The 3500/22M Transient Data Interface (TDI) Module is a high-performance communication and data acquisition module developed by Baker Hughes under the Bently Nevada™ brand, specifically designed for the 3500 Machinery Monitoring System. This module not only incorporates all the functions of the traditional 3500/20 Rack Interface Module (RIM) but also integrates data acquisition capabilities similar to a communication processor like TDXnet, making it a key component for enabling condition monitoring and diagnostic systems.

The TDI module resides in the slot adjacent to the power supplies in a 3500 rack. It interfaces with M-Series monitor modules (e.g., 3500/40M, 3500/42M) to continuously collect steady-state and transient dynamic (waveform) data, transmitting this data to host software, such as System 1™ Condition Monitoring and Diagnostic software or the 3500 System Configuration software, via an Ethernet connection.

2. Key Features and Detailed Functional Principles

2.1 Data Acquisition Capabilities

The core function of the TDI module is the real-time acquisition and transmission of multiple data types, detailed as follows:

a) Static Values Data Acquisition

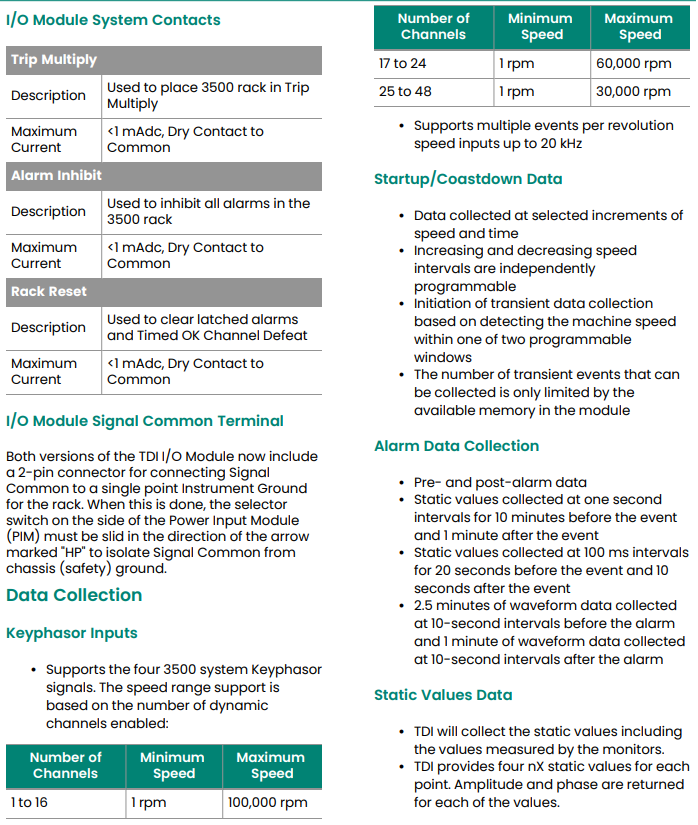

The TDI module continuously collects static values from the monitor modules, including parameters like vibration, temperature, and displacement. These values are recorded at 1-second intervals and retained for 10 minutes before and 1 minute after an alarm event. Furthermore, as an alarm moment approaches, the data acquisition frequency increases to 100-millisecond intervals to ensure critical transient changes are captured.

