The TWW 103 M1 is a high-performance, single-channel vibration and position measurement transmitter from VM product line. Designed for condition monitoring and protection of rotating machinery in industrial environments, its core function is the non-contact measurement of the relative position (displacement) of a target. It is typically used in conjunction with a WW 018 eddy current proximity sensor (probe) to form a complete displacement measurement system, offering a static measuring range of up to 10 mm.

Renowned for its high precision, reliability, and robust design, the TWW 103 M1 is suited for harsh industrial environments and even hazardous areas (potentially explosive atmospheres). Its core output is a 4 to 20 mA current loop signal, which can be directly connected to control systems (e.g., PLC, DCS) or monitoring systems for machine protection and/or condition monitoring. The transmitter is available in standard versions and Ex versions certified for use in hazardous areas, meeting the safety requirements of different application scenarios.

The device features an aluminum alloy housing with a high protection rating of IP66, ensuring stable operation under demanding conditions. Its built-in self-diagnostics continuously monitor system status and provide clear fault indication via LEDs and the output signal, making it an ideal choice for safeguarding critical equipment such as turbines, compressors, pumps, and fans.

Working Principle

The operation of the TWW 103 M1 transmitter is based on the eddy current effect, the physical foundation of non-contact displacement measurement. The complete measurement system consists of a WW 018 eddy current proximity sensor (probe) and the TWW 103 M1 transmitter.

1. Eddy Current Effect and Signal Generation:

The head of the WW 018 sensor contains a coil. When high-frequency current from the transmitter passes through this coil, it generates a high-frequency electromagnetic field. If this sensor is aimed at a conductive metal target (e.g., a shaft surface), this electromagnetic field induces eddy currents on the target's surface. These eddy currents, in turn, generate a new magnetic field opposing the original one, resisting changes in the initial field, which consequently alters the impedance of the sensor coil. The magnitude of this impedance change is directly related to the distance between the probe tip and the target surface: the closer the distance, the stronger the effect and the greater the impedance change; the farther the distance, the weaker the effect and the smaller the impedance change.

2. Signal Conditioning and Processing:

The transmitter's primary role is to detect and process this impedance change caused by distance variation. Its internal circuitry performs these key steps:

Signal Demodulation: Receives the raw RF signal from the sensor and demodulates it into a DC voltage signal that is a function of the distance.

Linearization: The relationship between distance and the voltage signal generated by the eddy current effect is not perfectly linear. The transmitter's internal linearization circuitry compensates for this, ensuring the final output has a highly linear relationship with the actual distance.

