The 3500/77M Reciprocating Cylinder Pressure Monitor is a 4-channel high-performance monitoring module under the 3500 Machinery Protection System, specifically designed for cylinder pressure monitoring in reciprocating compressors. As a key component of the 3500 series, this monitor is engineered to continuously and precisely monitor pressure changes within the compressor cylinders. It provides vital machine information to operations and maintenance personnel and effectively prevents mechanical failures caused by pressure abnormalities through real-time alarm protection for critical parameters, ensuring safe, efficient, and reliable compressor operation.

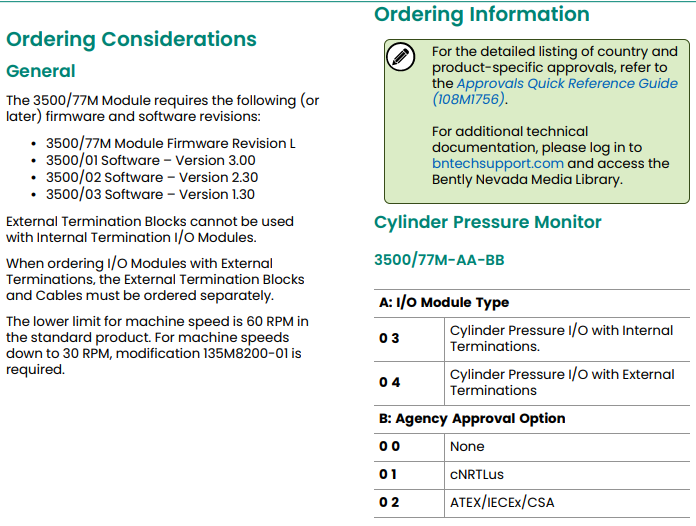

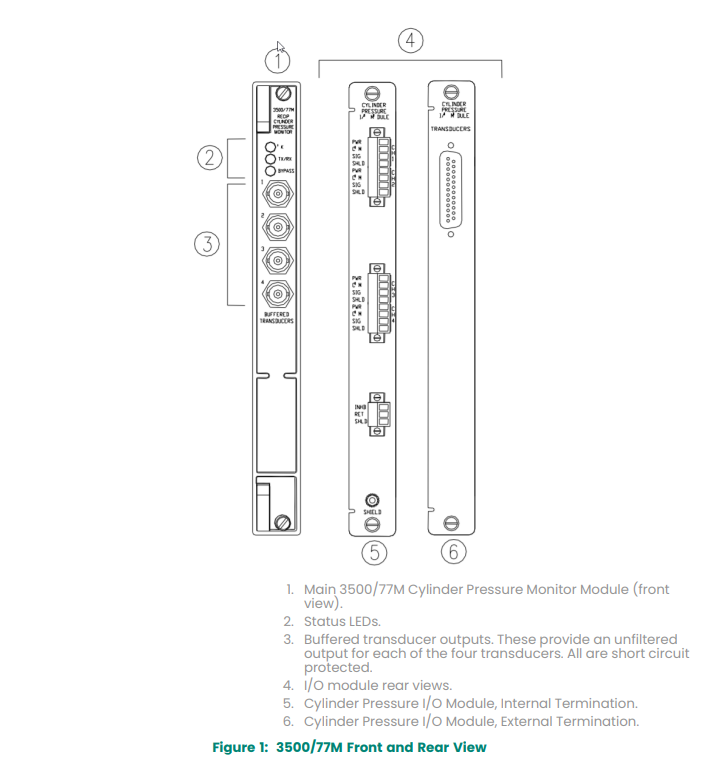

The 3500/77M consists of one fixed front card (176449-07) and two different types of rear cards (143729-01 and 143737-01. See Ordering section for more details). The 176449-07 forms a complete system when paired with any one of the rear cards.

This monitor accepts signals from Bently Nevada-approved third-party absolute pressure (psia) transducers. Through a series of advanced signal conditioning and processing steps, it calculates various pressure parameters closely related to compressor performance and mechanical load. It provides a comprehensive depiction of the compressor's working cycle state, making it a critical device for predictive maintenance and avoiding catastrophic failures.

Features

Core Pressure Parameter Monitoring: A single monitor can simultaneously monitor the pressure of four cylinders, providing eight core measured variables per channel for a comprehensive assessment of cylinder pressure status:

Basic Pressure Values: Discharge Pressure, Suction Pressure, Maximum Pressure, Minimum Pressure, Compression Ratio.

