The 3500/72M Reciprocating Rod Position Monitor is a 4-channel monitoring module under the 3500 Machinery Protection System, specifically designed for the protection of critical components in reciprocating compressors. It continuously and precisely measures both dynamic and static position information of the piston rod. Through real-time comparison with user-programmable alarm setpoints, it provides ultra-early fault warning and dangerous shutdown protection for equipment, effectively preventing catastrophic failures and meeting the stringent requirements of API 618 standards for reciprocating compressors.

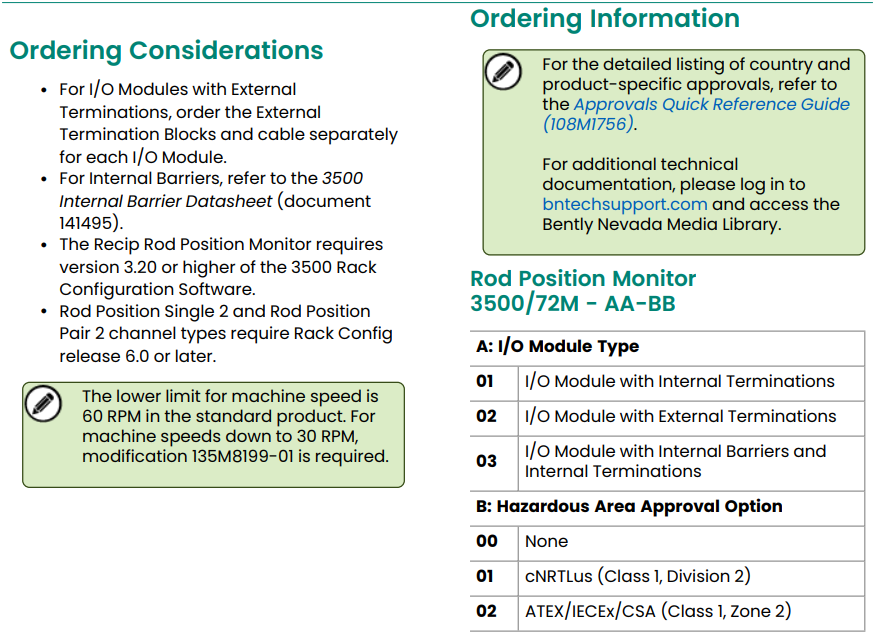

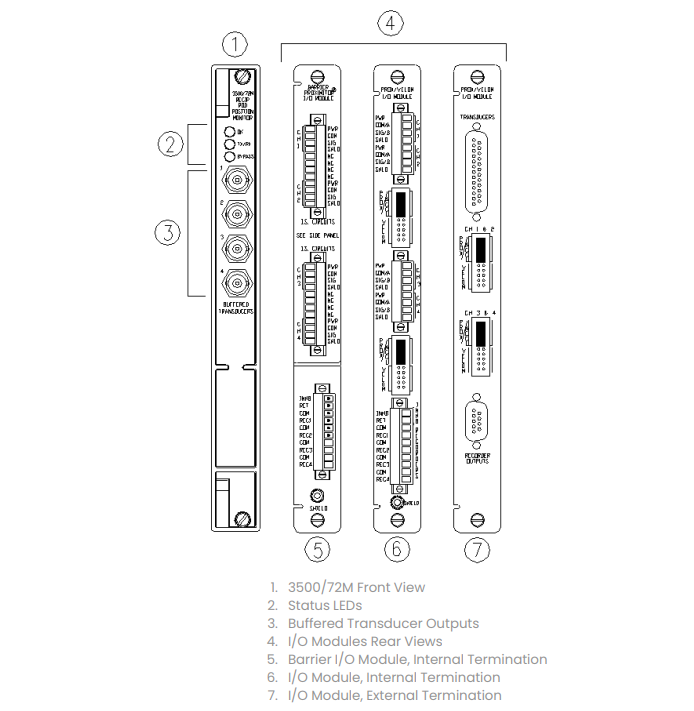

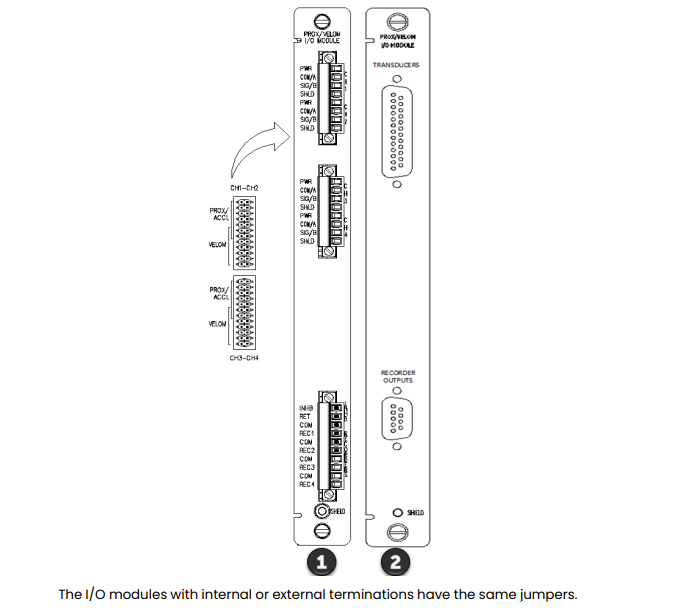

The 3500/72M consists of one fixed front card (176449-08) and three different types of rear cards (for details, please refer to the Ordering page). The 176449-08 can form a complete system when paired with any one of the rear cards.

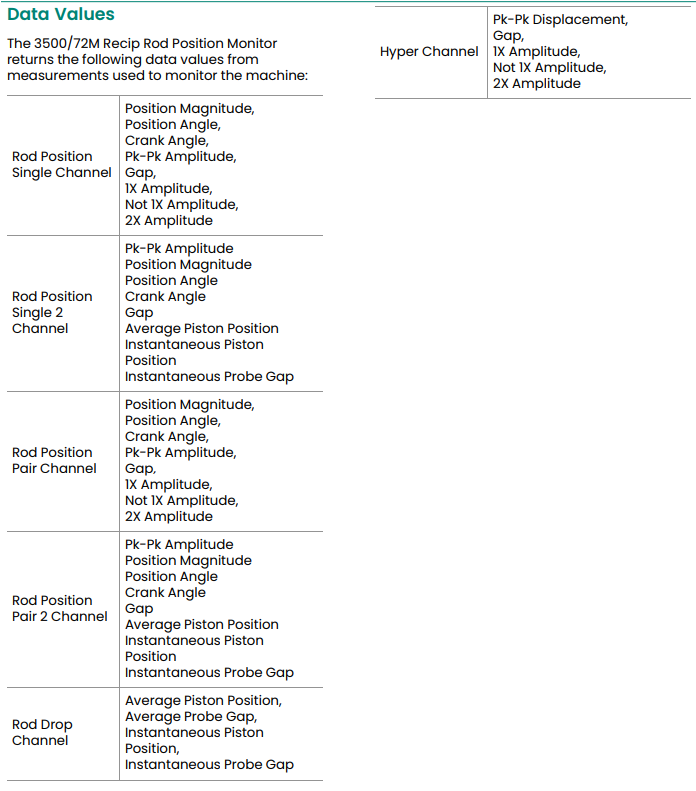

This monitor accepts input signals from eddy current proximity probes. Through a series of advanced signal conditioning and processing steps, it extracts up to over ten key measured values, providing a comprehensive depiction of the piston rod's operating condition. Its channels are programmed in pairs, allowing it to perform up to two different monitoring functions simultaneously. This offers flexible configuration to adapt to various complex monitoring requirements.

Features

Comprehensive Monitoring Capabilities: A single monitor can simultaneously perform three core functions: Rod Position Monitoring, Rod Drop Monitoring, and Hyper Compressor Monitoring, providing complete coverage for the health management of reciprocating compressor piston rods.

Extensive Measurement Parameters: Depending on the configuration, each channel can provide up to over ten key measured values, including:

Position Information: Position Magnitude, Peak-Peak Amplitude, Average/Instantaneous Piston Position, Crank Angle.

Gap Information: Gap Voltage, Average/Instantaneous Probe Gap.

Frequency Components: 1X Amplitude, 2X Amplitude, Not 1X Amplitude.

Phase Information: Position Angle (for paired channels).

Flexible Channel Configuration: The four monitoring channels use a paired programming mode, allowing flexible configuration to perform two different monitoring functions (e.g., Channels 1&2 for rod position monitoring, Channels 3&4 for rod drop monitoring), significantly enhancing configuration flexibility and cost-effectiveness.