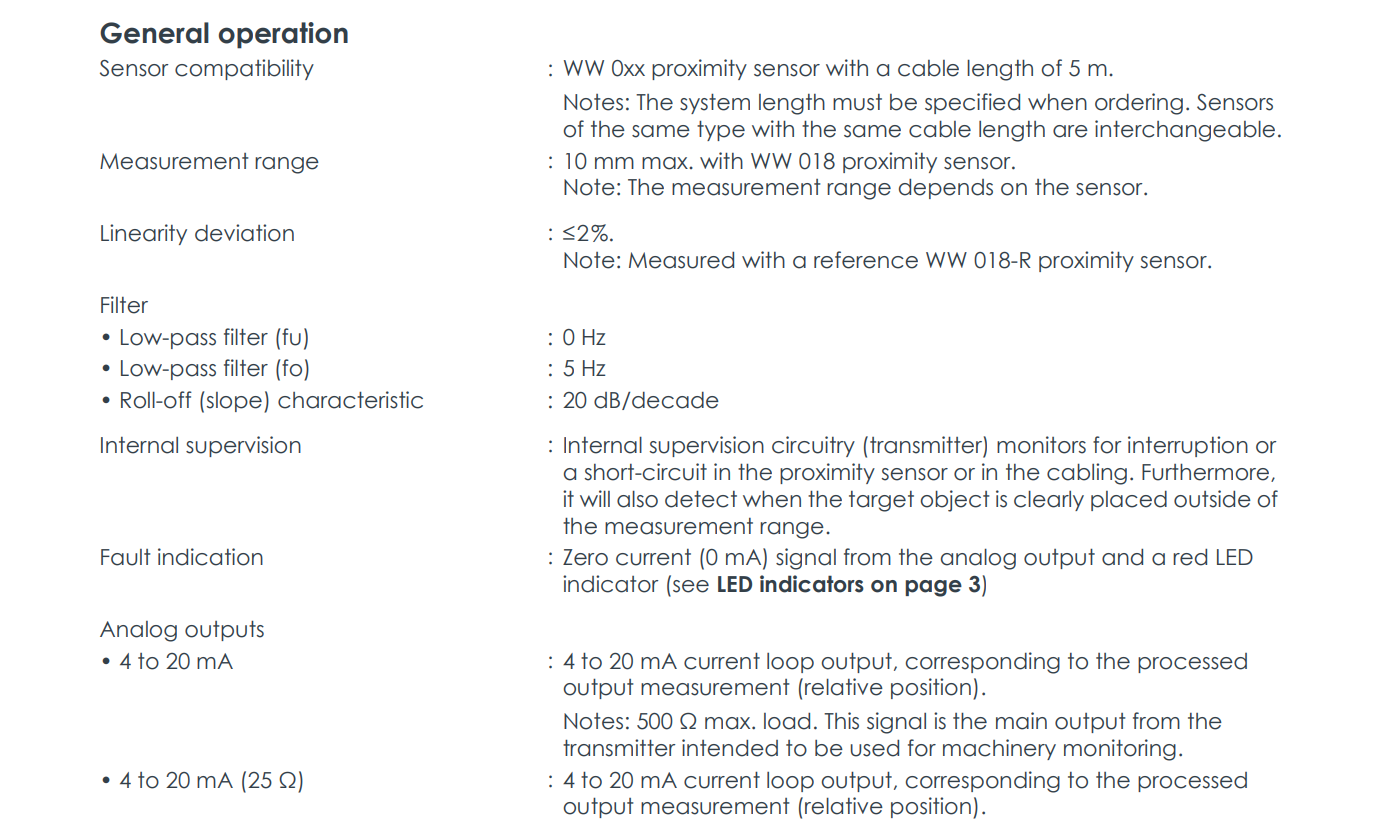

Filtering: The transmitter incorporates a low-pass filter with a cut-off frequency (fo) of 5 Hz and a roll-off of 20 dB/decade. This filter is designed to preserve the DC or very low-frequency signals reflecting slow changes in shaft position while effectively suppressing high-frequency vibration noise and other electrical interference, ensuring a stable, clean output signal that accurately reflects the static position of the shaft.