b) Dynamic Waveform Data Acquisition

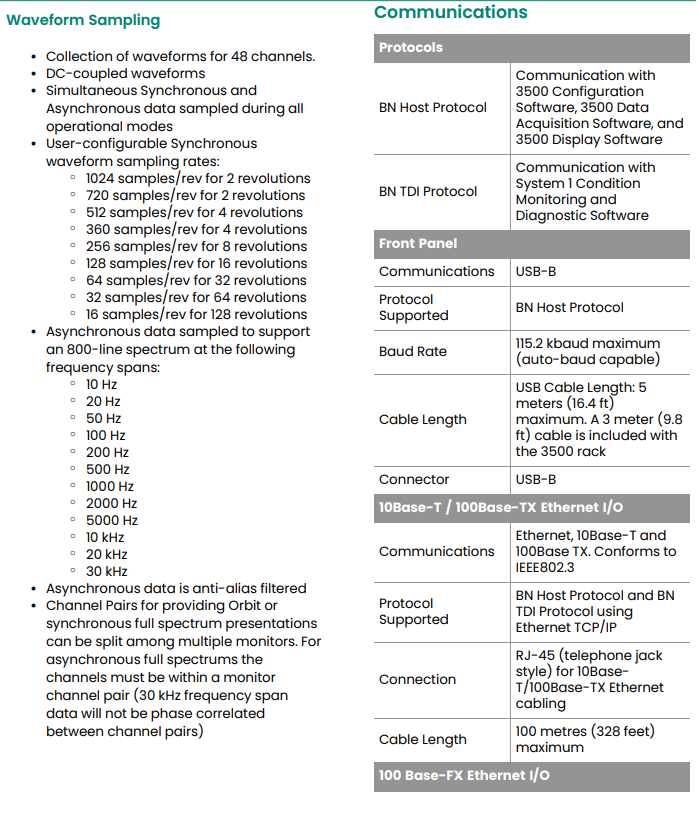

The TDI supports waveform data acquisition for up to 48 channels, featuring DC-coupled inputs and the ability to perform simultaneous synchronous and asynchronous sampling:

Synchronous Sampling: Based on Keyphasor® signals, it supports multiple user-configurable sampling rates per revolution (e.g., 1024, 720, 512, 360, 256, 128, 64, 32, 16 samples/rev), covering sampling periods from 2 to 128 revolutions.

Asynchronous Sampling: Supports various frequency spans from 10 Hz to 30 kHz, providing 800-line spectrum analysis capability. Asynchronous data is anti-alias filtered to ensure accuracy.

c) Transient Data Acquisition

Using an optional Channel Enabling Disk, the TDI module can activate high-resolution transient data acquisition. This feature allows data recording to be triggered based on preset speed or time increments during machine startup, coastdown, or other operational transients, which is vital for fault diagnosis and performance analysis.

d) Alarm Data Capture

The TDI module includes pre- and post-alarm data buffering. It can record waveform data at 10-second intervals for 2.5 minutes before and 1 minute after an alarm trigger, alongside denser static value recording, providing a complete event context for post-incident analysis.