Mechanical Load Calculated Values: By combining configured mechanical parameters, it calculates Peak Rod Load Compression, Peak Rod Load Tension, and Degree of Rod Reversal, directly reflecting the stress condition of key components such as piston rods, connecting rods, and crossheads.

High-Precision Pressure Measurement: Utilizes high-precision signal conditioning circuitry. Offers pressure measurement accuracy as high as ±0.5% of the transducer's full scale (FS) at room temperature (+25°C), and guarantees ±1.0% FS accuracy over a broad temperature range (-30°C to +65°C), ensuring data reliability.

Wide Frequency Response: All configured pressure channels feature a wide frequency response of 0 to 5.5 kHz, enabling accurate capture of rapidly changing pressure dynamics during the compressor work cycle, providing high-fidelity data for analyzing valve operation status and pressure fluctuations.

Powerful Alarm Management: Users can independently set programmable Alert and Danger setpoints for each active measured variable via the 3500 Configuration Software, enabling early warning and emergency shutdown protection for faults such as pressure anomalies, overloads, and abnormal compression ratios.

Comprehensive Diagnostics and Outputs:

Front Panel Buffered Outputs: Each channel provides a coaxial connector outputting the raw transducer signal, which is inverted and offset by -2.265 Vdc, facilitating connection to an oscilloscope for advanced waveform diagnostics and analysis.

Status Indicators: The front panel is equipped with OK (Normal Operation), TX/RX (Communicating), and Bypass (Bypass Mode) LEDs to display the module's operating status in real time.

Transducer Power Supply: Provides a stable excitation voltage of +23.0 ± 0.8 Vdc for the pressure transducer on each channel, with 24.5 mA current limiting to protect the transducer.

Flexible Configuration & Integration: Supports both Internal and External Termination I/O module options, offering flexibility to adapt to various installation environments. Its design allows seamless integration with the 3500 system, sharing unified framework configuration software and platform.

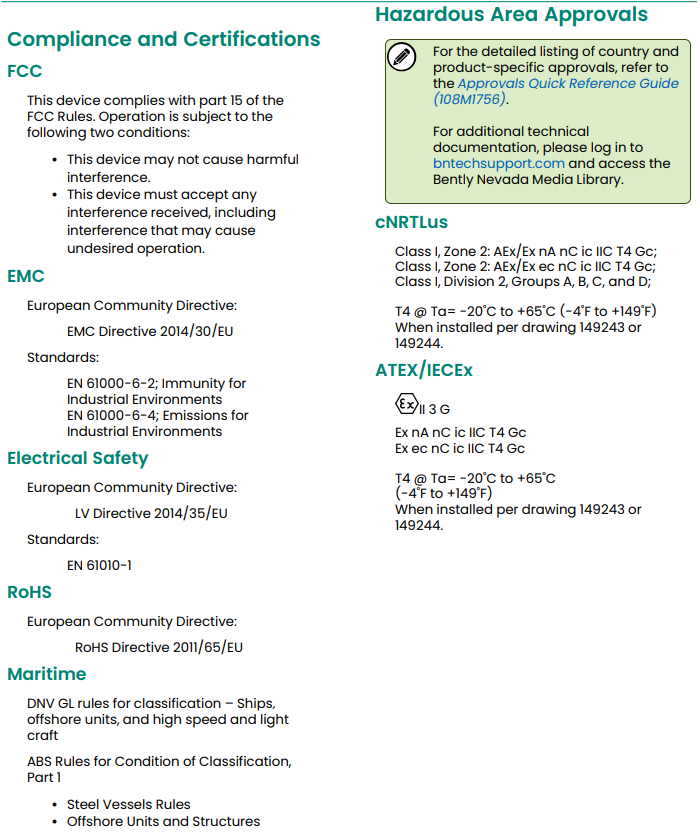

Extensive Certifications & Compatibility: The module has passed multiple international explosion-proof certifications such as cNRTLus, ATEX, and IECEx, as well as safety and maritime certifications like CE, DNV GL, and ABS, meeting installation requirements for various harsh environments worldwide. It is specifically designed for use with Bently Nevada-approved third-party pressure transducers.

Working Principle & Technical Details

The working principle of the 3500/77M monitor is based on the precise acquisition, conditioning, calculation, and logical judgment of voltage signals output by pressure transducers.