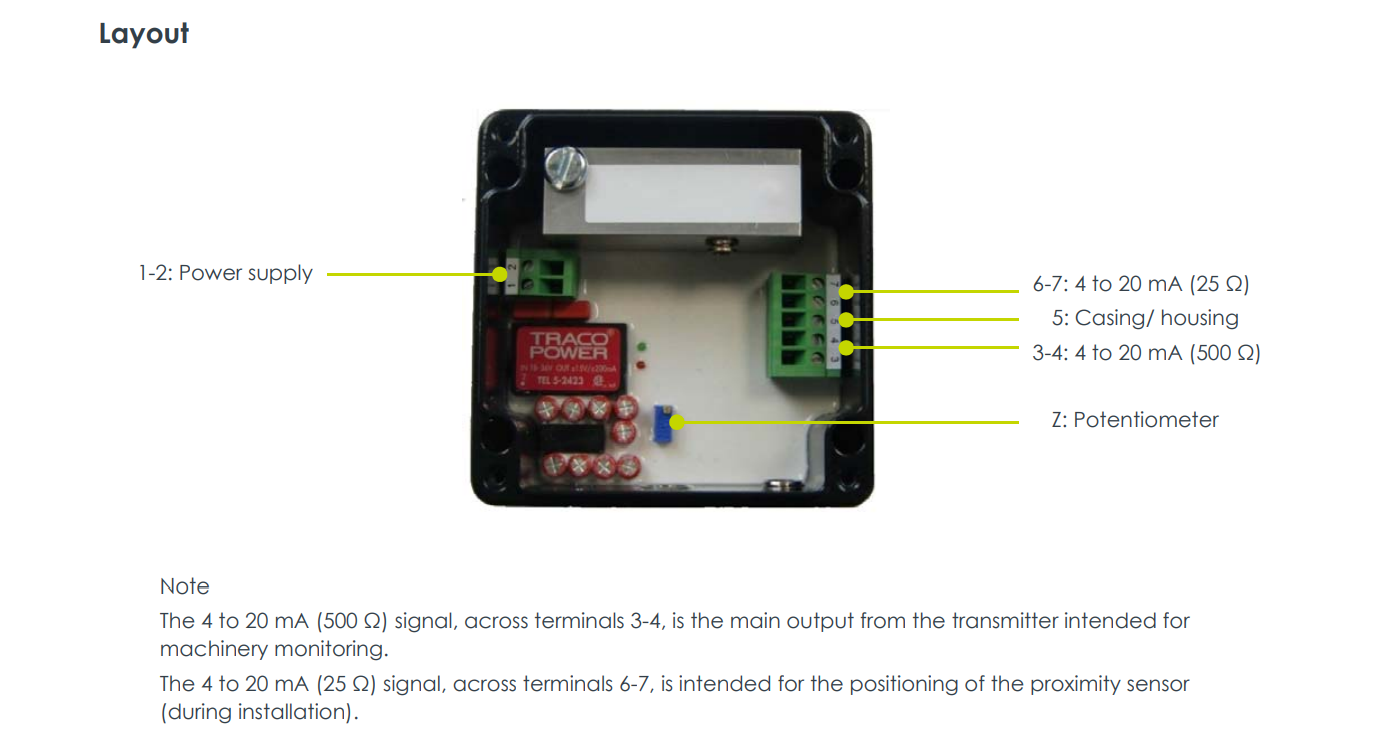

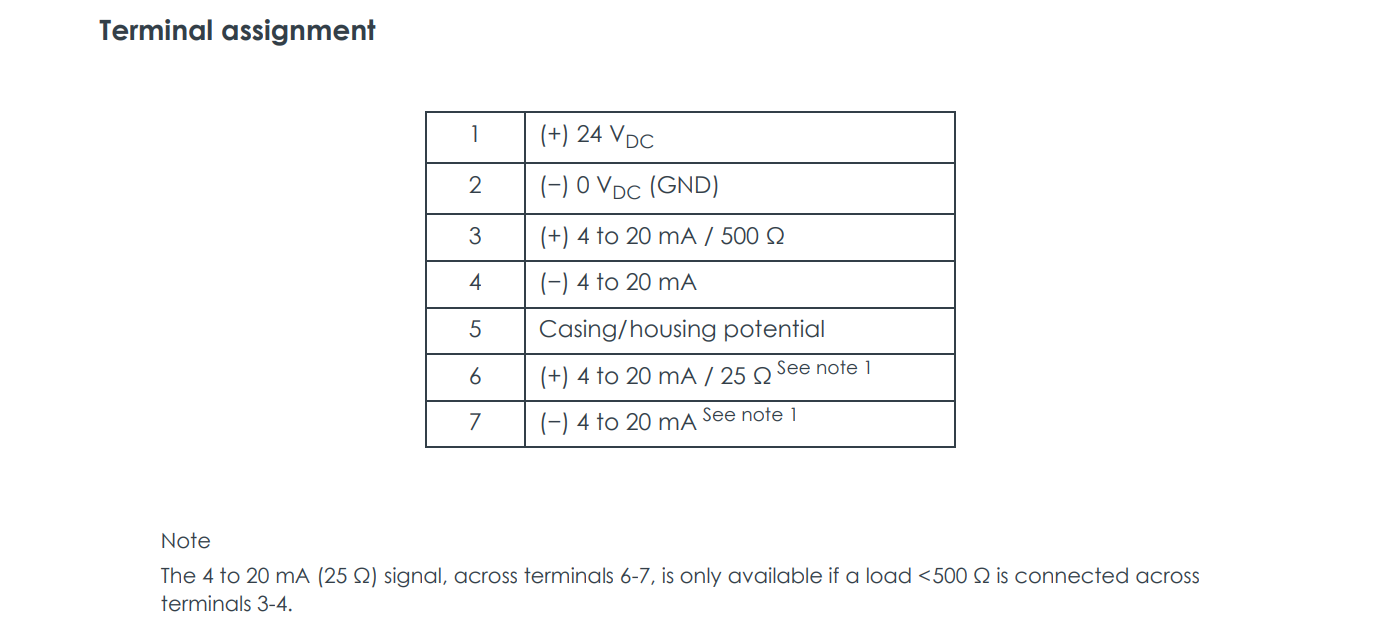

Signal Conversion & Output: The processed, linearized voltage signal is converted into a standard 4-20 mA analog current signal. A unique feature of the TWW 103 M1 is its provision of two independent, galvanically isolated 4-20 mA outputs:

Main Output (500 Ω load): Across terminals 3-4. This signal is dedicated to machinery monitoring, transmitted to the control room or monitoring system.

Auxiliary Output (25 Ω load): Across terminals 6-7. This signal is specifically intended for assisting sensor positioning during installation and commissioning. Technicians can connect a portable ammeter (load <25Ω) to this output on-site to read the position value in real-time, allowing precise adjustment of the sensor to a preset working gap (typically corresponding to a specific output voltage or current value) without relying on the main monitoring system in the control room.

3. Output Characteristic:

It is important to note that the transmitter's output characteristic is inverse: the output current decreases as the distance decreases (gap closes) and increases as the distance increases (gap opens). The specific correspondence is: 0 mm gap corresponds to 20 mA, 10 mm gap corresponds to 4 mA.

4. Self-Monitoring & Fault Diagnostics:

The transmitter incorporates internal monitoring circuitry that continuously checks for:

Open circuit or short circuit in the sensor or its cable.

The target being significantly outside the sensor's effective measuring range.

Upon detecting any fault, the transmitter immediately drives the analog output current to 0 mA and illuminates the red Fault LED on the front panel, providing both local and remote alarm indication, significantly enhancing system reliability.

Key Features & Functions

1. High-Precision Displacement Measurement

Measuring Range: Provides a maximum static displacement range of 10 mm when used with the WW 018 sensor.

Linearity: Linearity deviation ≤ 2% (measured using reference sensor WW 018-R), ensuring accurate and reliable measurements.

2. Dual Isolated Analog Outputs

Main Monitoring Output (500 Ω): 4-20 mA signal for machine protection and condition monitoring, supports long-distance transmission.

Installation Aid Output (25 Ω): 4-20 mA signal dedicated to sensor installation and commissioning, convenient for on-site reading.

Galvanic Isolation: The two outputs are isolated from each other and from the power supply, providing strong noise immunity and system safety.

Inverse Output Characteristic: 0 mm → 20 mA, 10 mm → 4 mA.

3. Comprehensive Internal Self-Diagnostics & Fault Indication

Real-time monitoring for sensor open circuit, short circuit, and target out-of-range faults.

