The IS220PRTDH1A is a member of the distributed I/O module family used in the Mark VIe and Mark VIeS Control Systems, specifically designed for the acquisition and processing of Resistance Temperature Detector (RTD) signals. It is an integrated I/O component that serves as a critical interface between RTD sensors and the upper-level control system, responsible for converting RTD resistance changes into high-precision digital temperature values and transmitting them to the Mark VIe controller via industrial Ethernet.

The core function of this module is to provide a stable, accurate, and diagnostically capable temperature input solution for industrial process control, especially for applications requiring high-reliability temperature monitoring such as gas turbines. The IS220PRTDH1A is designed to be used in conjunction with specific RTD input terminal boards (e.g., TRTDH1D, TRTDH2D, SRTD) to form a complete RTD signal acquisition subsystem.

2. Detailed Functional Description

Signal Acquisition Capability

100 Ohm Platinum (PT100, various standards: SAMA, DIN, PURE, USIND)

200 Ohm Platinum (PT200)

120 Ohm Nickel (N120)

10 Ohm Copper (CU10)

Users can select the corresponding RTD type for each channel via configuration software (ToolboxST), and the module automatically performs linearization and temperature calculation.

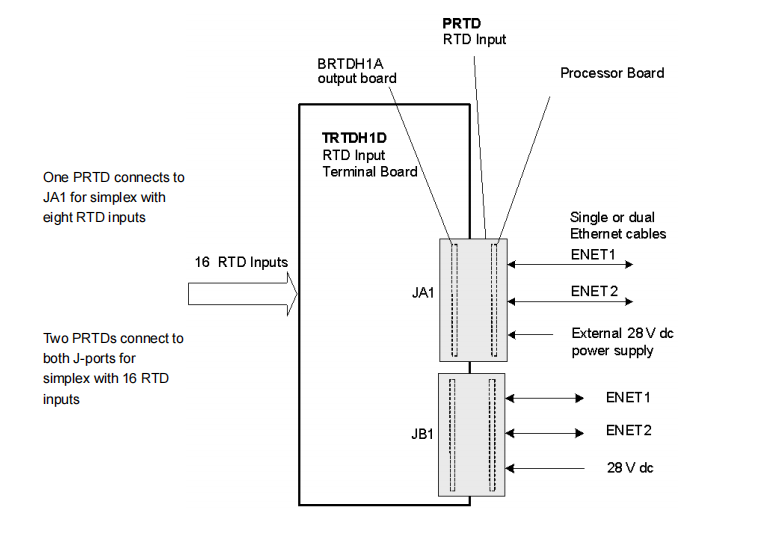

Channel Count: Each IS220PRTDH1A module can handle 8 independent RTD input channels. By installing two PRTD modules on a single TRTD terminal board, the system can be expanded to handle 16 RTD inputs.

Supported RTD Types: The module firmware supports multiple common RTD types, including:

3-Wire Connection: Supports 3-wire RTD connection, which helps compensate for measurement errors caused by lead resistance.

Electrical Interface and Communication

Terminal Board Interface: The module provides a DC-37 pin connector on its underside for direct plug-in connection to the corresponding RTD terminal board. This interface transmits the 8 RTD signals, module ID identification signal, and power.

Network Communication: The module provides dual RJ-45 Ethernet ports (ENET1 and ENET2) on its side, supporting redundant network connections. This is the primary channel for data exchange between the module and the Mark VIe controller. Standard practice is to connect ENET1 to the network associated with the R controller.

Power Input: A 3-pin power connector on the side of the module is used for connecting a 28V DC power supply, which powers both the I/O module itself and its connected terminal board. The module features soft-start capability to control inrush current during power-up.

Diagnostics and Status Indication

Hardware Limits: Checks are based on preset (non-configurable) high and low levels set near the ends of the operating range for each RTD type. If a limit is exceeded, a logic signal is set, and scanning of that input is stopped to prevent affecting other channels. Any single input exceeding its limit generates a composite diagnostic alarm L3DIAG_PRTD referring to the entire board.

System Limits: Checks are based on configurable high and low temperature limits. These can be used in application code to generate process alarms and can be configured for enable/disable and latching/non-latching.

Power-up Self-test: Checks RAM, Flash memory, Ethernet ports, and most processor hardware.

Continuous monitoring of internal power supplies.

Verifies the electronic ID information from the terminal board, acquisition board, and processor board to ensure hardware set matching, and checks that the loaded application code is correct for the hardware set.

LED Indicators: The module front panel provides a set of LED indicators for visual diagnostics, including processor status, network link status, power status, and fault indication.

Comprehensive Self-Diagnostics: The module performs a series of self-test functions:

Hardware and System Limit Checking:

Automatic Recovery: Features an AutoReset function to automatically restore RTD channels removed from scanning due to faults (not hardware damage), with a recovery time of approximately 20 seconds, or they can be restored manually.

3. In-Depth Working Principle Analysis

The operating principle of the IS220PRTDH1A module involves multiple stages: analog signal acquisition, digital conversion, data processing, and network communication.

Signal Excitation and Acquisition

In 4 Hz Normal Scan Mode (for 50/60 Hz line frequency rejection), a 22-millisecond long pulse is generated every 250 milliseconds (4 times per second).

