The IS420UCSBH1A is a standalone controller module in GE’s Mark VIe control system, part of the UCSB series. Designed for industrial control applications, it is especially suited for real-time monitoring and control of critical power equipment such as gas turbines, steam turbines, wind turbines, and hydroelectric systems. Equipped with a high-performance Intel processor and the reliable QNX Neutrino real-time operating system, it delivers powerful data processing capabilities, high reliability, and flexible communication interfaces to meet the demands of complex industrial environments.

Key Features

1. High-Performance Processing

The IS420UCSBH1A is powered by a 600 MHz Intel EP80579 processor, supported by 256 MB of DDR2 SDRAM with Error-Correcting Code (ECC), ensuring computational accuracy and system stability. It includes 2 GB of NAND flash memory for firmware and application storage, enabling fast boot-ups and reliable data retention.

2. Multiple Network Communication Interfaces

The controller offers multiple Ethernet ports, including:

2 Main Ethernet ports: For Unit Data Highway (UDH) and optional Control Data Highway (CDH), enabling communication with HMIs, engineering stations, and other control devices.

3 IONet ports: Dedicated to communication with I/O modules (e.g., PAIC, PDIA), supporting real-time data exchange and precision clock synchronization via the IEEE 1588 protocol.

3. Real-Time Operating System

Runs on the QNX Neutrino real-time OS, supporting multitasking and high-precision timing to ensure deterministic execution of control logic—ideal for high-speed, high-reliability industrial applications.

4. Flexible Programming and Logic Execution

Supports Control Block Language, including analog and digital control blocks, and Boolean logic in relay ladder diagram format. Supported data types include:

5. Redundancy and Reliability

Supports dual-network redundancy to maintain operation during network failure.

Battery-free design, requires no jumper settings, reducing maintenance needs.

Built-in watchdog timer and hardware reset circuit enhance system reliability.

6. Diagnostics and Status Indicators

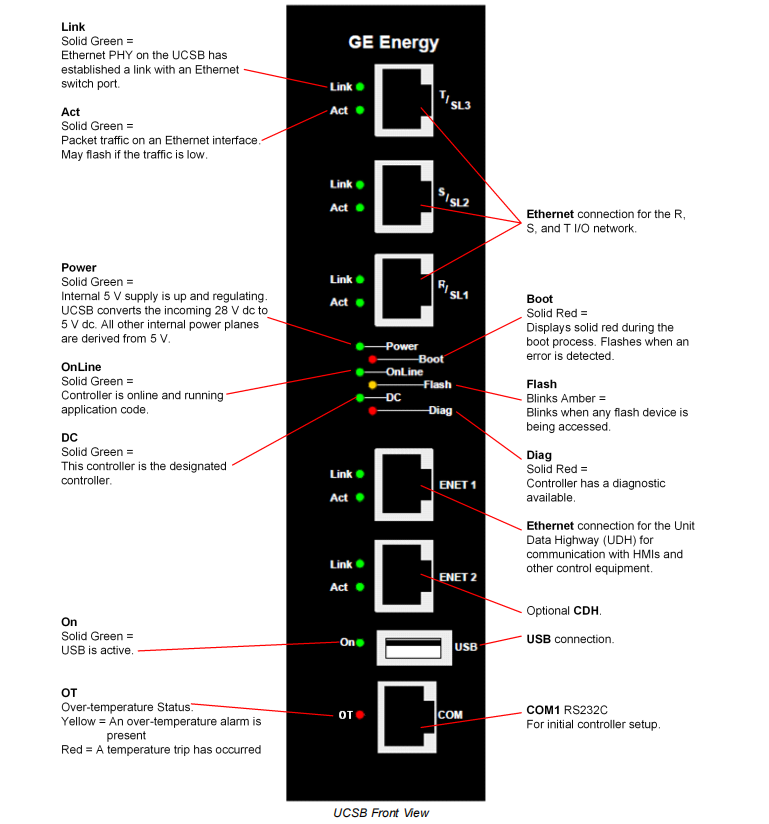

The front panel includes multiple LED indicators for real-time status monitoring:

Link/Act: Network connection and activity

Power: Power status

Online: Controller operational status

Flash: Flash memory access status

Diag: Diagnostic alarm status

Boot: Boot status (includes fault code indication)

7. USB Recovery Function

Allows system backup and restore via a front USB port using a FAT32-formatted USB drive—no dedicated programmer required.

8. Environmental Robustness

Operating temperature: -30°C to 65°C

Storage temperature: -40°C to 85°C

Humidity: 5% to 95% (non-condensing)

Complies with industrial standards for vibration, shock, and EMC

Functional Principle

1. System Architecture

As the core processing unit of the Mark VIe control system, the IS420UCSBH1A communicates with distributed I/O modules (e.g., PAIC, PDIA, PTCC) via IONet—a dedicated industrial Ethernet network. It executes application code, processes input signals from sensors, runs control algorithms, and outputs control signals to actuators.

2. Data Flow and Processing

Input Handling: Receives analog, digital, temperature, vibration, and other signals from I/O modules via IONet.

Control Logic Execution: Performs computations based on predefined control strategies (e.g., PID control, sequencing, protection logic).

Output Control: Sends computed results via IONet to I/O modules to drive valves, servos, relays, and other devices.

3. Network Synchronization and Fault Tolerance

Uses IEEE 1588 Precision Time Protocol (PTP) to synchronize clocks between the controller and I/O modules, ensuring timing accuracy within ±100 microseconds.

Supports Triple Modular Redundancy (TMR) architecture, where three controllers vote on critical signals to enhance system safety.

4. Fault Diagnosis and Handling

Continuously monitors hardware status (e.g., power, memory, communication links).

Triggers alerts via LEDs, ToolboxST software, or HMI upon detecting faults.

Supports online logic modifications without system shutdown, improving availability.

5. Power Management

Input voltage: 28 V DC (range: 18–36 V DC)

Internal DC-DC converters provide multiple voltage levels to power the processor and interface circuits.

Low power consumption: 15.6 W typical, 26.7 W peak.

Applications

The IS420UCSBH1A is widely used in:

Gas turbine control systems (Frame 6/7/9)

Steam turbine control

Wind turbine control systems

Hydroelectric plant monitoring

Balance of Plant (BOP) auxiliary control systems

Industrial process control and protection systems