The 3500/25 Enhanced Keyphasor Module is a critical component of the 3500 Machinery Protection System. It is a half-height, dual-channel dedicated module. Its core mission is to provide precise and reliable Keyphasor signals to all monitor modules within the rack (such as vibration, eccentricity, and differential expansion monitors). The Keyphasor signal is the "heartbeat" and timing reference for rotating machinery monitoring. It is a pulse signal generated once or multiple times per shaft revolution, used to accurately mark the instantaneous position of the rotor.

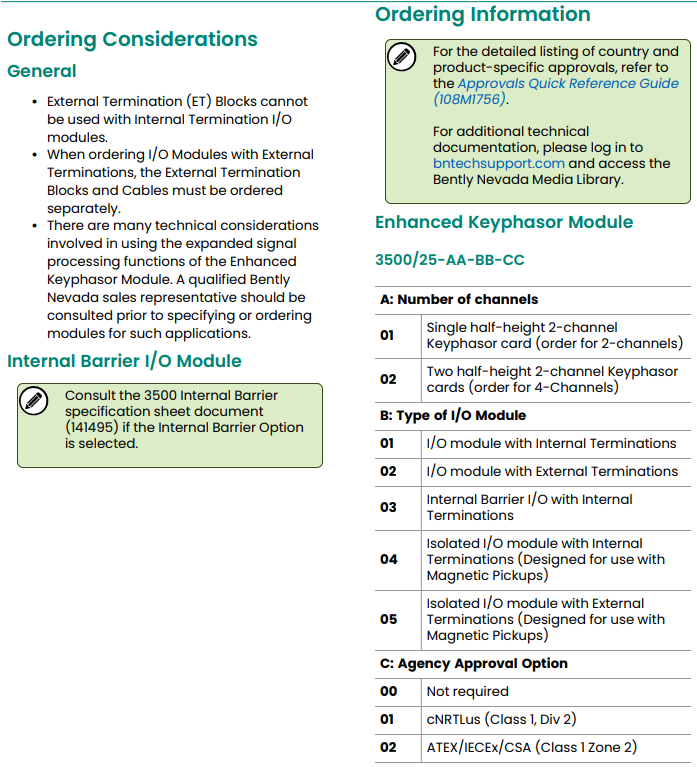

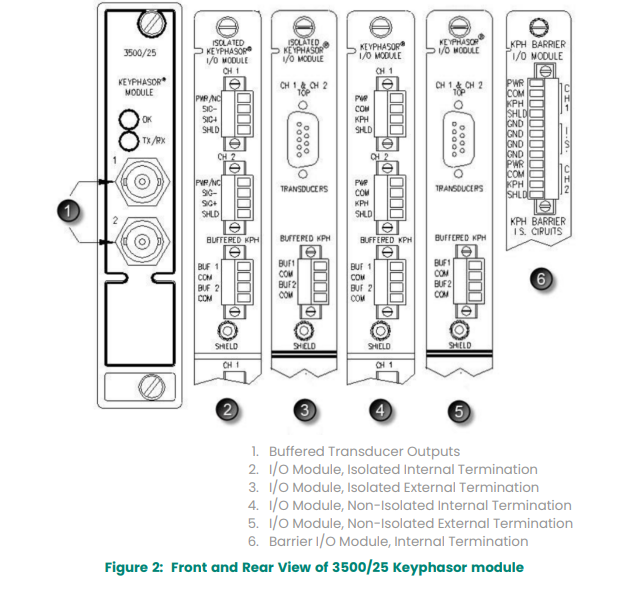

The 3500/25 includes a fixed front card (149369-01) and five different types of rear cards (see the Ordering page for details). The 149369-01 can form a complete system when paired with any one of the rear cards.

This module accepts raw signals from eddy current proximity probes or magnetic pickups and converts them into clear digital Keyphasor signals. This signal precisely indicates the moment when the Keyphasor mark on the shaft aligns with the Keyphasor transducer. The 3500 system can accept up to 4 Keyphasor signals in a standard configuration and up to 8 Keyphasor signals in a paired configuration to meet the monitoring needs of complex machinery. The 3500/25 module is an upgraded version of its predecessor (PWA 125792–01). While maintaining complete downward compatibility in form, fit, and function, it significantly expands signal processing capabilities and adds enhanced features such as field-upgradable firmware and asset management data reporting.

Features

High-Precision Timing Reference Provision: Acts as the "clock source" for the entire 3500 system, providing precise per-revolution pulse signals to all monitoring modules requiring phase reference. It is the cornerstone for measuring all vector parameters like rotational speed, vibration phase, and eccentricity direction.