In 25 Hz Fast Scan Mode (for special airflow measurements), a 4-millisecond long pulse is generated every 40 milliseconds (25 times per second).

Excitation Current: The module supplies a 10 mA DC, multiplexed (non-continuous) excitation current to each RTD sensor. This current is pulsed, with its duration and periodicity varying based on the module's scan mode settings.

Electrical Isolation and Protection: The PRTDH1A provides galvanic isolation for the RTD input circuit. The excitation circuitry operates on ±15V isolated DC supplies. Each RTD terminal is equipped with bipolar 15V clamp diodes and 0.001 uF filter capacitors for transient protection. The current and voltage levels comply with IEC60079-11 guidelines for Class IIC gases.

Voltage Measurement: The module measures the voltage drop across the RTD resulting from the excitation current. The supported input voltage range is approximately 0.069V to 4.054V, corresponding to an RTD resistance range of approximately 7 to 405 Ohms.

Signal Conversion and Processing

Normal Mode: 4 times per second (250 ms interval), sampling each RTD for 22 ms per cycle. This mode effectively rejects 50 Hz and 60 Hz line frequency interference.

Fast Mode: 25 times per second (40 ms interval), sampling each RTD for 4 ms per cycle. This mode provides faster response but sacrifices line frequency rejection.

A/D Conversion: The acquired analog voltage signals are sampled by a 14-bit resolution A/D converter within the module.

Sampling Rate:

Linearization and Calculation: The raw counts from the A/D converter are processed by the processor within the module. Based on the RTDType parameter selected for each channel in ToolboxST, the processor executes the corresponding algorithm to linearize the resistance value into a temperature value (Celsius or Fahrenheit). This software-based linearization offers greater flexibility.

Data Processing and Communication

The processed temperature data, channel status, and diagnostic information are packaged.

Via the Board Product Pack (BPPB) processor and Ethernet controller, these data packets are sent over the ENET1 or ENET2 port to the designated industrial Ethernet network, ultimately reaching the Mark VIe controller.

The module also receives configuration commands and queries from the controller.

Terminal Board Collaboration

The IS220PRTDH1A must work in conjunction with a compatible terminal board (e.g., TRTDH1D):

TRTDH1D: Provides filtering compatible with the PRTD standard scan rate. It incorporates noise suppression circuitry to protect the module from surges and high-frequency noise. The terminal board's barrier-type terminal blocks facilitate field wiring and support the use of double-shielded cables. All shields must be terminated at the shield terminal strip on the terminal board side, not at the sensor end.

The terminal board also provides ID information to the PRTD module via the DC-37 pin connector for system validation.

4. Installation and Configuration

Mechanical Installation

The IS220PRTDH1A employs a direct plug-in mounting style. Its bottom DC-37 pin connector is directly aligned and plugged into the JA1 (or JA2) connector of a securely mounted terminal board (e.g., TRTDH1D).

Use the threaded inserts adjacent to the Ethernet ports and the terminal board-specific mounting bracket to mechanically secure the I/O module, ensuring no right-angle force is applied to the DC-37 pin connector.

Electrical Connections

Power: Connect the 28V DC power supply to the 3-pin power connector on the side of the module.

Network: Connect at least one Ethernet cable (and a second for redundancy, based on system requirements) to the ENET1 (and ENET2) ports.

RTD Sensors: The three leads (Signal, Excitation, Return) of the RTD sensors are connected to the corresponding barrier terminals according to the markings on the terminal board (e.g., the wiring diagram for TRTDH1D). Double-shielded cable must be used, with the shield grounded at the terminal board end.

Software Configuration

Use the GE ToolboxST software to configure the module. Key parameters include:

RTDType: Select the corresponding RTD sensor type or set to "Unused" for each channel.

GroupRate: Select the scan rate and line frequency filter (4 Hz/50Hz, 4 Hz/60Hz, 25 Hz).

RTDGain: Select the sensor gain, e.g., Gain_2_0 can be used for higher accuracy when ohms <190.

RTDUnit: Select the temperature unit (Celsius or Fahrenheit). Note: Changing this parameter affects the actual value sent to the controller; ensure consistency with application code and HMI settings. It is generally not advised to change this arbitrarily.

SysLimitEnable, SysLimitLatch, SysLimitType, SysLimit1/2: Configure system temperature limit alarms.

AutoReset: Enable or disable automatic recovery of RTD channels.

5. Diagnostics and Specific Alarms

The IS220PRTDH1A module reports specific diagnostic alarms to aid in rapid troubleshooting:

Alarms 32-39: RTD [ ] Voltage out of range - Raw Counts [ ]. Possible Cause: RTD wiring open circuit, high impedance, terminal board connection issue, RTD failure, or internal module hardware fault.

Alarms 64-71: RTD [ ] Current out of range - Raw Counts [ ]. Possible Cause: RTD wiring or sensor issues, terminal board connection problem, module excitation current source failure, or measurement device failure.

Alarms 96-103: RTD [ ] Resistance out of range ([ ] Ohms). Possible Cause: Incorrectly configured RTD type, or high resistance values created by high voltage and/or low current.

Alarm 128: Internal reference out of range - Voltage circuit. Indicates failure of internal module hardware checks, typically requiring module replacement.

Alarm 144: Internal reference out of range - Current circuit. Also indicates internal module hardware fault, requiring replacement.