Dual Fault Indication:

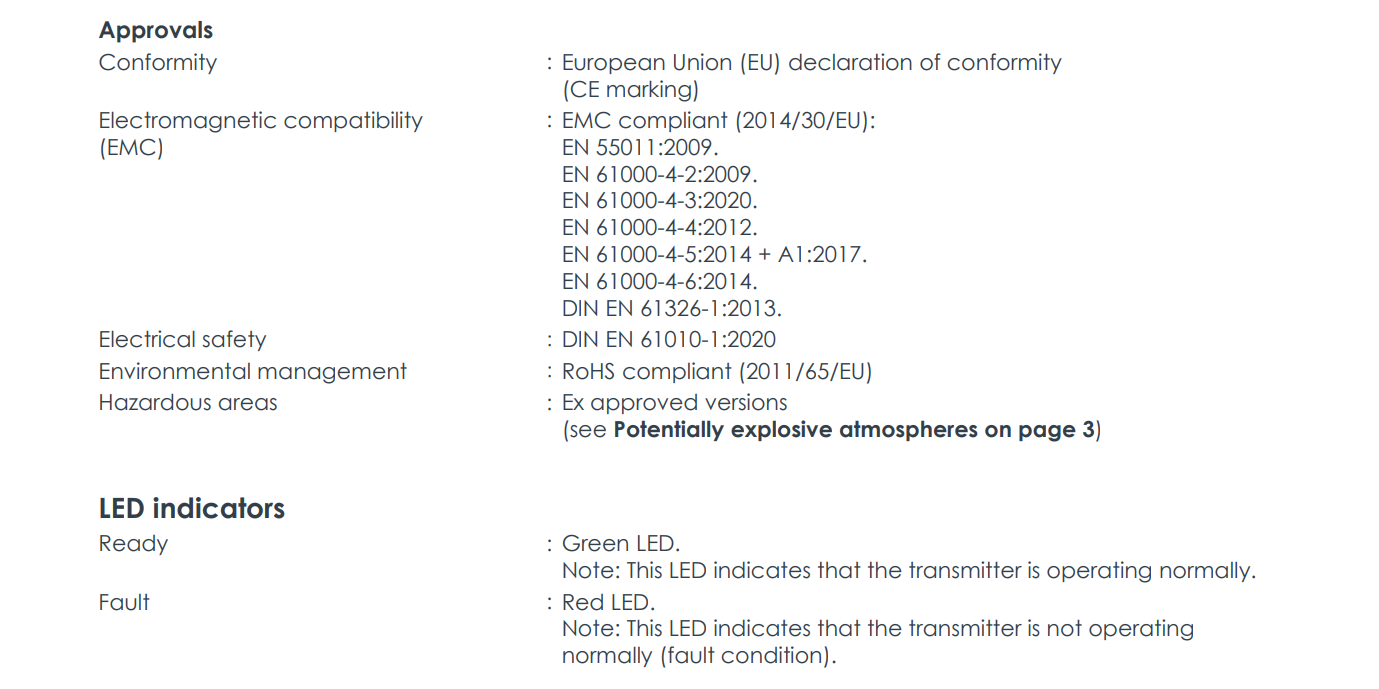

Green LED indicates normal device operation.