Extensive Signal Compatibility: Each module can accept up to two transducer signal inputs and is fully compatible with two mainstream Keyphasor sensor types:

Eddy Current Proximity Probes: Provide high-precision, high-resolution Keyphasor signals, preferred for most high-speed rotating machinery.

Magnetic Pickups: Suitable for applications like gears or notched wheels, particularly ideal for low-speed or harsh environments (requires speed > 200 RPM).

Advanced Signal Conditioning Capabilities:

Auto Threshold: Automatically adapts to signal changes, with a minimum trigger signal of 2 V peak-to-peak, simplifying setup.

Manual Threshold: Users can customize the trigger level (0 to -20 Vdc), can trigger weak signals as low as 500 mV peak-to-peak, and features adjustable hysteresis for effective anti-interference.

Wide Frequency Response Range: Supports input frequencies up to 1,200,000 CPM (20 kHz), capable of handling complex multi-event-per-turn signals, such as generating a synthetic once-per-turn signal from a gear.

Dual Threshold Trigger Modes:

Flexible Configuration and Redundancy Schemes:

TMR (Triple Modular Redundancy) Support: For applications requiring极高安全等级 (extremely high safety levels), the system can use two Keyphasor modules working in parallel to provide primary and backup Keyphasor signals, enhancing system reliability.

Paired Configuration: By pairing two modules in adjacent half-height slots, the system's Keyphasor channel capacity can be expanded, enabling more complex multi-axis monitoring.

Isolated I/O Module Option: Provides dedicated isolated I/O modules that offer electrical isolation when Keyphasor signals need to be paralleled to multiple devices (e.g., control systems), preventing ground loop interference and inter-system conflicts. Although designed for magnetic pickups, these modules can also be used with proximity probes if an external power supply is provided.

Multiple Output Interfaces: Provides buffered Keyphasor signal outputs via both front panel coaxial connectors and rear Eurostyle connectors, facilitating connection to external diagnostic equipment (e.g., spectrum analyzers).

Comprehensive Status Monitoring and Diagnostics: The front panel is equipped with an OK LED (module fault indication) and a TX/RX LED (communication status with the Rack Interface Module), enabling quick diagnosis of module health.

Enhanced Features: Supports generating single-event signals from multi-event signals, field-upgradable firmware, and asset management data reporting, enhancing system intelligence and maintainability.

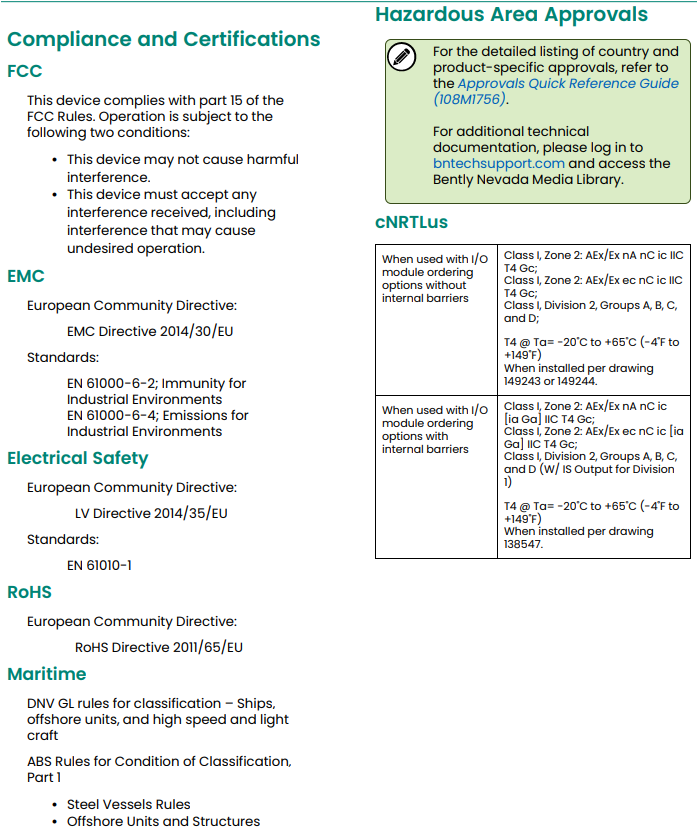

Global Certifications and Applicability: The module and its I/O options have passed multiple international explosion-proof certifications such as cNRTLus, ATEX, and IECEx, as well as safety and maritime certifications like CE, DNV GL, and ABS, meeting installation requirements for various harsh environments worldwide.

Working Principle & Technical Details

The working principle of the 3500/25 module is an intricate process from "analog signal acquisition" to "digital pulse generation."

