The VM600 CPUR2 is a next-generation high-performance rack controller and communication interface card from VM product line, designed to be used with the matching IOCR2 input/output card. Specifically engineered for VM600 rack-based monitoring systems, this product builds upon the functionality of previous generations while significantly enhancing mathematical processing capabilities, communication protocol support, and system security. As the intelligent core of the entire monitoring system, the CPUR2 handles configuration management, data coordination, and advanced data processing for various monitoring cards within the rack. Through its advanced fieldbus interfaces, it enables efficient data exchange with third-party control systems (such as DCS and PLC). Its exceptional performance and reliability make it widely applicable in rotating machinery protection and condition monitoring systems across power generation, oil and gas, and other industries.

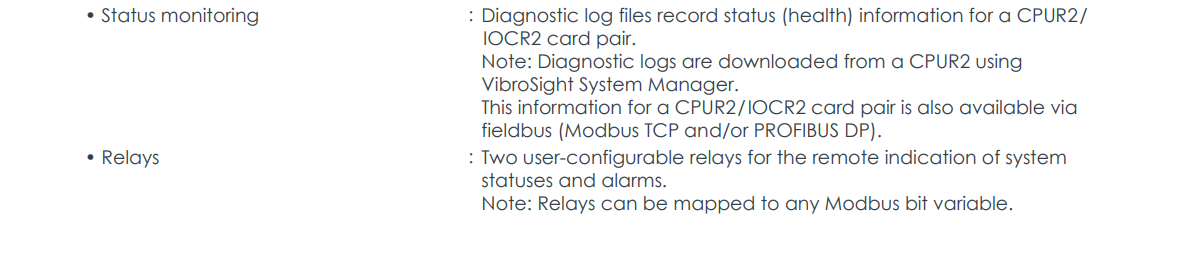

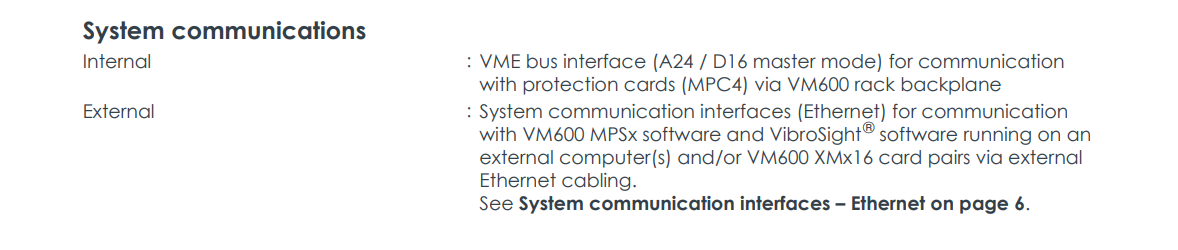

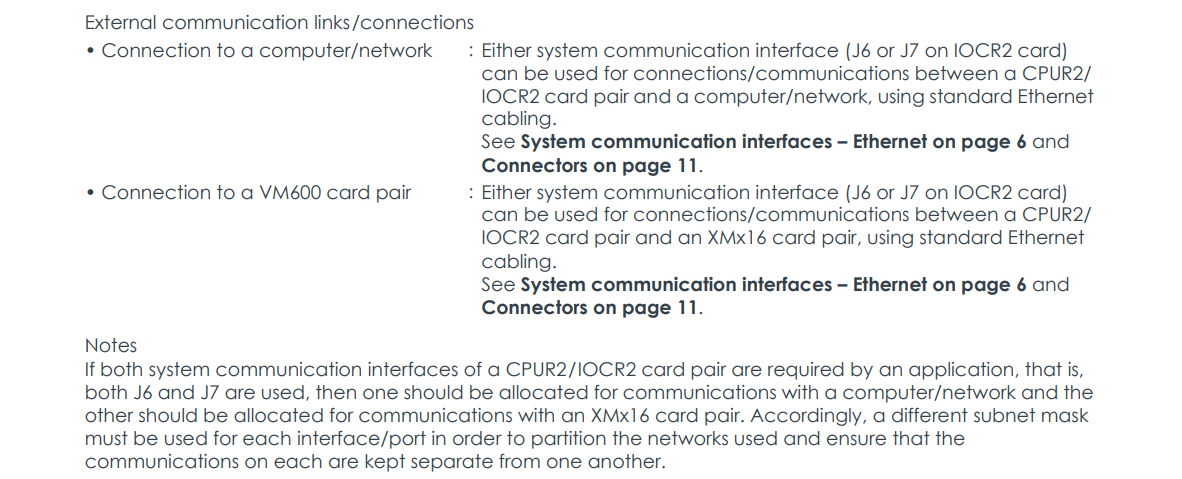

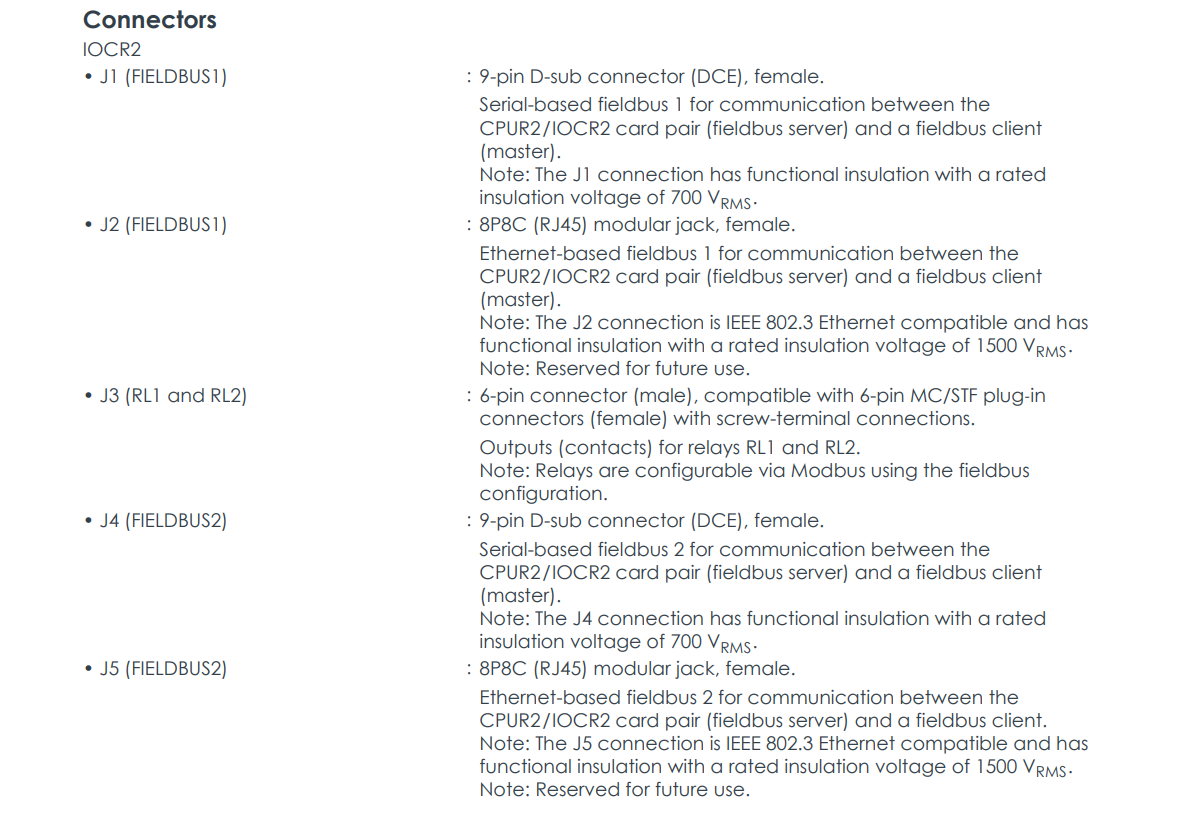

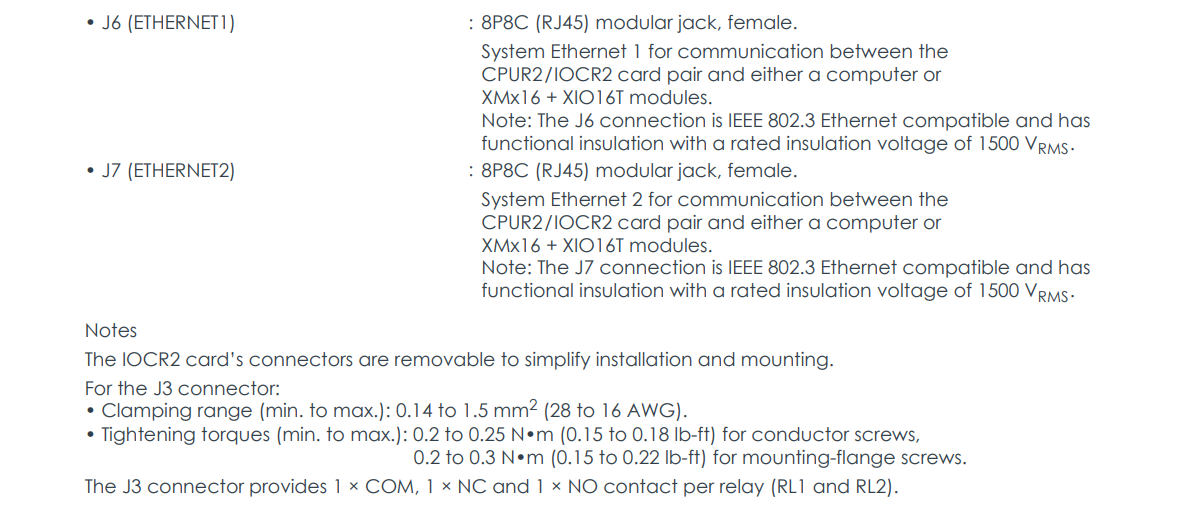

Within the VM600 system architecture, the CPUR2 card occupies a central position in the control layer, serving as the main processing unit responsible for all data processing, protocol conversion, and system management tasks. The card works in coordination with the rear-mounted IOCR2 card to form a complete communication and control unit. The CPUR2 establishes connections with various monitoring cards through the VM600 rack backplane, processing raw measurement data from protection cards like MPC4/IOC4T, while also acquiring condition monitoring data from XMx16/XIO16T monitoring cards via system Ethernet interfaces.