4. Flexible Installation & Commissioning Support

5. Suitability for Harsh & Hazardous Environments

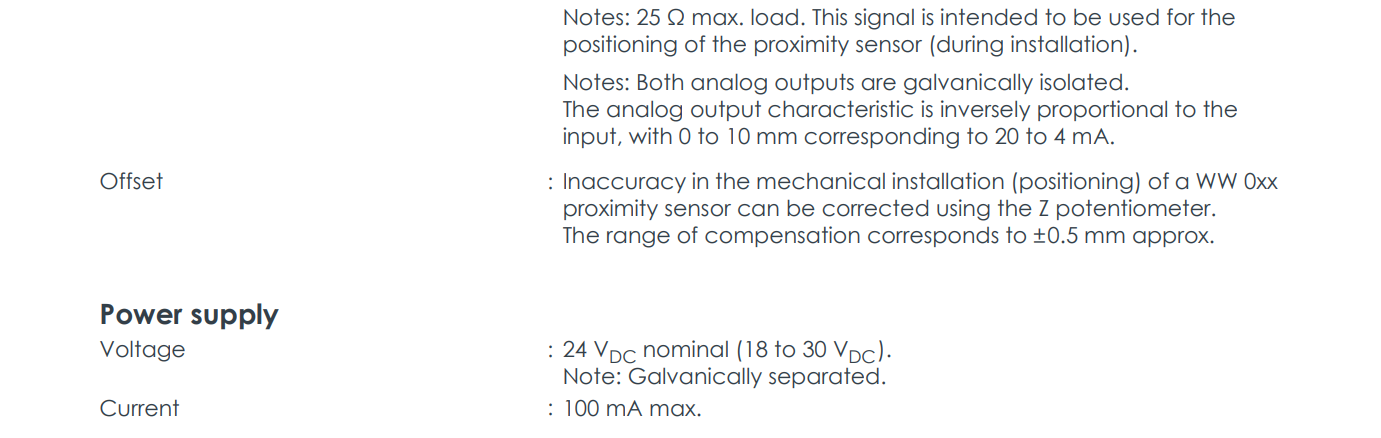

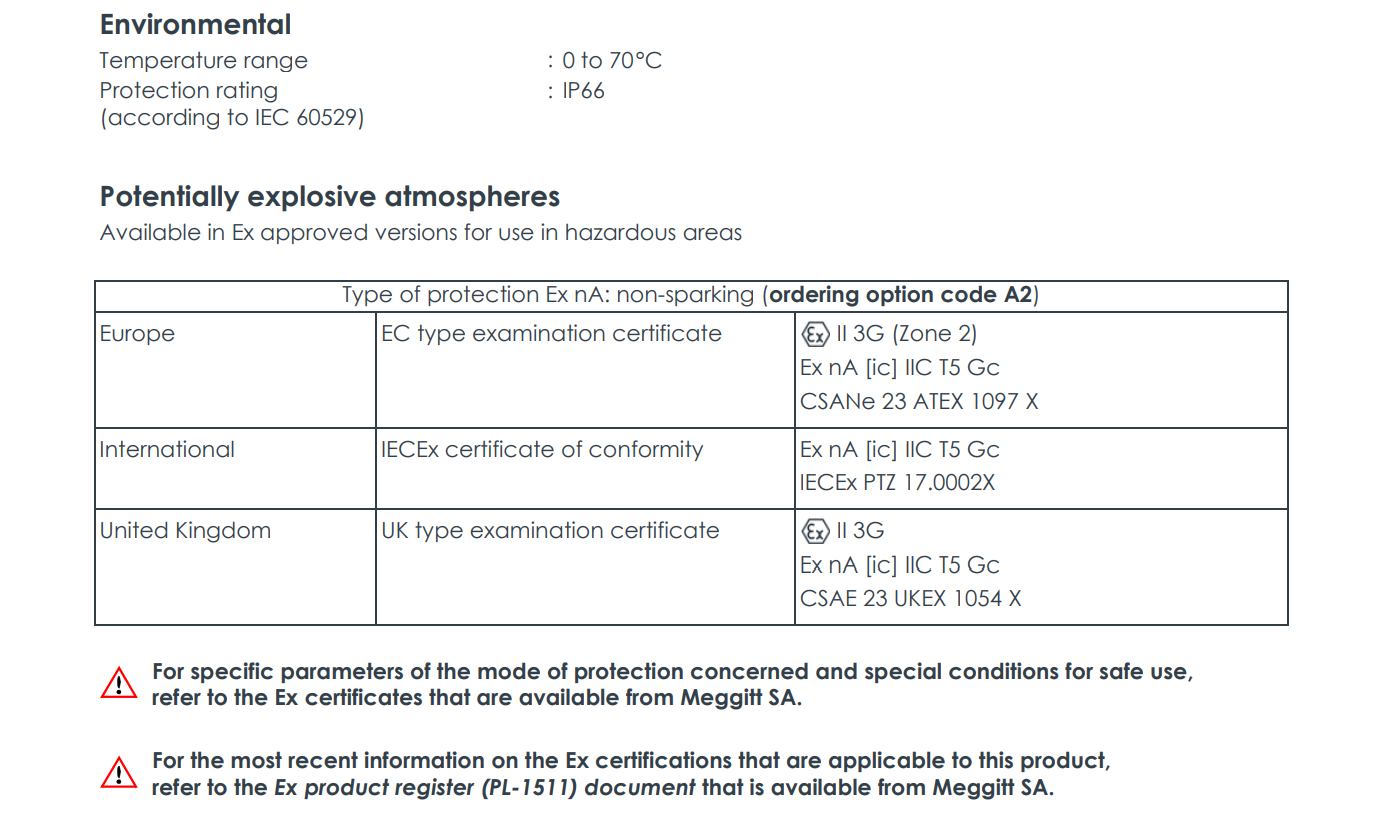

Wide Temperature Range: Operating ambient temperature 0 to +70°C.

High Protection Rating: IP66, dust-tight and protected against powerful water jets, suitable for dusty and wet environments.

Explosion-Proof Certification (Optional): Available in Ex nA certified versions for use in Zone 2 hazardous areas (potentially explosive atmospheres), certified according to ATEX, IECEx, and UKEX standards.

6. Strong Noise Immunity

Built-in Low-Pass Filter: 5 Hz cut-off frequency effectively suppresses high-frequency interference.

Galvanically Isolated Design: Isolation between power supply, inputs, and outputs prevents ground loops and signal crosstalk, ensuring signal integrity.