Signal Acquisition & Input Conditioning:

Sensor Interface: The monitor connects to Bently Nevada-approved absolute pressure (psia) transducers. These transducers typically use a standard voltage output: +0.5 Vdc at 0 psia and +10.0 Vdc at full scale (e.g., 100, 250, 500...10,000 psia).

Input Characteristics: The input circuit impedance is 50 kΩ, capable of receiving 1 to 4 transducer signals. The monitor internally stores scale factors for various standard ranges (e.g., 95,000 mV/psi for a 100 psia transducer, 9,500 mV/psi for a 1000 psia transducer) to accurately convert voltage signals into pressure values.

Signal Conditioning & Digitization:

Buffering & Adjustment: The input voltage signal is first buffered and conditioned. Notably, when using the Cylinder Pressure I/O module, the front panel buffered output signal is inverted and offset by -2.265 Vdc, a step taken for compatibility with certain diagnostic equipment input requirements.

High-Speed Sampling: The conditioned analog signal is sampled by a high-speed Analog-to-Digital Converter (ADC). Its wide frequency response up to 5.5 kHz ensures distortion-free capture of rapid pressure change details.

Digital Processing: The digitized signal is then processed and calculated by the built-in microprocessor.

Measured Value Calculation & Generation:

The processor analyzes the pressure waveform of each work cycle (triggered by the Keyphasor signal) to calculate all measured variables:

Peak Rod Load Compression/Tension: Calculates the maximum axial compressive and tensile forces acting on the piston rod based on the measured in-cylinder pressure and the effective area.

Degree of Rod Reversal: Calculates the extent to which the load on the piston rod changes from compression to tension (or vice versa) during the cycle. Severe load reversal is a primary cause of fatigue failure in connecting rod bolts and crosshead pins.

Directly Measured Values: By directly analyzing the waveform, it identifies the Maximum Pressure and Minimum Pressure within a cycle. By identifying stable plateau periods, it determines Suction Pressure and Discharge Pressure. The Compression Ratio is calculated by dividing Discharge Pressure by Suction Pressure.

Advanced Calculated Values (Require Mechanical Parameters): These values require users to pre-configure mechanical parameters (e.g., piston rod diameter, piston area) in the software.

Alarm Logic Judgment:

The processor continuously compares all calculated measured values with the alarm setpoints preset by the user via the 3500 Configuration Software. Once any parameter (e.g., overpressure, excessive rod load, abnormal compression ratio) exceeds the set limit and meets the configured delay condition, the monitor immediately issues an alarm command through the rack backplane. This drives the corresponding relays to activate audible/visual alarms or execute a shutdown protection sequence, thereby protecting the compressor from damage.

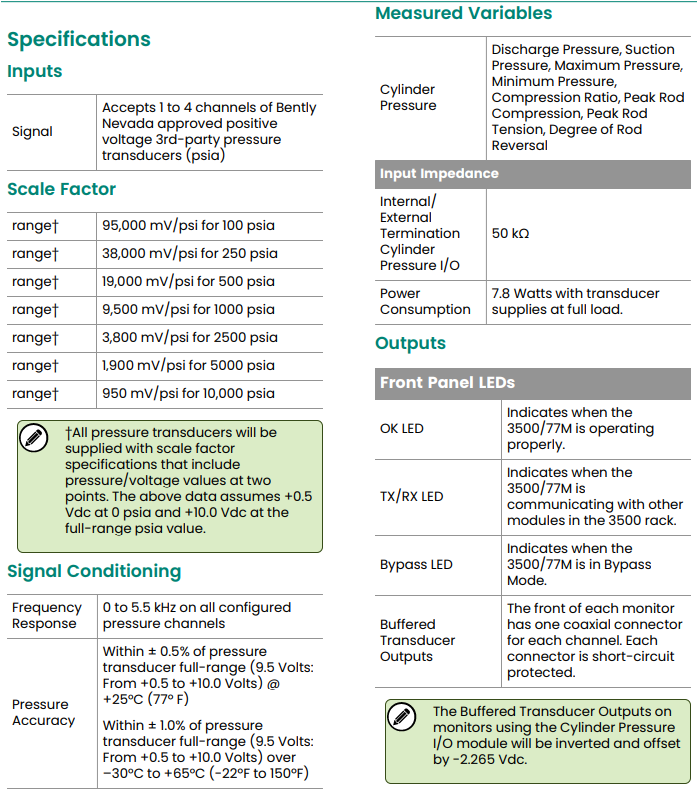

Specifications

| Item | Specification Description |

| Number of Channels | 4 channels |

| Input Signal | 1 to 4 channels of Bently-approved 3rd-party absolute pressure (psia) transducer signals (+0.5 to +10 Vdc) |

| Input Impedance | 50 kΩ |

| Pressure Accuracy | @ +25°C: ±0.5% FS (Full Scale);