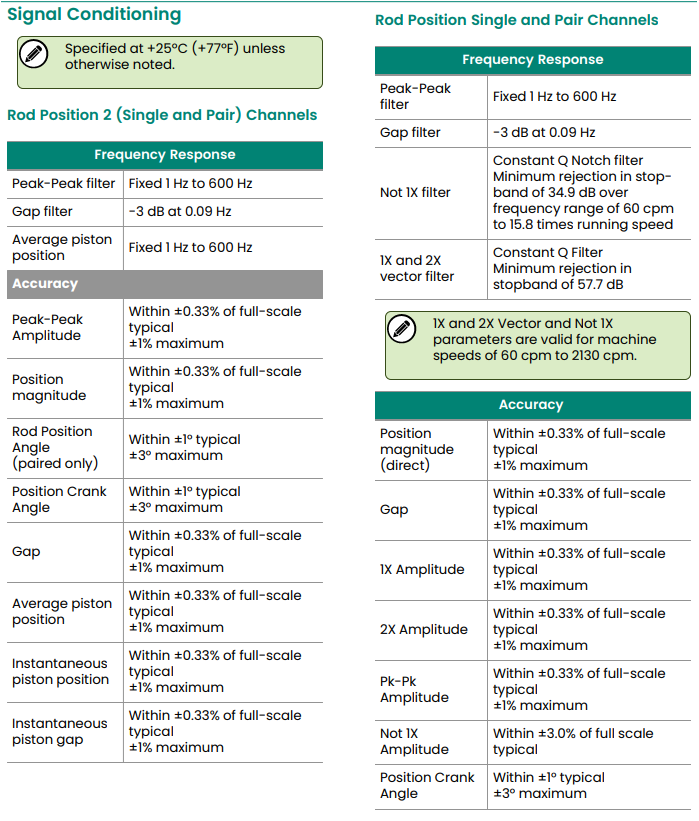

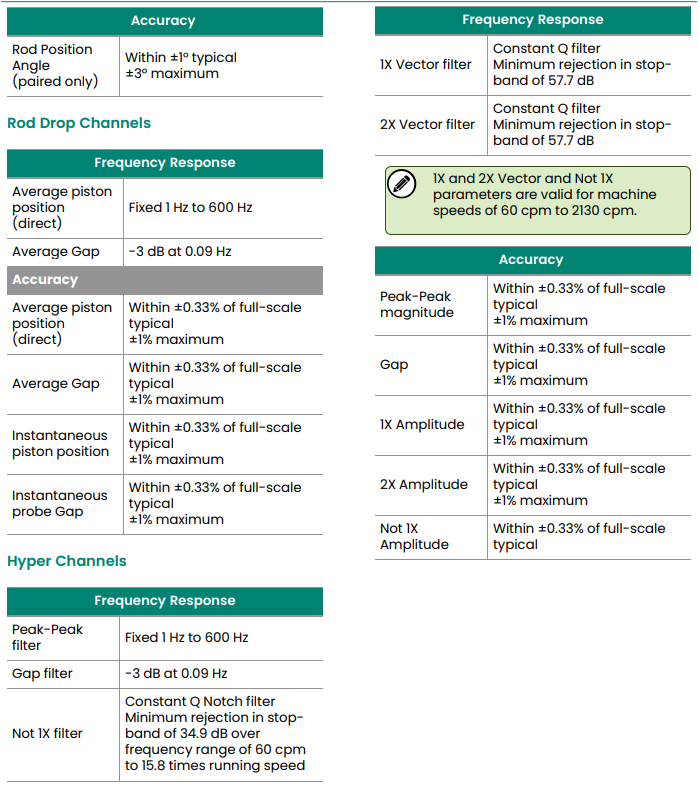

High Precision and Reliability: Utilizes advanced signal conditioning technology and digital processing algorithms. The typical accuracy for most measured parameters is as high as ±0.33% FS, and angle measurement accuracy reaches ±1°, ensuring alarm accuracy and reliability.

Powerful Alarm Management: Users can independently set programmable Alert and Danger setpoints for each measured value via the 3500 Configuration Software, featuring adjustable delay functions to effectively prevent false alarms and achieve precise protection.

Comprehensive Diagnostics and Outputs:

Front Panel Buffered Outputs: Each channel provides an independent buffered sensor signal output for connecting to oscilloscopes for advanced diagnostics.

Recorder Outputs: Provides 4-20 mA analog output to transmit selected measured values to a DCS or recording system.

Status Indicators: The front panel is equipped with OK, TX/RX, and Bypass LEDs to display module operation and communication status in real time.

Extensive Certifications and Compatibility: The module and its I/O options have passed multiple international explosion-proof certifications such as cNRTLus, ATEX, and IECEx, as well as safety and maritime certifications like CE, DNV GL, and ABS, meeting installation requirements for various harsh environments worldwide. Its design allows seamless integration with the 3500 system and is compatible with various I/O modules (Internal/External Termination, Barrier versions).