2.2 Communication Interfaces and Protocols

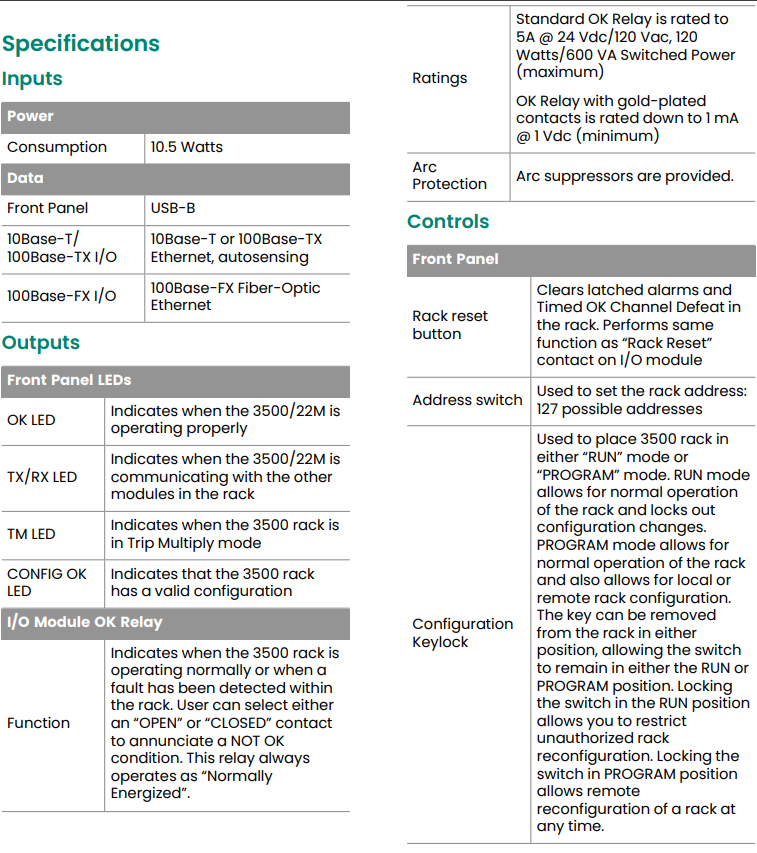

The TDI module offers multiple communication interfaces to suit different industrial network environments:

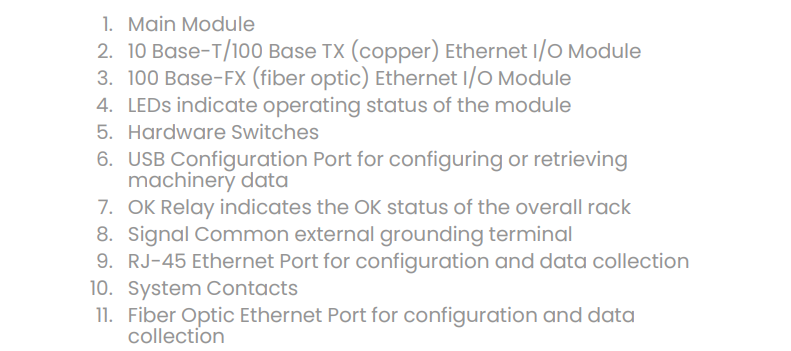

a) Front Panel USB-B Port

Supports the BN Host Protocol with a maximum data rate of 1.5 kbaud (auto-baud capable), used for local configuration or data retrieval. A standard 3-meter USB cable is included, with support for cables up to 5 meters maximum.

b) Ethernet Interfaces

10Base-T/100Base-TX I/O: Uses an RJ-45 connector, supports auto-negotiation, with a maximum cable length of 100 meters.

100Base-FX I/O: Uses an MT-RJ connector, supports full-duplex multimode fiber optic cable, with a maximum distance of 2000 meters, ideal for environments with high electromagnetic interference.

Both Ethernet interfaces support the BN Host Protocol and the BN TDI Protocol over TCP/IP, ensuring efficient data transmission to host software.

2.3 System Control and Status Indication

a) Front Panel LEDs

OK LED: Indicates normal module operation.

TX/RX LED: Indicates communication with other modules in the rack.

TM LED: Indicates the rack is in Trip Multiply mode.

CONFIG OK LED: Indicates the rack has a valid configuration.

b) OK Relay Output

The TDI includes an OK Relay that indicates the overall operational status of the rack. The user can configure the relay contact to be "open" or "closed" to annunciate a NOT OK condition. It is rated for 5A @ 24 Vdc/120 Vac.

c) Controls and Switches

Rack Reset Button: Clears latched alarms and the Timed OK Channel Defeat state.

Address Switch: Sets the rack address, supporting 127 possible addresses.

Configuration Keylock: Switches the rack between "RUN" mode (normal operation, configuration locked) and "PROGRAM" mode (allows local or remote configuration). The key can be removed in either position to prevent unauthorized changes.

2.4 System Contact Functions

The TDI module provides several system contacts for external control and interlocking:

Trip Multiply: Used to place the 3500 rack in Trip Multiply mode.

Alarm Inhibit: Used to inhibit all alarms in the 3500 rack.

Rack Reset: Used to clear latched alarms and the Timed OK Channel Defeat state.

All contacts are dry contacts (<1 mAdc, to Common), suitable for interfacing with PLC or DCS systems.

2.5 Electrical and Mechanical Specifications

Power Consumption: 10.5 Watts

Operating Temperature: -30°C to +65°C (-22°F to +149°F)

Storage Temperature: -40°C to +85°C (-40°F to +185°F)

Humidity: 95% non-condensing

Battery Life (Real-Time Clock):

Module dimensions are 241.3 mm x 24.4 mm x 241.8 mm (9.50 in x 0.96 in x 9.52 in), and it weighs approximately 0.91 kg (2.0 lbs). It is designed for installation in a standard 3500 rack.