The CPUR2 plays multiple critical roles in the system: As a rack controller, it unifiedly manages the configuration of all monitoring cards, supporting hot-swapping and automatic identification functions; secondly, as an advanced data processing unit, it provides powerful mathematical operations capable of real-time processing and analysis of monitoring data; finally, as a communication coordination center, it enables efficient data exchange between the VM600 system and external control networks.

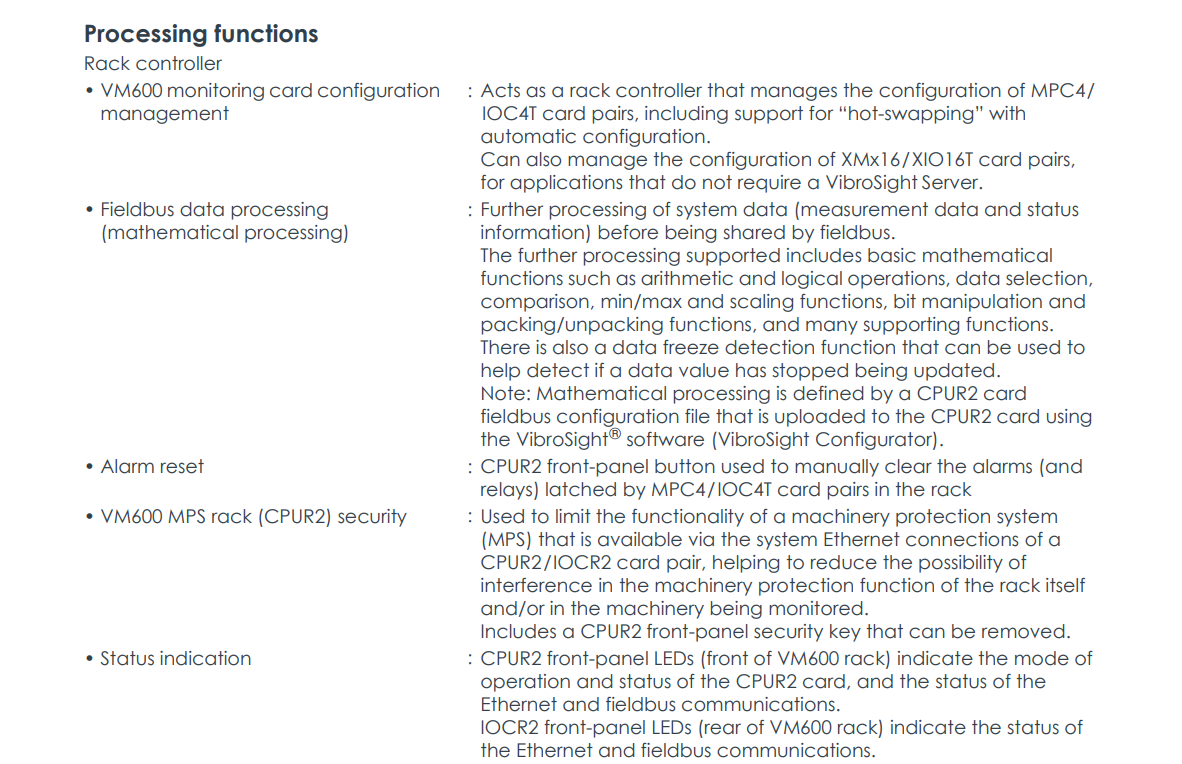

Key Features and Functions

1. Enhanced Mathematical Processing Engine

The core advantage of CPUR2 lies in its embedded advanced mathematical processing capabilities:

Supports complex arithmetic operations (addition, subtraction, multiplication, division) and logical operations (AND, OR, NOT)

Provides data selection, comparison, min/max extraction, and scaling functions

Includes advanced bit manipulation and data packing/unpacking functions

Features data freeze detection function to intelligently identify abnormal data update conditions

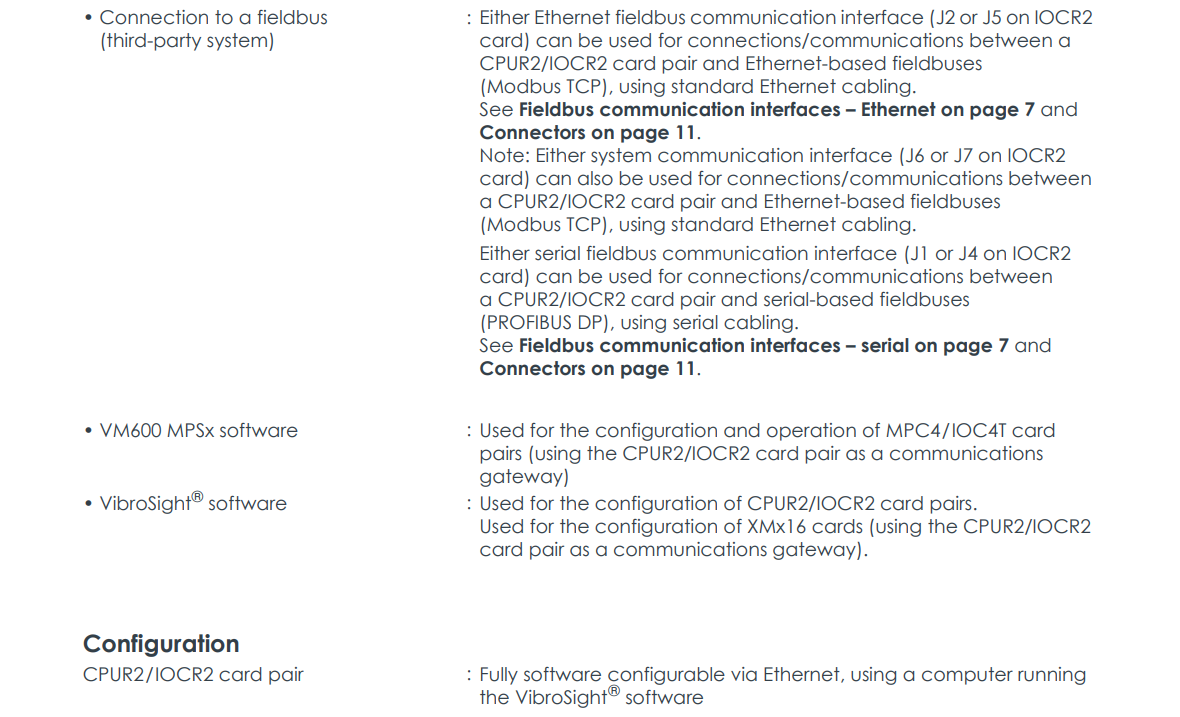

Supports visual configuration through VibroSight software, generating dedicated fieldbus configuration files