Working Principle & Technical Details

The working principle of the 3500/72M monitor is based on the eddy current effect. Its workflow involves precise signal acquisition, conditioning, and analysis:

Signal Acquisition: The monitor provides operating power to the eddy current proximity probes installed near the piston rod. The high-frequency electromagnetic field generated by the probe induces eddy currents on the conductive surface of the piston rod. These eddy currents react back on the probe coil, and their intensity is inversely proportional to the gap between the probe and the rod surface. Consequently, the output signal from the probe is a modulated signal containing both a DC (Direct Current) gap component and an AC (Alternating Current) dynamic displacement component.

Signal Conditioning & Separation: After receiving the probe signal, the monitor performs the following key processing steps:

1X/2X Vector Filters: Used to accurately extract vibration components synchronous with the compressor running speed (1X) and its second harmonic (2X), with a stopband rejection of up to 57.7 dB.

Not 1X Notch Filter: Used to filter out the 1X component, thereby obtaining the remaining non-synchronous vibration energy, which aids in diagnosing non-synchronous faults. It provides a minimum stopband rejection of 34.9 dB over a frequency range from 60 CPM to 15.8 times the running speed.

Input Conditioning: The input circuit is impedance-matched at 10 kΩ, supporting various standard probe sensitivities like 20 mV/mil, 100 mV/mil, and 200 mV/mil.

Gap Signal Extraction: Uses a high-pass filter with a very low cutoff frequency (~0.09 Hz), essentially a DC blocker, to separate the slowly changing average DC voltage signal. This voltage is proportional to the average gap and is the direct basis for Rod Drop Monitoring.

Dynamic Signal Extraction: Uses a fixed band-pass filter (1 Hz - 600 Hz) to extract the AC dynamic signal for analyzing piston rod swing and position changes.

Advanced Filtering Analysis: Incorporates built-in Constant Q tracking filters and notch filters.

Digital Processing & Calculation: The conditioned analog signal is sampled by a high-speed ADC and converted into a digital signal. The built-in processor then performs calculations to finally generate all measured parameter values, such as peak-to-peak, vector values, phase angles, etc.

Alarm Logic Judgment: The processor continuously compares the generated measured values with the alarm setpoints preset by the user via the software. Once any parameter exceeds the set limit and meets the configured delay condition, the monitor immediately issues an alarm command through the rack backplane, driving the corresponding relays to activate and execute the shutdown protection sequence.

