the four screws evenly to 15 N·m. Do NOT exceed this torque!

4. Cable Routing and Fixing

Bend Radius: The minimum bend radius for the cable (including stainless sleeve) must not be less than 50 mm. Avoid sharp bends.

Fixation Interval: Use cable clips suitable for ~Φ8 mm tubing to secure the cable to the machine or structure every 100 to 200 mm.

Avoid Interference: Route cables away from high-voltage or high-frequency power lines to minimize electromagnetic interference.

Stress Relief: Leave a loop of cable near the sensor and junction box to relieve stress (refer to ISO 5348 standard diagrams).

5. Electrical Connection (Typical Measurement Chain)

The CA202 standard version requires a separate charge amplifier (e.g., IPC XXX) to form a complete measurement chain:

CA202 Sensor → Integral Cable → Charge Amplifier (IPC XXX) → Transmission Cable (K 2XX) → Galvanic Separation Unit (GSI XXX) → Monitoring System

Connection to Charge Amplifier: Connect the flying leads (two signal wires and shield) of the CA202 integral cable to the input terminals of the IPC XXX charge amplifier as per its manual.

Charge Amplifier Mounting: The IPC XXX is typically installed in an industrial junction box (e.g., ABA 160) with at least IP65 protection, in an environment between -25°C and +70°C.

Transmission Cable Connection: Use a 2-wire shielded transmission cable (e.g., K 2XX) to connect the output of the charge amplifier to the remote Galvanic Separation Unit (GSI XXX).

Galvanic Separation Unit (GSU): The GSI XXX provides power isolation and signal conversion for the 2-wire transmission system, eliminating ground loops. Its output is a voltage signal proportional to vibration, which can be directly fed into monitoring systems (e.g., VM600, MMS).

Shielding: Ensure cable shielding is properly grounded at the sensor/charge amplifier end. Follow the monitoring system's requirements for single-point grounding at the other end to prevent ground loops.

6. Comparison of Mounting Methods

The mounting method directly affects the sensor's frequency response. Screw mounting is preferred for the widest, flattest frequency response (up to 30 kHz).

Adhesive Mounting (Cyanoacrylate, Double-sided tape): Suitable for temporary use or surfaces that cannot be drilled. Limited high-temperature performance and reduced frequency response.

Magnetic Base: Convenient for temporary diagnostics, but only works on ferromagnetic surfaces. Mass and contact stiffness affect frequency response.

Hand-held Probe: For rough measurements only. Frequency response is severely limited (can be as low as 2 kHz) and repeatability is poor.

Conclusion: For permanent, high-precision industrial monitoring, rigid screw mounting is strongly recommended.

5. Maintenance and Important Notes

Routine Inspection: Periodically check the sensor for physical damage (dents), cable sleeve for cracks, and connection integrity.

Cleaning: Clean the sensor surface with a soft cloth. Avoid corrosive solvents.

Avoid Abuse: Do not subject the sensor to mechanical shock beyond its specifications (e.g., dropping), excessive temperature, or severe cable bending.

ESD Precautions: Before handling cables, especially in dry environments, personnel should discharge themselves by touching grounded metal.

Repairs: The sensor is a precision instrument. Users must not disassemble it. Any repair must be performed by Vibro-Meter/Meggitt authorized personnel. Unauthorized repair voids the warranty.

Calibration: The product is precisely calibrated at the factory. Under normal use and maintenance, it offers good long-term stability and does not require periodic recalibration. If accuracy is in doubt, contact the manufacturer or authorized service center.

Safety Disclaimer: The user is responsible for evaluating the product's suitability for their specific application. Failure to follow installation and safety instructions, or unauthorized modification of the equipment, may result in personal injury, equipment damage, and will void all warranties and liability statements.