Signal Acquisition and Input:

The module receives raw analog signals from Keyphasor sensors via the rear I/O module:

For Proximity Probes: The input signal range is +0.8 V to -21.0 V (non-isolated I/O). The module provides -24 Vac excitation power to the probe.

For Magnetic Pickups: Generate AC voltage signals, with a minimum input impedance of 21.8 kΩ.

The module's internal protection circuitry clamps out-of-range input signals to protect internal components.

Signal Conditioning and Digitization:

When the signal voltage exceeds (or falls below, depending on polarity) the set threshold, the comparator state flips.

The Hysteresis function is crucial here. It sets the voltage difference between trigger and reset, effectively preventing repeated comparator flipping caused by signal jitter or noise, ensuring only one clean, clear pulse is generated per Keyphasor mark.

The input analog signal is first amplified and shaped by the conditioning circuit.

The signal then enters the comparator stage, where it is compared with the user-set Threshold.

The output of the comparator is converted into a digital square wave pulse, which is the final Keyphasor signal.

Logic Processing and Output:

The generated digital Keyphasor signal is sent to the module's logic processing unit.

This signal is broadcast via the backplane bus to all monitor modules within the 3500 rack. Vibration monitors use this rising edge to lock the phase of the vibration waveform and calculate 1X amplitude, etc.

Simultaneously, the signal is also sent to the buffered output amplifiers at the front and rear (output impedance ≤ 504 Ω) for use by external devices.

Special Considerations for Isolated I/O:

Isolated I/O modules use isolation components like transformers or optocouplers to completely electrically isolate the input Keyphasor signal from the internal circuitry of the 3500 system.

This isolation sacrifices a small amount of response time and introduces phase error. As shown in Figure 1, the phase error varies with machine speed (typically more noticeable at lower speeds). Therefore, while it can be used for phase measurement, its primary design purpose is accurate speed measurement. For applications requiring extremely high phase accuracy, non-isolated I/O modules should be prioritized.

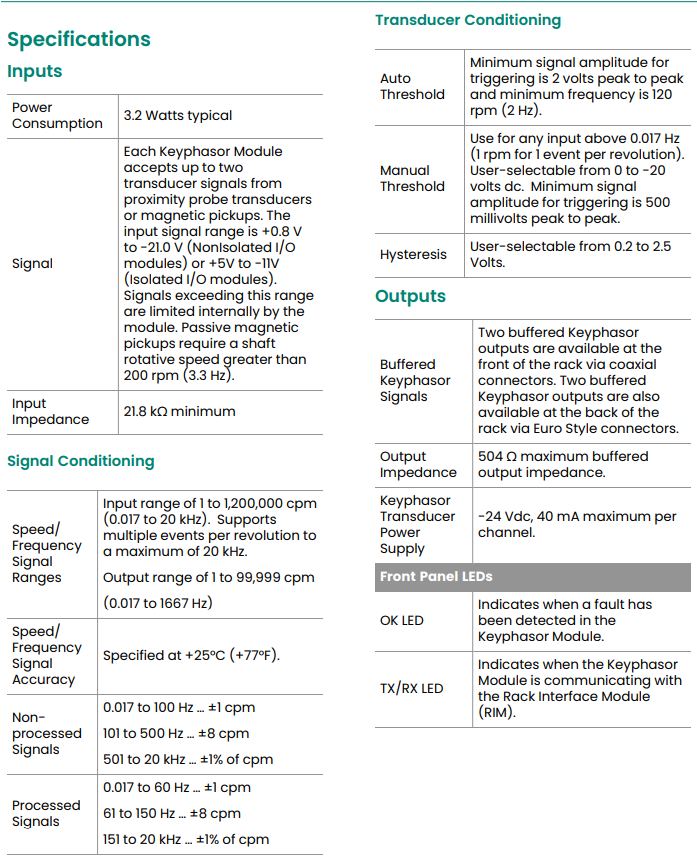

Specifications

| Item |

Specification Description |

| Number of Channels |

2 independent channels (per module) |

| Input Signal Type |

Eddy Current Proximity Probe or Magnetic Pickup (MPU) |

| Input Signal Range |

Non-Isolated I/O: +0.8 V to -21.0 V; Isolated I/O: +5V to -11V |

| Input Impedance |

≥ 21.8 kΩ |

| Minimum Speed (MPU) |

> 200 RPM (3.3 Hz) |

| Frequency Range |

Input: 0.017 Hz to 20 kHz (1 to 1,200,000 CPM) |

| Speed Accuracy |

±1 CPM (0.017-100 Hz) to ±1% (501 Hz-20 kHz) |

| Trigger Threshold |

Auto Mode: Min 2 V p-p; Manual Mode: User adjustable (0 to -20 Vdc), Min 500 mV p-p |

