The IS220PPRAH1A is a critical I/O module within the GE Mark VIe control system, designed for emergency turbine protection. It is part of the PPRA series and, when combined with the TREA terminal board and WREA option board, forms a fully independent backup overspeed protection system. This system features a Triple Modular Redundant (TMR) architecture to ensure reliable turbine trip protection even in the event of a primary control system failure.

The IS220PPRAH1A incorporates a BPPB processor board and supports six speed input signals. These inputs can be configured in different groupings to suit various turbine configurations (e.g., single-shaft, two-shaft, three-shaft units). The module provides protection functions implemented in both hardware and firmware, including overspeed detection, acceleration/deceleration detection, main control system monitoring, and contact trip input processing. It is a core component for safeguarding rotating machinery such as gas turbines and steam turbines.

System Architecture and Compatibility

1.System Components

IS220PPRAH1A I/O Module: Responsible for signal acquisition, logic processing, and protection decisions.

TREA Terminal Board: Provides relay outputs, trip input interfaces, and supports Emergency Stop (E-Stop) and overspeed protection functions.

WREA Option Board: Expands system capabilities with speed signal repeater outputs, enhancing reliability.

2.Compatibility Notes

The IS220PPRAH1A is part of the PPRA series alongside the PPRAS1A and PPRAS1B variants. However, it is not certified to IEC 61508 standards and therefore must not be used in safety loops requiring a Safety Integrity Level (SIL) certification. For SIL-certified applications, the PPRAS1A or S1B versions must be used. The PPRAH1A has an operating temperature range of -30°C to 65°C, making it suitable for general industrial environments.

3.Installation Requirements

It must be used with a TREA terminal board and requires the WREA option board to be installed.

Three PPRA modules must be installed simultaneously to form the TMR system; single or dual-pack operation is not supported.

The module plugs directly into the TREA board via a DC-62 pin connector and is secured using threaded posts.

Detailed Core Functions

1. Speed Input and Signal Processing

The IS220PPRAH1A accepts six speed sensor inputs, configurable based on the turbine shaft arrangement:

Three Groups of Two Sensors (two sensors per shaft, up to three shafts)

Two Groups of Three Sensors (three sensors per shaft, up to two shafts)

Each speed signal is processed through a High Select or Median Select algorithm to output a single pulse rate value representing the actual speed for each shaft. The module performs difference detection between sensors on the same shaft. If the difference exceeds a configurable threshold (e.g., 25 RPM), a "Dual speed sensors mismatch" diagnostic alarm is generated.

2. Overspeed Protection Function

2.1. Firmware Overspeed Protection

Implemented in programmable logic. The overspeed trip setpoint can be sourced from Signal Space or from a local configuration value.

Supports online and offline overspeed testing. During testing, the trip setpoint can be temporarily reduced (down to 94% of the configured value).

Includes a setpoint agreement check; if the configuration value does not match the value received from Signal Space when the speed is zero, an error is declared, and operation is inhibited.

2.2. Hardware Overspeed Protection

Implemented entirely in hardware logic, independent of the processor firmware, with a response time of less than 20 ms.

The overspeed setpoint is loaded only when the module boots or is power-cycled and cannot be changed during operation.

Each of the six speed inputs is individually monitored for hardware overspeed, ensuring protection even if the firmware fails.

Requires two adjacent shaft revolutions to exceed the setpoint to initiate a trip, preventing spurious trips.

3. Acceleration and Deceleration Protection

The module calculates the real-time rate of change of speed (acceleration) and supports a configurable acceleration trip threshold.

Deceleration protection uses a fixed trip threshold of 100% per second and is not configurable.

Acceleration is calculated by comparing two adjacent speed samples over a configurable period (AccelCalTime, 10-100 ms).