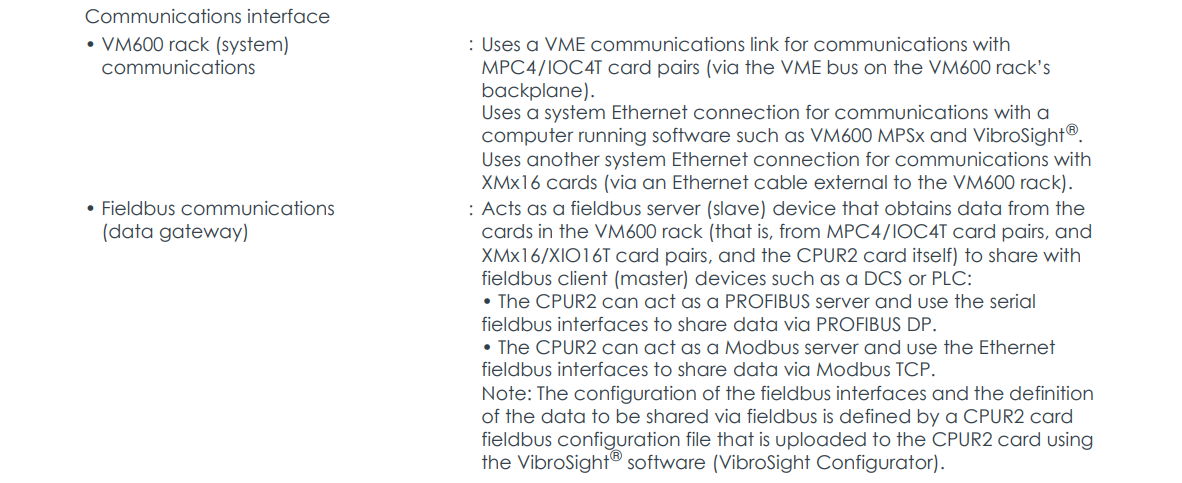

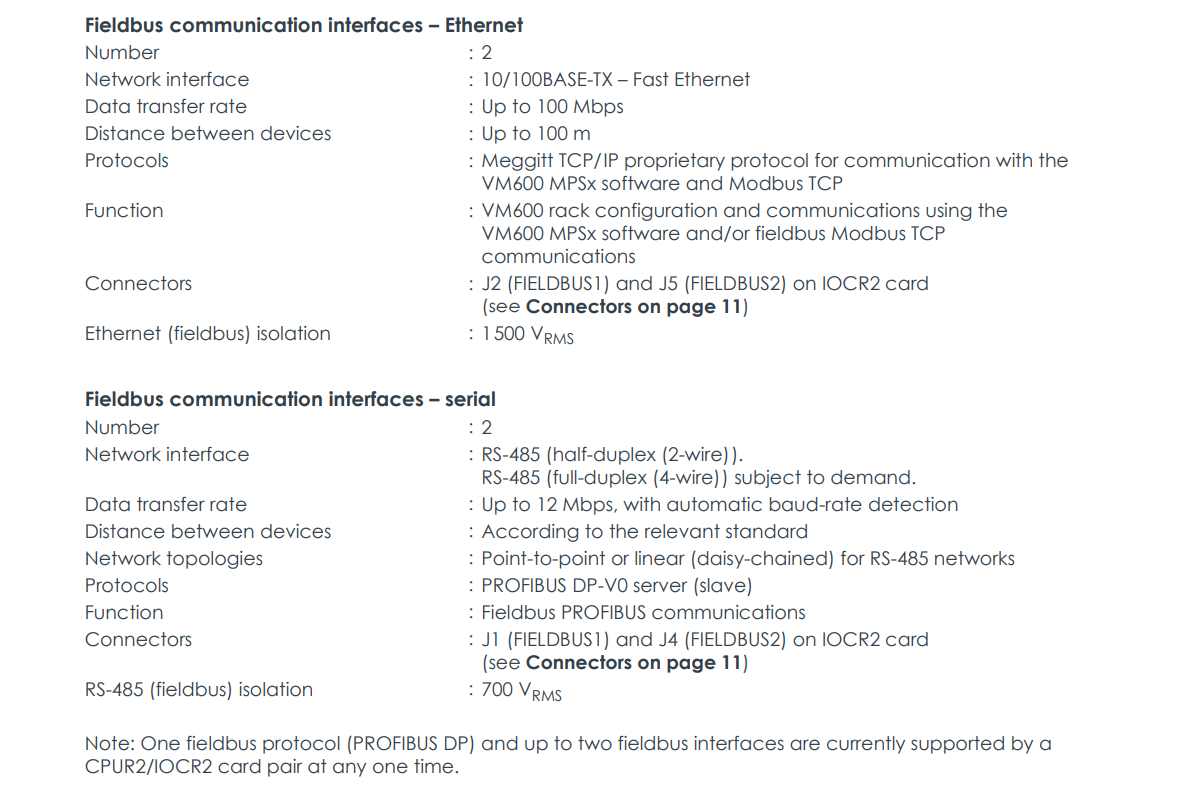

2. Advanced Fieldbus Support

CPUR2 provides dual fieldbus interface support:

Supports Ethernet-based Modbus TCP communication protocol

Supports RS-485-based PROFIBUS DP communication protocol

Each fieldbus interface supports up to 244 input bytes and 244 output bytes

Supports communication rates up to 12 Mbps with automatic baud rate detection

3. Enhanced System Security Mechanism

CPUR2 incorporates multi-level security protection:

Front panel equipped with removable physical key lock for hardware-level protection

Supports VM600 MPS rack security functions, restricting access via system Ethernet connections

Provides dual protection through software password verification (VM600 MPSx password validation)

Security event recording and audit functions, meeting critical infrastructure compliance requirements