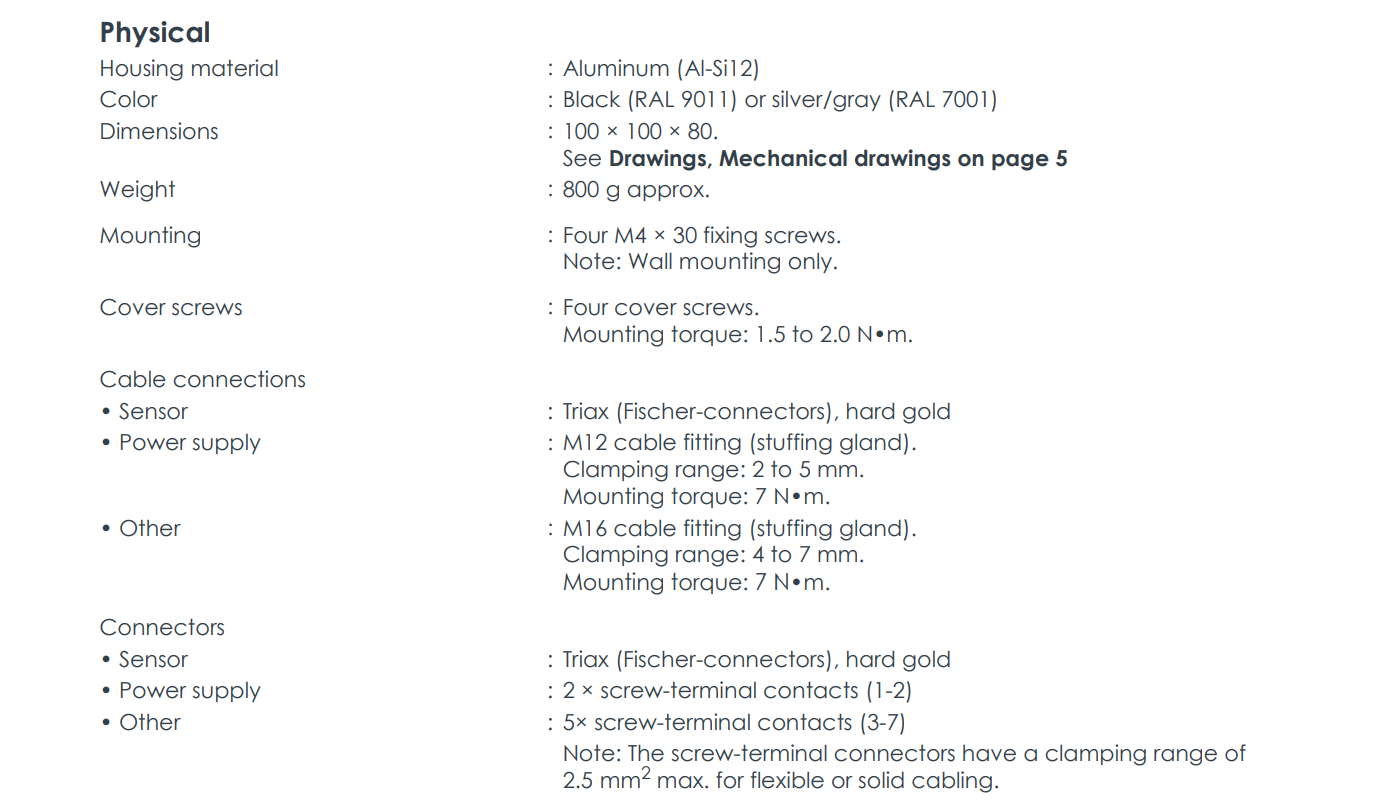

7. Robust Mechanical Design

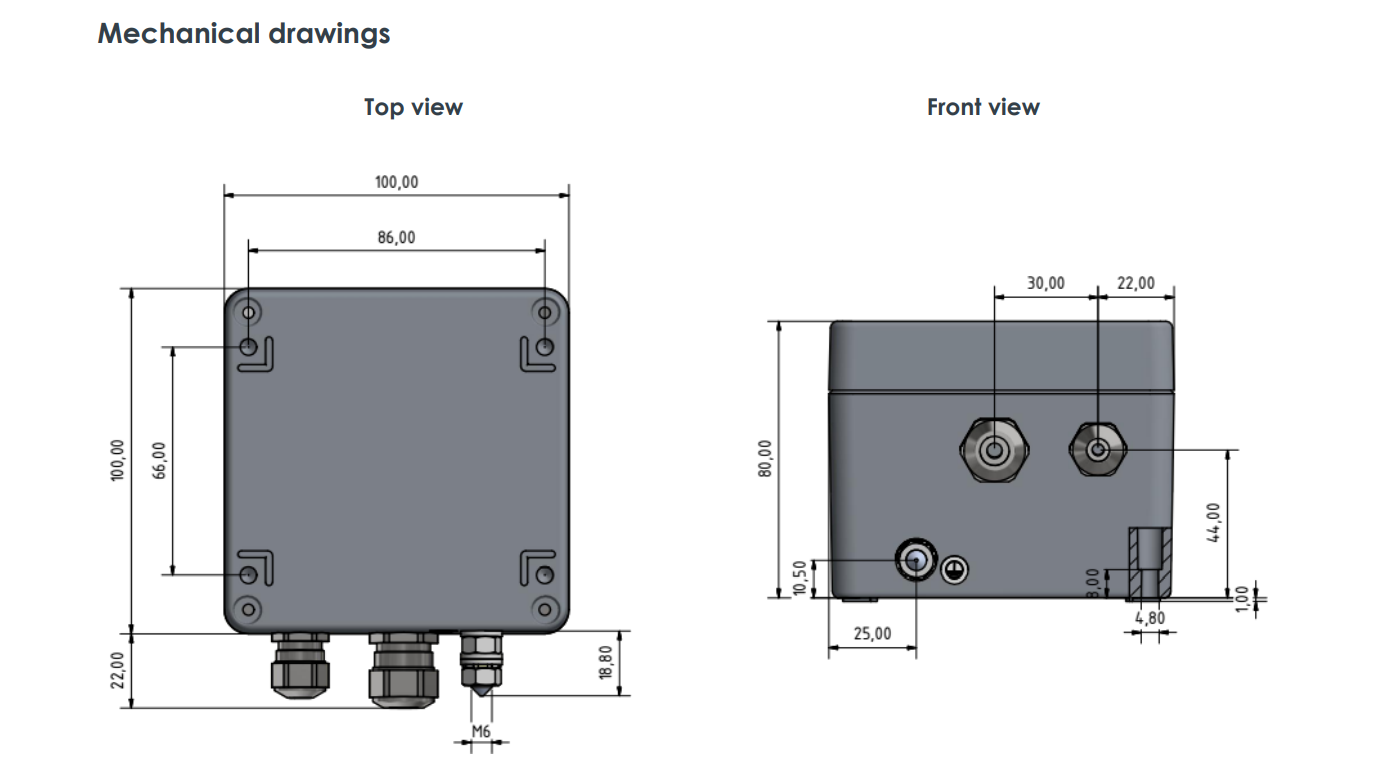

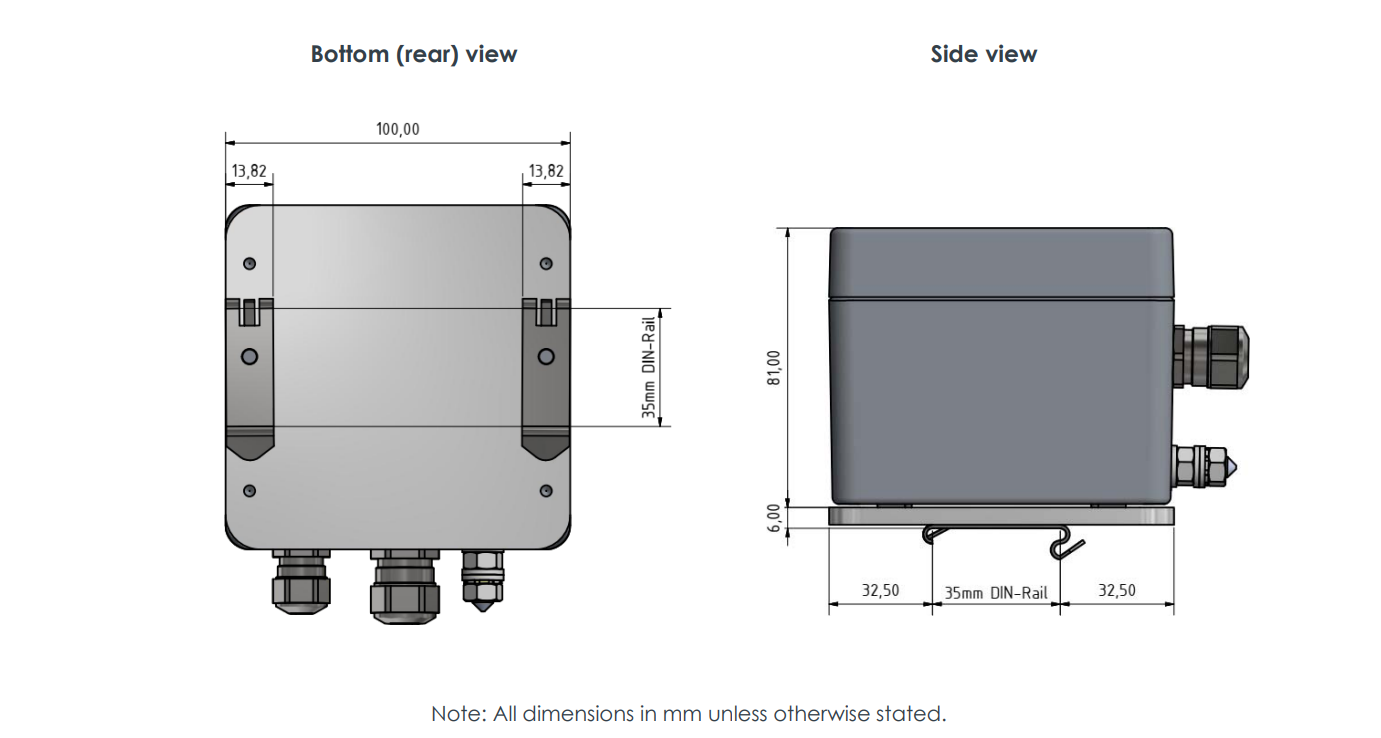

Housing Material: Aluminum alloy (Al-Si12), lightweight (approx. 800g), robust construction, good heat dissipation.

Mounting: Wall-mounted via 4 x M4 x 30 mm screws, secure and reliable.

Cable Entries:

Sensor Connection: Triax (Fischer) hard gold connector, reliable connection, excellent signal transmission performance.

Power Supply: M12 cable gland (clamping range 2-5 mm).

Other Connections: M16 cable gland (clamping range 4-7 mm).

Terminals: Screw terminals (power: 2; signals: 5), max. clamping range 2.5 mm², suitable for solid or flexible wiring.

8. Extensive Compliance & Certifications

EU Declaration of Conformity (CE Marking): Complies with relevant directives.

Electromagnetic Compatibility (EMC): Complies with EN 55011, EN 61000-4-2/3/4/5/6, EN 61326-1, etc.

Electrical Safety: Complies with DIN EN 61010-1.

Environmental: RoHS compliant (2011/65/EU).