2.6 Compatibility and Upgrade Considerations

The TDI module is compatible with 3500 M-Series monitor modules. However, when upgrading from a 3500/20 RIM to a 3500/22 TDI, it is crucial to follow the correct sequence to prevent damage:

Remove the existing RIM module.

Remove the RIM I/O module.

Install the TDI I/O module.

Install the TDI module.

Dynamic Data Enabling Disk:

An optional 3500/09 series disk is required to enable transient data acquisition capabilities. The disk allows configuration of Steady-State Points and Transient Points, with the sum of both not exceeding 672 points across potentially multiple TDIs.

2.7 Approvals and Compliance

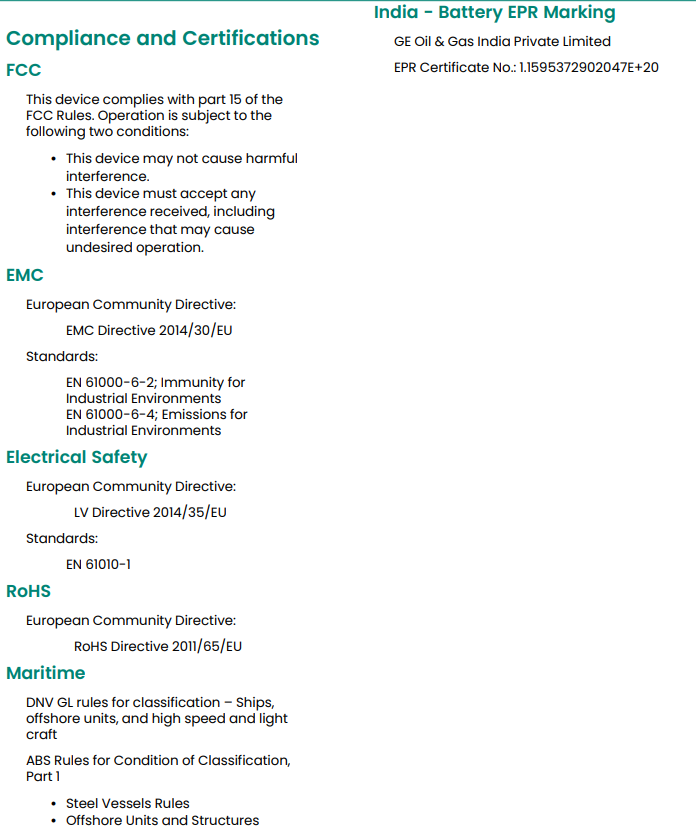

The TDI module complies with numerous international standards and certifications:

FCC Part 15: Electromagnetic Compatibility.

EMC Directive 2014/30/EU: Immunity and Emissions for Industrial Environments (EN 61000-6-2, EN 61000-6-4).

Low Voltage Directive 2014/35/EU: Electrical Safety (EN 61010-1).

RoHS Directive 2011/65/EU: Restriction of Hazardous Substances.

Maritime Classifications: Includes DNV GL and ABS rules.

Hazardous Area Approvals:

Class I, Zone 2: AEx/Ex nA nC ic IIC T4 Gc; AEx/Ex ec nC ic IIC T4 Gc

Class I, Division 2, Groups A, B, C, D

ATEX/IECEx: Ex II 3 G Ex nA nC ic IIC T4 Gc; Ex ec nC ic IIC T4 Gc

(T4 @ Ta = -20°C to +65°C when installed per specific drawings).

3. Application Scenarios

The 3500/22M TDI module is widely used in various industries for monitoring critical rotating equipment, including:

Steam and Gas Turbines in Power Generation

Compressors and Pumps in Oil & Gas Production and Pipelines

Marine Propulsion Systems and Auxiliary Machinery

Critical rotating equipment in Chemical, Petrochemical, and Metallurgical processing plants.