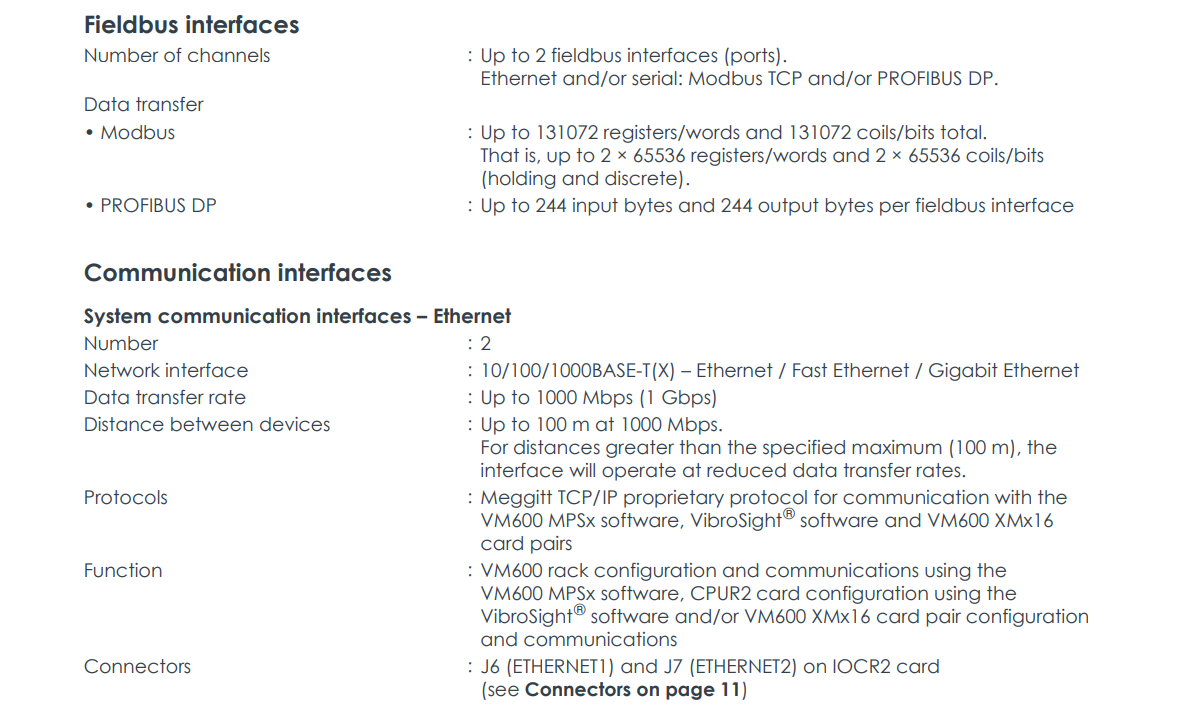

4. Gigabit Ethernet Communication Capability

CPUR2 significantly enhances system communication performance:

Two system Ethernet interfaces support 10/100/1000BASE-T(X) standards

Maximum data transfer rate up to 1 Gbps

Supports simultaneous communication with computers running VM600 MPSx or VibroSight software

Enables high-speed data exchange with XMx16/XIO16T monitoring card pairs

5. Comprehensive Status Monitoring Function

CPUR2 provides complete system status monitoring:

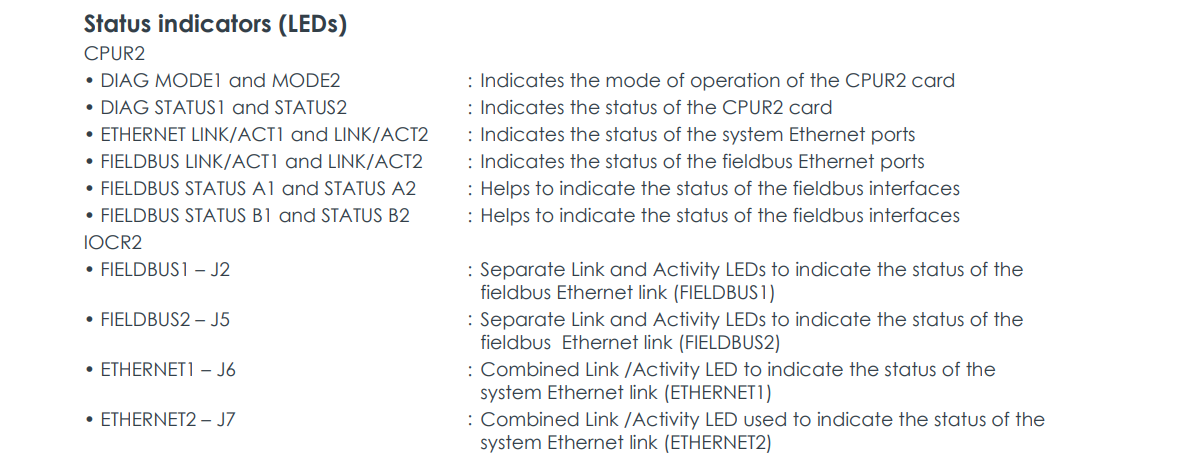

Multiple groups of front panel LED status indicators for real-time operational status display