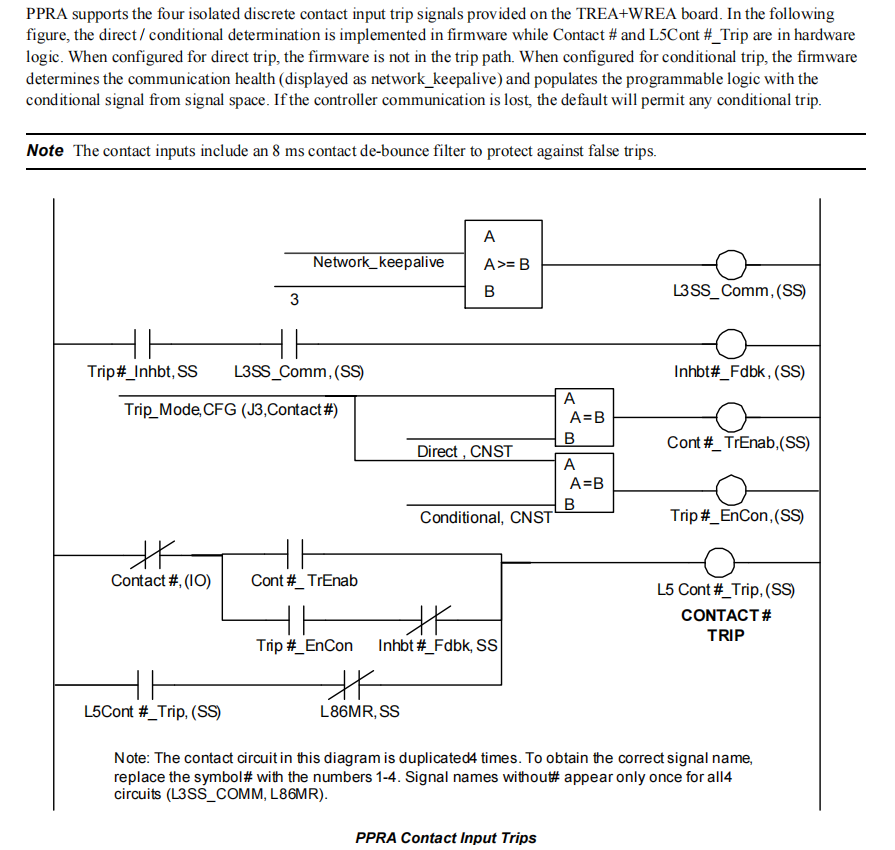

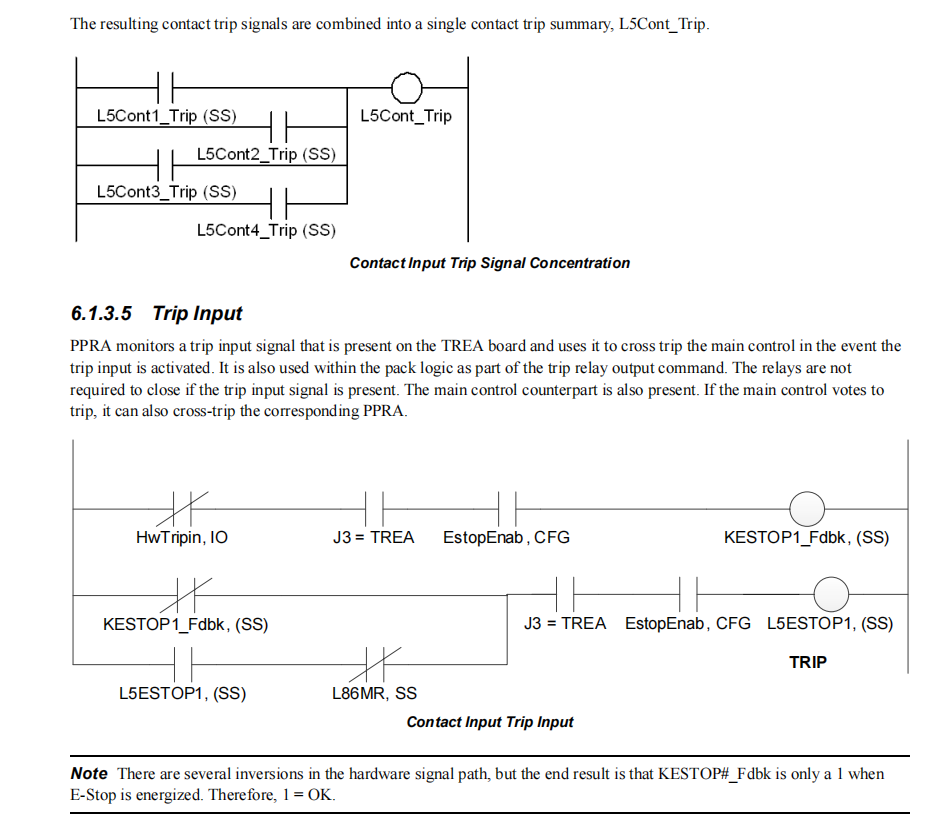

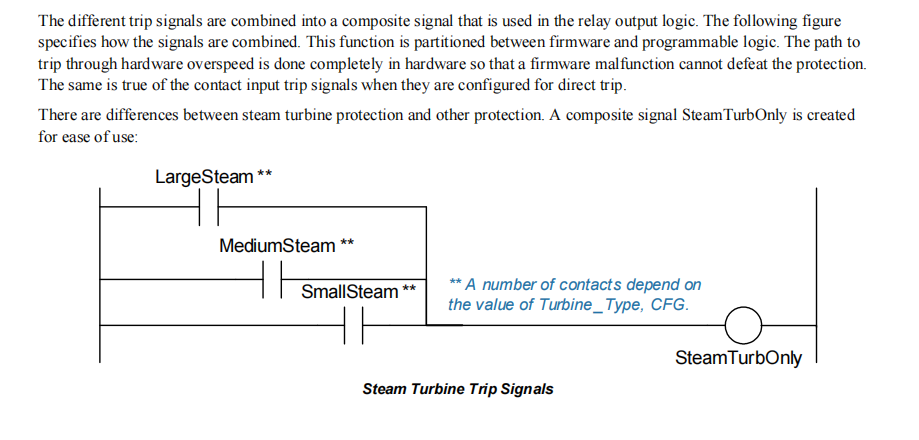

4. Discrete Contact Input Trip Function

The IS220PPRAH1A supports four isolated discrete contact trip inputs, which can operate in two modes:

Direct Trip: The input signal directly triggers a hardware trip, bypassing firmware logic for maximum speed.

Conditional Trip: The trip action depends on communication health (indicated by a network keep-alive signal). If controller communication is lost, conditional trips are automatically permitted.

All contact inputs include an 8 ms de-bounce filter to prevent false trips due to contact chatter.

5. Main Control Watchdog Function

The module continuously monitors a heartbeat signal (Device Heartbeat) provided by the main controller.

If no change in the heartbeat value is detected for five consecutive data frames, a control watchdog trip is latched.

If the main controller recovers and communicates correctly for 60 seconds, the trip condition is automatically reset.

6. Speed Difference and Stale Speed Detection

Speed Difference Protection: Compares the speed calculated by the PPRA (PulseRate1) with the speed value (Speed1) provided by the main controller. If the difference exceeds a configurable percentage (based on RatedRPM_TA) for three consecutive samples, a trip is initiated.

Stale Speed Protection: If the speed value from the main controller (Speed1) remains unchanged for 100 consecutive data frames (indicating a loss of signal integrity), a trip is latched. This protection is based on the principle that a live speed signal always exhibits minor variations ("dithering").

7. Time Synchronization and Frame Sync Monitoring

The module relies on time synchronization across the IONet. It monitors the synchronization frame number.

If gross errors or a loss of synchronization are detected (e.g., out-of-sequence frames), a Frame Sync trip is activated.

This ensures the PPRA remains time-synchronized with the main controller, preventing protection malfunctions due to communication delays.