@ -30°C to +65°C: ±1.0% FS |

| Frequency Response | 0 to 5.5 kHz (all pressure channels) |

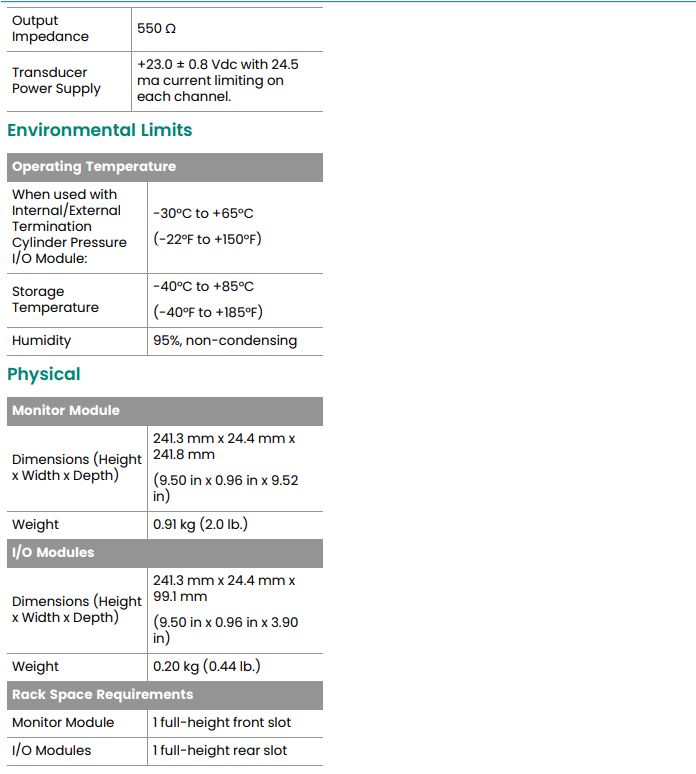

| Transducer Excitation | +23.0 ± 0.8 Vdc / channel, current limited to 24.5 mA |

| Buffered Output | Inverted and offset by -2.265 Vdc |

| Output Impedance | 550 Ω |

| Power Consumption | 7.8 Watts (with transducer supplies at full load) |

| Operating Temperature | -30°C to +65°C (when used with Internal/External Termination I/O Module) |

| Module Dimensions (HxWxD) | Monitor Module: 241.3 mm x 24.4 mm x 241.8 mm |

| Rack Space | 1 front slot (Monitor) + 1 rear slot (I/O Module) |

| Explosion-Proof Certification | cNRTLus (CL I, Div. 2), ATEX/IECEx (Ex nA/ec nC ic IIC T4 Gc), etc. |

Application Scenarios

The 3500/77M Cylinder Pressure Monitor is an ideal choice for the following scenarios and equipment:

Process Monitoring & Optimization: Used in large reciprocating compressors in the chemical, oil, gas, and fertilizer industries to monitor Discharge Pressure, Suction Pressure, and Compression Ratio in real time, ensuring the compressor operates within designed process parameters and optimizing its efficiency.

Mechanical Load & Component Health Monitoring: Critically applied to monitor:

Piston Rod Load: Continuously monitors Peak Rod Load and Degree of Rod Reversal to prevent overload and fatigue fracture of piston rods, connecting rods, crossheads, and bearings caused by liquid slugging, valve failure, or process anomalies.

Valve Condition Diagnostics: Analyzing pressure waveforms can help diagnose faults such as leakage, damage, or delayed closing of inlet and discharge valves.

Performance Analysis & Fault Diagnosis: The front panel buffered output interface connects to oscilloscopes or data acquisition systems to record pressure indicator diagrams (P-V diagrams) for in-depth analysis of compressor performance, power calculation, and identification of various potential mechanical issues.

Safety Interlock Protection: Serves as part of the compressor's Safety Instrumented System (SIS), providing hardwired shutdown protection for extreme hazardous conditions like overpressure and overload, preventing catastrophic equipment failures.