Supports system Ethernet and fieldbus communication status monitoring

Provides detailed diagnostic log recording

Card status information accessible in real-time via fieldbus

6. Hot-Swapping Support and Automatic Configuration

CPUR2 supports advanced hot-swapping functionality:

Allows replacement or installation while system remains powered

Automatic detection and identification of card status

Intelligent loading of corresponding configurations ensuring continuous system operation

Significantly improves system maintainability and availability

Detailed Working Principle

1.System Architecture and Data Processing

The CPUR2 adopts an advanced embedded system architecture based on high-performance processors and real-time operating systems. Its workflow begins with acquiring raw measurement data from protection cards such as MPC4/IOC4T through the VME bus, while simultaneously collecting condition monitoring data from XMx16/XIO16T monitoring cards via Gigabit Ethernet interfaces. This data undergoes multiple processing stages within the CPUR2: first, data verification and format standardization to ensure data integrity and consistency; then, necessary mathematical operations and processing according to preset configurations; finally, preparing the processed data for fieldbus transmission or internal system use.

2.Mathematical Processing Engine Operation Mechanism

The mathematical processing functionality of CPUR2 is based on a configurable execution engine. Users define complex data processing logic through VibroSight Configurator software, including arithmetic operations, logical operations, data comparison, and scaling. The generated configuration files are downloaded to the CPUR2 and executed in real-time by the built-in mathematical processor. Particularly noteworthy is the data freeze detection function, which uses intelligent algorithms to continuously monitor the update status of data points, accurately identifying abnormal conditions where data updates cease, providing important basis for system maintenance.

3.Communication Protocol Processing Architecture

As the communication processing core, the CPUR2 implements complex protocol conversion functions. When handling Modbus TCP communication, it maps internal data structures and variables to standard Modbus holding registers and coils, allowing external clients to access this data through standard Modbus protocols. When processing PROFIBUS DP communication, it organizes data according to PROFIBUS protocol specifications, supporting both periodic and aperiodic data exchange. The CPUR2 supports two fieldbus protocols but can only use one protocol at a time, ensuring both flexibility and communication efficiency.

4.Security Mechanism Implementation Principle

The CPUR2's security mechanism employs a multi-level protection strategy. At the hardware level, physical key locks restrict access to system functions, with the system automatically entering security mode when keys are removed. At the software level, the VM600 MPSx password verification system implements user authentication and access control. All security-related operations and events are detailed in system logs, supporting post-incident auditing and analysis. This design ensures the system meets functional requirements while complying with industrial environment security standards.

5.Hot-Swapping and Status Management

The CPUR2's hot-swapping functionality is achieved through careful power design and status management. When the card is inserted into a powered rack, special power management circuits ensure power pins make contact before signal pins, preventing current surges and signal conflicts. The status detection circuit on the card continuously monitors the operational status of various functional modules, providing intuitive status display through front panel LED indicators. The system management unit coordinates card initialization, configuration loading, and operational status monitoring, ensuring smooth and reliable hot-swapping processes.

Hardware Specifications

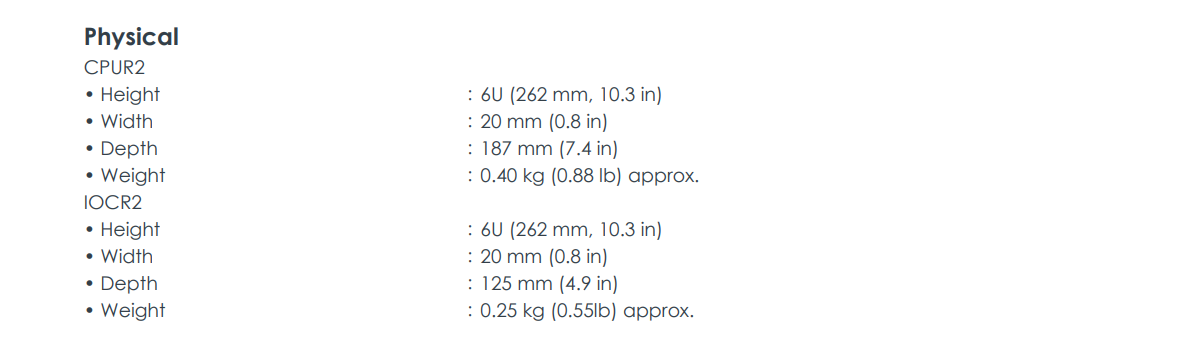

Physical Characteristics

Card dimensions: 6U height (262mm) × 20mm width × 187mm depth

Weight: Approximately 0.40kg

Installation method: Front slot of VM600 rack (single-slot installation)