| Hysteresis Range |

User adjustable, 0.2 to 2.5 V |

| Output Signal |

Buffered Keyphasor Digital Pulse (TTL compatible) |

| Output Impedance |

≤ 504 Ω |

| Transducer Power Supply |

-24 Vac / channel, max 40 mA |

| Power Consumption |

3.2 Watts (typical) |

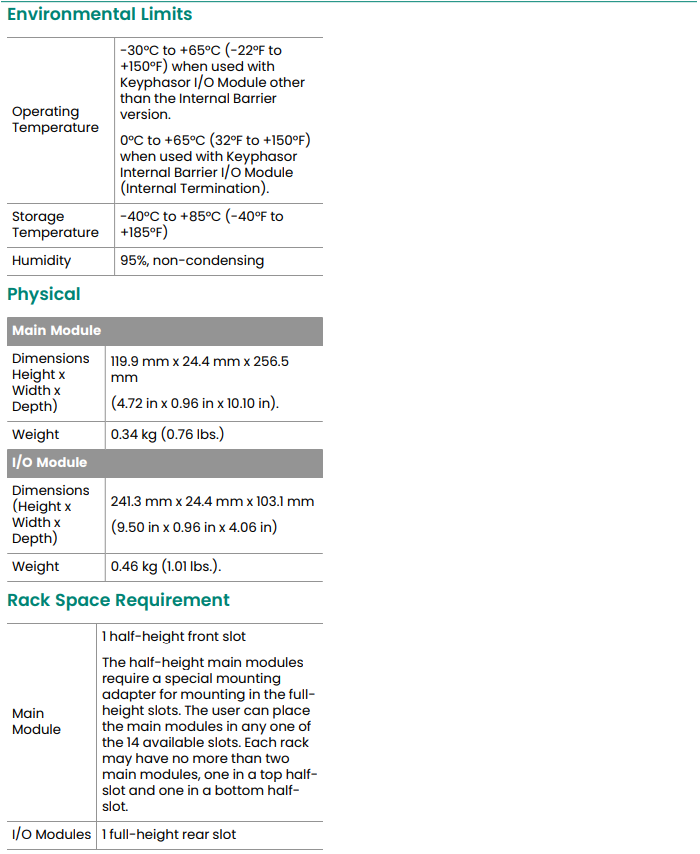

| Operating Temperature |

Standard I/O: -30°C to +65°C; Internal Barrier I/O: 0°C to +65°C |

| Module Dimensions (HxWxD) |

Main Module: 119.9 mm x 24.4 mm x 256.5 mm (Half-Height) |

| Rack Space |

1 half-height front slot (Main Module) + 1 full-height rear slot (I/O Module) |

| Explosion-Proof Certification |

cNRTLus (CL I, Div 2), ATEX/IECEx (II 3G Ex nA nC ic IIC T4 Gc) |

Application Scenarios

The 3500/25 Enhanced Keyphasor Module is an ideal choice for the following scenarios:

Large Critical Rotating Machinery: Provides reliable Keyphasor reference for steam turbines, gas turbines, compressors, water pumps, fans, etc., used for monitoring vibration phase, differential expansion, eccentricity, speed, etc. It is an essential tool for performing dynamic balancing and analyzing fault characteristics.

Multi-Shaft Trains: By using multiple modules or paired configurations, provides independent Keyphasor measurements for multiple shafts in complex units like parallel shaft or tandem compressors.

Gearbox Monitoring: Utilizes its multi-event processing capability to generate a synthetic once-per-turn signal from multiple gear teeth for precise analysis of gear mesh frequency and its sidebands.

Systems Requiring Signal Isolation: When Keyphasor sensors need to be connected simultaneously to the 3500 system and other control systems like DCS/PLC, using isolated I/O modules prevents mutual interference between systems and ensures signal integrity.

Safety-Critical Applications: In TMR (Triple Modular Redundancy) configurations, provides redundant Keyphasor signal sources for Safety Instrumented Systems (SIS), ensuring the absolute reliability of critical functions like overspeed protection.

Low-Speed Equipment Monitoring: The manual threshold mode enables effective capture of Keyphasor signals from low-speed equipment (minimum可达 1 RPM - can reach 1 RPM).

Offshore Platforms and Ship Power Systems: Provides stable performance in vibration-intensive and environmentally harsh maritime applications thanks to its rugged design and maritime certifications.