Explosion Protection: Optional Ex versions available, with ATEX, IECEx, and UKEx certificates.

9. System Compatibility & Interchangeability

Dedicated Matching Sensor: Used with the WW 018 type eddy current proximity sensor.

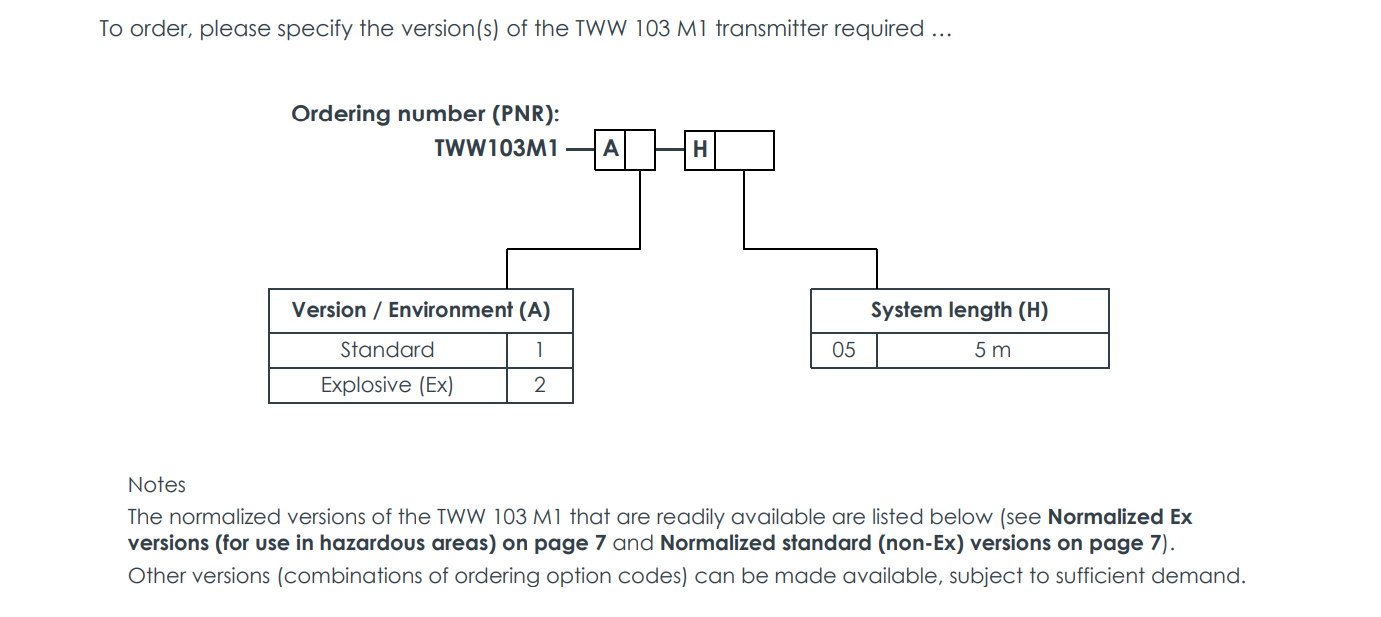

Cable Length: Standard system cable length is 5 meters (specified when ordering).

Interchangeability: Sensors of the same type and cable length are interchangeable, facilitating maintenance and replacement.

Technical Specifications Summary

| Item | Specification |

| Measurement Type | Relative Position (Displacement) |

| Compatible Sensor | WW 018 Proximity Sensor |

| Measuring Range | Max. 10 mm (static) |

| Linearity Deviation | ≤ 2% |

| Filter | Low-Pass, 5 Hz cut-off, 20 dB/decade |

| Analog Outputs | 2 isolated 4-20 mA (Main: 500Ω; Aux: 25Ω) |

| Output Characteristic | Inverse (0mm=20mA, 10mm=4mA) |

| Fault Indication | 0 mA output, Red LED |

| Power Supply | 18-30 VDC, nominal 24VDC, max. 100 mA, galvanically isolated |

| Operating Temperature | 0 to +70 °C |

| Protection Rating | IP66 (IEC 60529) |

| Housing Material | Aluminum alloy (Al-Si12) |

| Weight | approx. 800 g |

| Dimensions (WxHxD) | 100 x 100 x 80 mm |

| Ex Certification (Optional) | Ex nA, Suitable for Zone 2 (ATEX, IECEx, UKEX) |

Application Areas

The TWW 103 M1 is designed for the following applications:

Shaft Position Monitoring in Rotating Machinery: Measuring the static position of shafts relative to bearings (e.g., shaft eccentricity) and axial displacement in turbines, compressors, gas turbines, steam turbines, hydro turbines, pumps, fans, etc.

Machine Protection Systems: Continuously monitoring shaft position to prevent destructive rubbing collisions (e.g., blades vs. casing), triggering alarms or shutdown signals upon abnormal displacement.

Condition Monitoring & Predictive Maintenance: Assessing machine health and planning maintenance activities by trending changes in shaft position.

Harsh Industrial Environments: Suitable for general industrial settings with oil, moisture, dust, and vibration.

Hazardous Areas: Ex-certified versions can be used in potentially explosive gas atmospheres classified as Zone 2 in industries such as oil, gas, and chemicals.