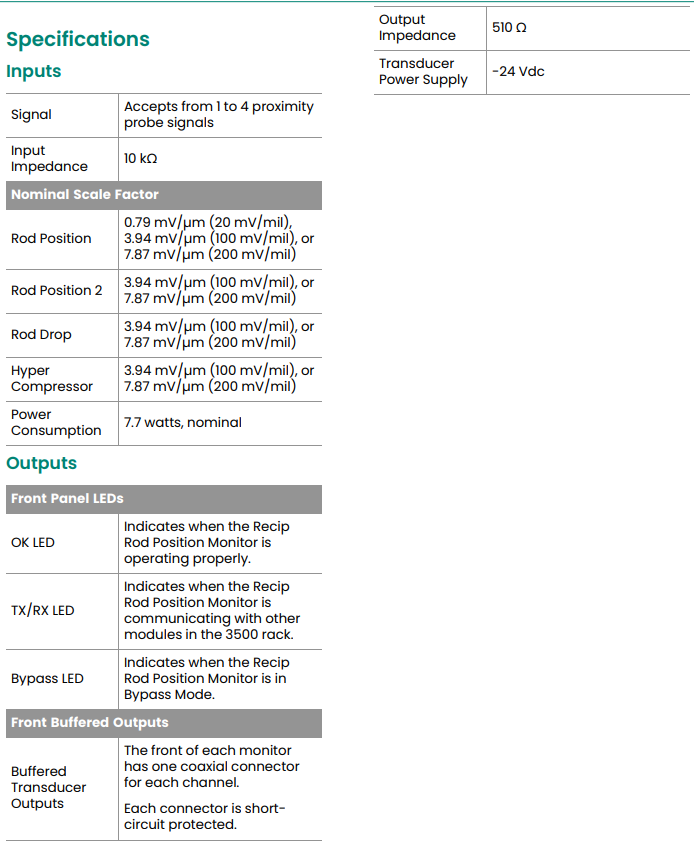

Specifications

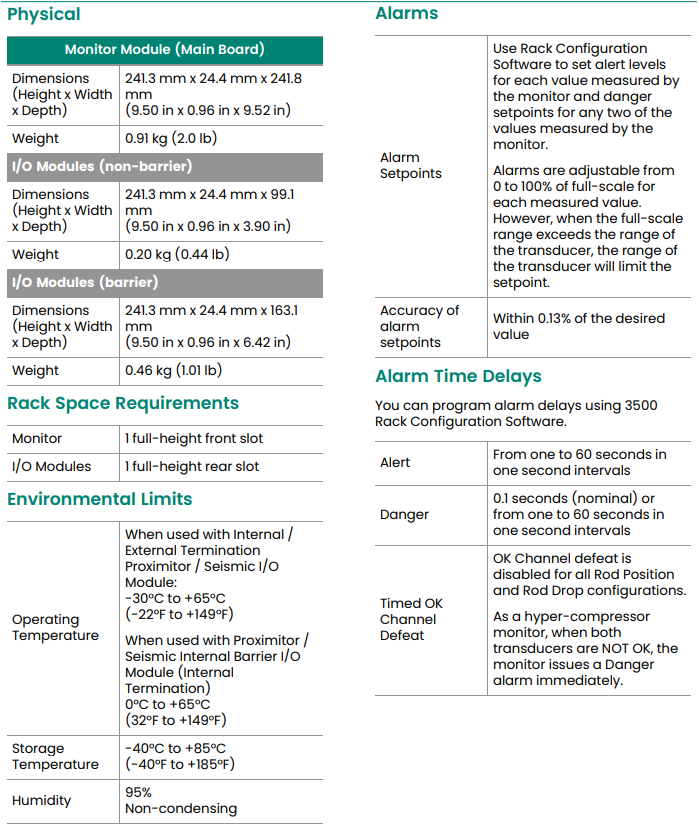

| Item | Specification Description |

| Number of Channels | 4 channels |

| Input Signal | 1 to 4 channels of eddy current proximity probe signals |

| Input Impedance | 10 kΩ |

| Probe Sensitivity | 0.79 mV/µm (20 mV/mil), 3.94 mV/µm (100 mV/mil), or 7.87 mV/µm (200 mV/mil) |

| Measurement Accuracy | Typical ±0.33% FS, Max ±1% FS (Position, Gap, etc.); Angle Typical ±1°, Max ±3° |

| Frequency Response | Dynamic Channel: 1 Hz - 600 Hz; Gap Channel: ~0.09 Hz (-3dB) |

| Alarm Delay | Alert: Adjustable 1-60 seconds; Danger: 0.1 seconds (fixed) or adjustable 1-60 seconds |

| Alarm Setpoint Accuracy | Within ±0.13% of desired value |

| Power Consumption | 7.7 Watts (typical) |

| Operating Temperature | Standard I/O Module: -30°C ~ +65°C; Internal Barrier I/O Module: 0°C ~ +65°C |

| Module Dimensions (HxWxD) | Monitor Module: 241.3 mm x 24.4 mm x 241.8 mm |

| Rack Space | front slot (Monitor) + 1 rear slot (I/O Module) |

| Explosion-Proof Certification | cNRTLus (CL I, Div. 2), ATEX/IECEx (II 3 G Ex nA/ec nC ic IIC T4 Gc), etc. |

Application Scenarios

The 3500/72M monitor is an ideal choice for the following scenarios and equipment:

Oil & Gas Industry: Protection for piston rods in large reciprocating compressors used in natural gas boosting, associated gas treatment, CNG compression, gas injection for oil recovery, etc.

Chemical & Petrochemical Industry: Condition monitoring and protection for high-pressure reciprocating compressors in processes such as ethylene, polyethylene, fertilizer (ammonia synthesis, urea), and coal chemical production.

Critical Equipment Protection: Particularly suitable for monitoring:

Rod Drop: Prevents piston rod sinking and subsequent damage to the crosshead and crankshaft caused by piston ring wear, breakage, or packing failure.

Rod Bend & Fracture: Early detection of fault precursors such as connecting rod bushing wear, loose crosshead pins, or liquid slugging through monitoring position trajectory and swing.

Rod Misalignment & Wear: Assesses the alignment condition and wear state between the piston rod and packing by analyzing position angle and dynamic signals.

Hypercompressor Applications: Its Hyper Compressor monitoring mode is specifically designed to provide customized protection for compressors operating in extreme conditions like those used in high-pressure polyethylene production.