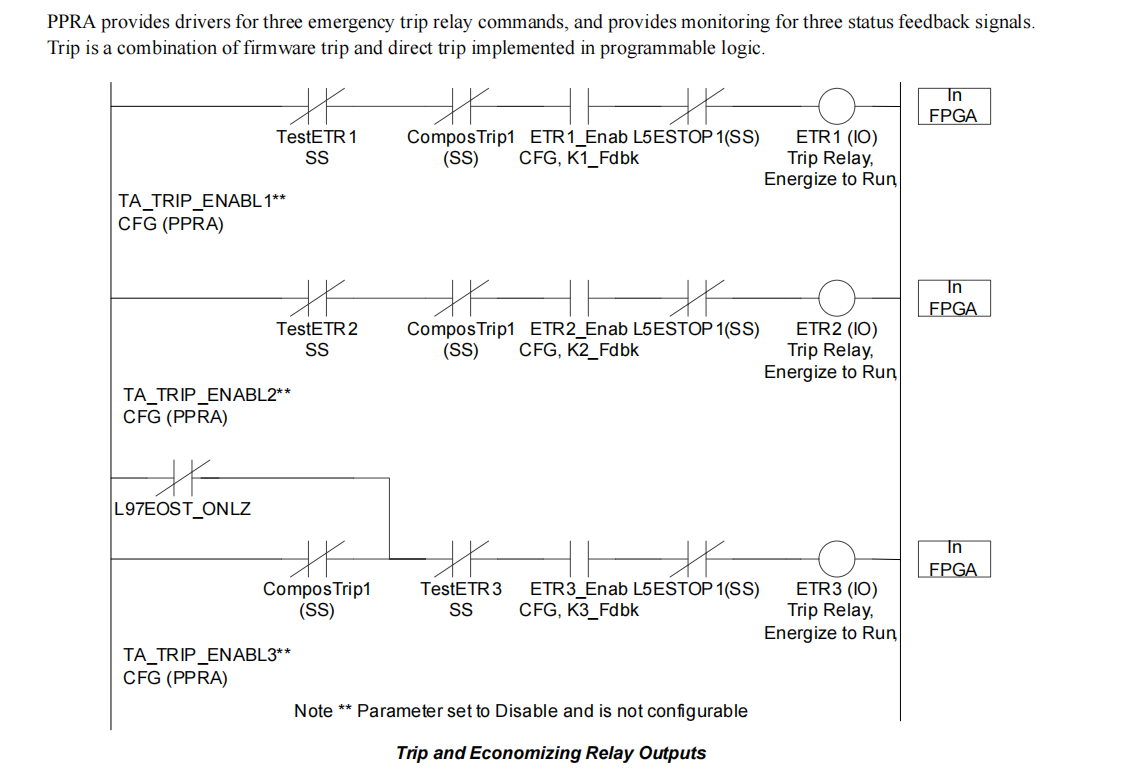

8. Relay Outputs and Feedback

The IS220PPRAH1A provides the drive signals for three Emergency Trip Relays (ETR1–ETR3) and monitors their feedback status signals.

The commanded state of each relay driver is compared to its actual feedback state. A mismatch generates a diagnostic alarm.

A test function allows de-energizing each relay individually for testing purposes without causing a system trip.

Operational Principles and Signal Flow

Signal Type Conventions

Ends with (SS): Signal is generated within the PPRA and sent out to the controller's Signal Space.

Ends with SS: Signal is generated in the controller and received by the PPRA via Signal Space.

Ends with (IO): Signal is generated within the PPRA and output to the hardware.

Ends with IO: Signal is a hardware input into the PPRA.

Ends with CFG: Denotes a configuration parameter.