Electrical Characteristics

Power requirements: 5 VDC

Power consumption: <6.5 W

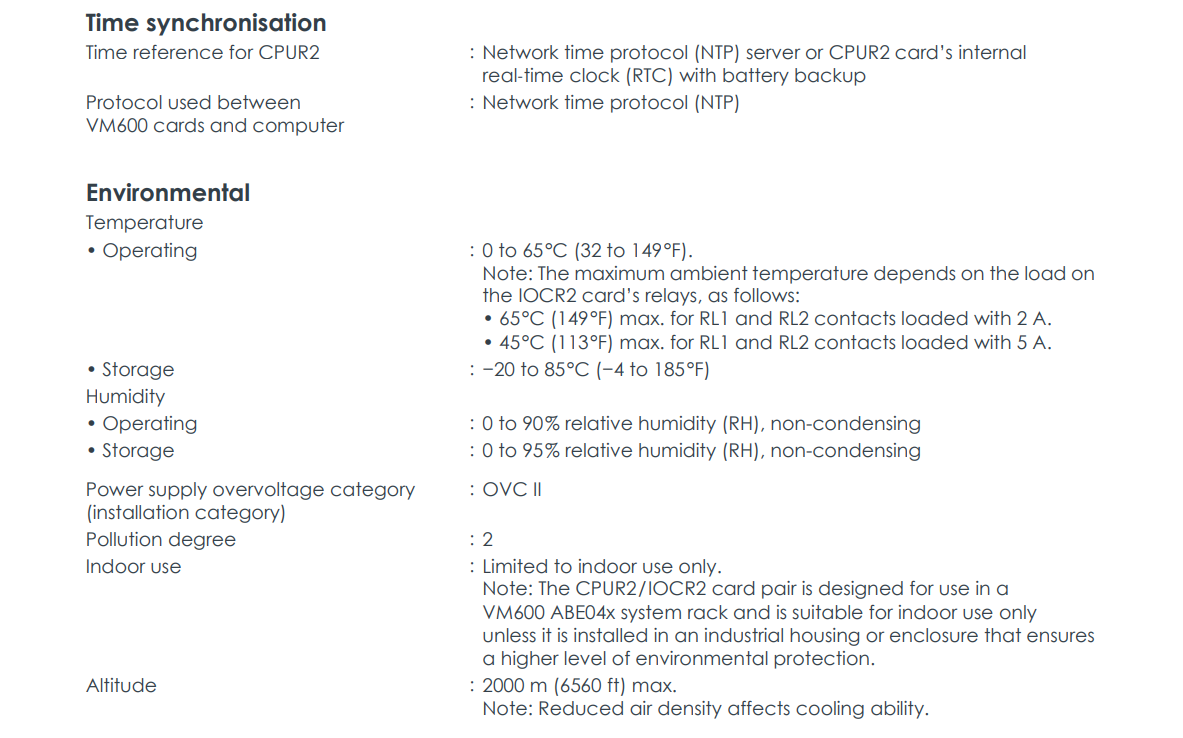

Operating temperature: 0°C to 65°C (ambient temperature)

Storage temperature: -20°C to 85°C

Humidity range: 0 to 90% relative humidity (non-condensing)

Front Panel Interfaces

Alarm reset button: For resetting latched alarms of all protection cards in the rack

Security key lock: Enables or disables rack security functions

Admin button: For resetting security passwords

Status indicators: Multiple groups of LEDs displaying card operation and communication status

Typical Application Scenarios

1. Complex Data Processing Applications

In monitoring systems requiring advanced data processing, CPUR2's mathematical processing engine can perform complex operations such as vibration signal analysis, trend prediction, and multi-parameter comprehensive judgment, providing more accurate basis for equipment condition assessment.

2. Multi-Protocol Communication Environments

In environments requiring connection to multiple control systems, CPUR2's dual fieldbus interface support allows flexible protocol selection, supporting both traditional Modbus TCP and PROFIBUS DP to meet different integration requirements.

3. High-Security Requirement Applications

In industries with extremely high security requirements such as nuclear power and petrochemicals, CPUR2's hardware security locks and software password protection provide dual guarantees, ensuring secure and reliable operation of monitoring systems.

4. Large-Scale Monitoring Systems

In large monitoring systems with numerous measurement points, CPUR2's Gigabit Ethernet interfaces provide sufficient bandwidth to ensure real-time performance and integrity of data transmission, supporting complex monitoring and protection functions.