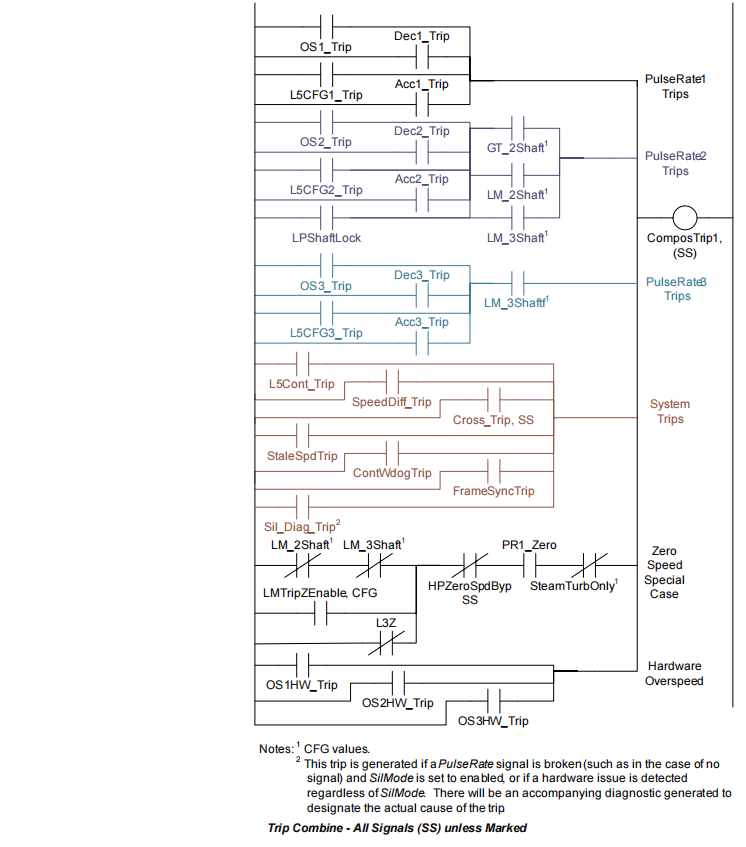

Trip Signal Combination

All individual trip signals (e.g., overspeed, acceleration, contact input, watchdog) are combined into a single Composite Trip signal (ComposTrip1), which is used in the relay output logic. Crucially, hardware overspeed trips and direct contact trips have paths that are implemented entirely in hardware or programmable logic, not firmware. This ensures that a processor firmware malfunction cannot prevent these critical signals from initiating a trip.

Fail-Safe Design

The module defaults to a "trip" state when power is off, during startup, during a hardware reset, or when not online.

A hardware watchdog circuit monitors firmware operation. If a firmware malfunction is detected, it triggers a hardware reset, which forces a trip.

All critical signals (speed, heartbeat, frame sync) incorporate timeout or discrepancy detection mechanisms, ensuring the system fails safely to a trip condition under abnormal circumstances.

Configuration and Diagnostics

Configuration Tool

The module is configured using GE's ToolboxST software. Key configuration parameters include:

Turbine Type (e.g., Gas Turbine, Steam Turbine)

Speed Input Grouping (ThreeGroups or TwoGroups)

Overspeed Setpoints, Acceleration Setpoint, Difference Limits

Enable/disable settings for functions like Watchdog, Speed Difference, and Stale Speed detection.

Self-Diagnostics

Power-Up Self-Test: Checks RAM, flash memory, Ethernet ports, and processor hardware.

Continuous Monitoring: Monitors internal power supplies, analog feedback currents, and relay command/feedback states.

Electronic ID Verification: Checks that the module, terminal board, and option board hardware are compatible and match the loaded application code.

Status Indicator LEDs

The module faceplate features six status LEDs:

RUN: Green when the relays are energized (Run), Red when the relays are de-energized (Trip).

ESTP: Green when the E-Stop input (if supported) is in the run state, Red when E-Stop is active.

OSPD: Red when an overspeed condition is detected and latched.

WDOG: Red when a trip based on watchdog functions (Control Watchdog, Speed Difference, etc.) is active.

SIL: The PPRAH1A does not support SIL functionality; this LED is not applicable.

KREA: Green indicates power is detected on the KREA sub-module.